Toro GreensPro 1260 User manual

FormNo.3429-810RevA

GreensPro™1260GreensRoller

ModelNo.44913—SerialNo.404680001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3429-810*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisaride-ongreensrollerintendedfor

usebyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforrollinggreens,

tenniscourts,andotherneturfsurfacesinparks,golf

courses,sportselds,andoncommercialgrounds.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

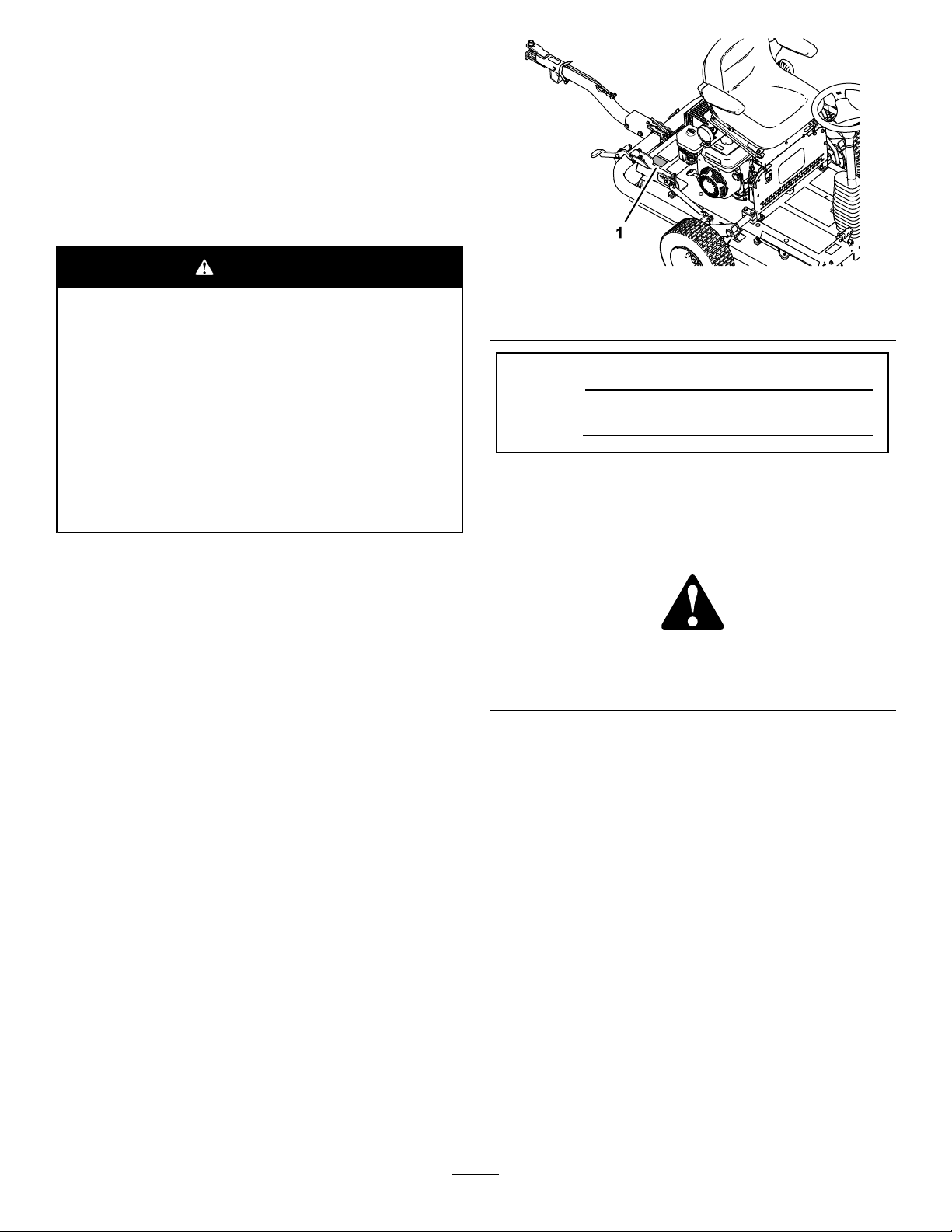

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g279976

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUK

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................7

1InstallingtheTransportWheels........................8

2InstallingtheHitchAssembly...........................8

3RemovingtheMachinefromthe

Pallet.............................................................10

4LubricatingtheMachine.................................10

ProductOverview....................................................11

Controls............................................................11

EngineControls............................................12

Specications..................................................13

Attachments/Accessories.................................13

BeforeOperation.................................................14

BeforeOperationSafety...................................14

PreparingtoUsetheMachine...........................14

FuelSpecication.............................................14

FillingtheFuelTank..........................................15

DuringOperation.................................................15

DuringOperationSafety...................................15

StartingtheEngine...........................................16

ShuttingOfftheEngine.....................................16

TransportingtheMachine.................................16

OperatingtheMachine.....................................19

OperatingTips.................................................19

AfterOperation....................................................19

AfterOperationSafety......................................19

HaulingtheMachine.........................................19

Maintenance...........................................................20

MaintenanceSafety..........................................20

RecommendedMaintenanceSchedule(s)...........20

NotationforAreasofConcern...........................21

DailyMaintenanceChecklist.............................21

Pre-MaintenanceProcedures..............................22

PreparingforMaintenance...............................22

RaisingtheOperator’sSeat..............................22

LoweringtheOperator’sSeat...........................23

Lubrication..........................................................23

LubricatingtheDrive-RollerBearing.................23

EngineMaintenance...........................................24

EngineSafety...................................................24

EngineOilSpecication....................................24

CheckingtheEngine-OilLevel..........................24

ChangingtheEngineOil...................................24

CheckingtheAir-FilterElements.......................26

ServicingtheAirCleaner..................................27

ServicingtheSparkPlug...................................27

CheckingandAdjustingtheValve

Clearance.....................................................28

FuelSystemMaintenance...................................28

CleaningtheSedimentCup..............................28

ElectricalSystemMaintenance...........................29

CheckingtheSafety-InterlockSystem..............29

BrakeMaintenance.............................................29

CheckingtheParkingBrake.............................29

AdjustingtheParkingBrake..............................29

HydraulicSystemMaintenance...........................30

HydraulicSystemSafety...................................30

CheckingtheHydraulicHosesand

Fittings..........................................................30

HydraulicFluidSpecication.............................31

CheckingtheHydraulic-FluidLevel...................31

ChangingtheHydraulicFluidand

Filter..............................................................32

ChassisMaintenance...........................................34

CheckingtheTireAirPressure..........................34

CheckingtheMachineforLoose

Hardware......................................................34

Cleaning..............................................................34

CleaningtheMachine.......................................34

Storage...................................................................35

PreparingtheMachineforShort-Term

Storage.........................................................35

PreparingtheMachineforLong-Term

Storage.........................................................35

StoringtheMachine..........................................35

3

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO12100:2010andANSIB71.4-2017.

Important:ForCErequiredregulatorydata,refer

totheDeclarationofConformitysuppliedwith

themachine.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Shutoffthemachine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

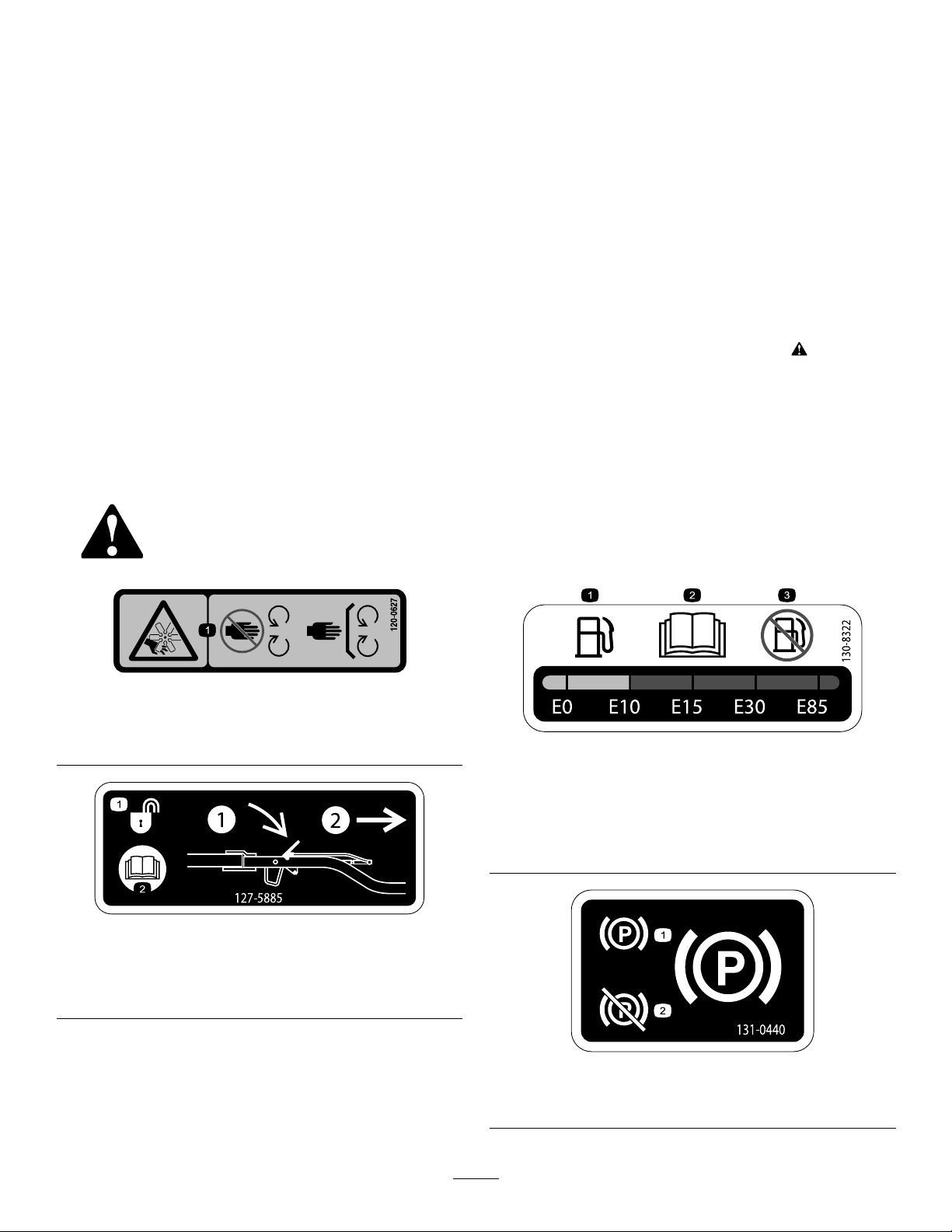

decal120-0627

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

decal127-5885

127-5885

1.Hitchunlock—1)push

downonthelatch;2)pull

outthehitch.

