Contents

Safety.......................................................................4

GeneralSafety...................................................4

EngineEmissionCertication.............................4

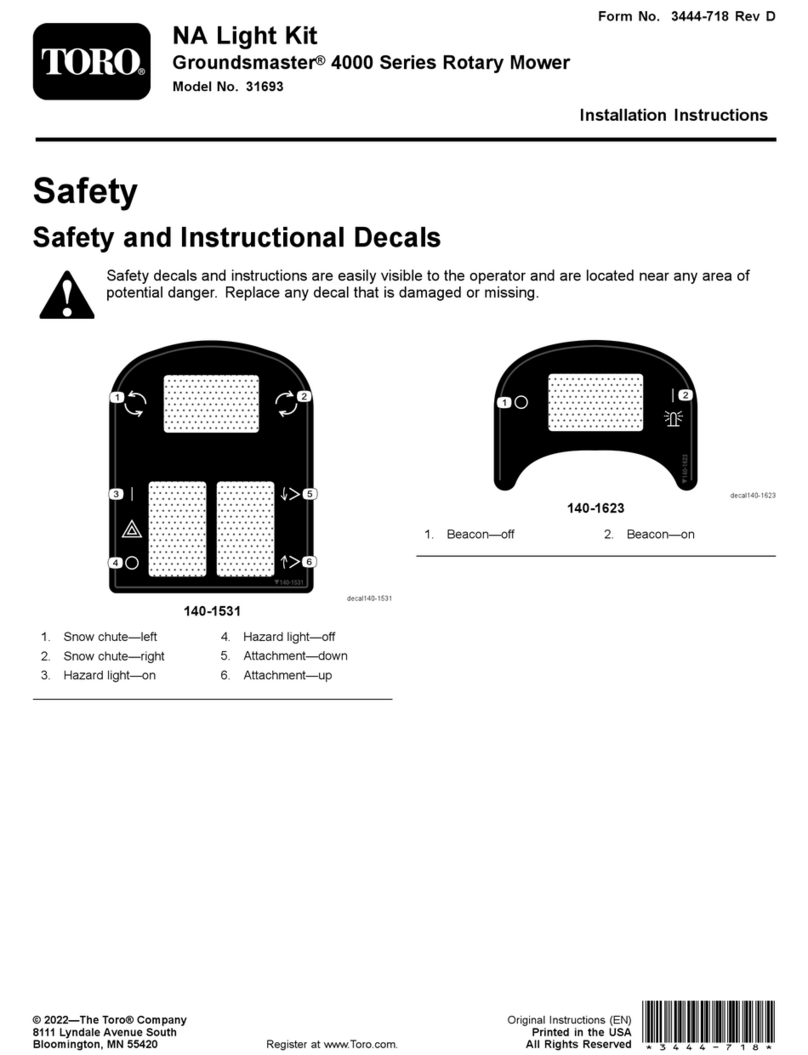

SafetyandInstructionalDecals..........................5

Setup......................................................................10

1AdjustingtheTirePressure.............................11

2InstallingtheCuttingUnits...............................11

3AdjustingtheTurf-Compensation

Spring...........................................................14

4UsingtheCutting-UnitKickstand....................15

5ApplyingtheCEDecals.................................15

ProductOverview...................................................16

Controls...........................................................16

Specications..................................................24

Attachments/Accessories.................................24

BeforeOperation.................................................24

BeforeOperationSafety...................................24

PerformingDailyMaintenance..........................25

FillingtheFuelTank..........................................25

DuringOperation.................................................26

DuringOperationSafety...................................26

StartingtheEngine...........................................27

ShuttingOfftheEngine.....................................27

BurnishingtheBrakes.......................................27

CuttingGrasswiththeMachine........................27

DieselParticulateFilterRegeneration...............28

AdjustingtheLift-ArmCounterbalance.............40

AdjustingtheLift-ArmTurnaround

Position.........................................................40

UnderstandingtheDiagnosticLight..................40

CheckingtheInterlockSwitches.......................41

OperatingTips.................................................42

AfterOperation....................................................42

AfterOperationSafety......................................42

HaulingtheMachine.........................................42

IdentifyingtheTie-DownPoints........................42

JackingPoints..................................................43

PushingorT owingtheMachine........................43

Hydraulic-ValveSolenoidFunctions.................44

Maintenance...........................................................45

MaintenanceSafety..........................................45

RecommendedMaintenanceSchedule(s)...........45

DailyMaintenanceChecklist.............................47

Lubrication..........................................................48

GreasingtheBearingsandBushings................48

EngineMaintenance...........................................49

EngineSafety...................................................49

ServicingtheAirCleaner..................................49

ServicingtheEngineOil....................................50

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................52

FuelSystemMaintenance...................................52

ServicingtheWaterSeparator.........................52

ServicingtheEngineFuelFilter........................53

CheckingtheFuelLinesand

Connections..................................................53

FuelPick-upTubeScreen.................................53

ElectricalSystemMaintenance...........................53

ElectricalSystemSafety...................................53

ServicingtheBattery.........................................53

CheckingtheFuses..........................................54

DriveSystemMaintenance..................................54

CheckingtheTirePressure...............................54

CheckingtheT orqueoftheWheel

Nuts..............................................................54

AdjustingtheTractionDriveforNeutral.............54

CheckingtheRearWheelToe-In......................55

CoolingSystemMaintenance..............................56

CoolingSystemSafety.....................................56

CoolantSpecication........................................56

CheckingtheCoolantLevel..............................56

RemovingDebrisfromtheCooling

System..........................................................57

BrakeMaintenance.............................................58

AdjustingtheParkingBrakes............................58

AdjustingtheParking-BrakeLatch....................58

BeltMaintenance................................................59

ServicingtheAlternatorBelt.............................59

HydraulicSystemMaintenance...........................59

HydraulicSystemSafety...................................59

HydraulicFluidSpecications...........................59

CheckingtheHydraulicFluid............................60

CheckingtheHydraulicLinesand

Hoses............................................................60

HydraulicFluidCapacity...................................61

ChangingtheHydraulicFluid............................61

ReplacingtheHydraulicFilters.........................61

UsingtheHydraulicSystemT estPorts..............62

CuttingUnitSystemMaintenance........................63

BladeSafety.....................................................63

CheckingtheReel-to-BedknifeContact............63

BacklappingtheCuttingUnits...........................63

Cleaning..............................................................65

WashingtheMachine.......................................65

Storage...................................................................65

StorageSafety..................................................65

PreparingtheTractionUnit...............................65

PreparingtheEngine........................................66

StoringtheBattery............................................66

3