Warning

CALIFORNIA

Pr oposition 65 W ar ning

T he engine exhaust fr om this pr oduct contains

chemicals kno wn to the State of Calif or nia to

cause cancer , bir th defects, or other r epr oducti v e

har m.

T his spark ignition system complies with Canadian

ICES-002

Contents

Introduction ......................................................... 2

Safety .................................................................. 4

Safe Operating Practices ........................... 4

T oro Mo w er Safety .................................. 5

Sound Pressure Lev el ............................... 6

Sound P o w er Lev el .................................. 6

Vibration Lev el ....................................... 6

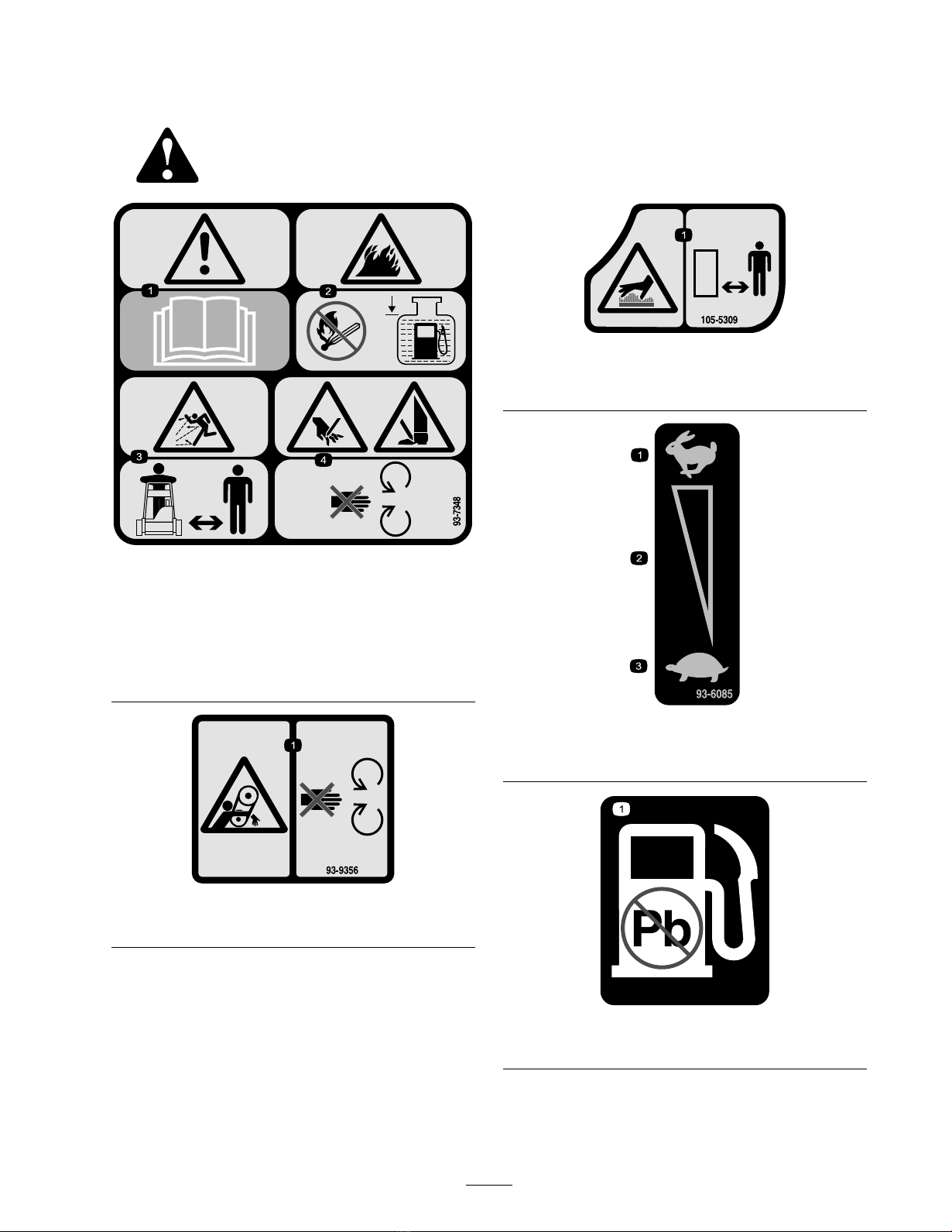

Safety and Instr uctional Decals . . . . . . . . . . . . . . . . . 7

Setup ................................................................... 9

1 Installing the Handle ............................. 9

2 Adjusting the Handle ........................... 10

3 Installing the T ranspor t W heels . . . . . . . . . . . . . 10

4 Chec king Fluid Lev els ......................... 11

5 Installing the Grass Bask et . . . . . . . . . . . . . . . . . . . 11

6 R eading the Man uals and Viewing the

Video .................................... 11

Product Ov er view ............................................... 13

Controls .............................................. 13

Specifications ....................................... 14

Operation .......................................................... 15

T hink Safety First .................................. 15

Chec king the Engine Oil Lev el . . . . . . . . . . . . . . . . 15

Filling the Fuel T ank .............................. 15

Chec king the Interloc k Switc h

Operation .............................. 16

Star ting and Stopping the Engine . . . . . . . . . . . . . 16

T ranspor t Operation ............................. 16

Pre paring to Mo w ................................. 17

Mo wing Operation ................................ 17

Maintenance ....................................................... 19

R ecommended Maintenance

Sc hedule(s) ................................... 19

Daily Maintenance Chec klist . . . . . . . . . . . . . . . . . . . 20

Engine Maintenance .................................... 21

Engine Oil ........................................... 21