2.ReadtheOperator's

Manual.

decal130-8322

130-8322

1.Useonlygasolinethat

contains10%ethanolby

volume(E10)orless.

3.Donotusegasolinethat

containsmorethan10%

ethanolbyvolume(E10).

2.ReadtheOperator's

Manual.

decal131-0440

131-0440

1.Parkingbrake—engage2.Parkingbrake—disengage

4

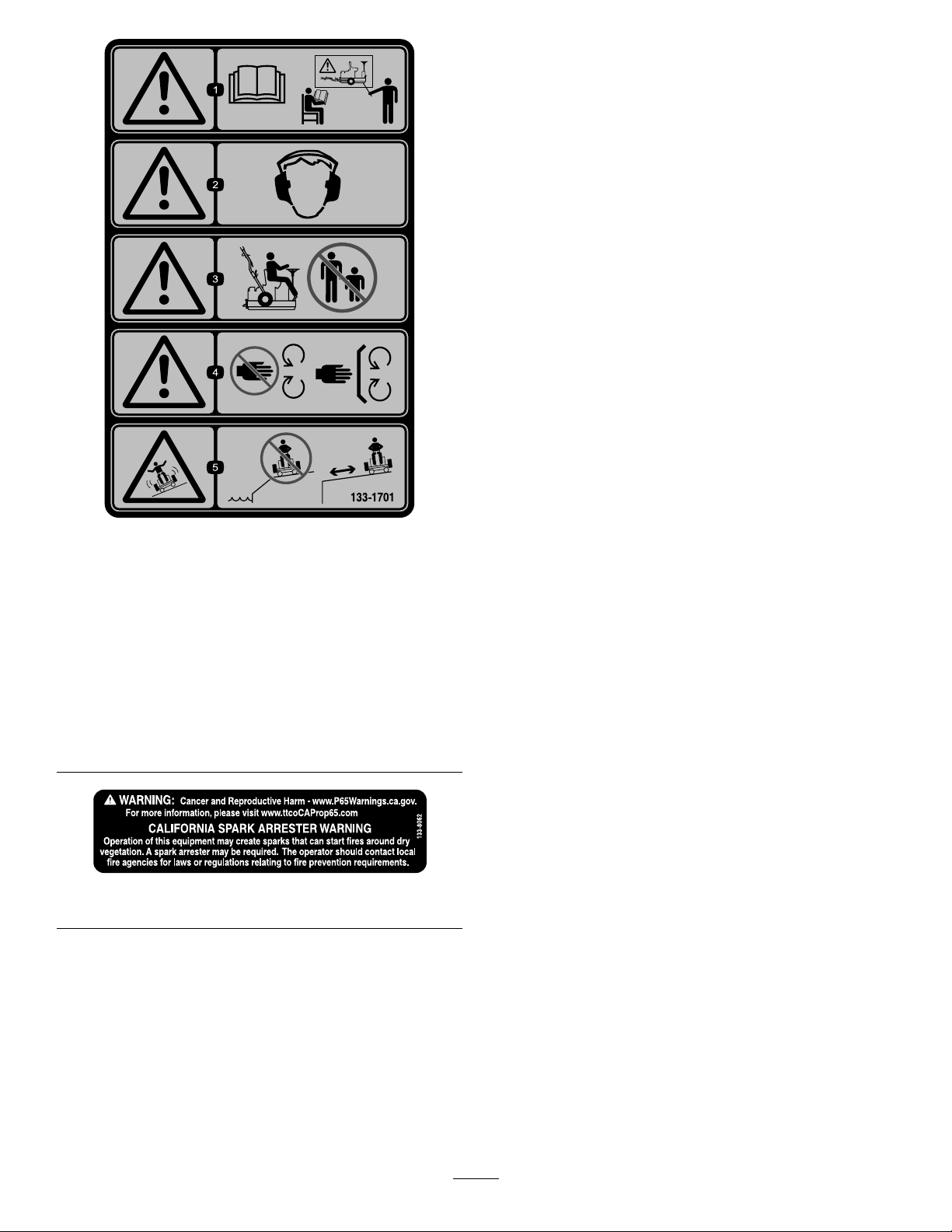

decal133-1701

133-1701

1.Warning—readthe

Operator'sManual;do

notoperatethemachine

unlessyouhavereceived

training.

4.Warning—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

2.Warning—wearhearing

protection.

5.Tippinghazard—donot

operatethemachinenear

water;stayawayfrom

embankmentsordropoffs.

3.Warning—keep

bystandersawayfrom

themachine.

decal133-8062

133-8062

5

decal127-5884

127-5884

1.ReadtheOperator’sManual.3.1)Pushthehitchup;2)Releasethelatchlever;3)Pullthe

hitchdown;4)Steponthefootpedaluntilthehitchsnapsinto

place;5)Insertthelockpin.

2.1)Pullthelockpin;2)Tipthemachineup;3)Unlatchthe

hitch;4)Raisethehitchuntiltheleverlatchlocksintheslide.

decal138-9134

138-9134

6

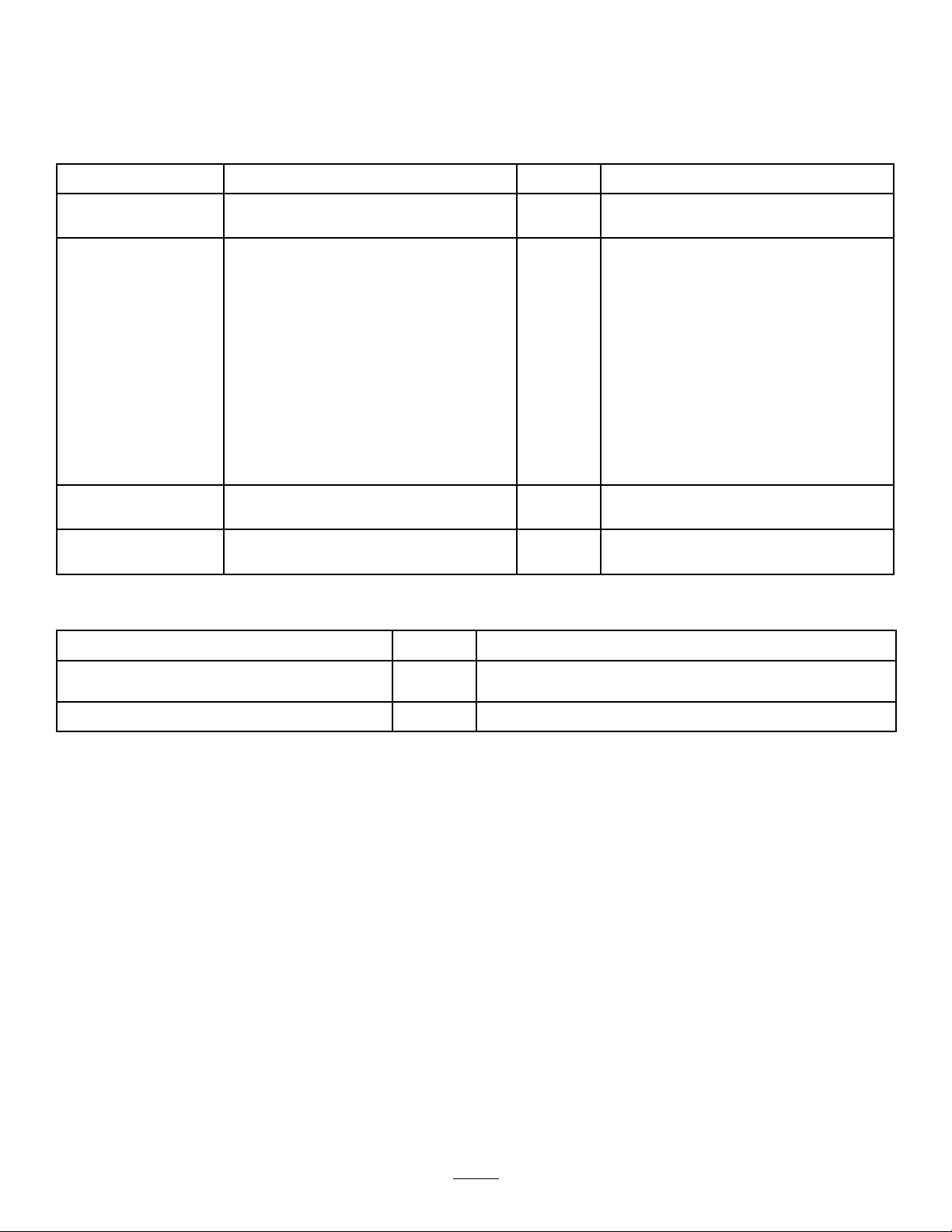

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Transportwheel2Installthetransportwheels.

