Eoslift W20 Series User manual

BEFORE YOU BEGIN

Operating Instructions

Electric Pallet Truck

W20 Series

Welcome to use the electric pallet truck. For your safety and correct operation, please carefully read this

instruction book and warnings on the truck before using it.This Operation Instruction of the truck is edited for

you to completely acquire and master the safety operation of the truck.

The majority of this truck consists of steel, it can be completely recycled. Waste material in conjunction with

repairs, maintenance, cleaning or scrapping, must be collected and disposed of in an environment-friendly way

and in accordance with the directives of respective countries. Such work must be carried out in areas intended

for this purpose. Recyclable material should be taken care of by specialized authorities. Environmentally

hazardous waste, such as oil filters, batteries and electronics, will have a negative effect on the environment, or

health, if handled incorrectly.

All of the information reported herein is based on data available at the moment of printing. Our products are

constantly being developed and renewed, we reserves the right to modify our own products at any moment

without prior notice and incurring in any sanction. So, it is suggested to always verify possible updates.

Electric Pallet Truck

W20 Series

Eoslift Warehousing Equipment Co., Ltd.

No.99, Yanjia Road, Yuantong Town, Haiyan, Zhejiang

1.Safety Operation Regulation

1

1.1 Requirement on operator

The truck must be operated by trained person, who can demonstrate the moving and operating of the truck to

user and can instruct vividly the user how to operate the truck. During operation, the operator must be

responsible for the truck and prevent unauthorized person in driving or operating the truck. The truck is strictly

forbidden to lift or carry person.

1.2 Failure and fault

In case of any failure or fault, please notify the administrator immediately. In case that truck can not work safely

(such as wheel worn-out or brake fault), please stop using the truck until they are properly repaired.

1.3 Danger area

Danger area refers to: the area where the truck or its lifting device (such as fork or attachment) is working or

lifting, which brings potential dangerous factors to person; or the area for load transportation. Generally, the

range of danger area extends to the point of load lowering or truck attachment lowering.

Unauthorized person must be kept away from danger area. For any circumstance with potential danger to

person, the operator must give warning notice. If someone still stays in danger area while being requested to

leave, the operator must stop the truck immediately.

1.4 Safety device and warning signs

Enough importance should be attached to safety device, warning sign and warning notice introduced above in

Operation Instruction.

The truck should always be driven with the height of forks less than 300mm except when placing or removing

load!

1.5 Passengers

Never ride on the truck or let any one else ride.

1.6 Keep Distance

The truck should not be driven on public roads outside a specific area. Remember that the vehicle in front of

you may brake suddenly. Keep a reasonable distance.

1.7 Visibility

The operator must stare at driving direction to ensure legible sight for the road condition ahead. In case that

cargo carried interrupts the sight, reverse driving is requested. If it doesn’t help in this way, there must be

another person walking ahead of truck to give guidance and warning.

1.8 Operation protection

Keep your hands and feet away from all moving parts such as forks and wheels

, .

1. AFETY OPERATION REGULATION

2. CONTROL BAR ASSEMBLY LNSTRUCTION page 4

3. OPERATION INSTRUCTIONS page 5

4.TECHNICAL SPECIFICATION page 10

5. MAINTENANCE OF THE TRUCK page 11

6.MAINTENANCE PROCESS page 22

7. PARTS LIST WITH DRAWINGS page 31

S page 2

Fig. 4 图4 Fig. 5 图5

Fig. 6 图6

1.16 Parking

The truck should always be parked on a level surface, engaged with a parking brake. The forks must be

lowered to their lowest position, so that no one may accidentally trip over them. Always turn the ignition to the

“OFF” position and remove the ignition key from the electrical lock when leaving the truck.

If the truck is left unused for a prolonged period without it being recharged, the battery plug should be

disconnected.

1.17 Repair

Without professional training and specific authorization, the operator is forbidden to repair or change any

part of the truck. Any change of installation position of switches and safety devices is strictly forbidden by

operator to avoid efficiency decrease of the truck.

