5

•Reduce the throttle setting during engine run-out and, if

the engine is provided with a shut-off valve, turn the

fuel off at the conclusion of mowing.

•Keep hands and feet away from the cutting units.

•Look behind and down before backing up to be sure of

a clear path.

•Slow down and use caution when making turns and

crossing roads and sidewalks. Stop cylinders/reels if not

mowing.

•Do not operate the mower under the influence of

alcohol or drugs

•Use care when loading or unloading the machine into a

trailer or truck

•Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

Maintenance and Storage

•Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

•Never store the equipment with fuel in the tank inside a

building where fumes may reach an open flame or

spark.

•Allow the engine to cool before storing in any

enclosure.

•To reduce the fire hazard, keep the engine,

silencer/muffler, battery compartment and fuel storage

area free of grass, leaves, or excessive grease.

•Check the grass catcher frequently for wear or

deterioration.

•Keep all parts in good working condition and all

hardware and hydraulic fittings tightened. Replace all

worn or damaged parts and decals.

•If the fuel tank has to be drained, do this outdoors.

•Be careful during adjustment of the machine to prevent

entrapment of the fingers between moving blades and

fixed parts of the machine.

•On multi-cylinder/multi-reel machines, take care as

rotating one cylinder/reel can cause other

cylinders/reels to rotate.

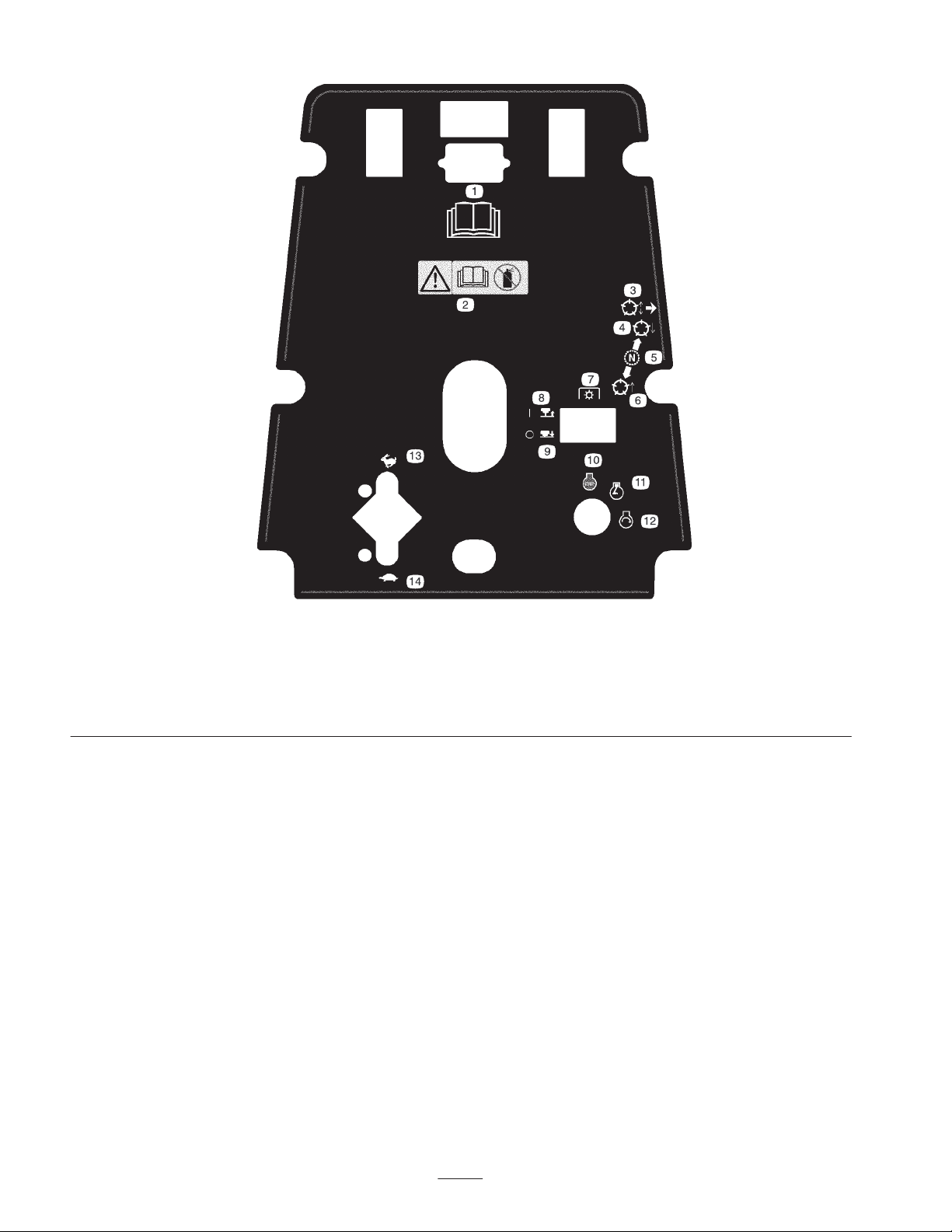

•Disengage drives, lower the cutting units, set parking

brake, stop engine and remove key and disconnect spark

plug wire. Wait for all movement to stop before

adjusting, cleaning or repairing.

