9

Brakes: Individual totally enclosed, multi-disc, wet

brakes and parking brakes on front traction wheels.

Hydrostatic braking through traction drive.

Electrical Features: 12-volt, 530 cold-cranking

amperes at 0° F (–18° C), 85-minute reserve capacity

at 80° F (27° C), maintenance-free battery. 55-amp

alternator with l° C regulator/rectifier. Automotive-type

electrical system. Seat switch, reel and traction inter-

lock switches.

Controls: Foot-operated traction and brake pedals.

Hand operated throttle, speed control lever, parking

brake lock, ignition switch with automatic preheat

cycle, single joy stick control for cutting unit on/off

and lift lower. Cutting unit backlap switch under the

operator's seat. Height-of-cut selector knob located

under the control panel.

Gauges: Hour meter, speedometer, fuel gauge, temper-

ature gauge, 4-bank warning lamp: oil pressure, water

temperature, amps, and glow plug. 2-bank warning

lamp: water in fuel, water level.

Diagnostics; The Automatic Control Electronics,

ACET system allows precise timing and control of

machine functions for maximum reliability. Toro stan-

dard diagnostic display connects to an electronic con-

trol unit to pinpoint any electrical problems quickly

and easily. Available DATA LOGT system allows

mechanic to find intermittent problems.

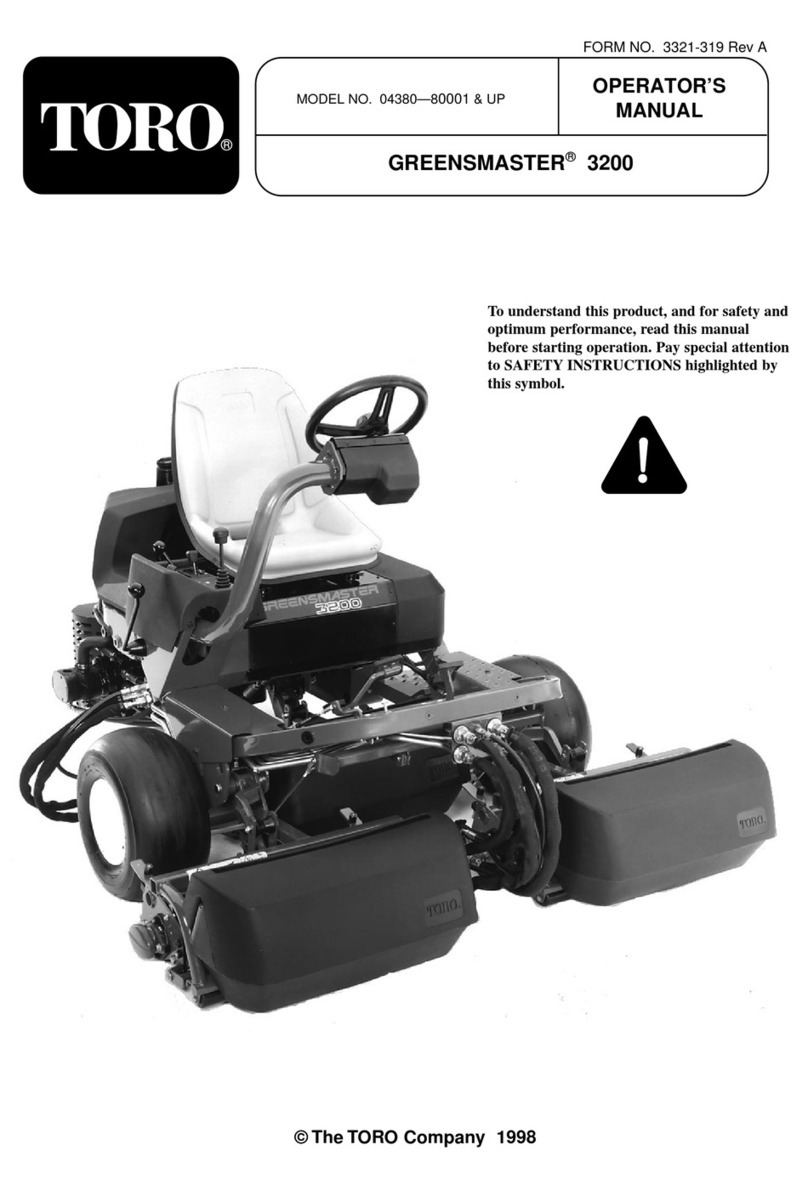

General Specifications (approx.):

Width-of-Cut: 338 cm

Overall Width:

Transport 213 cm

Operational 373 cm

Overall Length: 305 cm

Height:

Without roll-over protection system installed: 152

cmWith roll-over protection system

installed: 213 cm

Weight: 1,474 kg*

*With 5-Blade Cutting Units & full fluid levels

Engine: Peugeot, 4-cylinder, 4-cycle, overhead cam,

116 cu. in (1.9 liter) displacement liquid-cooled diesel

engine. 42 hp (31 kW); governed to 2750 rpm high idle;

23.5:1 compression ratio, 3.27" (83 mm) bore x 3.46"

(88 mm) stroke. Automatic glow plug/starter interlock

system. Heavy-duty, 2-stage, remote air cleaner.

Main Frame: All-welded formed steel frame, includes

tie-down loops.

Cooling System: Rear-mounted, cross-flow agricultural

type radiator; 7 fins per inch. 7.1 liter capacity. Air to

oil cooler mounted to the rear of the radiator tips out-

ward for cleaning. Removable oil cooler/radiator

screen.

Fuel System: Rotary fuel injection pump with ener-

gized-to-run (ETR) fuel flow solenoid. Replaceable

spin-on fuel filter/water separator with water sensor.

Fuel capacity: 64 liter.

Traction System: Servo-controlled hydrostatic system

driving double-planetary, gear-reduction, front-wheel

drives. Foot pedal control of forward/reverse ground

speed.

Toro 4-MaticR 4-Wheel Drive System only: Rear

drive axle coupled to hydrostatic transmission via an

overrunning clutch for full-time, on-demand 4-wheel

drive. A Roll Over Protective Structure and seat belt are

standard.

Ground Speed: 0–16 kmh forward; 0–6 kmh reverse.

Cutting Unit Drive System: Reel motors feature quick

disconnect for removal or installation onto the cutting

unit. Cutting units can be driven from either end.

Seat: Deluxe high-back suspension seat with adjustable

fore and aft travel, weight and height. Tool box at the

left side of the seat.

Steering System: Power steering with dedicated power

source.

Tires: Two rear steering tires: 20 x 10.00–10, tubeless,

6-ply rating. Two front traction drive tires: 29 x

12.00–15 tubeless, 6-ply rating. Recommended tire

pressure for front and rear tires is 103–138 kPa.

Specifications