All spare parts from original manufacturer are qualified by Quality Assurance Authorities. To ensure the

safety and reliability of truck operation, only spare parts from manufacturer can be applied. The parts

replaced, including oils and fuels, must be disposed according to related environmental protection

regulations.

1.9 No unbalanced load or overload

An unbalanced load will lead to the goods fall off the ground or more severely the truck will turn over.

1.10 Speed

Adjusting the speed to the floor conditions, the line of sight and operational safety. Avoid fast acceleration,

rapid braking and cornering at speed, there is a risk for overturning or that the load may fall off.

Speed option is only available when protection arm is open.

1.11 Signaling

Use the signal horn to attract attention when make a turning.

1.12 Floor Load

Carefully check notices or directives about the max. floor load or max. wheel pressure to ensure that these

are not exceeded.

1.13 Smooth Travel

Drive the truck smoothly. Quick steering will be dangerous. Avoid sudden movement of controls. And always

remember to travel with forks at low position close to the ground.

1.14 Loaded travel/ unload travel

When operating loaded truck, keep the rear end of the truck pointed downhill. When operating unloaded truck,

keep the rear end of the truck pointed upgrade.

1.15 Driving on Slope

The cargo carried must face to upward direction of the slope.

Take safety measures to the downward slip direction of the truck: when control button at “ 0” position,

please pull the handle backwards immediately and release it according to actual requirement to enable the

electromagnetic brake to work automatically and control the speed and direction of truck (for downward slip).

2

3

2.Control Bar Assembly Instruction

(1) Screw off the bolts #1,#2,#3,#4,#5,#6

Warning: not to screw off the middle bolt #7

(2)Push the cover aside

(3) Join the wire connection #9 (4) Fix the cover back and tightening

The 6 pieces of bolts

3.4 Horn

3.5 Steering

Control steering by moving the control handle from

side to side.

3.1Power on & off

3.1.1Turn on the truck by turning the key to right—power on.

3.1.2Turn on the truck by turning the key to left—power off.

3.1.3Always turn off the truck when leaving the truck.

\

3.2 Braking

Loose the throttle button will make truck slow down and stop.

3. Operation Instructions

4

5

Throttle button

Horn Button

Move the handle all the way down or all the way up to apply the brake.

3.3 Raising and lowing

Raise: Push raise button until the forks are at the desired height.

Lower: Push lower button until the forks are at the desired height.

3.6 Travelling

Rotate the throttle button in the direction you want to travel.The farther you rotate the throttle button from the

neutral position, the faster the truck will travel.

3.7 Reversing button

If you accidentally hit the reversing button while working in the close corner the truck will move in the direction of

the forks.

Be careful, the reversing button can not prevent all injuries.

3.8 Emergency stop button

Push down emergency stop button will cut any current of the machine, make immediately stop.

6

7

3.9 Battery indicator

Discharging status of battery is indicated on battery capacity meter with ten indicator bars

for each 10% increase. On the bottom, the machine's working hour can be displayed.

If the battery capacity meter indicates capacity insufficient soon after lifting system works, the lifting function

will be resumed only after recharging the battery to at least 70% of the capacity.

Battery sufficient

Battery charger requirement, to be re-charged

Before charging the battery

(1)Make certain the charge is the same voltage and amperage as your battery.

(2)Be sure the charger is turned off before connecting the battery to the charger. Otherwise you might create a

spark which could cause the battery explosion.

(3)Make sure the truck key switch is turned off.

3.10 Charge the battery

When the battery indicator shows “charger require”, the battery should be charged at once. It is not

necessary to open the battery cover when you want to charge, please operate as following steps:

(1) Turn off the key switch of truck.

(2) Connect the charger plug to the truck charger plug.

(3) See charge instruction to operate charger.

