Safety

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitoperatorsmanual’s

beforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetraction

unitorcuttingunitswithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanual

shouldoperatethetractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenunderthe

inuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisillegibleordamaged,

repairorreplaceitbeforeoperationiscommenced.

Alsotightenanyloosenuts,bolts,andscrewsto

ensurecuttingunitisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperate

cuttingunitswhilewearingsandals,tennisshoes,

sneakersorshorts.Also,donotwearloosetting

clothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantialshoes.

Wearingsafetyglasses,safetyshoesandahelmetis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Removealldebrisorotherobjectsthatmightbe

pickedupandthrownbythecuttingunitreelblades.

Keepallbystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.

Checkcuttingunitfordamagedparts.Repairany

damagebeforerestartingandoperatingthecutting

unit.

•Lowerthecuttingunitstothegroundandremove

keyfromignitionswitchwhenevermachineisleft

unattended.

•Besurecuttingunitsareinsafeoperatingcondition

bykeepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,

adjustingorstoringthemachine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsand

accessoriestokeeptheToroallTORO.Neveruse

"will-t"replacementpartsandaccessories

madebyothermanufacturers.Lookforthe

Torologotoassuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthe

warrantyofTheToroCompany.

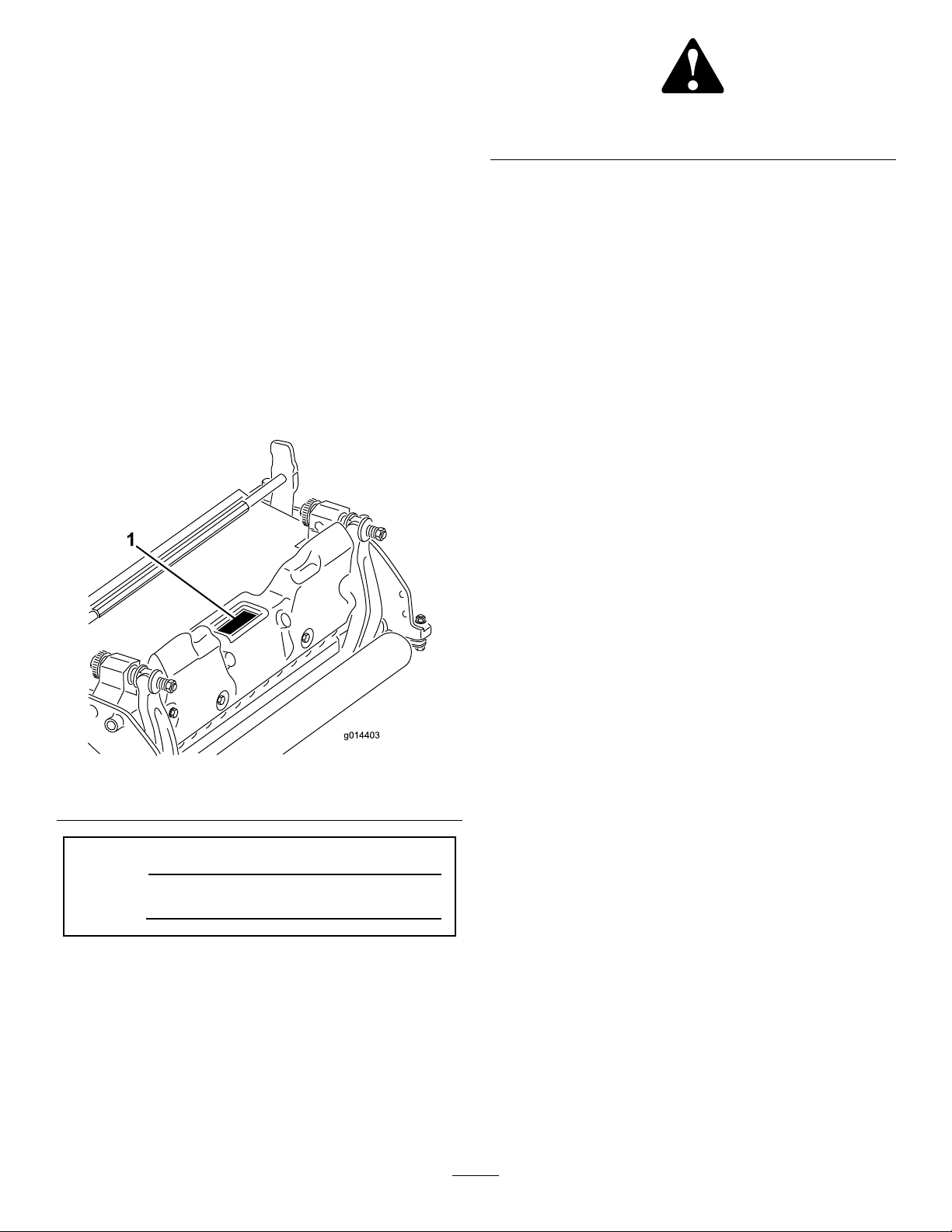

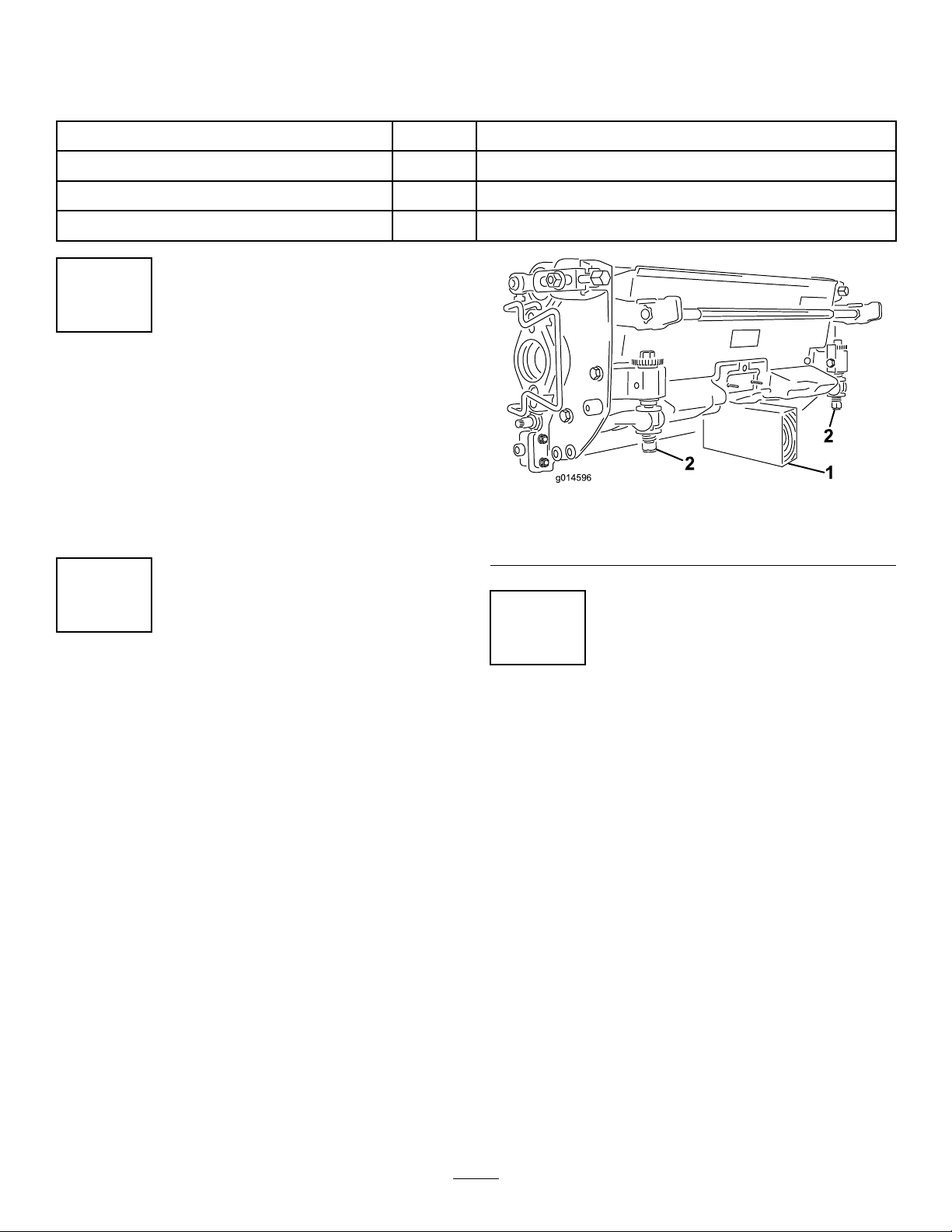

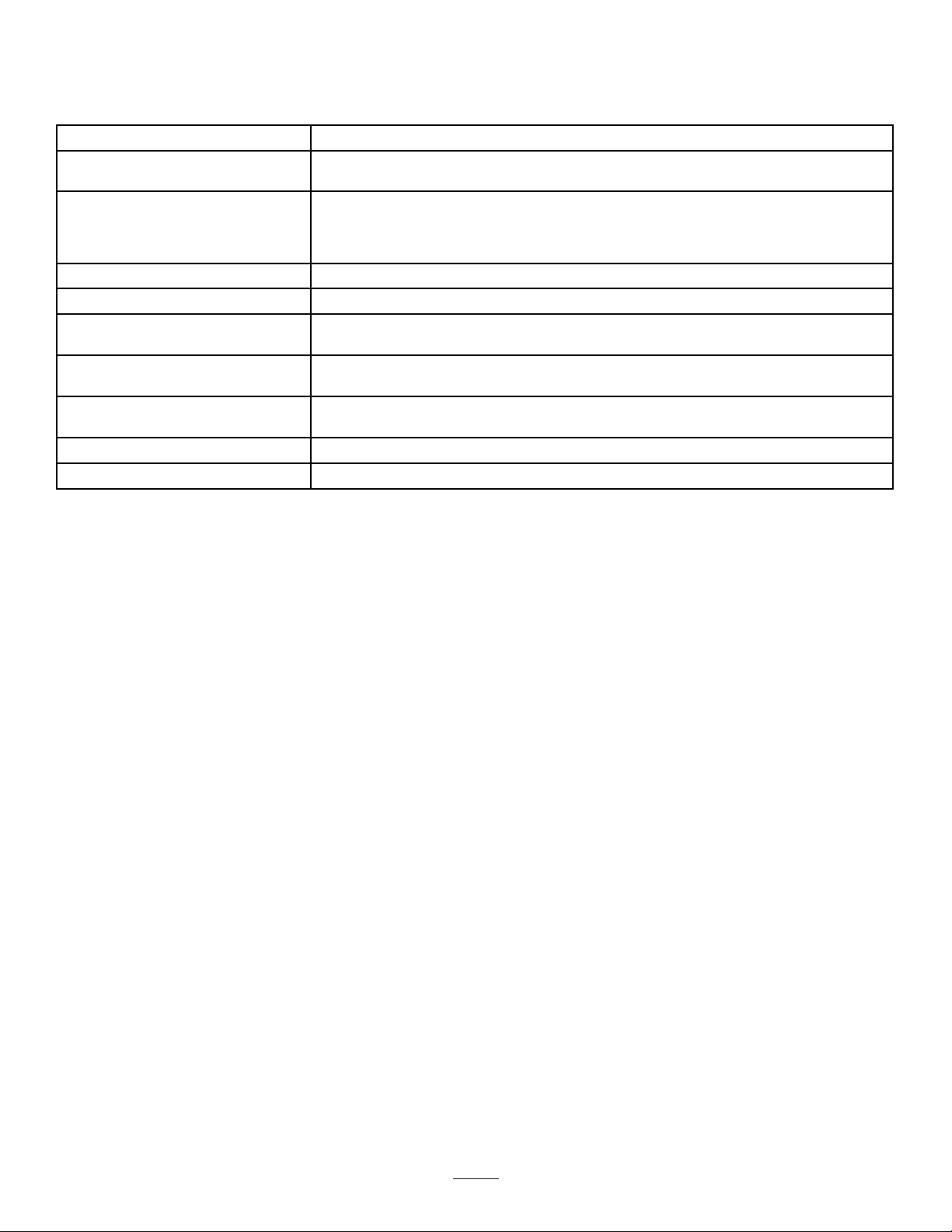

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

104–7729

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cutting/dismemberment

hazard;handorfoot—stop

theengineandwaitfor

movingpartstostop.

3