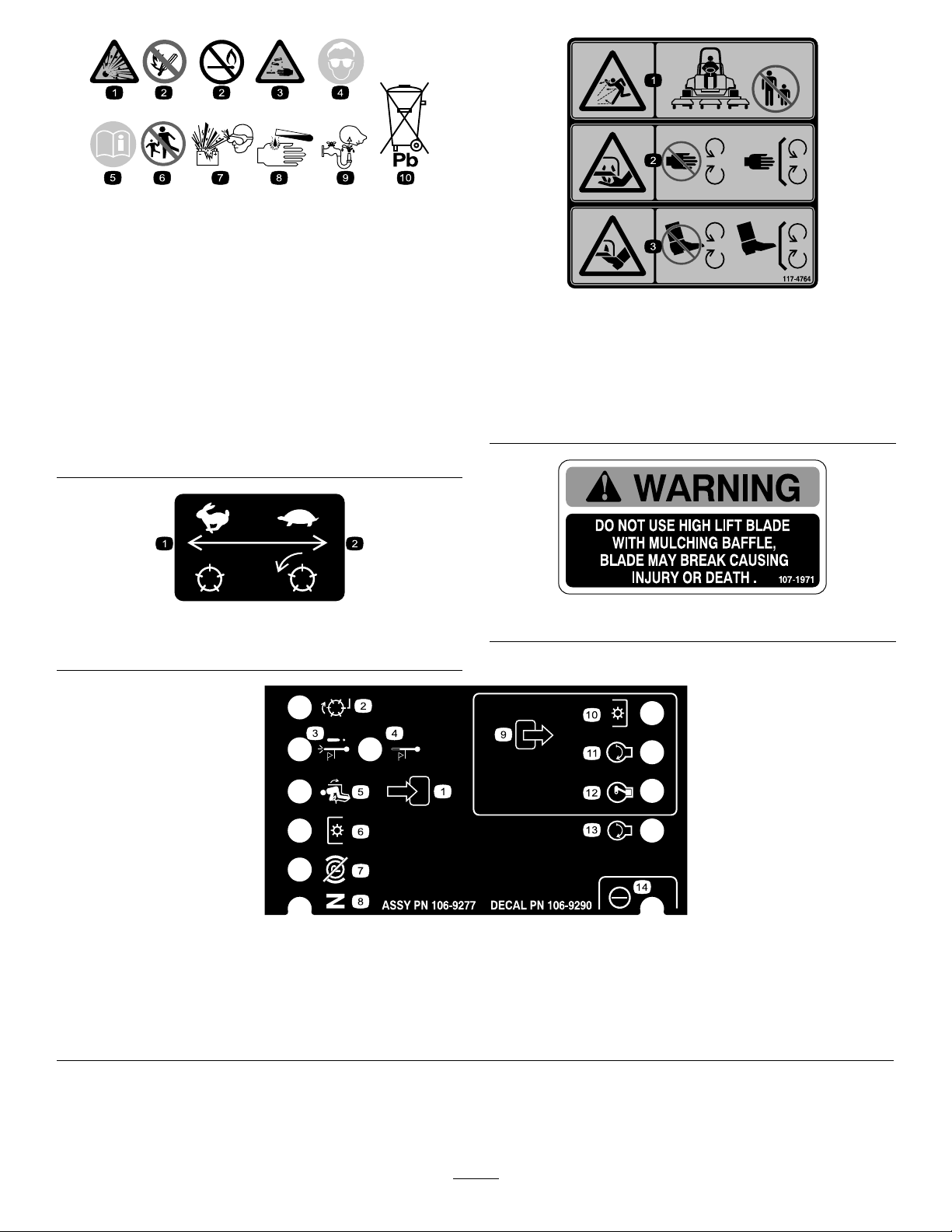

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Whenstartingtheengine,engagetheparkingbrake,put

thetractionpedalinneutral,anddisengagetheblade

drive.Aftertheenginestarts,releasetheparkingbrake

andkeepyourfootoffofthetractionpedal.Themachine

mustnotmove.Ifmovementisevident,refertothe

Maintenancesectionofthismanualtoadjustthetraction

drive.