3.11 Steering motor control fault codes

8

9

4.Technical specification

AC 1.5

DC 2

3PZS210(Maintenance-free)

24/210(140/70)

¢73X98/80X58

¢115X55/252X67

200(100/50)

kg

kg

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

km/h

mm/s

mm/s

%

kw

kw

V/Ah

Lb

W20

2000

600

1375

610/510/460

PU

2(4)/1+1

110

870/1220

85

1730

720

540/685

2140

2100

1655

3.5/3.5

56/60

57/59

5/7

1150/1200X180X55

5. Maintenance of the Truck

5.1 Safety Operation and Environmental Protection

The instructions in the chapter of “ Operation of Inspection and Maintenance” should be

performed based on the time interval specified in Maintenance List.

Any part on the truck, especially safety device, can not be changed without permission. Change of

operation speed of the truck is strictly forbidden.

All spare parts from original manufacturer are qualified by Quality Assurance Authorities. To ensure

the safety and reliability of truck operation, only spare parts from manufacturer can be applied. The

parts replaced, including oils and fuels, must be disposed according to related environmental

protection regulations.

5.2 Safety Rules for Maintenance of Pallet Truck

Maintenance staff: Repair and Maintenance of the truck should only be performed by qualified

professionals trained by manufacturer. The after-sales service department of manufacturer has

dispatched special technicians who can be commissioned to sign on the maintenance record in the

maintenance service appointed by manufacturer.

Lifting of truck: For lifting of the truck, the hoisting equipment should be safe and reliable (especially

the hoisting position). When the truck is lifted, necessary measures should be taken to avoid slip and

turnover of the truck (wedge block or wood block can be applied). The truck can be lifted by hoisting

equipment only when the forks are fixed and connecting cable with enough strength is applied.

Cleaning operation: Flammable fluid is strictly forbidden in cleaning of the truck. Before cleaning work starts,

safety measures must be taken to avoid sparkle (e.g. caused by short circuit). Any operation of battery

should be performed after cutting off the power of the battery. All electric elements and electronic assemblies

can only be cleaned by weak wind blower or compressed air, or by in conductive and anti-static brush.

If the truck is cleaned by water jet cleaner or high pressure cleaner, all electric elements and electronic

assemblies should be covered in advance to avoid humidity which will cause fault of function. Cleaning by

steam nozzle is prohibited.

Operation of electrical system: Operation of electrical system of the truck should be

performed by trained professionals only. Before any operation of electrical system, protection measures to

avoid electric shock should be properly taken. During operation of battery, separate the socket of battery

apart to cut off the power of the truck.

Operation of Welding: To avoid damage of electric and electronic assemblies, the assemblies should be

removed away from the truck before welding.

Installation: After repair or replace the hydraulic components, electric elements and electronic assemblies,

please install and confirm them at original positions.

Wheels: The quality of wheels take great effect on the stability and driving performance of the truck. Any

change of wheels should be discussed with and approved by the manufacturer. During replacement of

wheels, the truck must be kept horizontally as original state (wheels must be replaced by pairs, e.g. both

left and right).

Lifting chains: Without lubrication, the lifting chains will be soon worn out. The time interval in maintenance

manual is applicable for normal operation condition. In case of poor operation condition (dust, temperature),

it is necessary to feed lubrication regularly.

Hydraulic oil pipe: Oil pipe should be replaced every six years. Together with replacement of hydraulic

assembly, the oil pipe of hydraulic system should be replaced.

5.3 Maintenance and Inspection

Complete and professional maintenance is an important part for safety operation of pallet truck. Any

negligence of maintenance of stipulated time interval will cause failure of truck and cause potential danger to

person and equipment.

The maintenance cycle stated in instruction manual refers to the normal condition with single shift operating.

Under dusty condition, temperature varying greatly or under multiple shifts operating, the maintenance cycle

should be shortened.

