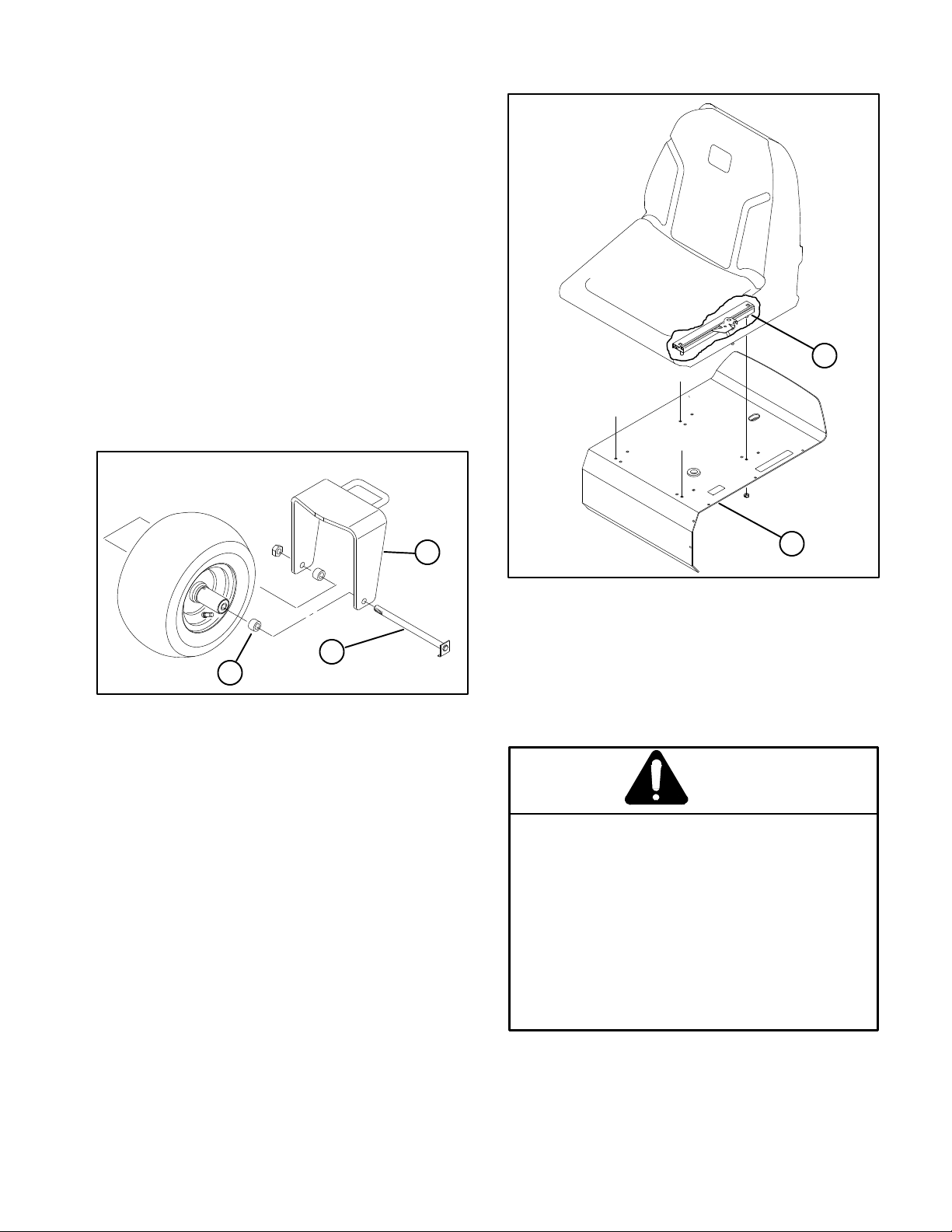

# !

+( 5$)(6: $/(46 5:0%2/ 0($15

! " 24 <

= ;3(4521$/ 5$)(6:

,15647&6,21 ($' $1' 71'(4

56$1' 6+( ,15647&6,21 %(&$75(

,6 +$5 62 '2 9,6+ 5$)(6: $,/74( 62 &203/: 9,6+

6+( ,15647&6,21 0$: 4(57/6 ,1 3(4521$/ ,1-74:

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of

the personnel involved in the operation, transport,

maintenance, and storage of the machine. Improper

use or maintenance of the machine can result in injury

or death. To reduce the potential for injury or death,

comply with the following safety instructions.

