g000502

Figure 2

Safety-alert symbol

This manual uses 2 words to highlight information.

Important calls attention to special mechanical

information and Note emphasizes general information

worthy of special attention.

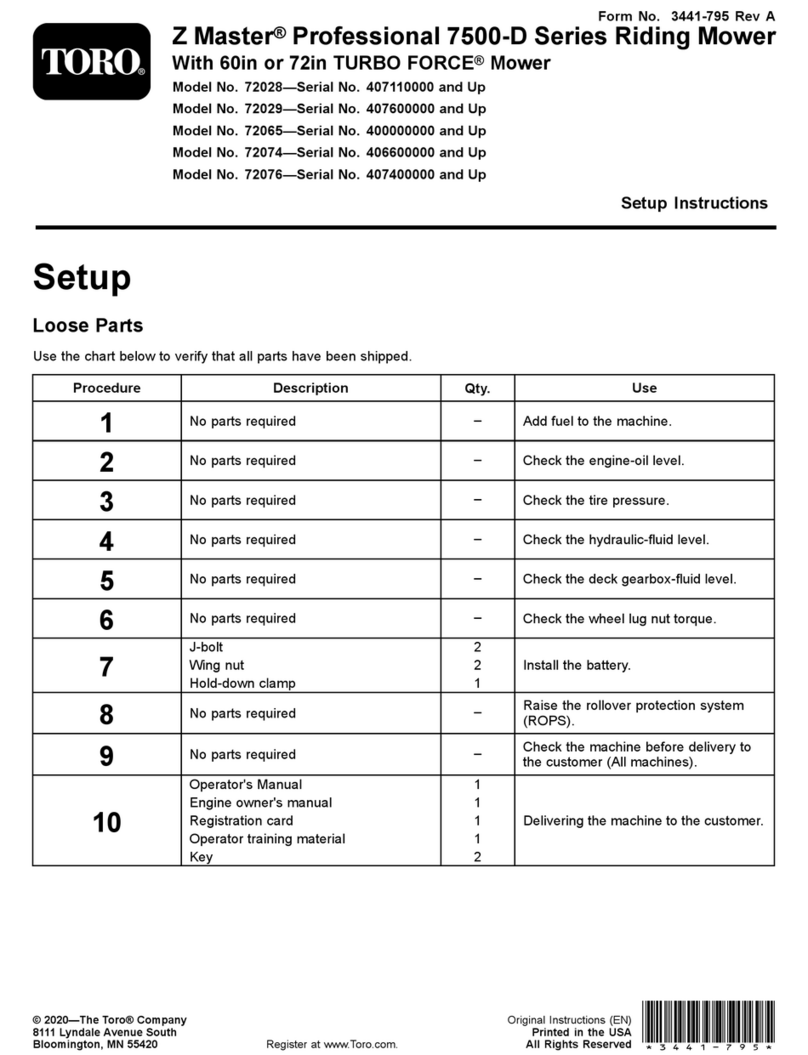

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

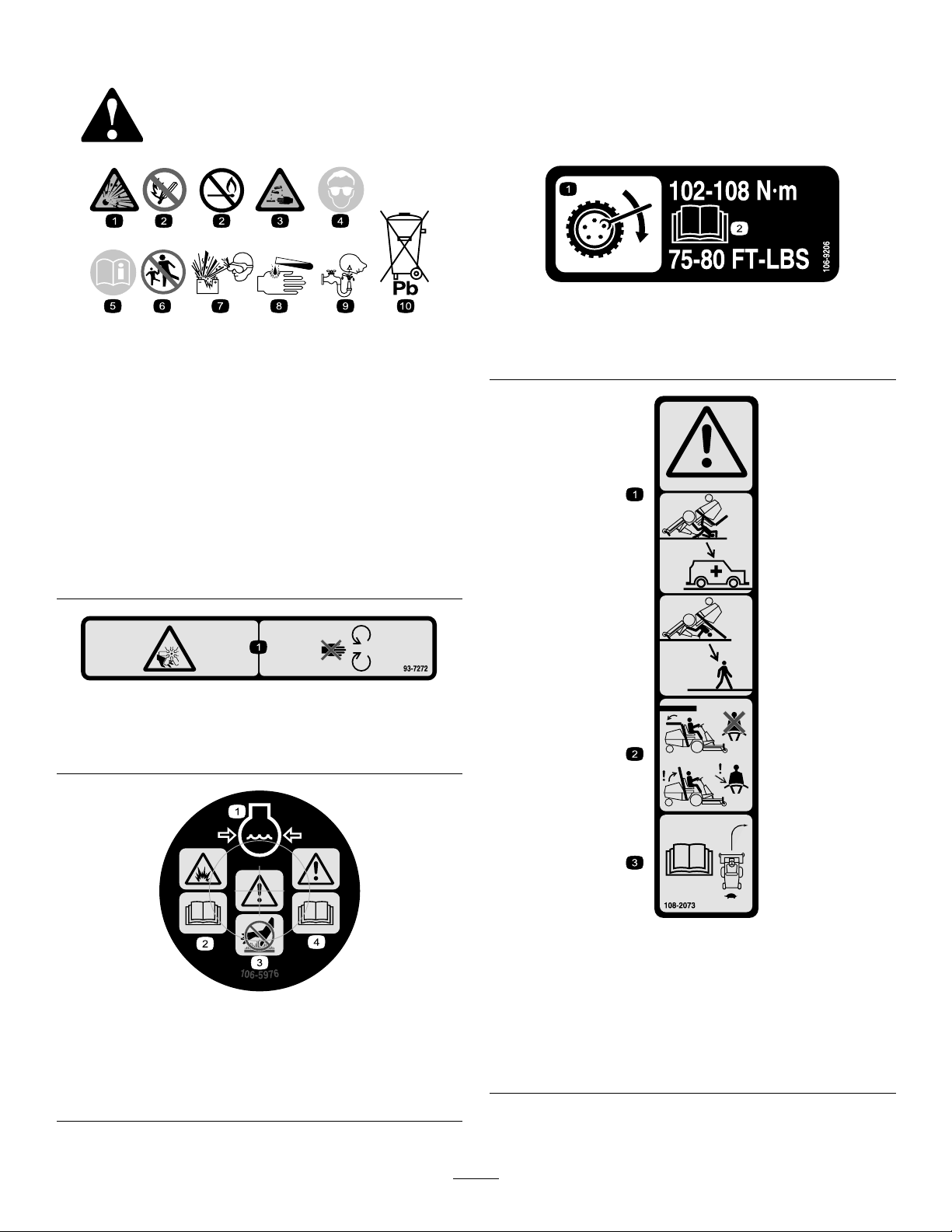

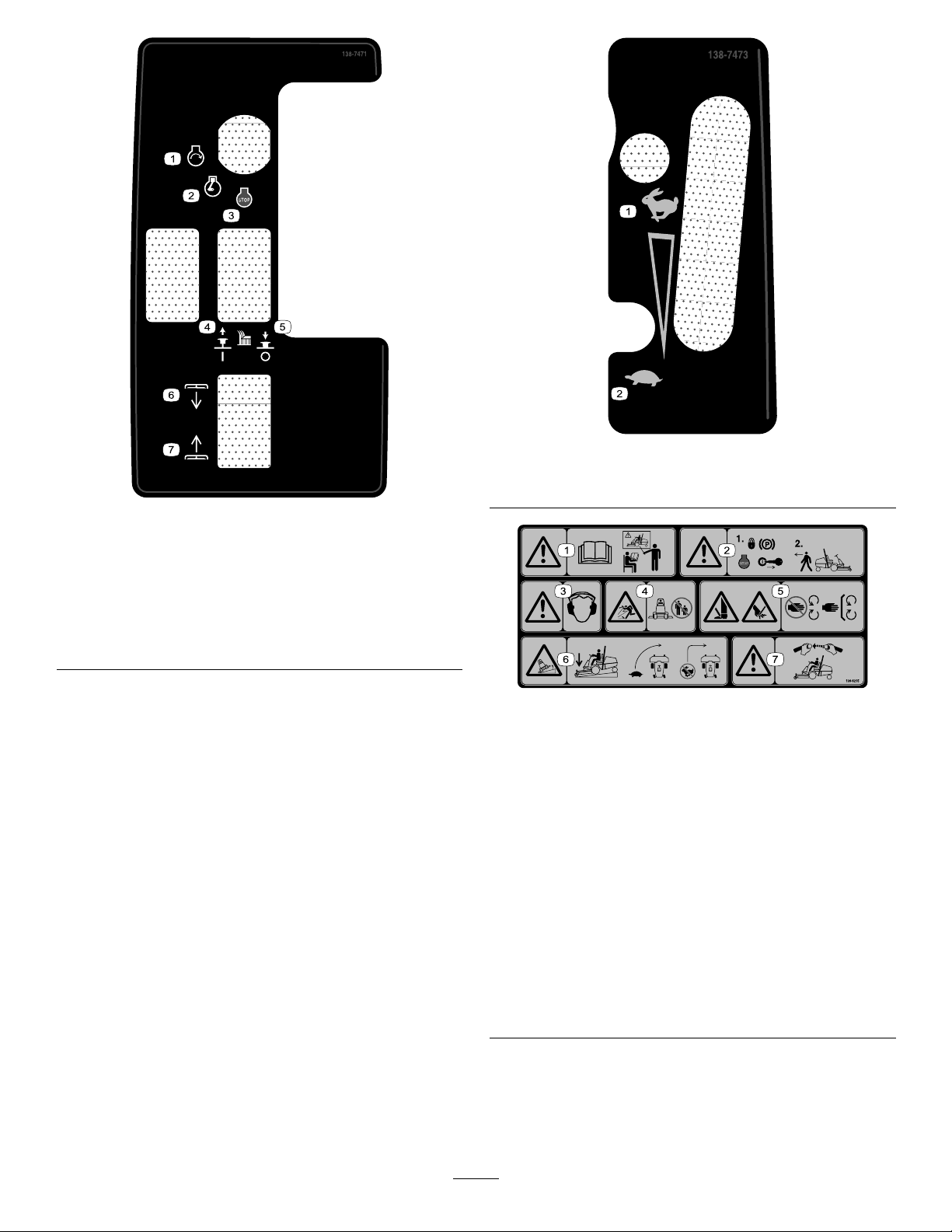

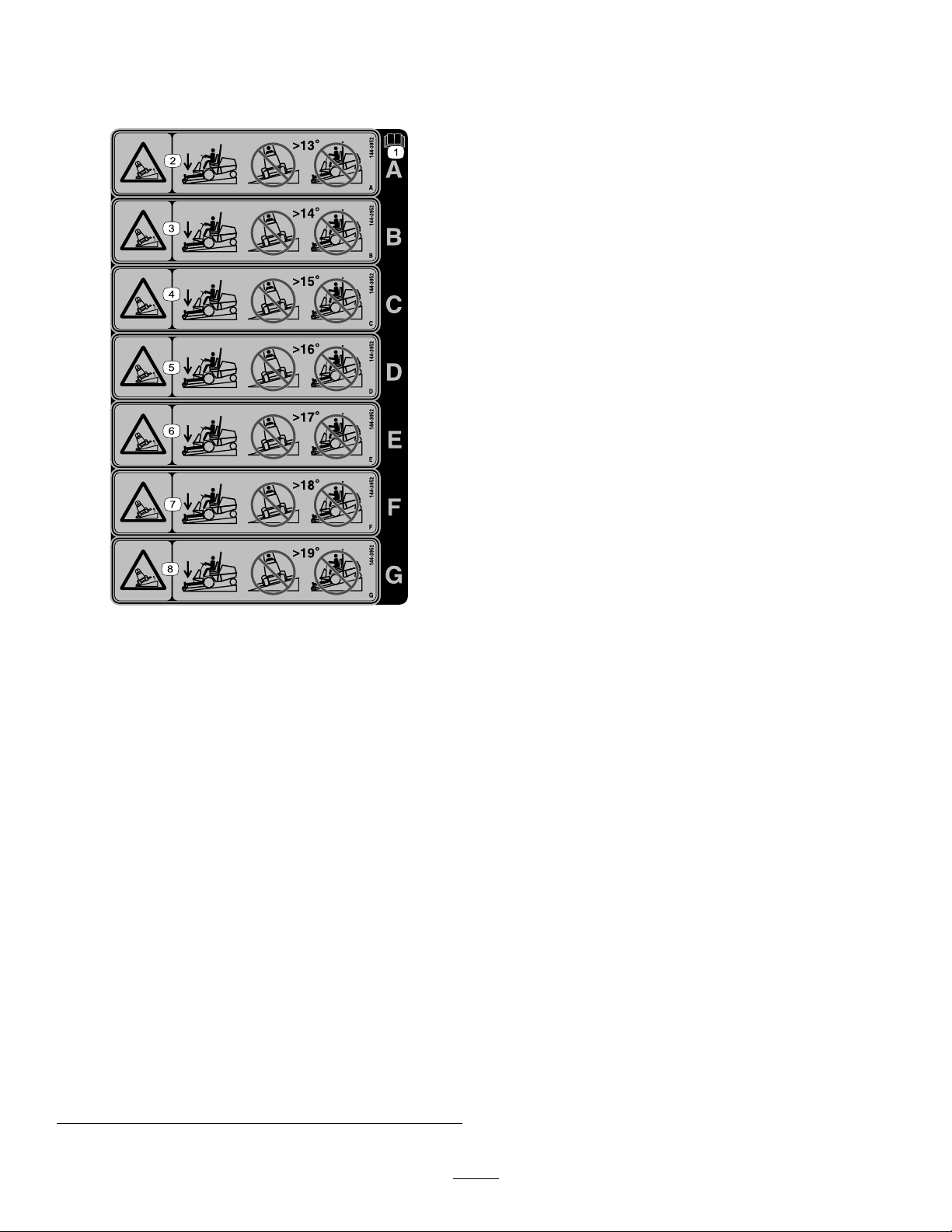

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

1 Removing the Machine from the Shipping

Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Installing the Rear T ires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Removing the Front T ires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Installing the Lift-Arm Assembly . . . . . . . . . . . . . . . . . . . . . 13

5 Installing the Front T ires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Installing the T ie-Down Bracket . . . . . . . . . . . . . . . . . . . . . . 15

7 Installing the Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Installing the Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9 Installing the Sound Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10 Installing the Bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1 1 Adjusting the Roll-Bar Position . . . . . . . . . . . . . . . . . . . . . 18