Lockbracket1

Bolt(M10x30mm)4

Lockwasher(M10)4

Washer(M10)6

Nut(M10)4

Hitchassembly1

Bolt(M10x100mm)1

Locknut(M10)1

Bolt(M12x100mm)1

Washer(M12)2

Locknut(M12)1

2

Spacerwasher(whenapplicable)2

Installthehitchassembly.

3Nopartsrequired–Removethemachinefromthepallet.

4Lubricants(notincluded)–Lubricatethemachine.

MediaandAdditionalParts

DescriptionQty.Use

Operator’sManual1

Engineowner’smanual1Readthemanualsbeforeoperatingthemachine.

CerticateofCompliance1ThecerticateisrequiredforEuropeanCEcompliance.

7

1

InstallingtheTransport

Wheels

Partsneededforthisprocedure:

2Transportwheel

RemovingtheShippingBrackets

1.Removethelugnutssecuringthewheelhubsto

theshippingbracket(Figure3).

g279735

Figure3

1.Lugnut3.Shippingbracket

2.Lagbolt

2.Removetheotherlugnutthreadedontothe

wheel-hubstud(Figure3).

3.Removethelagboltsthatsecuretheshipping

bracketstothepallet,andremovethebracket

(Figure3).

4.Repeatsteps1through3fortheshipping

bracketattheothersideofthemachine.

InstallingtheWheels

1.Looselyassemblethe2transportwheelsonto

thewheelhubswiththelugnutsthatyou

removedinRemovingtheShippingBrackets

(page8).

Note:Youwilltorquethelugnutsattheendof

2InstallingtheHitchAssembly(page8).

2.Adjustthetireairpressureto103kPa(15psi).

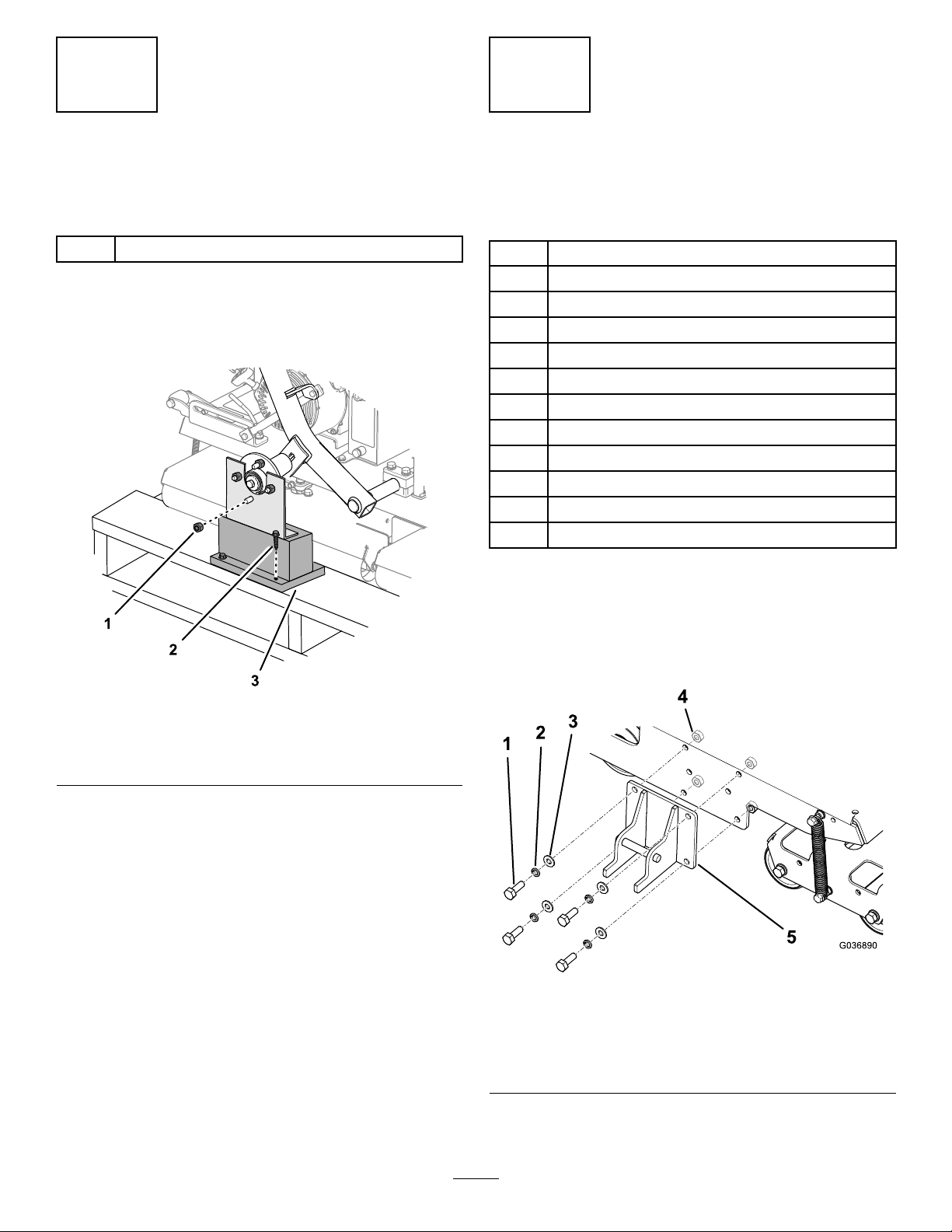

2

InstallingtheHitch

Assembly

Partsneededforthisprocedure:

1Lockbracket

4Bolt(M10x30mm)

4Lockwasher(M10)

6Washer(M10)

4Nut(M10)

1Hitchassembly

1Bolt(M10x100mm)

1Locknut(M10)

1Bolt(M12x100mm)

2Washer(M12)

1Locknut(M12)

2Spacerwasher(whenapplicable)

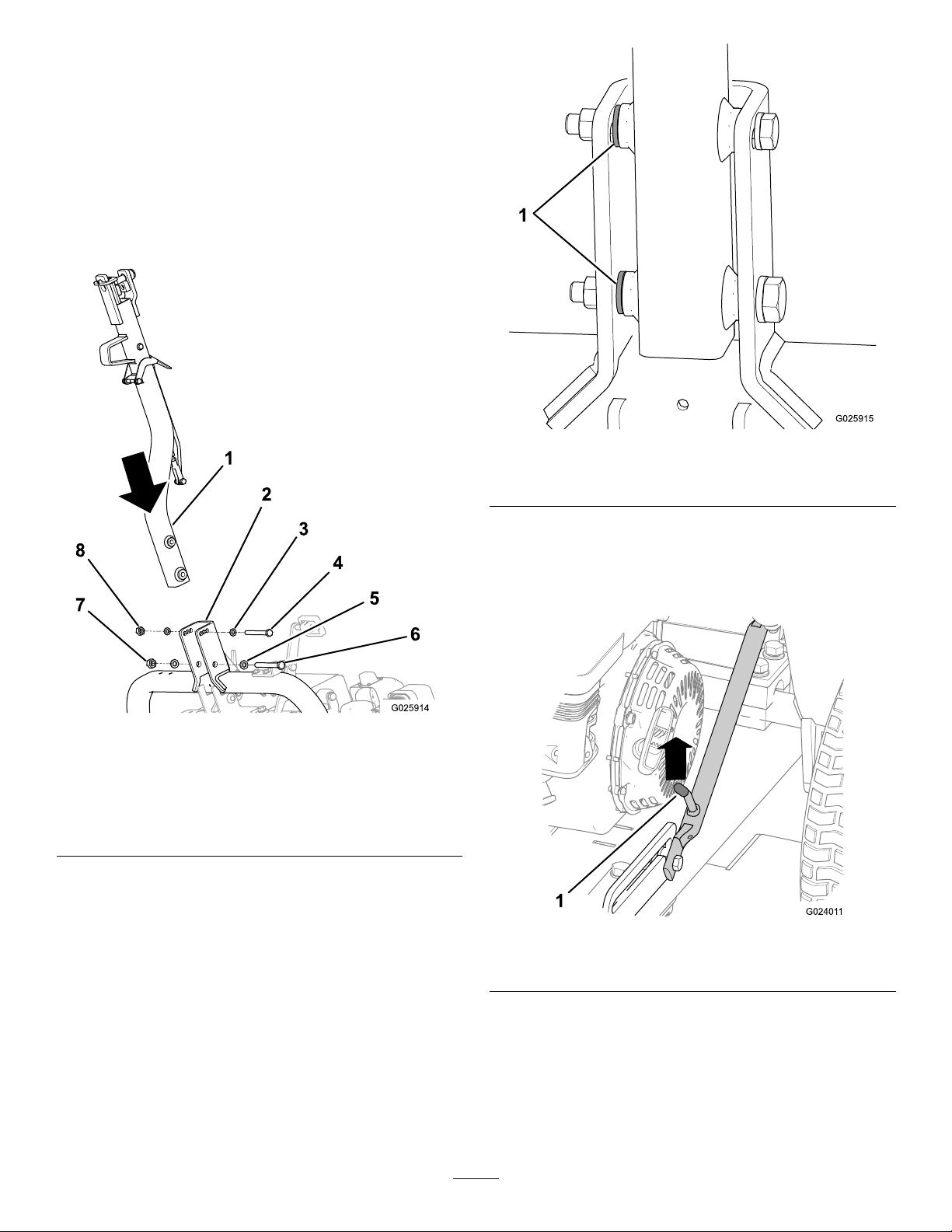

Procedure

1.Installthelockbrackettotheframeofthe

machineasshowninFigure4.

Note:Torquethenutsto52N∙m(38ft-lb).

g036890

Figure4

1.Bolt—M10x30mm(4)4.Nut—M10(4)

2.Lockwasher—M10(4)5.Lockbracket

3.Washer—M10(4)

2.Securethehitchtothehitchpivotbracketwith

theappropriatehardware;refertoFigure5.

