5. Do not carry passengers on the machine. Keep ev-

eryone, especially children and pets, away from the ar-

eas of operation.

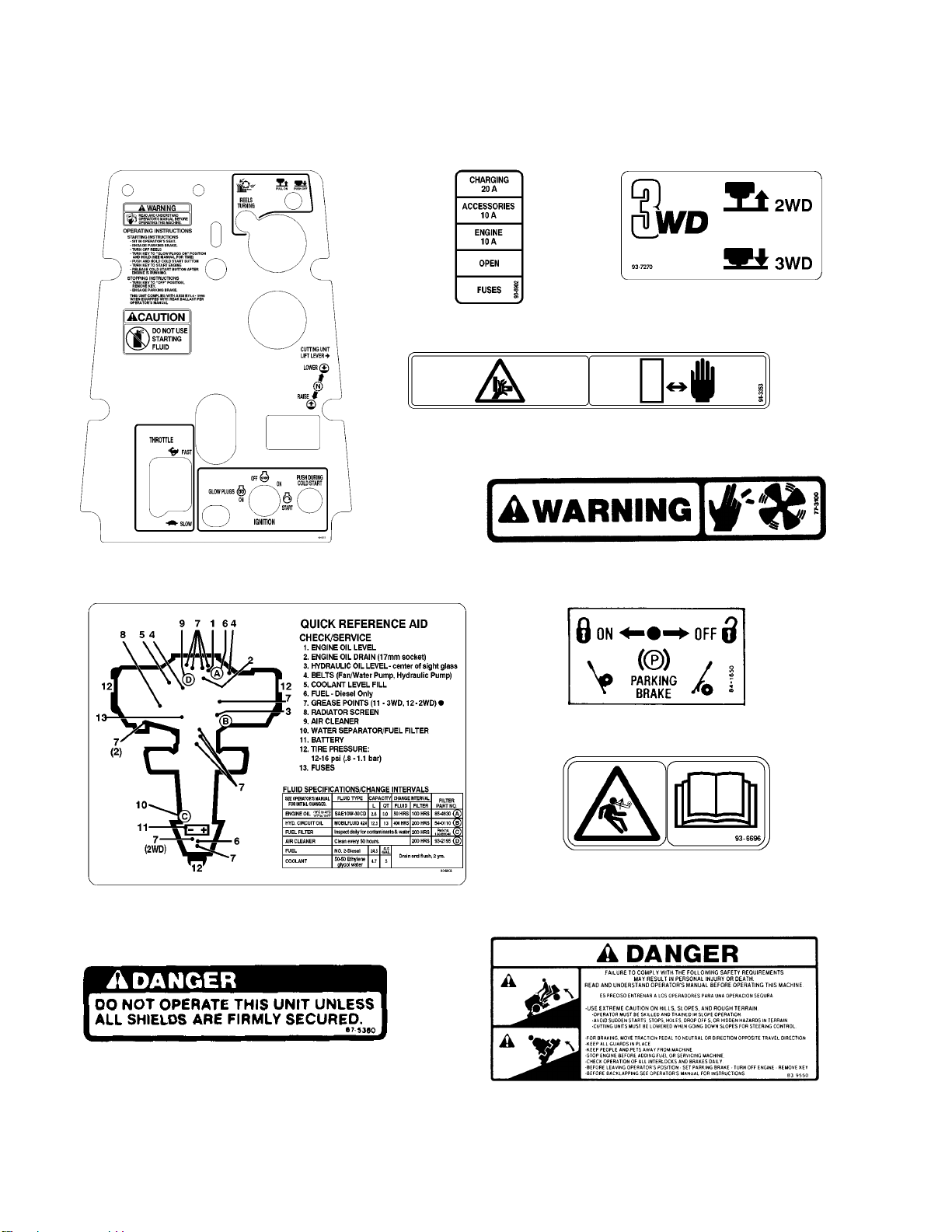

6. Keepallshields,safetydevicesanddecalsinplace.

lf a shield, safety device or decal is damaged, malfunc-

tioning or illegible, repair or replace it before operating

the machine.

7. Alwayswearsubstantial shoes.Do notoperatema-

chine while wearing sandals, tennis shoes or sneakers.

Do not wear loose fitting clothing because it could get

caught in moving parts and possibly cause personal in-

jury.

8. Wearing safety glasses, safety shoes, long pants

andahelmetisadvisableandrequiredbysomeIocalor-

dinances and insurance regulations.

9. Make sure the work area is clear of objects which

might be picked up and thrown by the reels.

10. Fill the fuel tank with diesel fuel before starting the

engine. Avoid spilling any fuel. Since fuel is highly flam-

mable, handle it carefully.

A. Use an approved fuel container.

B. Do not remove the cap from the fuel tank when

engine is hot or running.

C. Do not smoke while handling diesel fuel.

D. Fillfueltankoutdoorsandnotoveroneinchfrom

thetop ofthe tank,(bottom ofthe fillerneck). Donot

overfill.

While Operating

11. Donot runtheengineina confinedarea withoutad-

equate ventilation. Exhaust fumes are hazardous and

could be deadly.

12. Sit on the seat when starting and operating the ma-

chine.

13. Check interlock switches daily for proper operation

(see Checking Interlock Switches of the Operator’s

Manual).Donotrelyentirely onsafetyswitches;shutoff

engine before getting off the seat. If a switch fails, re-

placeitbeforeoperatingthemachine.Theinterlocksys-

tem is for your protection, so do not bypass it. Replace

all interlock switches every two years.

14. When starting the engine:

A. Engage parking brake.

B. Besure tractionpedal isinneutral andreel drive

is in the disengage position.

C. After the engine starts, release parking brake

and keep foot off the traction pedal. The machine

must not move. If movement is evident, the neutral

control linkage is incorrectly adjusted: therefore,

shut engine off and adjust until the machine does

not move when the traction pedal is released (see

Adjusting Transmission for Neutral of the Opera-

tor’s Manual).

D. Hills over 15 degrees should be mowed up and

down, not side to side (see Slope Gauge of the Op-

erator’s Manual).

E. Mowing hills may be dangerous. Hills over 20

degreesshould notbemowed(seeSlope Gaugeof

the Operator’s Manual).

F. Stay alert for holes in terrain and other hidden

hazards.Useextremecarewhen operatingcloseto

sand traps, ditches, creeks, steep hillsides or other

hazards.

G. Reduce speed when making sharp turns. Avoid

sudden stops and starts. Use reverse pedal for

braking. The cutting units must be lowered when

going down slopes for steering control.

H. Before backing up, look to the rear and assure

that no one is behind the machine. Watch out for

trafficwhennearorcrossingroads.Alwaysyieldthe

right of way.

15. Keep hands, feet, and clothing away from moving

parts and the reel discharge area. Grass baskets, if so

equipped, must be in place during reel operation for

maximum safety.

16. This product may exceed noise levels of 85 dB(A)

at the operator position. Ear protectors are recom-

mended for prolonged exposure to reduce the potential

of permanent hearing damage.

17. Raise the cutting units when driving from one work

area to another.

18. Do not touch engine, muffler, exhaust pipe, or hy-

draulic tank while engine is running or soon after it has

stopped. These areas could be hot enough to cause

burns.

19. If a cutting unit strikes a solid object or vibrates ab-

normally, stop cutting unit immediately. Turn the engine

off, wait for all motion to stop and inspect for damage.

A damaged reel or bedknife must be repaired or re-

placed before operation is continued.

Safety Page 1 – 2 Reelmaster 2300–D/2600–D