•Useextremecautionwhenoperatingclosetosandtraps,

ditches,creeks,steephillsides,orotherhazards.

•Reducespeedwhenmakingsharpturns.

•Donotturnonhills.

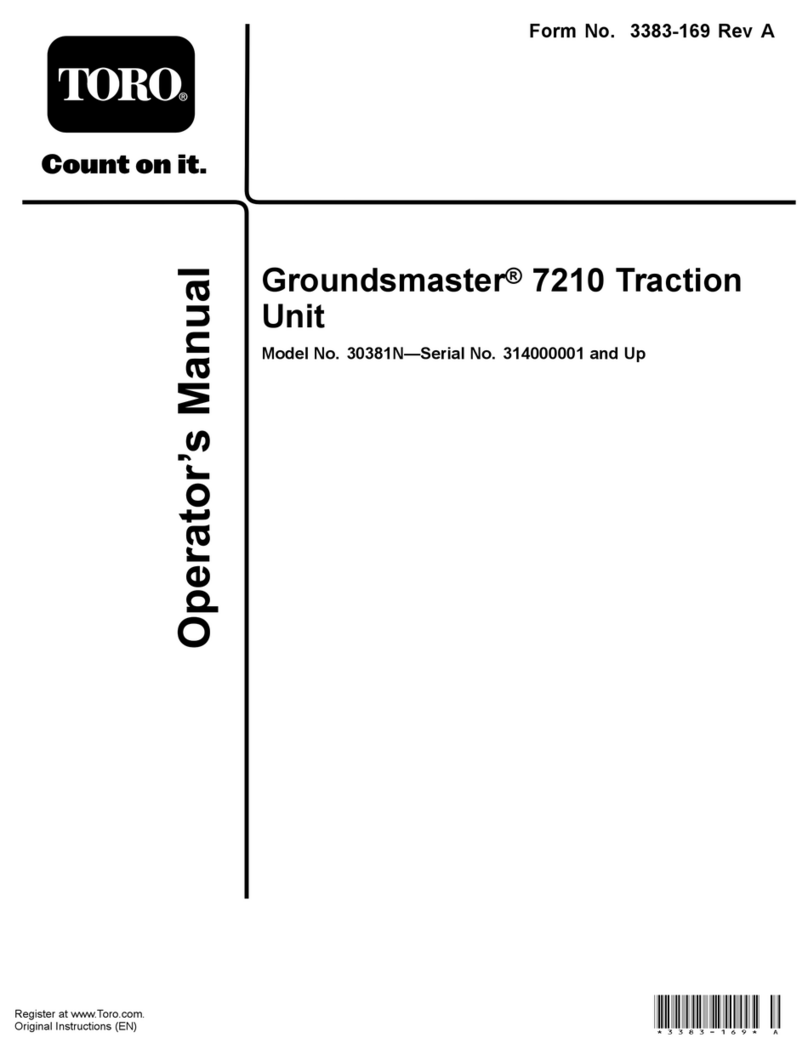

•Donotoperateonasidehillthatistoosteep.Arollover

mayoccurbeforelosingtraction.

•Theslopeangleatwhichthemachinewilltipisdependent

onmanyfactors.Amongthesearemowingconditions

suchaswetorundulatingterrain,speed(especiallyin

turns),positionofthecutting-units(withtheSidewinder),

tirepressure,andoperatorexperience.Atsidehillangles

of20degreesorless,theriskofarolloverislow .As

theslopeangleincreasestoarecommendedmaximum

limitof25degrees,theriskofarolloverincreasestoa

moderatelevel.Donotexceeda25degreesidehill

slopeanglebecausetheriskofarolloverandserious

injuryordeathisveryhigh.

•Forsteeringcontrol,lowerthecutting-unitswhengoing

downslopes.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

•Raisethecutting-unitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoonafterit

hasstopped.Theseareascouldbehotenoughtocause

burns.

•Thismachineisnotdesignedorequippedforon-roaduse

andisaslow-movingvehicle.Ifyoumustcrossortravel

onapublicroad,youshouldbeawareofandcomplywith

localregulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

RolloverProtectionSystem(ROPS)-

UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.

