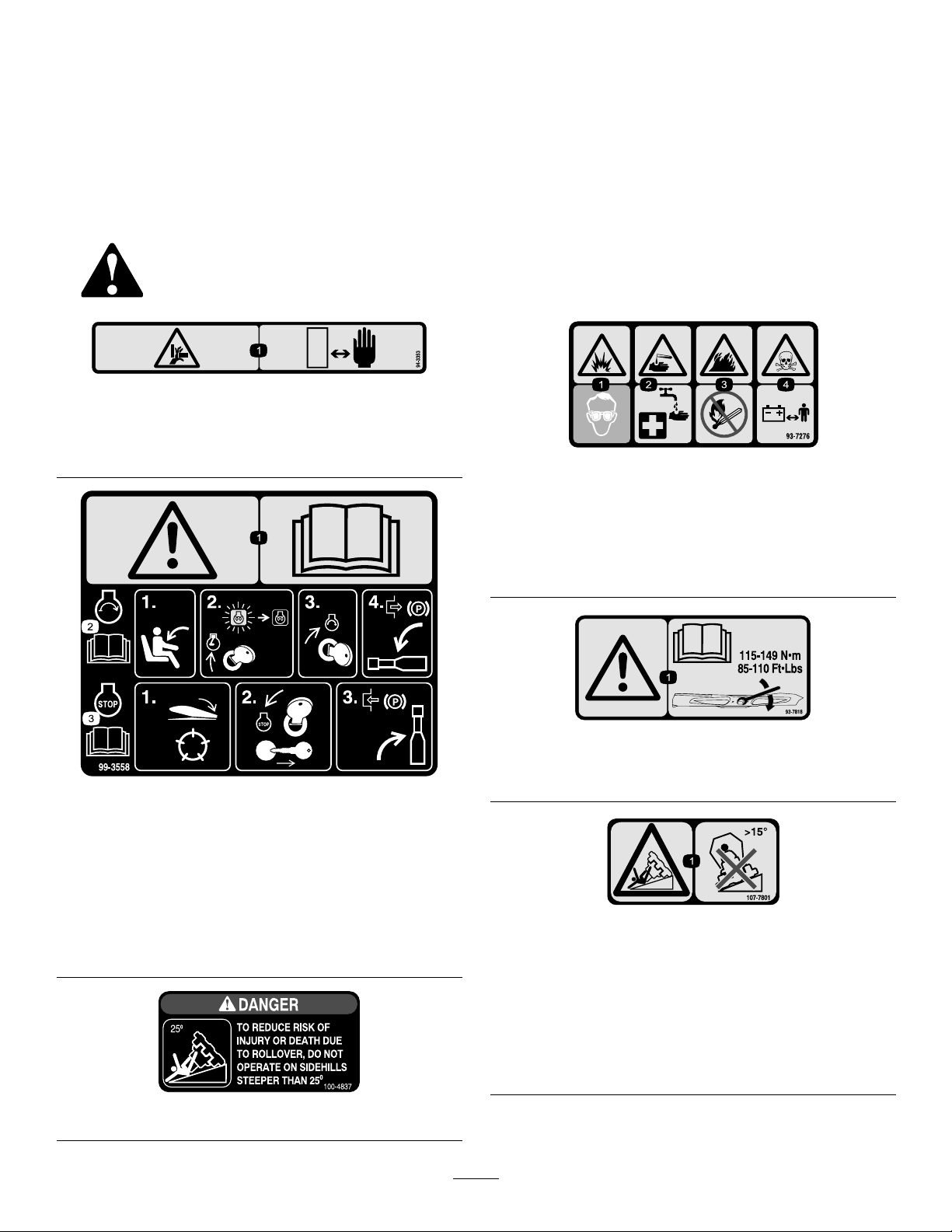

factors.Amongthesearemowingconditionssuchas

wetorundulatingterrain,speed(especiallyinturns),

positionofthecuttingunits(withtheSidewinder),

tirepressure,andoperatorexperience.Atsidehill

anglesof20degreesorless,theriskofarolloveris

low .Astheslopeangleincreasestoarecommended

maximumlimitof25degrees,theriskofarollover

increasestoamoderatelevel.Donotexceeda25

degreesidehillslopeanglebecausetheriskofa

rolloverandseriousinjuryordeathisveryhigh.

•Onmodel30826,theslopeangleatwhichthe

machinewilltipisdependentonmanyfactors.

