•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecareas

rotatingonecylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

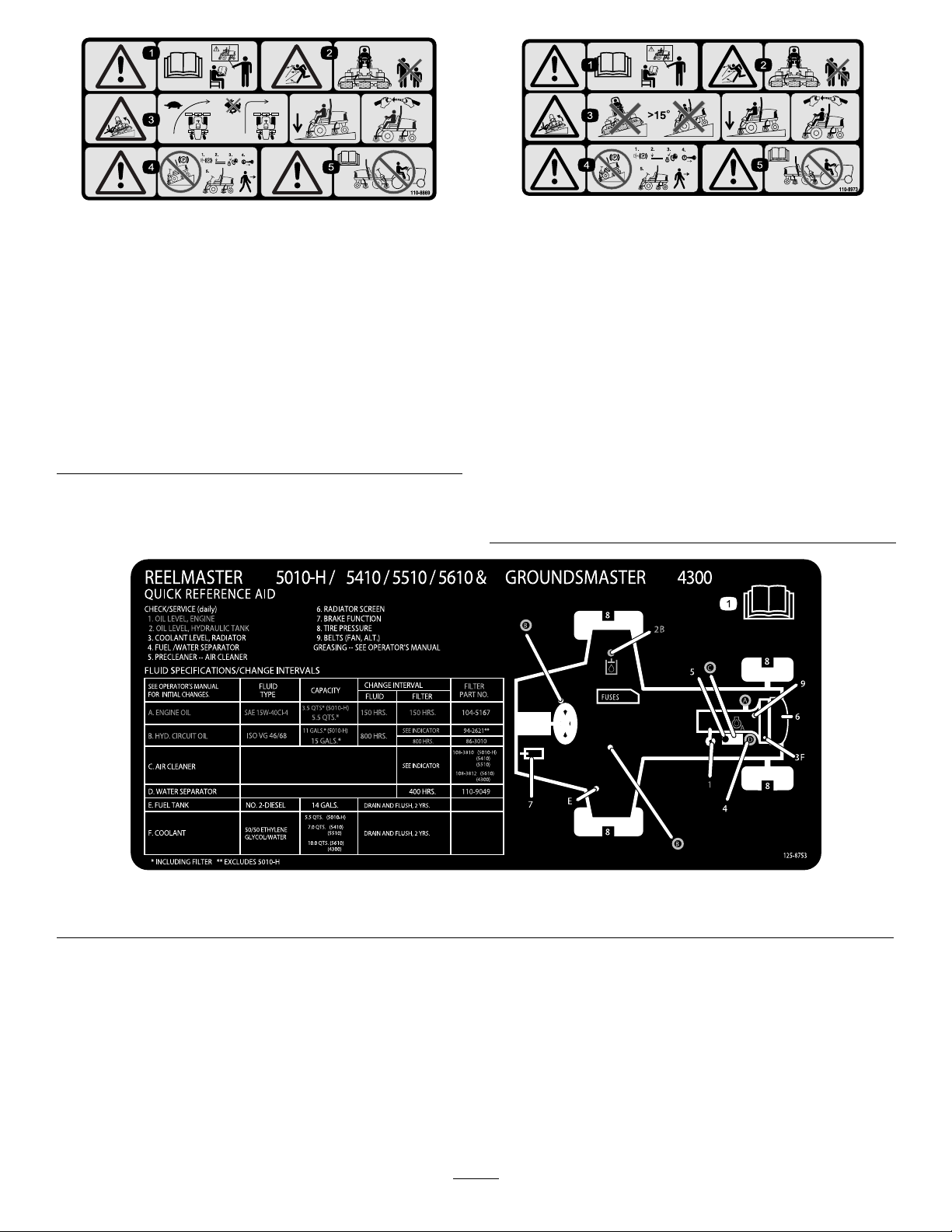

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

6