MaintenanceandStorage

•Parkthemachineonlevelground,disengagethedrives,

lowerthecuttingunits,settheparkingbrake,stopthe

engine,removethekey,anddisconnectsparkplugwire(s).

Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairingthemachine.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andtheenginetohelppreventres.Cleanupoilorfuel

spills.

•Lettheenginecoolbeforestoringanddonotstorethe

machinenearames.

•Shutoffthefuelwhilestoringortransportingthe

machine.Donotstorefuelnearamesordrainthefuel

tankindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryandremovethesparkplugwire(s)

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Connectthepositive

terminalrstandthenegativeterminallast.

•Usecareandweargloveswhencheckingthereels.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damageddecals.

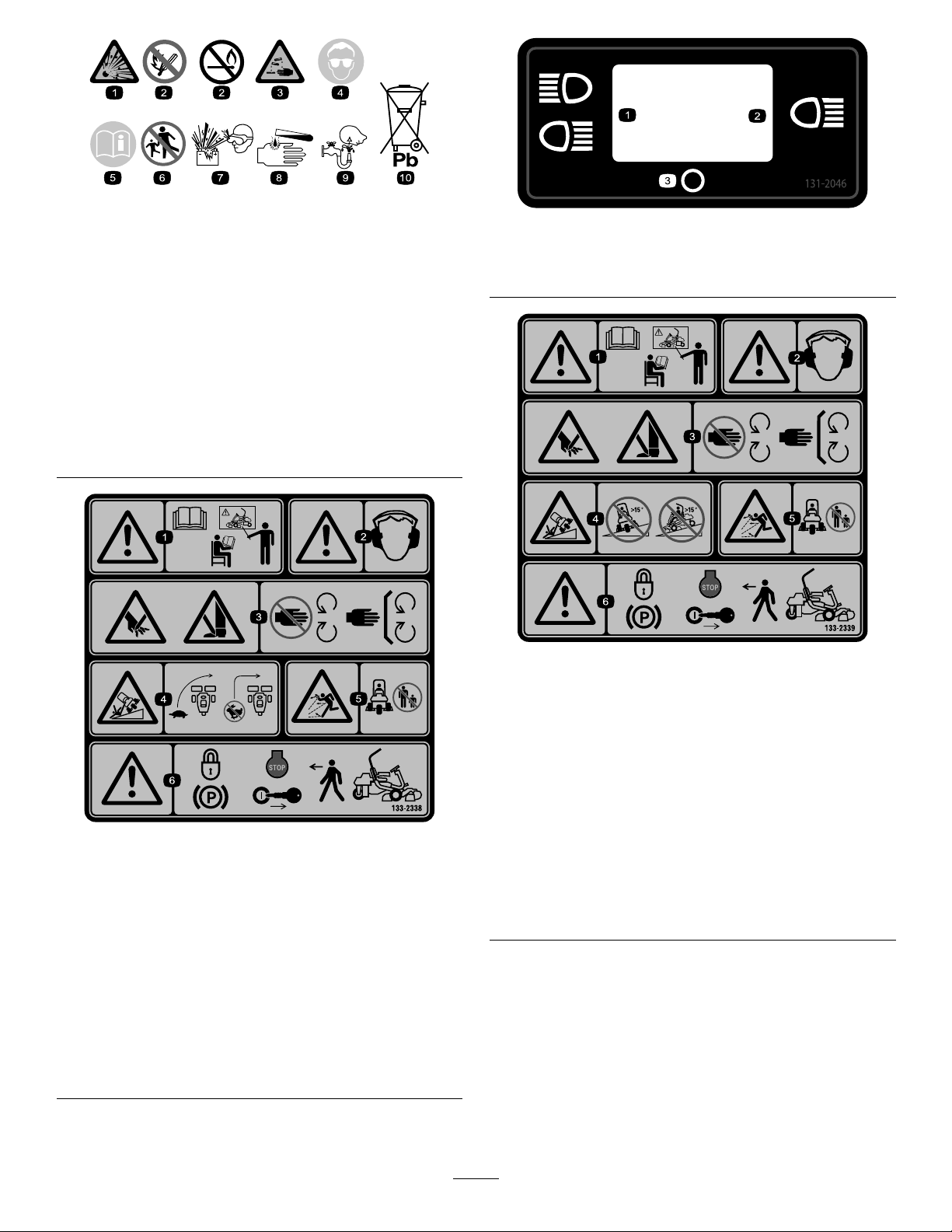

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Knowhowtostoptheenginequickly.

•Checkthesafetyinterlockswitchesdailyforproper

operation.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slow-movingvehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Thegrassbasketsmustbeinplaceduringoperation

ofthereelsorthatchersformaximumsafety.Shutthe

engineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Stayclearoftherotatingscreenatthesideoftheengine

topreventdirectcontactwithyourbodyorclothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately,turntheengineoff,waitfor

allmotiontostop,andinspectthemachinefordamage.

Repairorreplaceadamagedreelorbedknifebefore

continuingoperation.

•Beforegettingofftheseat,movethefunctionalcontrol

levertoNEUTRAL,raisethecuttingunits,andwaitforthe

reelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonoranimalappearsunexpectedlyinor

nearthemowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrown-objectinjuries.Do

notresumemowinguntiltheareaiscleared.

MaintenanceandStorage

•Ensurethatallhydrauliclineconnectorsaretightandthat

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompin-holeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

5