•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetheriskofrehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-reelmachines,takecareasrotatingonereelcan

causeotherreelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey.Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthereels.Wrapthereelsorwear

gloves,andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Knowhowtostoptheenginequickly.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

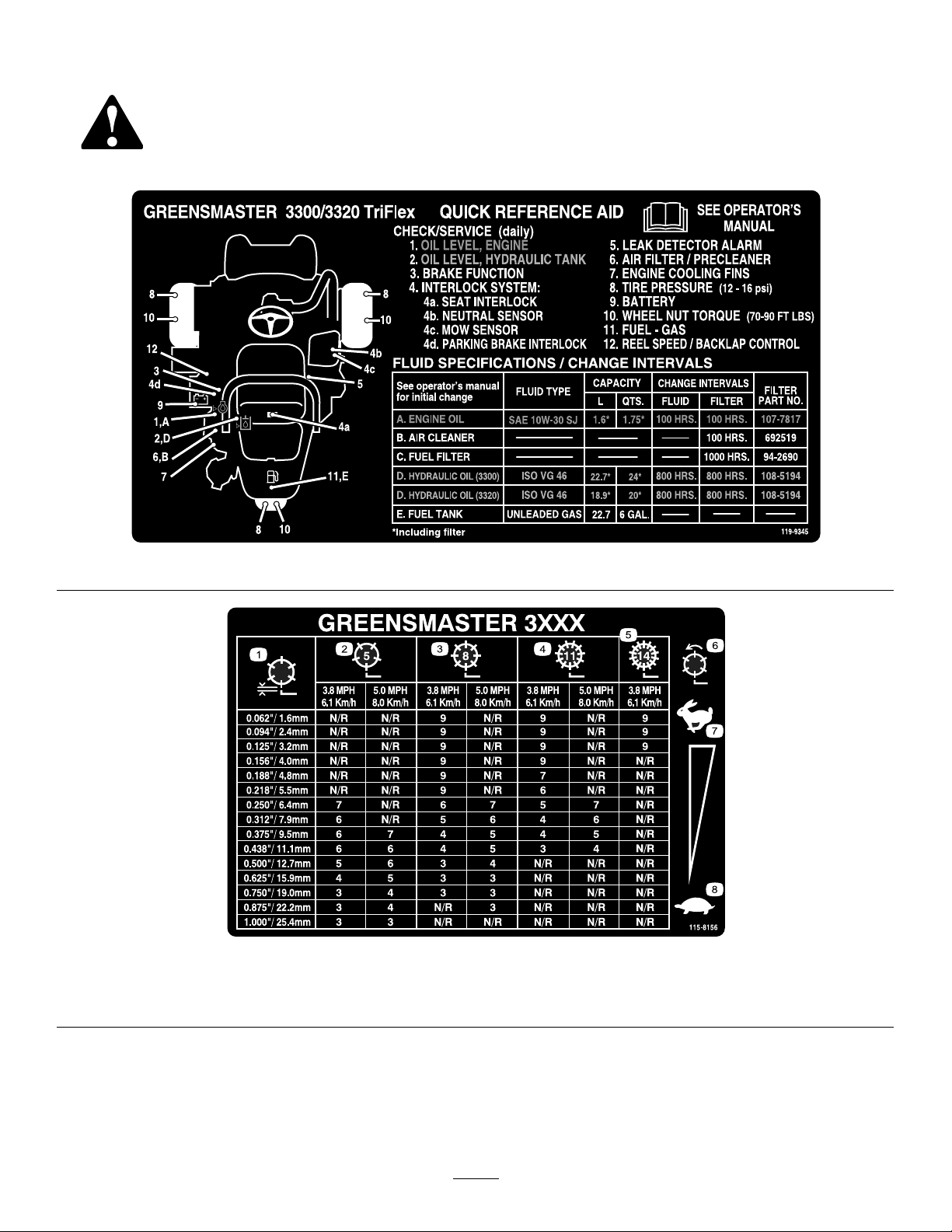

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchhasfailed,replacetheswitchbefore

operatingthemachine.

•Beforeattemptingtostarttheengine,sitontheseat,pull

ontheraise/lowermowcontroltoensurethatthecutting

unitsaredisengaged,ensurethatthetractionpedalisin

neutral,andengagetheparkingbrake.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

–Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Shuttheengineoffbeforeemptyingthebaskets.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Stayclearoftherotatingscreenatthesideoftheengine

topreventdirectcontactwithyourbodyorclothing.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately,turntheengineoff,waitfor

allmotiontostop,andinspectthemachinefordamage.

Adamagedreelorbedknifemustberepairedorreplaced

beforeoperationiscontinued.

•Beforegettingoffoftheseat,movethefunctionalcontrol

levertoneutral(N),raisethecuttingunitsandwaitfor

thereelstostopspinning.Settheparkingbrake.Stopthe

engineandremovethekeyfromtheignitionswitch.

•Traverseslopescarefully.Donotstartorstopsuddenly

whentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhillsmay

causelossofcontrolandcausethemachinetotiporroll,

possiblyresultinginpersonalinjuryordeath.

6