8

•Inthefrontholes,useabolt(M10x100

mm),2washers(M10),andalocknut(M10).

•Intherearholes,useabolt(M12x100mm),

2washers(M12),andalocknut(M12).

•Ifyourmachinehasathirdwasherincluded

witheachbolt,usethosewashersasspacers

betweenthehitchandtheinsideofthehitch

pivotbracket(Figure6).

Note:Usetheholesinthehitchpivotbracketto

matchthehitchheightofthetow-vehiclehitch.

g025914

Figure5

1.Hitch5.Washer—M12(2)

2.Hitchpivotbracket6.Bolt(M12)

3.Washer—M10(2)7.Locknut(M12)

4.Bolt(M10)8.Locknut(M10)

g025915

Figure6

1.Spacerwashers

3.Tightenthesmallboltto73N∙m(54ft-lb)and

thelargeboltto126N∙m(93ft-lb).

4.Pushuponthehitchassemblyuntilthelatch

leverisunlockedfromtheslidedetent(Figure7).

g024011

Figure7

1.Latchlever

5.Pullthehitchdown.

6.Ifinstalled,removethelockingpinfromthelatch

(Figure8).

9

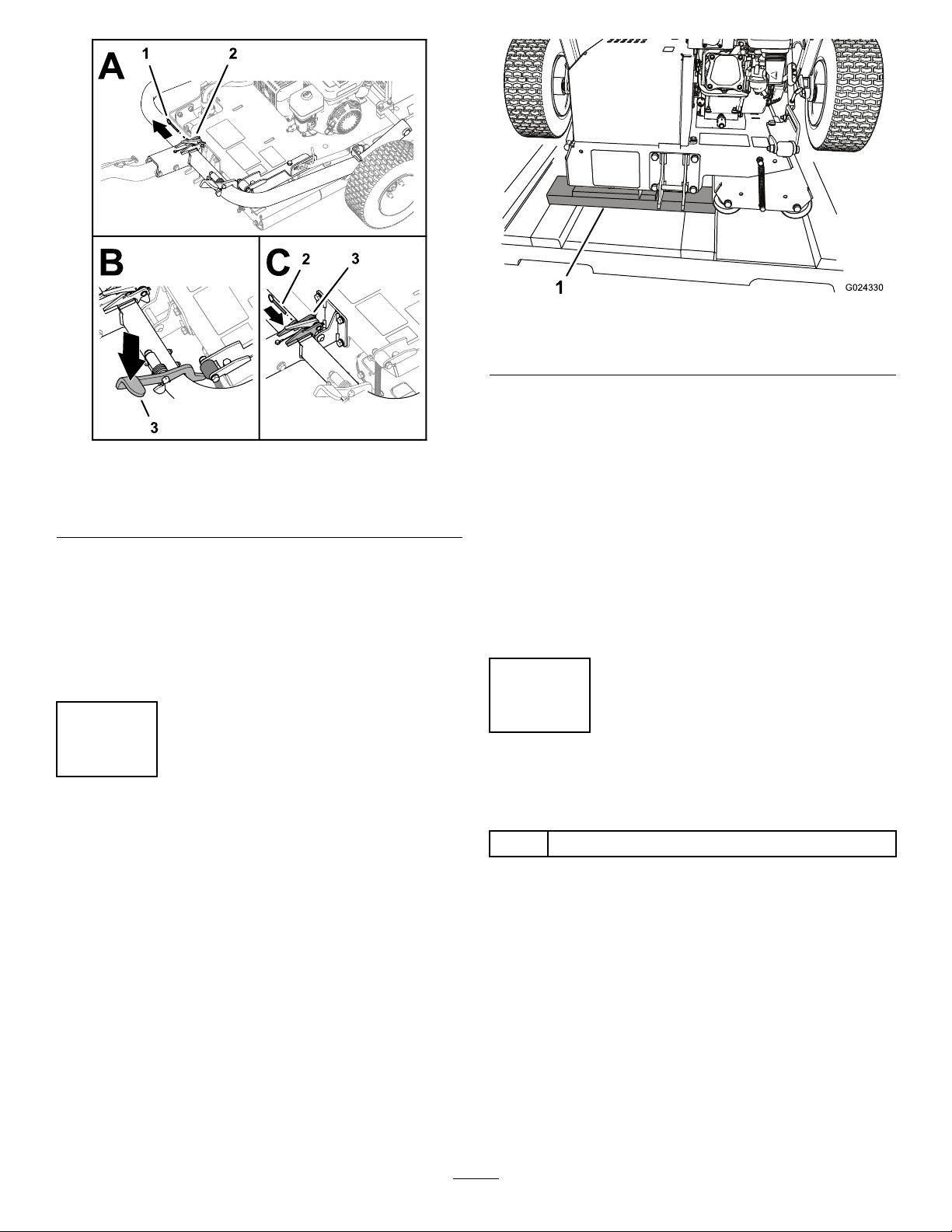

g279746

Figure8

1.Lockingpin3.Hitchpedal

2.Latch

7.Steponthehitchpedaluntilthehitchlocksinto

place(Figure8).

8.Insertthelockingpinthroughtheholesinthe

latch(Figure8).

9.Torquethelugnutsonthetransportwheelsto

108N∙m(80ft-lb).

3

RemovingtheMachine

fromthePallet

NoPartsRequired

Procedure

1.Removethewoodblocksatthehitchendofthe

pallet.

g024330

Figure9

1.Woodblocks

2.Placesomewoodboardsonthegroundatthe

endofthepallet.

Note:Theheightofthewoodboardsshouldbe

slightlylowerthanthepallet.Youcanusepieces

removedfromthesidesand/orendsofthecrate.

3.Carefullyrollthemachineoffthepallet,ontothe

woodboards,andthentotheground.

Important:Ensurethattherollersdonot

contactthepalletasthemachinedropsto

theground.

4.Removeanyremainingpackaging.

4

LubricatingtheMachine

Partsneededforthisprocedure:

–Lubricants(notincluded)

Procedure

Beforeyouoperatethemachine,lubricateittoensure

properoperatingcharacteristics;refertoLubricating

theDrive-RollerBearing(page23).Failuretoproperly

lubricatethemachinewillresultinprematurefailure

ofcriticalparts.

10

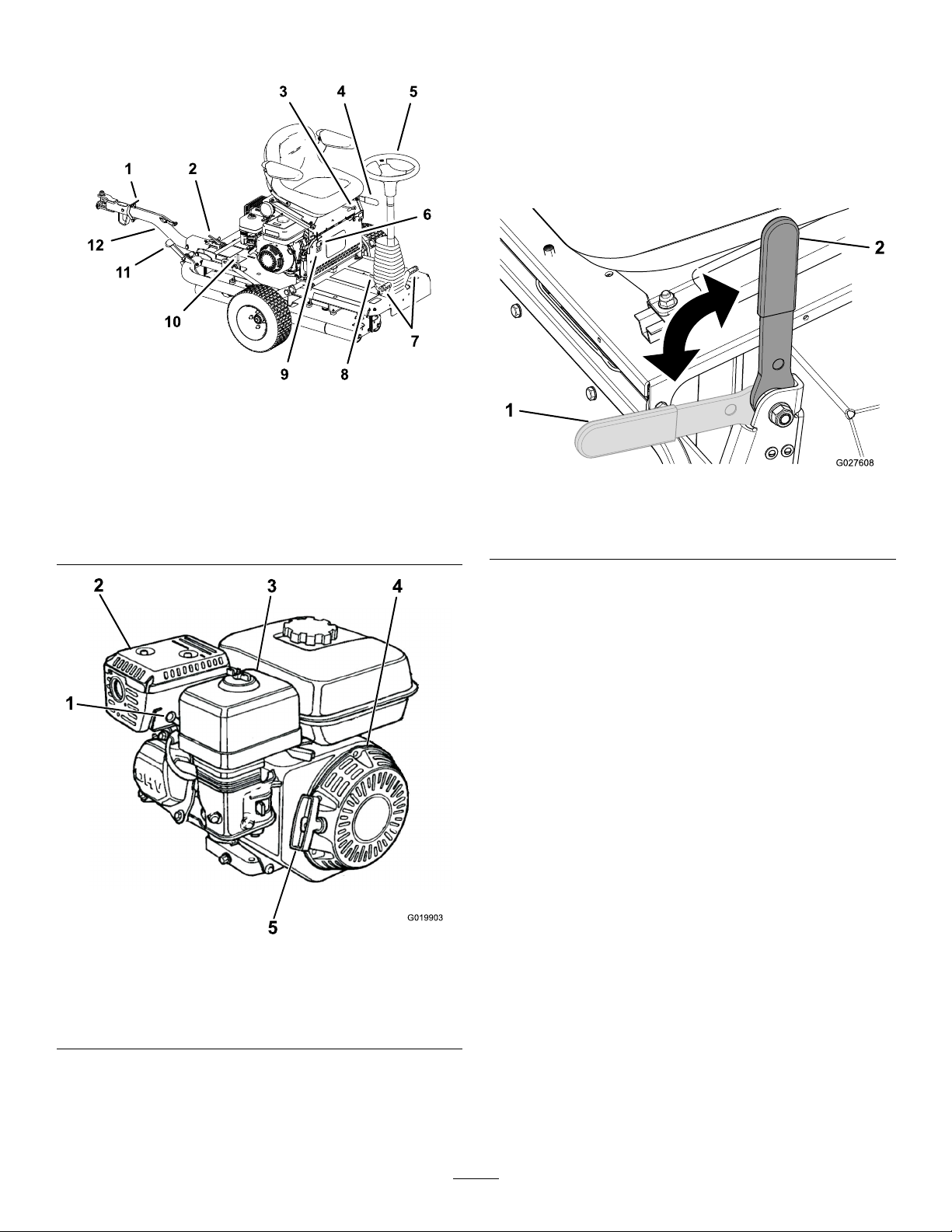

ProductOverview

g279748

Figure10

1.Hitch-locklever7.Motionpedals

2.Hitchlatch8.Tilt-steeringpedal

3.Seat-adjustmentlever9.Hourmeter

4.Parkingbrake10.Latchlever

5.Steeringwheel11.Hitchpedal

6.Lightswitch12.Hitchassembly

g019903

Figure11

1.Sparkplug4.Recoilstarter

2.Mufer5.Recoil-starthandle

3.Aircleaner

Controls

ParkingBrake

Engagetheparkingbraketoallowthemachineto

start.T oengagetheparkingbrake(Figure12),pull

backontheparking-brakelever.Todisengageit,

pushtheleverforward.

g027608

Figure12

1.Parking

brake—disengaged

2.Parkingbrake—engaged

SteeringWheel

Turnthesteeringwheel(Figure10)clockwisetoturn

themachineintheforwarddirection.

