2

All Rights Reserved

Printed in the USA

W2006 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Warning

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Mower Safety 5. . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 6. . . . . . . . . . . . . . . . .

Specifications 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

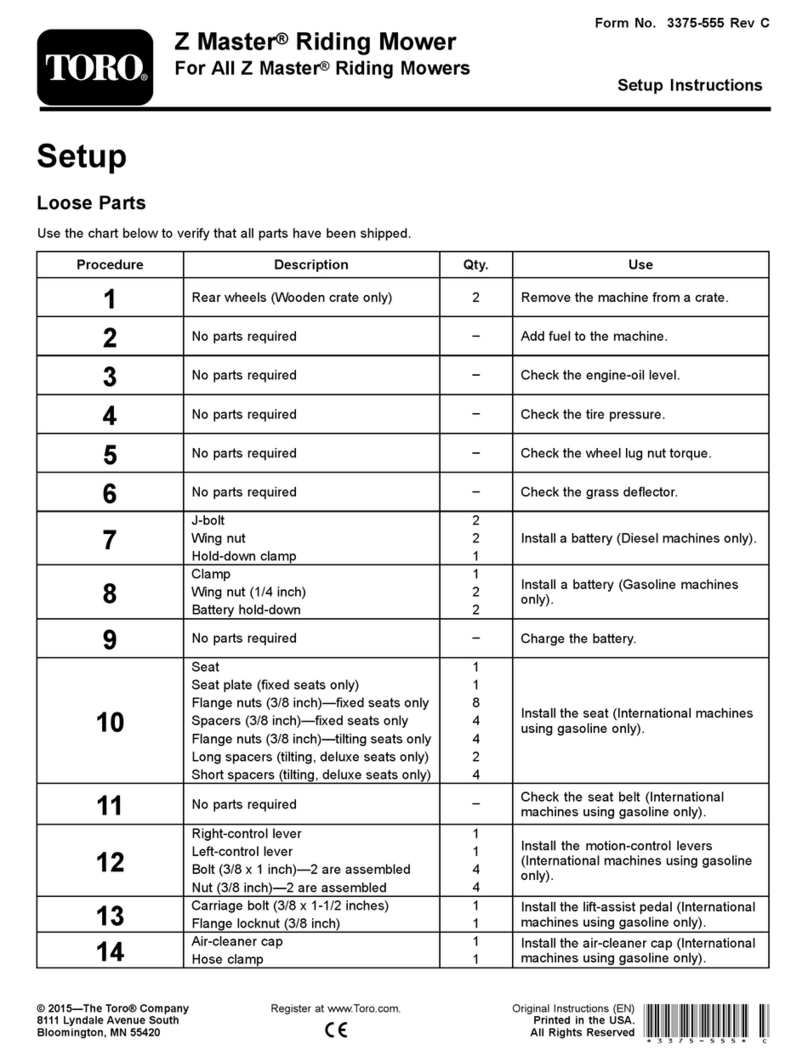

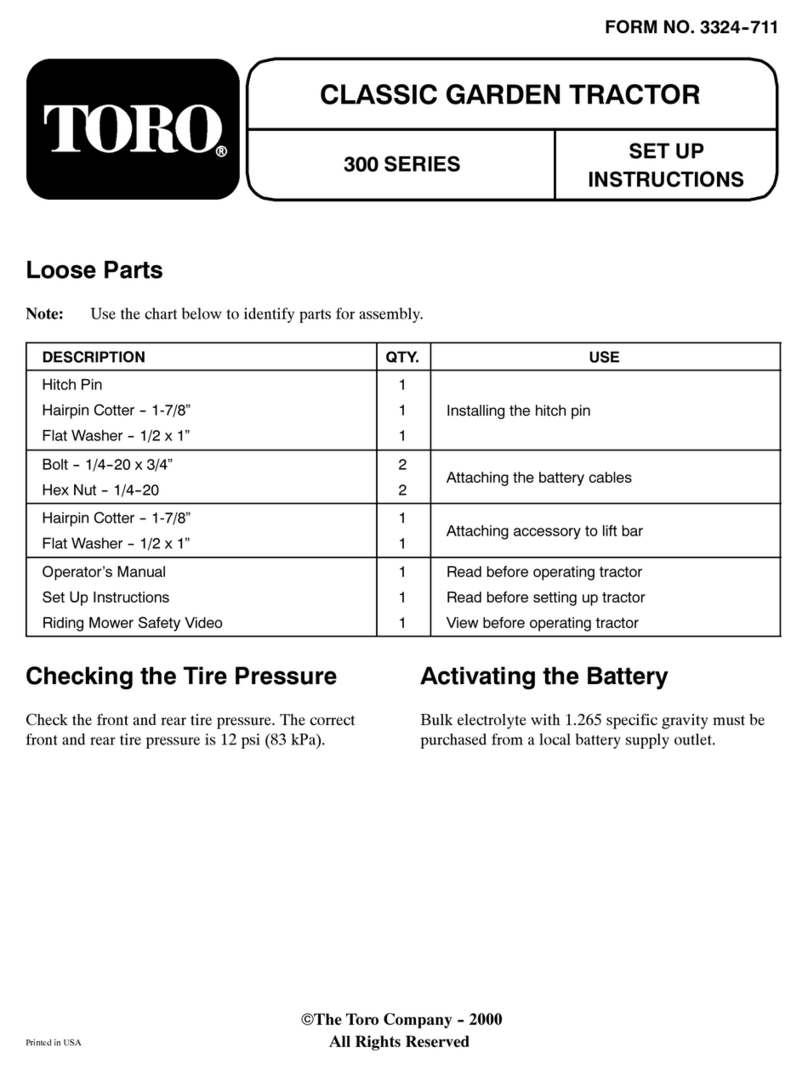

Loose Parts 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Rear Shields 10. . . . . . . . . . . . . . . . . . .

Installing the Castor Wheel Assemblies 11. . . . . . . .

Installing the Lift Arms to the Traction Unit 11. . . . .

Connecting the Lift Arms to the Cutting Unit 12. . . .

Connecting PTO Shaft to Cutting Unit Gear Box 12.

Greasing the Machine 12. . . . . . . . . . . . . . . . . . . . . .

Before Operating 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Lubricant in the Gear Box 13. . . . . . . .

Adjusting the Height-of-Cut 13. . . . . . . . . . . . . . . . .

Adjusting the Cutting Unit Pitch 14. . . . . . . . . . . . . .

Adjusting the Skids 15. . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Rollers 15. . . . . . . . . . . . . . . . . . . . . . .

Correcting Cutting Unit Mismatch 15. . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 18. . . . . . . . .

Greasing the Bearings, Bushings and Gear Box 19. .

Separating Cutting Unit from Traction Unit 20. . . . .

Mounting the Cutting Unit to Traction Unit 21. . . . .

Servicing the Castor Arm Bushings 21. . . . . . . . . . . .

Servicing the Castor Wheels and Bearings 22. . . . . .

Checking for a Bent Blade 22. . . . . . . . . . . . . . . . . . .

Removing and Installing the Cutter Blade(s) 22. . . . .

Inspecting and Sharpening the Cutter Blade(s) 23. . .

Correcting Cutting Unit Mismatch 24. . . . . . . . . . . .

Replacing the Drive Belt 24. . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 28. . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The numbers can be

found on a plate that is mounted on the mower housing.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

This machine meets or exceeds CEN standard EN

836:1997 , ISO standard 5395:1990 (when appropriate

decals applied), and ANSI B71.4-2004 specifications in

effect at the time of production when equipped with

rear weight as listed in the traction unit operator’s

manual.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means