Toro 8125 User manual

Other Toro Lawn Mower manuals

Toro

Toro Z Master Professional 7500-DSeries User manual

Toro

Toro Super Bagger 20192 User manual

Toro

Toro 74024 User manual

Toro

Toro 73547 Manual

Toro

Toro 72958 User manual

Toro

Toro TimeCutter MX 5075 User manual

Toro

Toro 74822 User manual

Toro

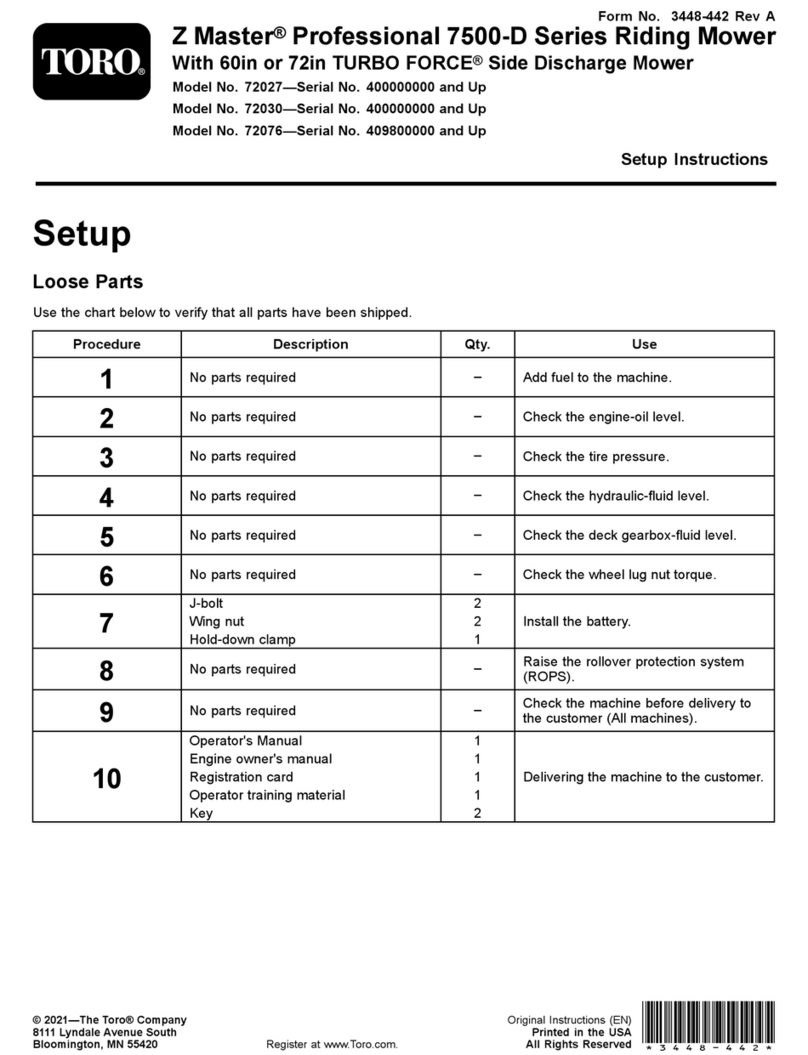

Toro 72076 Manual

Toro

Toro 22189TE User manual

Toro

Toro 03530 User manual

Popular Lawn Mower manuals by other brands

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual

MTD

MTD 795, 792, 791, 790 Operator's manual