Turnthesteeringwheelcounterclockwisetoturnthe

machineintherearwarddirection.

Note:Asthedirectionchangesattheendofevery

run,youwillneedtopracticewiththemachineto

becomeaccustomedtothesteering.

Thesteeringwheelcontrolstheangleofthesmoothing

rollers,whichinturnsteerthemachine.Theamount

thewheelcanbeturnedislimited,sotheturning

radiusofthemachineislarge.

Tilt-SteeringPedal

Totiltthesteeringwheeltowardyou,pressthefoot

pedal(Figure10)down,pullthesteeringtowertoward

youtothemostcomfortableposition,andreleasethe

pedal.

MotionPedals

Thefoot-operatedmotionpedals(Figure10),located

toeithersideofthebaseofthesteeringwheel,

controlthemotionofthedriveroller.Thepedalsare

connectedsothattheycannotbothbepresseddown

atthesametime,youcanpressonly1pedalata

11

time.Ifyoupressdowntherightpedal,themachine

movestotheright,andifyoupressdowntheleft

pedal,themachinemovestotheleft.Thefurtheryou

pressapedal,thefasteryourspeedinthatdirection.

Note:Cometoafullstopbeforechangingthe

directionofthemachine;donotabruptlychangethe

pedaldirection.Doingsooverstressesthetraction

driveline,resultinginprematurefailureofdrive-line

components.Actuatethepedalsslowlyandsmoothly

toavoidpotentialturfscufngdamageaswellas

drive-linecomponentdamage.

Whenoperatingthemachineonhills,ensurethat

thedriverollerisonthedownhillsideforadequate

traction.Failuretodosomayresultinturfdamage.

HitchAssembly

Usethehitchassembly(Figure10)totowthemachine

andtolower/raisethetransportwheels.

Seat-AdjustmentLever

Youcanmovetheseatforwardorbackward.Rotate

theseat-adjustmentlever(Figure10)upwardand

slidetheseatforwardorbackward,thenreleasethe

lever.

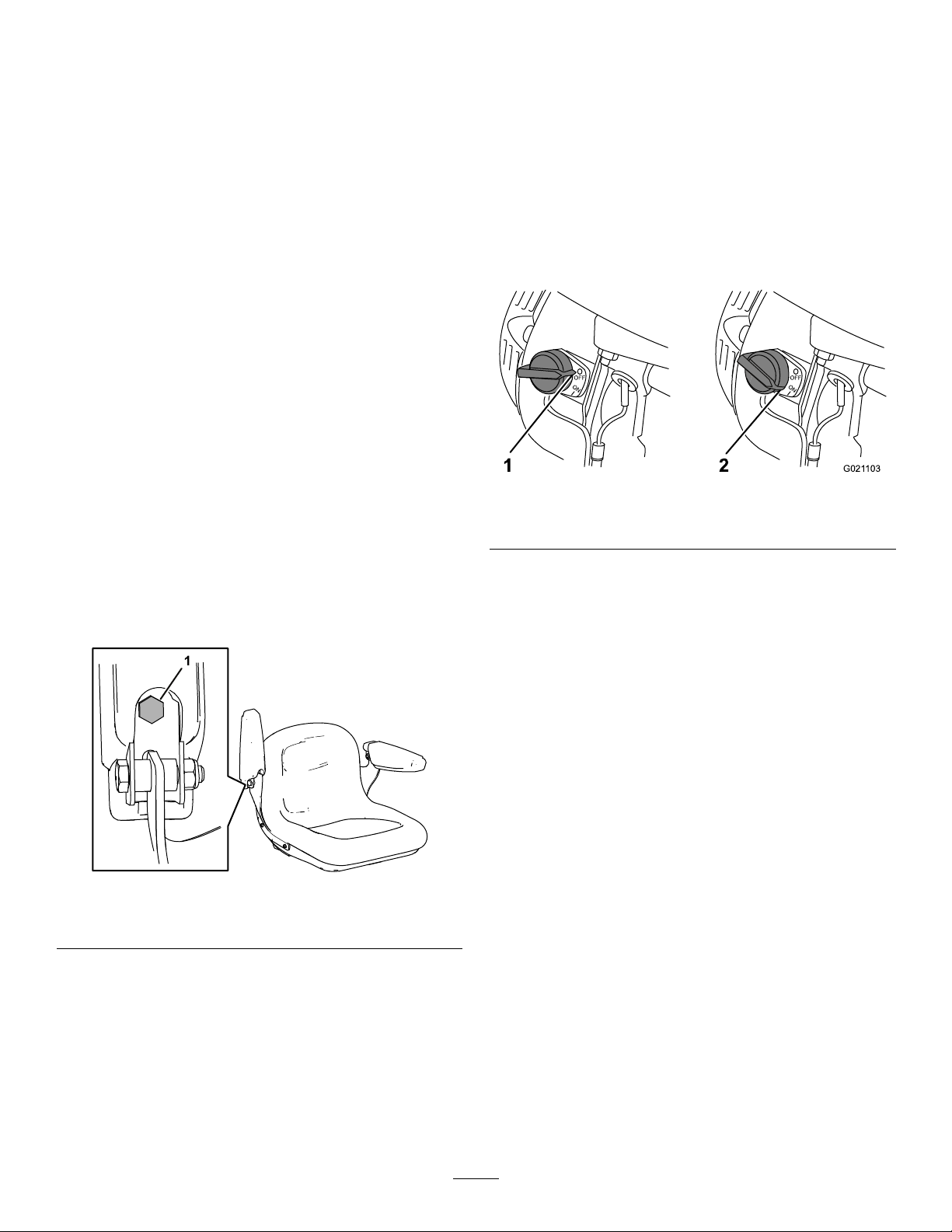

Armrest-AdjustmentBolts

Youcanadjusteacharmrestbyturningtherespective

adjustmentbolt(Figure13).

g279749

Figure13

1.Adjustmentbolt

LightSwitch

Usethelightswitchtoturnthelightsonandoff(Figure

10).

HourMeter

Thehourmeter(Figure10)indicatesthetotalhoursof

machineoperation.

EngineControls

Note:Refertoyourengineowner’smanualfor

additionalengine-controlinformation.

On/OffSwitch

TheOn/Offswitch(Figure14)allowstheoperatorof

themachinetostartandshutofftheengine.This

switchislocatedonthefrontoftheengine.Rotatethe

On/OffswitchtotheONpositiontostartandrunthe

engine.RotatetheOn/OffswitchtotheOFFposition

toshutofftheengine.

g021103

Figure14

1.OFFposition2.ONposition

ChokeLever

Thechokelever(Figure15)isrequiredwhenstarting

acoldengine.Beforepullingtherecoil-starthandle,

movethechokelevertotheCLOSEDposition.Once

theengineisrunning,movethechokelevertothe

OPENposition.Donotusethechokeiftheengineis

alreadywarmeduporiftheairtemperatureishigh.

