2

The Toro Company—2001

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

All Rights Reserved

Printed in the USA

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

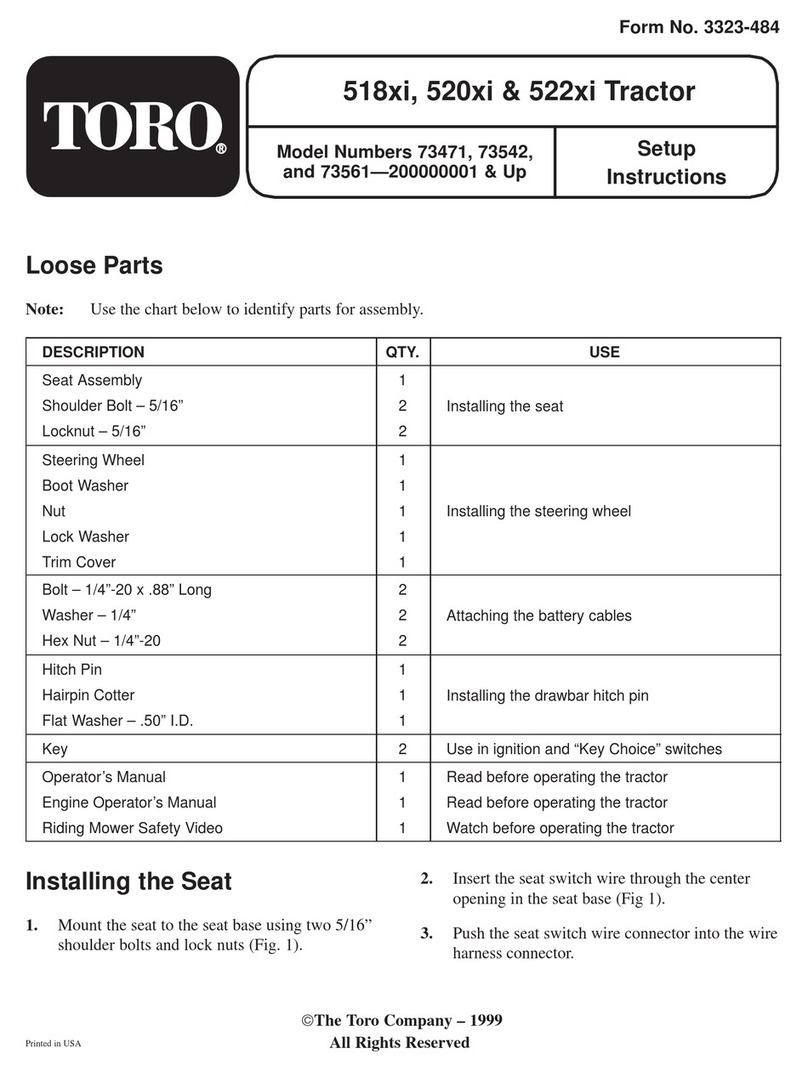

Loose Parts 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Axle 3. . . . . . . . . . . . . . . . . . . . . . . .

Installing the Sulky Assemblies 6. . . . . . . . . . . . . .

Adjusting the Handle Height 6. . . . . . . . . . . . . . . .

Installing the Transport Hooks 6. . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Sulky for Transport 7. . . . . . . . . . .

Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 8. . . . . . . .

Checking Tire Pressure 8. . . . . . . . . . . . . . . . . . . .

Greasing the Sulky 8. . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied with

your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

replacement parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number plate at the location shown in Figure 1.

m–5478

1

Figure 1

1. Modeland serial number plate

For your convenience, write the product model and serial

numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although we design, produce and market

safe, state-of-the-art products, you are responsible for

using the product properly and safely. You are also

responsible for training persons, who you allow to use the

product, about safe operation.

The warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury, even death. Danger,

Warning, and Caution are signal words used to identify

the level of hazard. However, regardless of the hazard, be

extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if the recommended precautions are not

followed.

Warning signals a hazard that may cause serious injury or

death if the recommended precautions are not followed.

Caution signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed.

Two other words are also used to highlight information.

Important calls attention to special mechanical

information, and Note emphasizes general information

worthy of special attention.

Safety

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

General Operation

•Do not modify the sulky or use it on non-approved

machines.

•Ensure that the sulky is properly attached to the

machine and is in good working order prior to use.

•Allow only the machine operator on the sulky.