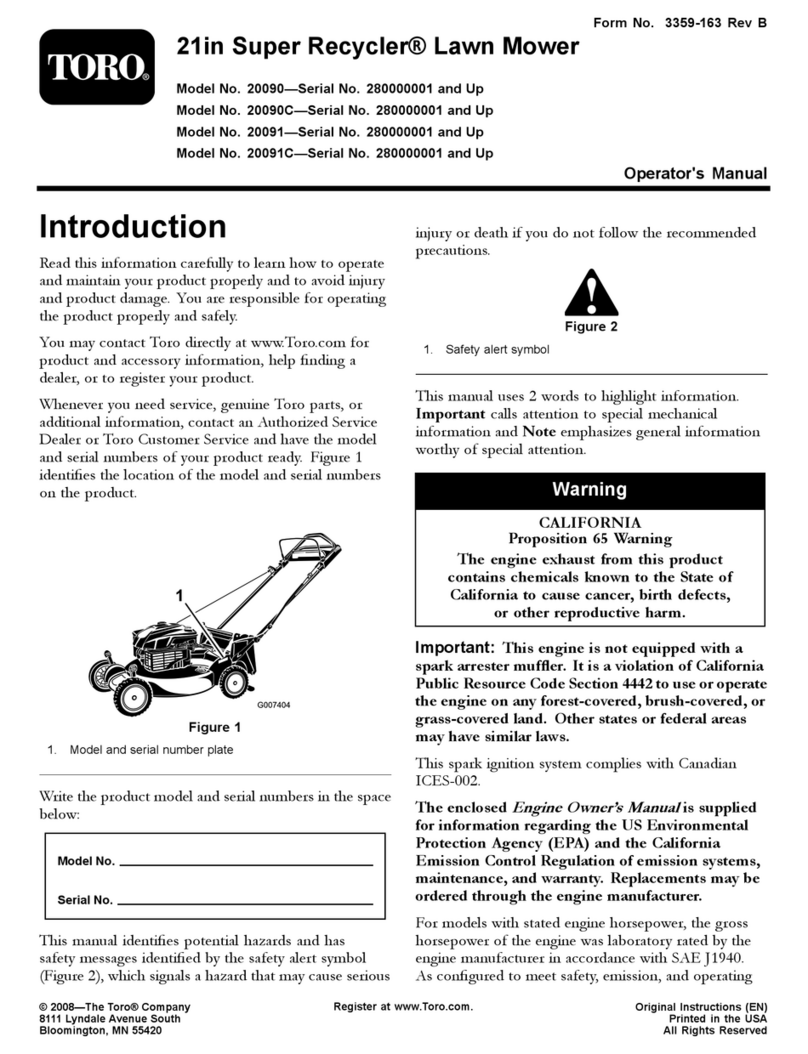

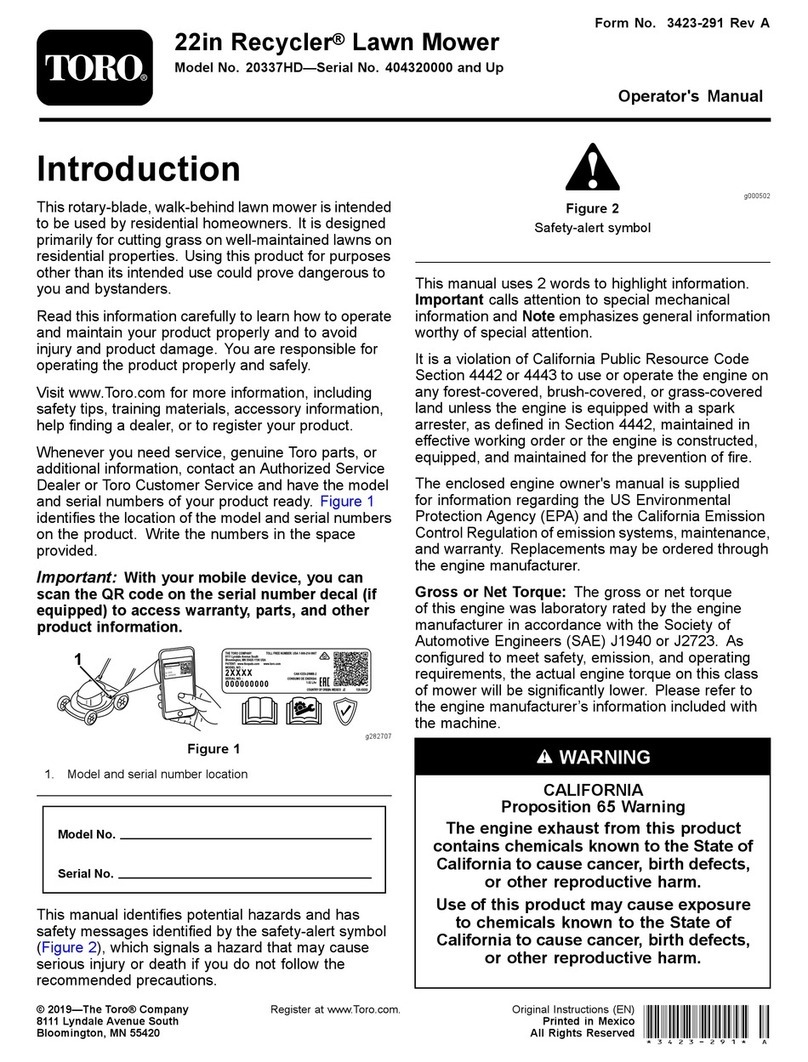

Read and understand the contents of this

Operator's Manual before starting and operating the

machine. Become familiar with all controls and know

how to stop quickly. A replacement manual is available

by sending complete Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, Minnesota 55420-1196

Never allow children to operate the machine or

adults to operate it without proper instructions.

Become familiar with the controls and know how to

stop the engine quickly.

Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is defective or

damaged, repair or replace it before operating the

machine.

Always wear substantial shoes. Do not operate

machine while wearing sandals, tennis shoes or

sneakers. Do not wear loose fitting clothing because it

could get caught in moving parts and possibly cause

personal injury.

Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some local

ordinances and insurance regulations.

Make sure work area is clear of objects which

might be picked up and thrown by the reels.

Do not carry passengers on the machine, and

keep everyone, especially children and pets, away

from the areas of operation.

Since diesel fuel is highly flammable, handle it

carefully.

A. Use an approved fuel container.

B. Do not remove cap from fuel tank when engine

is hot or running. Remove cap slowly.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to bottom of filler

neck. DO NOT OVERFILL.

E. Wipe up any spilled fuel.

"

Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous

and could be deadly.

Sit on the seat when starting and operating the

machine.