12

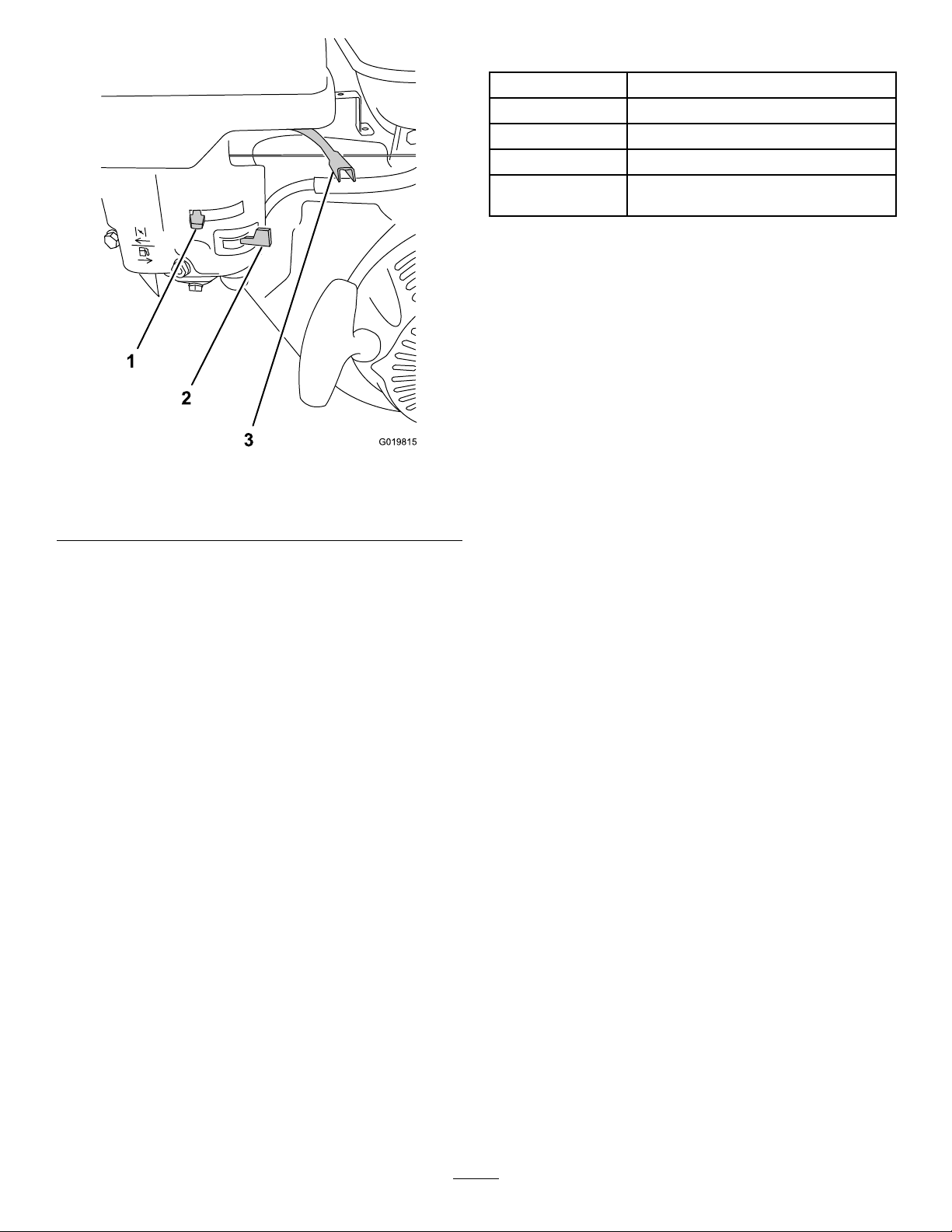

g019815

Figure15

1.Chokelever3.Throttlelever

2.Fuel-shutoffvalve

ThrottleLever

Thethrottlelever(Figure15)islocatednexttothe

chokecontrol;itcontrolsthespeedoftheengine

andthereforecontrolsthespeedofthemachine.For

bestrollingperformance,setthiscontroltotheFAST

position.

Fuel-ShutoffValve

Thefuel-shutoffvalve(Figure15)islocated

underneaththechokelever.Moveittotheopen

positionbeforeattemptingtostarttheengine.Once

youhavenishedusingthemachineandyouhave

turnedtheengineoff,movethefuel-shutoffvalveto

theCLOSEDposition.

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

11)quicklytoturntheengineover.Thecontrolson

theenginedescribedabovemustallbesetcorrectly

fortheenginetostart.

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine;it

preventstheenginefromrunningiftheoillevelfalls

belowthesafeoperatinglimit.

Specications

Weight308kg(679lb)

Length136cm(53.5inches)

Width122cm(48.0inches)

Height107cm(42.2inches)

Maximumground

speed

12.8km/h(8mph)@3600rpm

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

13

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Shutoffthemachineandwaitforallmovement

tostopbeforeyouleavetheoperator’sposition.

Allowthemachinetocoolbeforeadjusting,

servicing,cleaning,orstoringit.

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforeoperating,alwaysinspectthemachine

toensurethatthecomponentsandfasteners

areingoodworkingcondition.Replacewornor

damagedcomponentsandfasteners.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

PreparingtoUsethe

Machine

1.Clearanydebrisontopofandunderneaththe

machine.

2.Engagedtheparkingbrake.

3.Completethefollowingdailymaintenance

procedures:

•LubricatingtheDrive-RollerBearing(page

23)

•CheckingtheEngine-OilLevel(page24)

•CheckingtheAir-FilterElements(page26)

•CheckingtheSafety-InterlockSystem(page

29)

•CheckingtheParkingBrake(page29)

•CheckingtheHydraulicHosesandFittings

(page30)

•CheckingtheHydraulic-FluidLevel(page

31)

•CheckingtheTireAirPressure(page34)

•CheckingtheMachineforLooseHardware

(page34)

4.Ensurethatallguardsandcoversareinplace

andsecurelyattached.

5.Liftthetransportwheelsclearofthegroundand

ensurethattheylockinplace.

FuelSpecication

•Useunleaded(87pumpoctaneminimum)

gasoline.

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.EthanolandMTBE

arenotthesame.Gasolinewith15%ethanol

(E15)byvolumeisnotapprovedforuse.Never

usegasolinethatcontainsmorethan10%ethanol

byvolume,suchasE15(contains15%ethanol),

E20(contains20%ethanol),orE85(contains85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage,

whichmaynotbecoveredunderwarranty.

•Donotusemethanolorgasolinecontaining

methanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused

•Donotaddoiltogasoline.

14

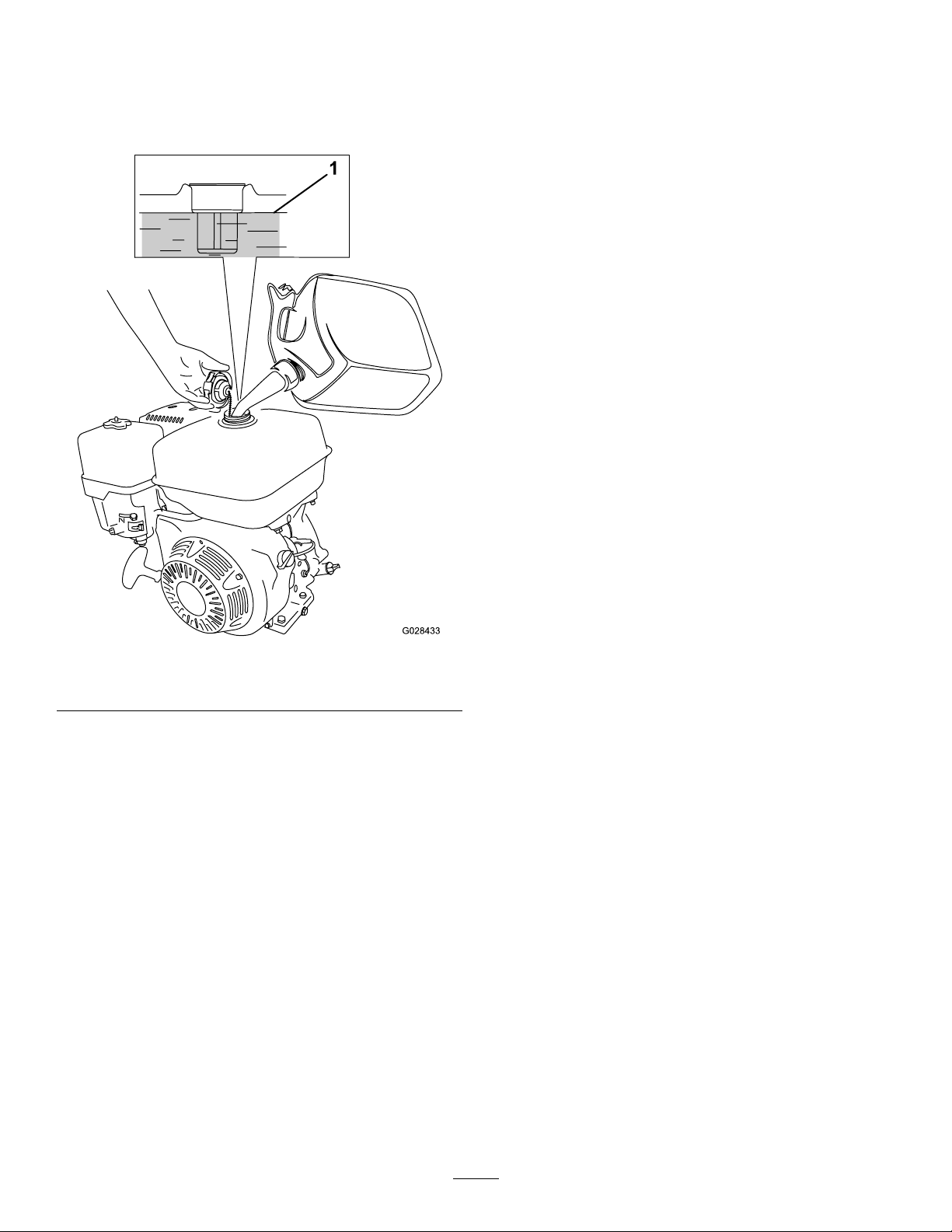

FillingtheFuelTank

Fuel-TankCapacity:3.6L(0.95USgallons)

1.Cleanaroundthefuel-tankcapandremovethe

capfromthetank(Figure16).

g028433

Figure16

1.Maximumfuellevel

2.Fillthefueltanktoapproximately25mm(1inch)

belowthetopofthetankwiththespeciedfuel.

Theairspacebelowthetopofthetankallows

thefueltoexpand.

Important:Donotoverllthefueltank.

Addingmorethatthespeciedlevelresults

indamagetothevaporrecoverysystem,

leadingtoengineperformancefailure.This

isnotawarrantablefailureandrequires

fuel-tankcapreplacement.

3.Installthefuel-tankcapandwipeupanyspilled

fuel.

DuringOperation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Keepbystandersandpetsoutoftheoperating

area.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidoperatingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotoperateneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifanedgegivesway.

•Stopthemachine,engagetheparkingbrake,

andshutofftheengineinspecttheattachment

afterstrikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonlevelground.

–Engagetheparkingbrake.

–Shutofftheengine.

–Waitforallmovingpartstostop.

15

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

•Keephandsandfeetawayfromtherollers.

•Usecarewhenconnectinganddisconnectingthe

machinetoandfromthetowvehicle.

