Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

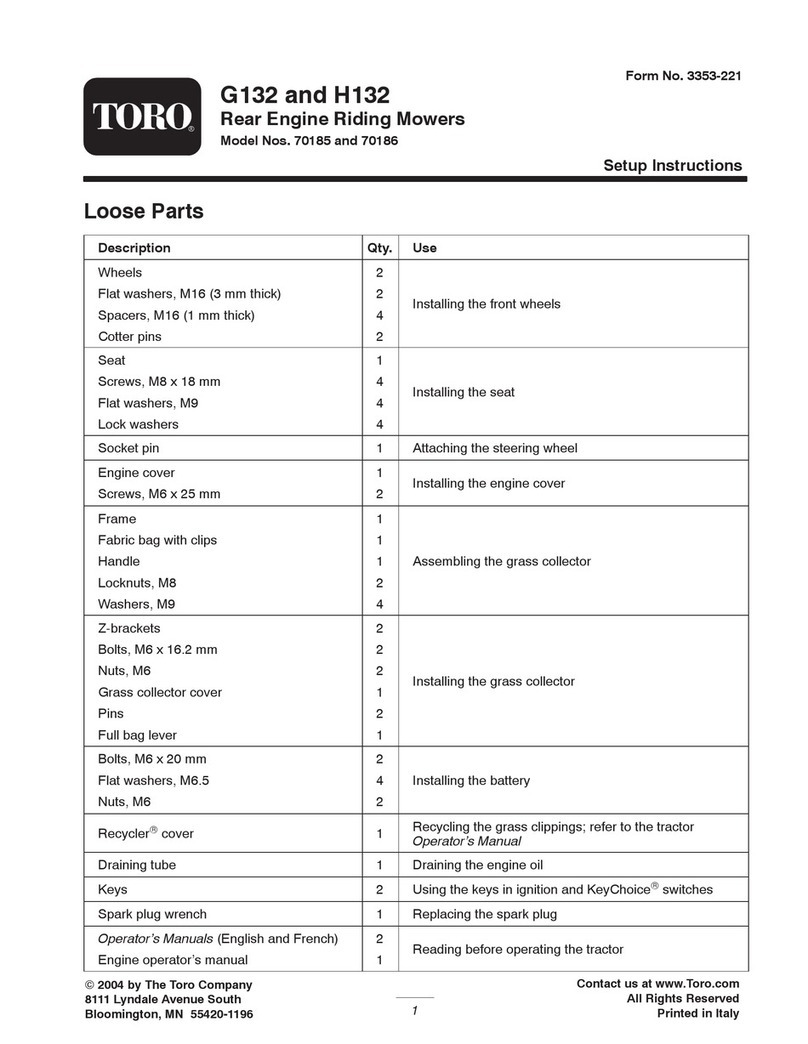

Setup........................................................................9

1Activating,Charging,andConnectingthe

Battery............................................................9

2AddingtheRearWheelBallast.......................10

3CheckingtheAngleIndicator..........................11

4AdjustingtheLiftArms...................................12

5AdjustingtheCarrierFrame...........................13

6AdjustingtheHeightofCut.............................13

7AdjustingtheRollerScraper...........................14

8InstallingtheMulchingBafe..........................15

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................18

Attachments/Accessories.................................19

BeforeOperation.................................................19

BeforeOperationSafety...................................19

FillingtheFuelTank..........................................19

CheckingtheEngine-OilLevel..........................21

CheckingtheCoolingSystem...........................21

CheckingtheHydraulicSystem........................21

SelectingaBlade..............................................21

ChoosingAccessories......................................22

CheckingtheSafety-InterlockSystem..............22

DuringOperation.................................................23

DuringOperationSafety...................................23

StartingtheEngine...........................................24

ShuttingOfftheEngine.....................................24

Standard-ControlModule(SCM)......................25

OperatingTips.................................................27

AfterOperation....................................................28

GeneralSafety.................................................28

HaulingtheMachine.........................................28

LocatingtheTie-DownPoints...........................28

PushingorTowingtheMachine........................29

Maintenance...........................................................30

MaintenanceSafety..........................................30

RecommendedMaintenanceSchedule(s)...........30

DailyMaintenanceChecklist.............................32

Pre-MaintenanceProcedures..............................33

RemovingtheHood..........................................33

UsingtheCuttingUnitServiceLatch

......................................................................33

Lubrication..........................................................34

GreasingtheBearingsandBushings................34

EngineMaintenance...........................................37

EngineSafety...................................................37

ServicingtheAirCleaner..................................37

CheckingtheEngine-OilLevel..........................37

ChangingtheEngineOilandFilter....................38

ReplacingtheSparkPlugs................................39

FuelSystemMaintenance...................................40

ReplacingtheFuel-PumpFilter.........................40

ServicingtheFuelT ank.....................................40

InspectingtheFuelLinesand

Connections..................................................40

ElectricalSystemMaintenance...........................41

ElectricalSystemSafety...................................41

ServicingtheBattery.........................................41

ServicingtheFuses..........................................41

DriveSystemMaintenance..................................42

CheckingtheTirePressure...............................42

CheckingtheTorqueoftheWheel-Lug

Nuts..............................................................42

AdjustingtheTractionDriveforNeutral.............42

CoolingSystemMaintenance..............................43

CoolingSystemSafety.....................................43

CheckingtheCoolingSystem...........................43

CleaningtheCoolingSystem............................44

BrakeMaintenance.............................................45

AdjustingtheParkingBrake..............................45

BeltMaintenance................................................45

ServicingtheEngineBelts................................45

ControlsSystemMaintenance.............................46

AdjustingtheThrottle........................................46

HydraulicSystemMaintenance...........................47

HydraulicSystemSafety...................................47

ServicingtheHydraulicFluid............................47

CuttingUnitMaintenance.....................................50

SeparatingtheCuttingUnitsfromthe

TractionUnit..................................................50

MountingtheCuttingUnitstotheTraction

Unit...............................................................50

ServicingtheBladePlane.................................50

ServicingtheFrontRoller.................................51

BladeMaintenance..............................................53

BladeSafety.....................................................53

ServicingtheBlade...........................................53

Storage...................................................................55

StorageSafety..................................................55

PreparingtheMachineforStorage...................55

3