•Clean grass and debris from cutting units, drives,

silencers/mufflers, and engine to help prevent fires.

Clean up oil or fuel spillage.

•Use jack stands to support components when required.

•Carefully release pressure from components with stored

energy.

•Disconnect battery and remove spark plug wire before

making any repairs. Disconnect the negative terminal

first and the positive last. Reconnect positive first and

negative last.

•Use care when checking the cylinders/reels. Wear

gloves and use caution when servicing them.

•Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

•Charge batteries in an open well ventilated area, away

from spark and flames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothing and use insulated tools.

Toro Riding Mower Safety

The following list contains safety information specific to

Toro products or other safety information that you must

know that is not included in the CEN, ISO, or ANSI

standard.

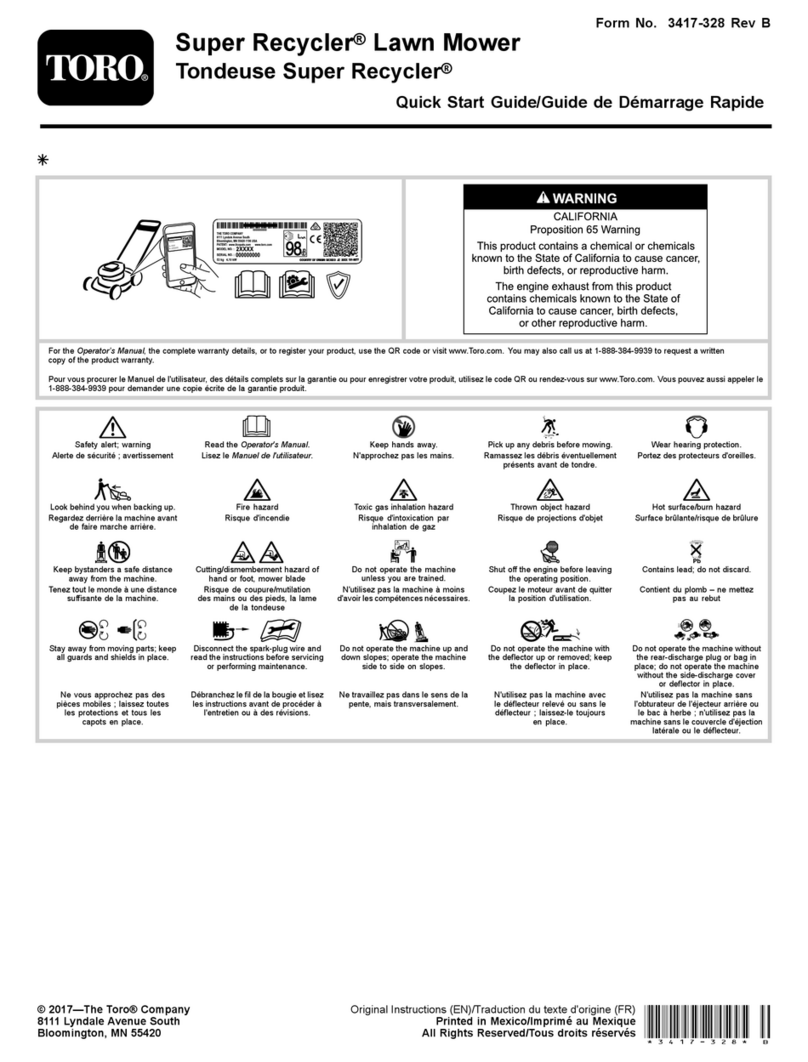

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

Use of this product for purposes other than its intended use

could prove dangerous to user and bystanders.

Engine exhaust contains carbon monoxide, which

is an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

Warning

•Know how to stop the engine quickly.

•Do not operate the machine while wearing tennis shoes

or sneakers.

•Wearing safety shoes and long pants is advisable and

required by some local ordinances and insurance

regulations.

•Handle fuel carefully. Wipe up any spills.

•Check the safety interlock switches daily for proper

operation. If a switch should fail, replace the switch

before operating the machine. After every two years,

replace all four interlock switches in the safety system,

whether they are working properly or not.

•Before starting the engine, sit on the seat.

•Using the machine demands attention. To prevent loss

of control: