5

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

Use of this product for purposes other than its intended use

could prove dangerous to user and bystanders.

Operation

•Always wear substantial shoes. Do not operate the

machine while wearing sandals, tennis shoes, or

sneakers.

•Wearing safety shoes and long pants is advisable and

required by some local ordinances and insurance

regulations.

•Fill fuel tank until level is 1 in. (25 mm) below the

bottom of the filler neck. Do not overfill.

•Check the safety interlock switches daily for proper

operation. If a switch should fail, replace the switch

before operating the machine. After every two years,

replace all three interlock switches in the safety system,

regardless if they are working properly or not.

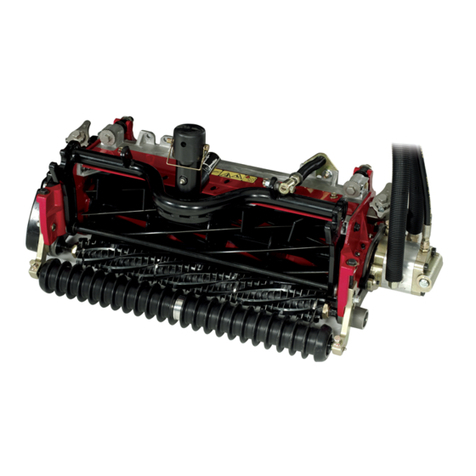

•The grass deflector(s) must always be installed and in

the lowest position on the cutting unit.

•Pay attention when using the machine. To prevent loss

of control:

– Drive slowly.

– Do not drive close to sand traps, ditches, creeks, or

other hazards.

– Reduce speed when making sharp turns. Avoid

sudden stops and starts.

– Lower the cutting unit when going down slopes.

•Do not touch the engine, radiator, or muffler while the

engine is running or soon after it has stopped because

these areas could be hot enough to cause burns.

•If a cutting blade strikes a solid object or vibrates

abnormally, disengage PTO, move throttle to Slow, set

the parking brake, stop the engine, and remove the

ignition key. Wait for all motion to stop, and inspect the

machine for damage. Repair or replace any damaged

parts before operating. Ensure that the cutting blades

are in good condition and the blade bolts are torqued to

proper specifications (see Cutting Deck Operator’s

Manual).

•Check carefully for overhead clearances such as

branches, doorways, and electrical wires before driving

under any objects. Do not contact the objects.

•Make sure that the set belt can be removed quickly if

the machine is driven or rolls into a pond or lake.

•If the engine stalls or the machine loses headway and

cannot make it to the top of a slope, do not turn the

machine around. Always back slowly straight down the

slope.

•If the cutting unit discharge area ever plugs, disengage

PTO and shut engine off before removing the

obstruction.

•When operating a 4 wheel drive machine or any

machine on slopes, by banks, or drop offs, always have

the ROPS (Roll Over Protection System) installed.

•When operating the machine with ROPS, always use

the seat belt and make sure that the seat pivot retaining

pin is installed.

Maintenance and Storage

•Before servicing or making adjustments, stop the engine

and remove the ignition key.

•Ensure that the entire machine is properly maintained

and in good operating condition. Frequently check all

nuts, bolts, and screws. Check all cutting unit blade

mounting bolts frequently to ensure that they are

torqued to proper specifications (see Cutting Deck

Operator’s Manual).

•Make sure all hydraulic line connectors are tight and all

hydraulic hoses and lines are in good condition before

applying pressure to the system.

•Keep your body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not your hands, to search for

leaks. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate the skin and cause serious

injury.

•Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be

relieved by stopping the engine and lowering the cutting

units to the ground.

•If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the cutting units, attachments, PTO

shaft, and any moving parts.

•Do not overspeed the engine by changing governor

settings. To ensure safety and accuracy, have an

Authorized Toro Distributor check the maximum engine

speed with a tachometer. Maximum governed engine

speed with no load should be 3200–3250 RPM.

•The engine must be shut off before checking the oil or

adding oil to the crankcase.

•Periodically inspect the roll bar and roll bar mounting.

Replace, if necessary. Do not modify roll over

protection frames or structures because they are