Check the safety interlock switches daily for proper

operation; refer to page18. If a switch should fail,

replace the switch before operating the machine.

)6(4 (8(4: 692 :($45 4(3/$&( $// 6+4(( ,16(4/2&.

59,6&+(5 ,1 6+( 5$)(6: 5:56(0 4(*$4'/(55 ,) 6+(: $4(

924.,1* 3423(4/: 24 126

To start the engine:

A. Sit on the seat, make sure cutting units are

disengaged.

B. Verify that functional control lever is in neutral.

C. Verify that parking brake is set.

D. roceed to start engine.

Using the machine demands attention, and to

prevent loss of control:

A. Mow only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not drive close to sand traps, ditches, creeks

or other hazards.

D. Reduce speed when making sharp turns. Avoid

sudden stops and starts.

E. Before backing up, look to the rear to be sure no

one is behind the machine.

F. Watch out for traffic when near or crossing roads.

Always yield the right-of-way.

G. Apply the service brakes when going downhill

to keep forward speed slow and to maintain control

of the machine.

Keep hands, feet and clothing away from moving

parts and the reel discharge area. The grass baskets

must be in place during operation of the reels or

thatchers for maximum safety. Shut the engine off

before emptying the baskets.

This product may exceed noise levels of 85 dB(A)

at the operator position. Ear protectors are

recommended, for prolonged exposure, to reduce the

potential of permanent hearing damage.

Raise the cutting units when driving from one work

area to another.

Do not touch engine, muffler or exhaust pipe while

engine is running or soon after it is stopped because

these areas could be hot enough to cause burns.