SlopeSafety

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.

•Operatethemachineatalowerspeedwhenyou

areonaslope.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.Tallgrasscanhideobstacles.

•Choosealowgroundspeedsothatyoudonot

needtostoporshiftwhileonaslope.

•Arollovercanoccuriftherollerslosetraction.

•Avoidoperatingthemachineonwetgrass.Rollers

maylosetraction,regardlessofwhetherthe

brakesareavailableandfunctioning.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

StartingtheEngine

Note:Makesurethatthespark-plugwireis

connectedtothesparkplug.

1.EnsurethatthelightsswitchisintheOffposition.

2.Ensurethattheparkingbrakeisengagedand

thatthemotionpedalsareintheNEUTRAL

position.

3.TurntheOn/OffswitchtotheONposition.

4.Turnthefuel-shutoffvalvetotheOPENposition.

5.MovethechokelevertotheONpositionwhen

startingacoldengine.

Note:Thechokemaynotberequiredwhen

startingawarmengine.

6.MovethethrottlecontroltotheFASTposition.

7.Standattherearofthemachine,pullthe

recoil-starthandleoutuntilpositiveengagement

results;thenpullitvigorouslytostarttheengine.

Important:Donotpulltherecoilropeto

thelimitorletgoofthestarterhandlewhen

theropeispulledout,becausetherope

maybreakortherecoilassemblymaybe

damaged.

8.Whentheenginehasstarted,pushthechoke

levertotheOFFposition.

9.MovethethrottlelevertotheFASTposition,for

bestrollerperformance.

ShuttingOfftheEngine

1.Afteroperatingthemachine,returnthemotion

pedalstotheNEUTRALpositionandengagethe

parkingbrake.

2.Settheenginespeedtoidle,andallowittorun

for10to20seconds.

3.TurntheengineOn/OffswitchtotheOFF

position.

4.Turnthefuel-shutoffvalvetotheCLOSED

position.

5.SetthelightsswitchtotheOFFposition.

TransportingtheMachine

PreparingtoTransportthe

Machine

1.Drivethemachinetothetransportvehicle.

2.Engagetheparkingbrake.

3.Shutofftheengine;refertoShuttingOffthe

Engine(page16).

4.Ensurethatthefuel-shutoffvalvetotheCLOSED

position.

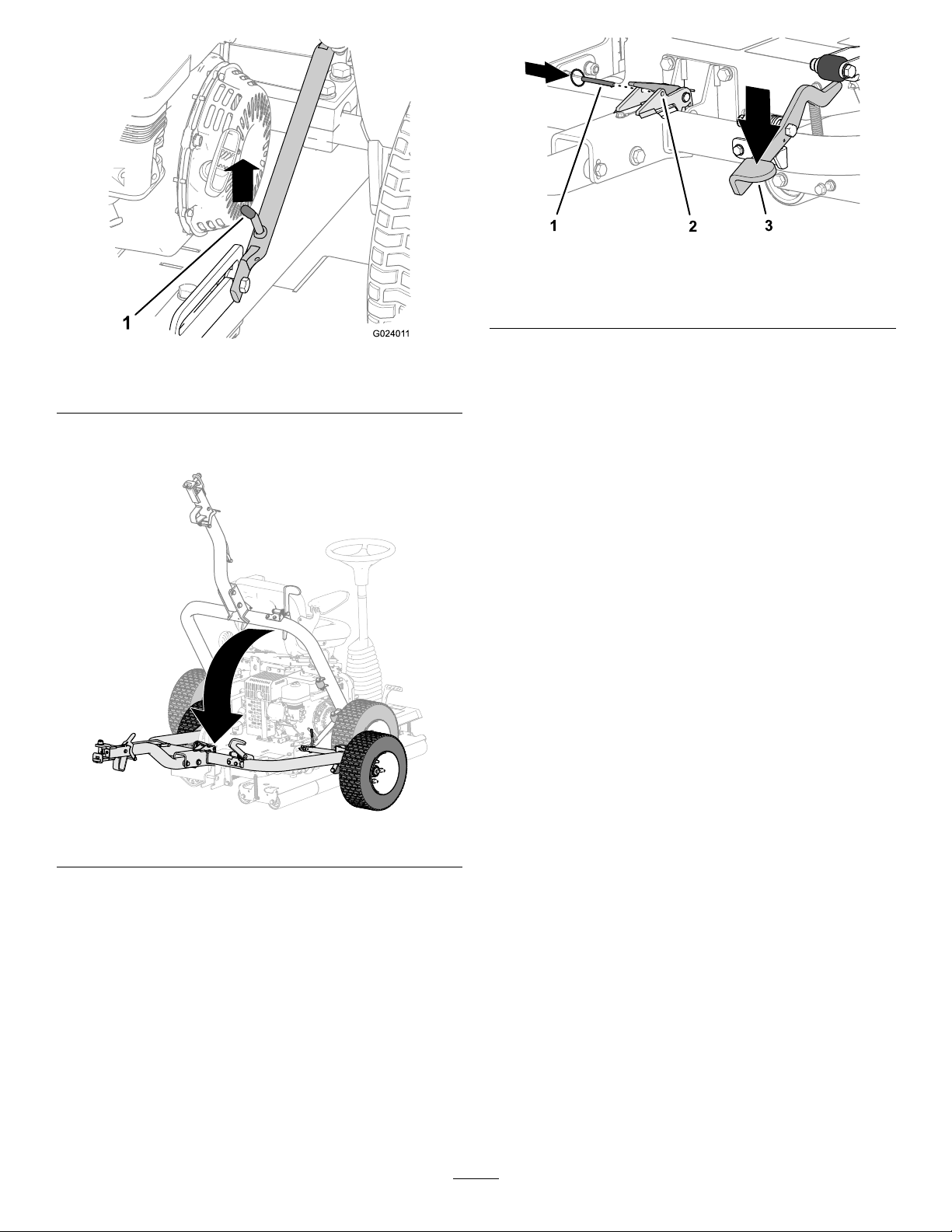

RaisingtheMachineontothe

TransportWheels

1.Pushuponthehitchassemblyuntilthelatch

leverisunlockedfromtheslidedetent(Figure

17).

16

g024011

Figure17

1.Latchlever

2.Liftthelatchleversothatitslidesfreely,andpull

thehitchdown.

g279826

Figure18

3.Steponthehitchpedaluntilthehitchlocksinto

place(Figure19).

g279795

Figure19

1.Lockingpin3.Hitchpedal

2.Latch

4.Insertthelockingpinthroughtheholesinthe

latch(Figure19).

5.Iftheyouaretransportingthemachine,connect

ittothetowvehicle;refertoConnectingthe

MachinetotheTowVehicle(page17).

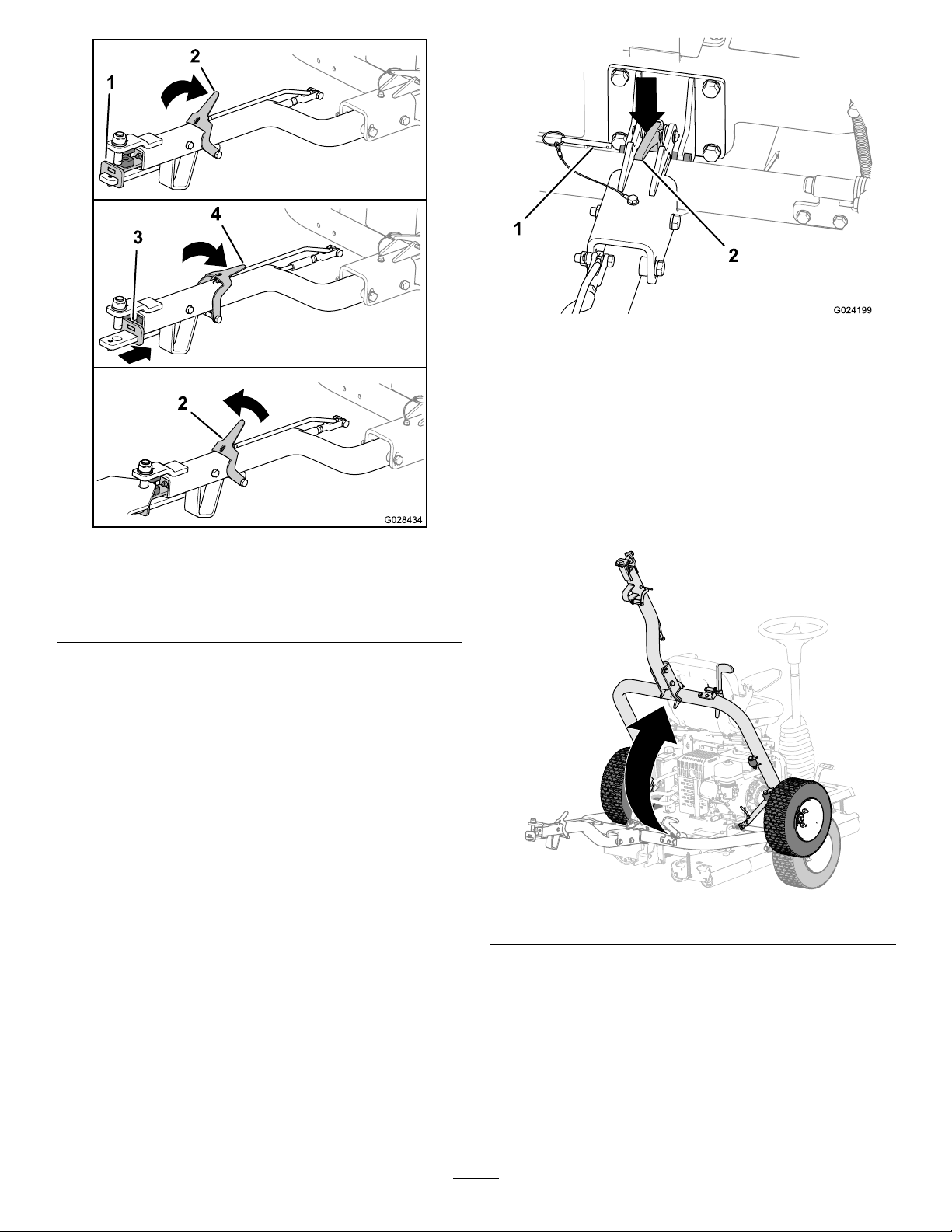

ConnectingtheMachinetothe

TowVehicle

Pushdownonthehitch-lockleverwhileinsertingthe

hitchassemblyontothetow-vehiclehitch.Release

theleverwhenthehitchandthehitchassemblyare

aligned(Figure20).