•DonotremovetheROPS.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

•KeeptheROPSinsafeoperatingcondition.Thoroughly

inspectfordamageperiodicallyandalwayskeepall

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

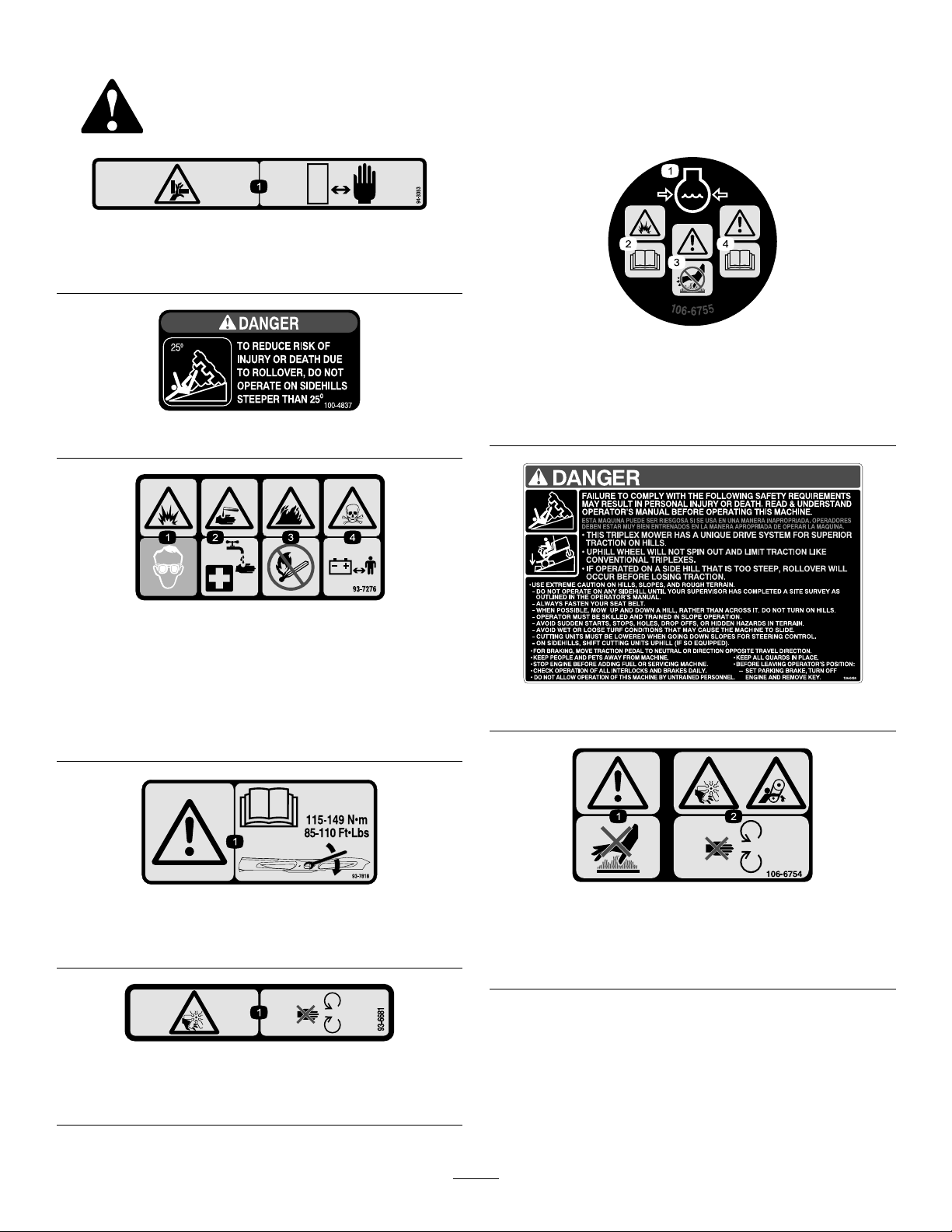

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelock-opendevice.

•Fillthefueltankuntillevelis6to13mm(1/4to1/2

inch)belowthebottomofthellerneck.Donotoverll.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectsparkplugwire.Waitforall

movementtostopbeforeadjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Setparkingbrake.

•Neverallowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

5