Amongthesearemowingconditionssuchaswet

orundulatingterrain,speed(especiallyinturns),

positionofthecuttingunits(withtheSidewinder),

tirepressure,andoperatorexperience.Atsidehill

anglesof15degreesorless,theriskofarolloveris

low .Astheslopeangleincreasestoarecommended

maximumlimitof20degrees,theriskofarollover

increasestoamoderatelevel.Donotexceeda20

degreesidehillslopeanglebecausetheriskofa

rolloverandseriousinjuryordeathisveryhigh.

•Forsteeringcontrol,lowerthecuttingunitswhen

goingdownslopes.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Thismachineisnotdesignedorequippedfor

on-roaduseandisaslow-movingvehicle.Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reectors.

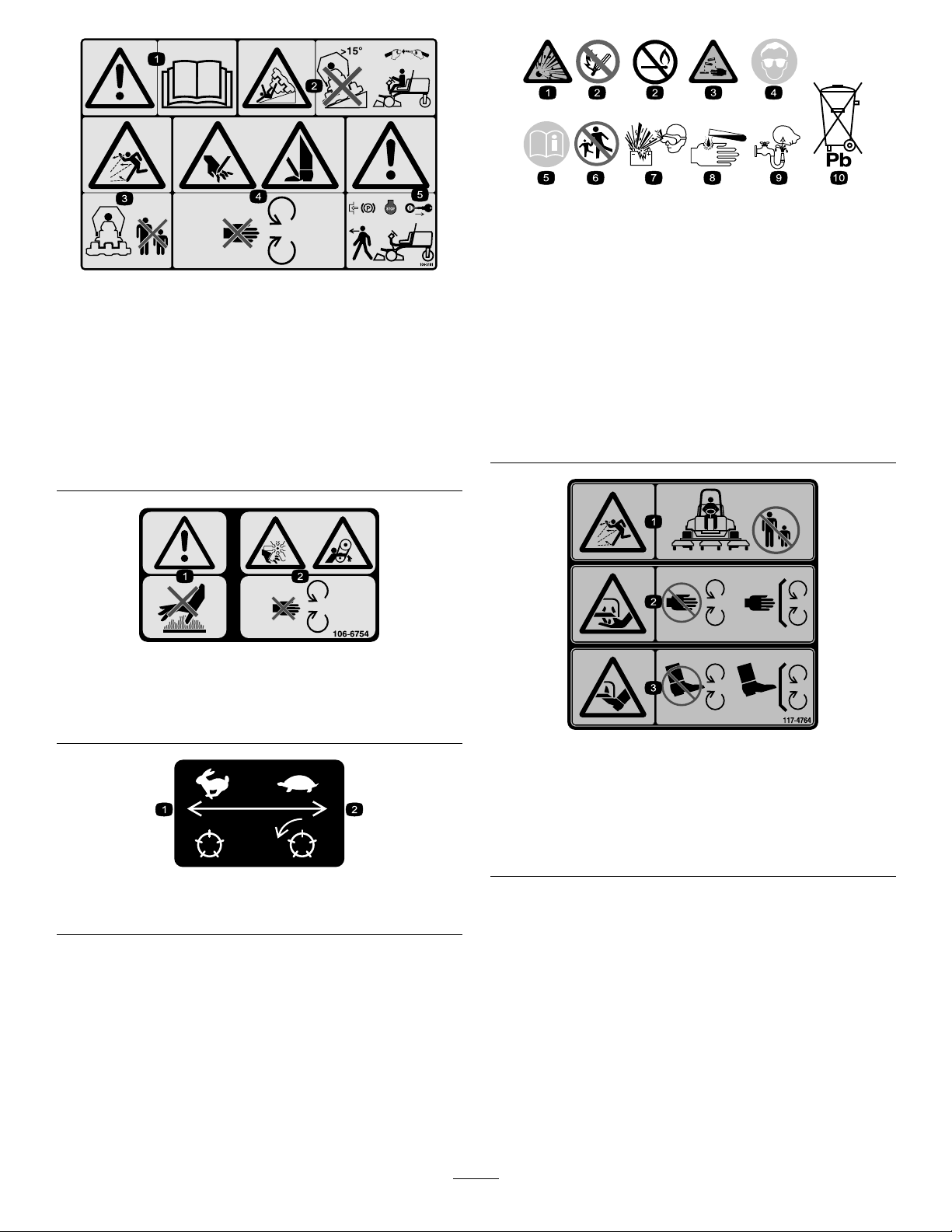

MaintenanceandStorage

•Beforeservicingormakingadjustments,stopthe

engineandremovetheignitionkey.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheck

allnuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.Ifuidisinjectedinto

theskinitmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitstotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof104dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof90dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

7