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . 21

R e placing the Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . 22

Fuel System Maintenance .............................. 23

Cleaning the Fuel Filter .......................... 23

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . 23

Ser vicing the Interloc k Switc h . . . . . . . . . . . . . . . . 23

Dri v e System Maintenance ............................ 23

Chec king the T ransmission Fluid

Lev el ..................................... 23

Changing the T ransmission Fluid . . . . . . . . . . . . . 24

Brak e Maintenance ...................................... 24

Adjusting the Ser vice/P arking

Brak e .................................... 24

Belt Maintenance ......................................... 24

Adjusting the Belts ................................ 24

Controls System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 27

Adjusting the T raction Control . . . . . . . . . . . . . . . . 27

Adjusting the R eel Control . . . . . . . . . . . . . . . . . . . . . 28

Cutting Unit Maintenance .............................. 28

Se parating the Cutting Unit from the

T raction Unit ......................... 28

Lev eling the R ear R oller to the

R eel ...................................... 29

Adjusting the Bedknife to the R eel . . . . . . . . . . . 29

Adjusting the Height of Cut . . . . . . . . . . . . . . . . . . . . 30

Adjusting the Cut-Off Bar . . . . . . . . . . . . . . . . . . . . . . 31

Ser vicing the Bedbar .............................. 31

Bac klapping the R eel ............................. 32

Storag e .............................................................. 33

Introduction

R ead this infor mation carefully to lear n ho w to operate

and maintain y our product properly and to a v oid injur y

and product damag e . Y ou are responsible for operating

the product properly and safely .

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a

dealer , or to register y our product.

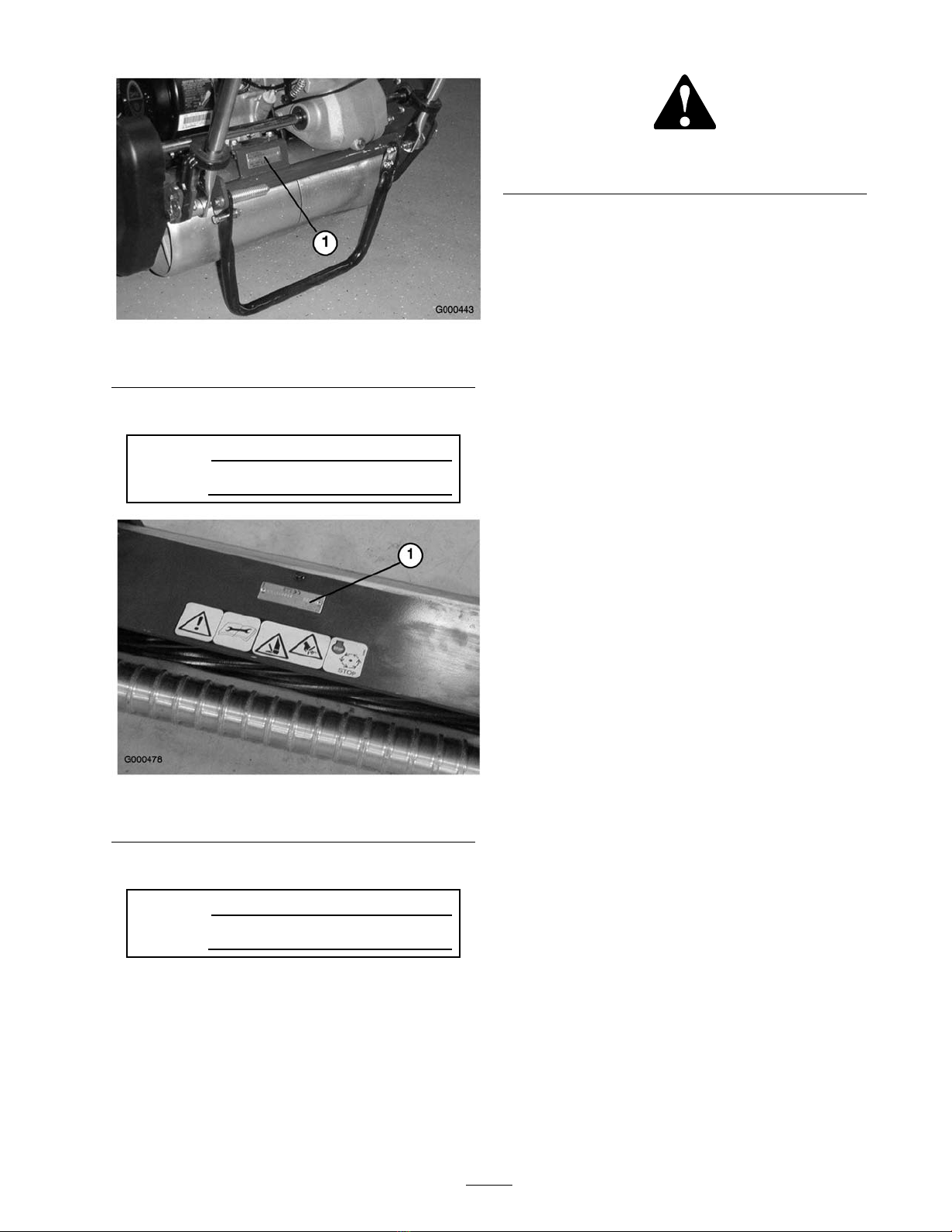

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model

and serial n umbers of y our product ready . Figure 1

and Figure 2 identify the location of the model and

serial n umbers on the product. W rite the n umbers in

the space pro vided.

© 2004—The Toro® Company8111 Lyndale Avenue SouthBloomington, MN 55420

2

Contact us at www.Toro.com.

Printed in the USA.All Rights Reserved