12 Connecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13 Installing the Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14 Checking the Fluid Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

15 Checking the T ire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16 Installing the CE Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

17 Adding Rear W eight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18 Adjusting the W eight T ransfer of the

Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cab Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Width Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Before Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Checking the Machine Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Checking the T ire Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adding Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking the Safety-Interlock System . . . . . . . . . . . . . . 37

Adjusting the Roll Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Understanding the Display-Screen

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

During Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Resetting the PT O Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Understanding T urnaround Mode . . . . . . . . . . . . . . . . . . . . . 43

Shutting Of f the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

After Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

After Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Servicing the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

T owing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Hauling the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Recommended Maintenance Schedule(s) . . . . . . . . . . . 47

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pre-Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Raising the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Raising the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Greasing the Bearings and Bushings . . . . . . . . . . . . . . . . 51

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Engine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Servicing the Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Servicing the Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Draining W ater from the Fuel/W ater

Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Servicing the Fuel/W ater Separator

...................................................................... 56

Servicing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning the Fuel T ank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Inspecting the Fuel Lines and

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electrical System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Accessing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Disconnecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing or Installing the Battery . . . . . . . . . . . . . . . . . . . . 60

Checking the Battery Condition . . . . . . . . . . . . . . . . . . . . . . . . . 60

Locating the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Drive System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

T orquing the Wheel-Lug Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Aligning the PT O Driveshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Cooling System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cooling System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Coolant Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Checking the Cooling System and Coolant

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Checking the Hood-Air-Intake Screen . . . . . . . . . . . . . . . 64

Checking the Cooling Fins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Inspecting the Cooling-System Hoses . . . . . . . . . . . . . . 64

Brake Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Checking and Adjusting the Parking

Brake ............................................................ 65

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Checking the Alternator-Belt T ension . . . . . . . . . . . . . . . . 66

Servicing the T raction Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Controls System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Adjusting the PT O-Clutch Gap . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3