Important:EnsurethattheleverreturnstotheUp

positionandthatthehitchandthehitchassembly

areengaged.

17

g028434

Figure20

1.Hitchassembly(forward)3.Hitchassembly

(backward)

2.Hitch-locklever(up)4.Hitch-locklever(down)

DisconnectingtheMachinefrom

theTowVehicle

Parkthemachineonlevelgroundandchockthe

wheels.

Pushdownonthehitch-lockleverwhileremoving

thehitchassemblyfromthetow-vehiclehitch(Figure

20).Releasethelatchwhenthehitchandthehitch

assemblyaredisengaged.

LowertheMachineontothe

Rollers

1.Ifthemachineisconnectedtoatowvehicle,

disconnectthemachinefromthetowvehicle;

refertoDisconnectingtheMachinefromtheT ow

Vehicle(page18).

2.Removethelockingpin(Figure21).

g024199

Figure21

1.Lockingpin2.Hitchlatch

3.Liftuponthehitchassemblytotipthemachine

upslightly.

4.Pushdownonthehitchlatchtounlatchthehitch

(Figure21).

5.Raisethehitch(Figure22)untilthelatchlever

locksintheslidedetent(Figure17).

g279827

Figure22

18

OperatingtheMachine

1.Ensurethattheparkingbrakeisengaged.

2.Sitontheoperatorseat,takingcarenotto

contactthemotionpedalsasyousitdown.

3.Adjusttheseatandthesteeringwheeltoa

comfortableoperatingposition.

4.Disengagetheparkingbrake.

5.Holdontothesteeringwheel,andslowlypress

eithertheleftorrightmotionpedalwithyour

correspondingfoot,inwhicheverdirectionyou

wishtomove.

Note:Thefurtheryoupressthepedal,the

fasteryouwilltravelinthatdirection.

6.Tostopthemachine,releasethemotionpedals.

Important:Donotpressthemotionpedals

tooquickly;thismaycausethemachines

toskidandscufftheturfunderthedrive

roller,aswellascausedamagetothedrive

system.Youshouldalwaysoperatethe

motionpedalsinacontrolledmanner.

Note:Asyoubecomefamiliarwiththemachine,

youwillgetthefeelforwhenyoushouldrelease

themotionpedals,whichwillbepriortowhere

youwanttonishtherun,asthemachine

continuestorollforashorttimeafteryourelease

thepedal.Asyoucometoacompletestop,

gentlypresstheothermotionpedalforyour

returnpass.

7.Turnthesteeringwheelclockwisetoturnthe

machineintheforwarddirection.

Turnthesteeringwheelcounterclockwisetoturn

themachineintherearwarddirection.

Note:Asthedirectionchangesattheendof

everyrun,youwillneedtopracticewiththe

machinetobecomeaccustomedtothesteering.

Important:Tostopthemachineinan

emergency,presstheothermotionpedalto

theNEUTRALposition.Asanexample,with

therightpedalpressedandtravelingtothe

right,presstheleftpedaltotheNEUTRAL

positiontobringthemachinetoastop.This

actionmustbermbutnotsudden,asitmay

causethemachinetotipsideways.

8.Beforeleavingtheoperator’sseat,parkedona

levelsurfaceandengagetheparkingbrake.

OperatingTips

•Whenoperatingthemachineonhills,ensurethat

thedriverollerisonthedownhillsideforadequate

traction.Failuretodosomayresultinturfdamage.

•Forthebestrollingeffect,periodicallyremoveany

buildupthataccumulatesontherollers.

AfterOperation

AfterOperationSafety

•Shutoffthemachine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Cleangrassanddebrisfromthemuferand

enginecompartmenttohelppreventres.Clean

upoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

HaulingtheMachine

•Usefull-widthrampsforloadingthemachineonto

atrailerortruck.

•Tiethemachinedownsecurely.

19

Maintenance

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Movethethrottlelevertotheidleposition.

–Ensurethatthemotionpedalsareinneutral

position.

–Engagetheparkingbrake.

–Shutofftheengine.

–Waitforallmovingpartstostop.

–Allowthemachinetocoolbeforeadjusting,

servicing,orcleaning.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

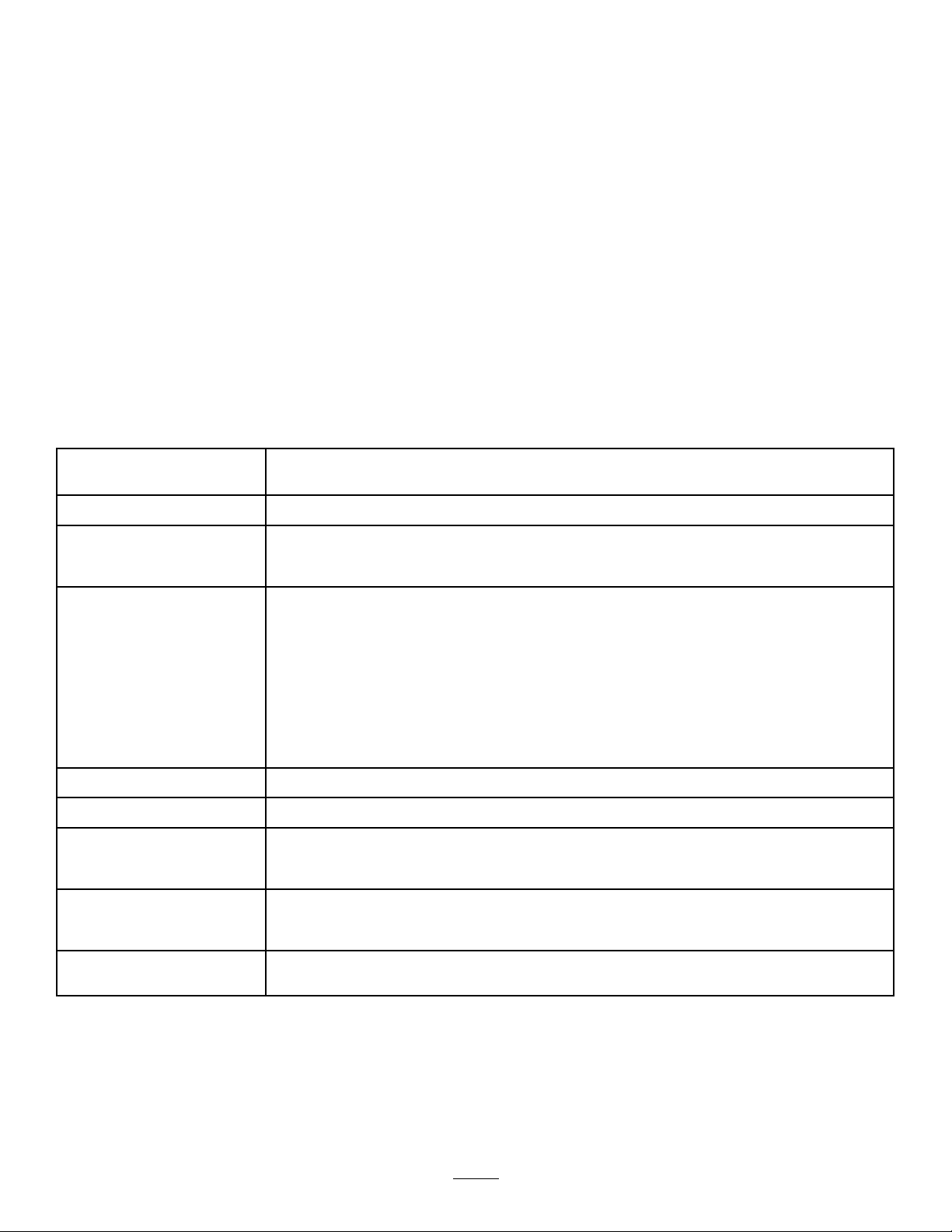

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst5hours•Checkthemachineforanyloosehardware.

Aftertherst20hours

•Changetheengineoil.

•Changethehydraulicuidandlter.

•Changethehydraulicuidandlter.

Beforeeachuseordaily

•Lubricatethedrive-rollerbearing.

•Checktheengine-oillevel.

•Checktheaircleaner.

•Checktheaircleaner.

•Checkthesafety-interlocksystem.

•Checktheparkingbrake.

•Checkthehydraulichosesandttings.

•Checkthehydraulic-uidlevel.

•Checkthetireairpressureinthetransportwheels.

•Checkthemachineforanyloosehardware.

Aftereachuse•Cleanthemachine.

Every50hours•Cleantheaircleaner(moreoftenindirtyordustyconditions).

Every100hours

•Changetheengineoil.

•Check/adjustthesparkplug.

•Cleanthesedimentcup.

Every300hours

•Replacethepaperelement.

•Replacethesparkplug.

•Checkandadjustthevalveclearance.

Every400hours•Changethehydraulicuidandlter.

•Changethehydraulicuidandlter.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

20

Other manuals for GreensPro 1260

1

This manual suits for next models

1

Table of contents