Set-Up Instructions

5

2

1

3

m–2481

4

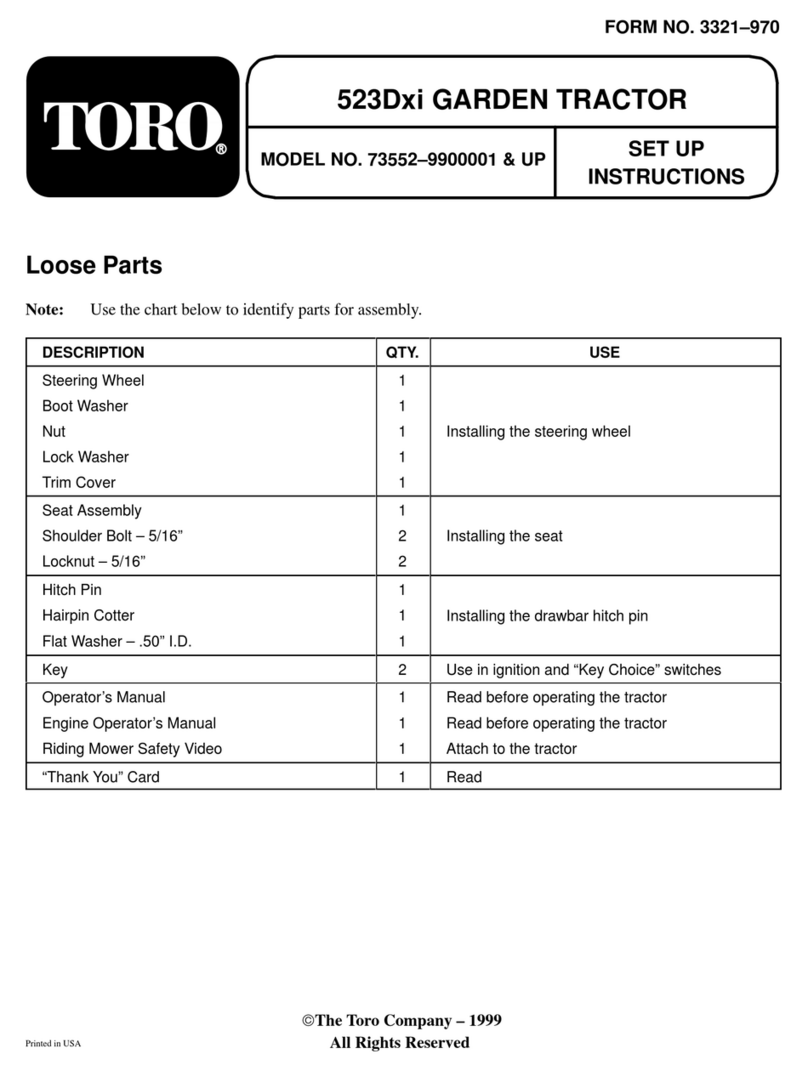

Figure 6

1. Drawbar

hitch pin

2.

Drawbar hitch

3.

.50” Flat washer

4.

Hairpin cotter

Checking

the W

iring and

Fasteners

•Inspect the tractor for any loose electrical

connections and secure them as required. Check

the wire routing to make sure moving parts do

not interfere with wires and cause a short.

•Assure all fasteners are tight.

Burnishing

the Clutch

The following break–in procedure must be performed

as part of predelivery service or when a new clutch is

installed.

Note: There must be a PTO driven

attachment installed to provide a load

in order to burnish the clutch facings

properly.

1. Run the engine at full throttle and engage the

clutch bringing the load to full speed. Then

disengage the clutch.

2. Let the load come to a full stop, then engage

again.

3. Repeat these procedures (1 and 2) 5 times.

Test

Driving the T

ractor

1. Check the oil level in the crankcase (refer to

Engine Oil in your tractor Operator’s Manual for

oil type, viscosity and crankcase capacity).

2. Check the oil level in the transaxle (refer to

Transaxle Fluid in your tractor Operator’s

Manual for oil type, viscosity and capacity).

3. Check the coolant level in the coolant recovery

tank.

4. Check to make sure all lubrication points have

been greased as shown in the Maintenance

section of tractor Operator’

s Manual.

5. Fill the tank with unleaded regular gasoline with

an octane rating of at least 85. Open the fuel

shutoff valve and check the fuel hose and fittings

for leaks.

6. As applicable, check and test the operation of the

following:

•Engine, choke and throttle controls

•Gauges

•

Headlights and taillights

•Indicator lights

•PTO clutch and brake

•Lift system

•Service and parking brakes

•T

ransmission controls

•Steering

•Tractor operation in forward and reverse

7. Test the operation of the safety interlock system

(refer to the tractor Operator’s Manual for the

correct procedure).