— Check if any loosened nut on wheels and tighten it if necessary

— Check if any leakage of hydraulic parts and tighten it if required

— Replace hydraulic filter

13

12

5.4 Maintenance List

LED

CODE

0.1

1.1

1.2

1.3

1.4

2.1

2.2

2.3

2.4

3.1

3.2

PROGRANNER

LCD DISPLAY

NO KNOWN

FAULTS

FAULT

CATEGORY

0

CURRENT SHUNT

FAULT

HW FAILSAFE

M-SHORTED

SRO

THROTTLE

WIPER HI

EMR REV

WIRING

HPD

SRVC TOTAL

SRVC TRAC

TOTAL

DISABLED

TRAC DISABLE

THROTTLE

WIRPERLO

FIELD SHORT

MAIL CONT

WELDED

POSSIBLE CAUSE

N/A N/A

FAULT CLEARANCE

1

1

1

3

1

1

3

3

3

3

3

1

1

1

1. Abnormal vehicle operation

causing high current spikes

2. Current sensor out of range

3. Controller failure

1. Noisy environment

2. Self-test or watchdog fault

3. Controller failure

1. Inernal or external short of M-to B-

2. Incorrect motor wiring

3. Controller failure

1. Improper sequence of KSI,interlock

and direction inputs

2. Interlock or direction switch circuit

open

3. Sequencing delay too short

4. Wrong SRO of throttle type selected

5. Misadjusted throttle pot

1. Throtte input wire open or shorted to

B+

2. Defective throttle pot.

3. Wrong throttle type selected

1. Improper sequence wire or wire open

1. Improper sequence of KSI,interlock,

and throttle inputs

2. Misadjusted throttle pot

3. Sequencing delay too short

4. Sequencing delay too short

5. Wrong HPD or throttle type selected

1. Total maintence timer expired

1. Traction maintenance timer expired

1. Total disable timer expired

1. Traction disable timer expired

1. Throttle pot wire open of shorted to B+

2. Wrong throttle type selected

3. Defective throttle pot

1. Main contactor coil shorted

2. Field winding shorted to B+ or B-

3. Field resistance too low

1. Main contactor stuck closed

2. Main contactor driver shorted

Cycle KSI. if problem

persists, replace the

controller

Cycle KSI. if problem

persists, replace the

controller

Check wiring;Cycle

KSI.

if problem persists,

replace the controller

Follow proper

sequence;

adjust throttle if

necessary;

adjust programmable

parameters if

necessary

When Throttle wiper

high

input returns to valid

range

Re-apply emergency

reverse or cvcle interlock

Follow proper sequence;

adjust throttle if

necessary;

adjust programmable

parameters if necessary

Reset with proqrammer

Reset with proqrammer

Reset with proqrammer

Reset with proqrammer

When throttle Wiper

Low

input returns to valid

range

Check contactor coil

and

field winding;cycle KSI

Check wiring and

contactor; cycle KSI

3.3

3.4

FIELD OPEN 1

1

MISSING

CONTACTOR

1. Field winding connection open

2. Field winding open

1. Main contactor coil open

2. Main contactor missing

3. Wire to main contactor open

Check wiring and

cycle KSI

Check wiring and

cycle KSI

14

15

Medium term

of overhaul

Name Symbol

Maintenance

level 1

Maintenance

level 2

Maintenance

level 3

Large-scale

over haul

B1

B2

B3

Z

D

Maintenance

level 1

Maintenance

level 2

Maintenance

level 3

Large-scale

over haul

Name Symbol

Maintenance

level 1

Maintenance

level 2

Maintenance

level 3

Large-scale

over haul

B1

B2

B3

Z

D

Check for oil

lesks

looseness

collapse

deformation

and damage

18

19

Maintenance

level 1

Maintenance

level 2

Maintenance

level 3

Large-scale

over haul

Unable to move forward

Unable to move backward

22

23

Unable to lift Unable to lower

26

27

Trouble showing code of controller

Trouble showing code of controller

20

30

31

Parts List

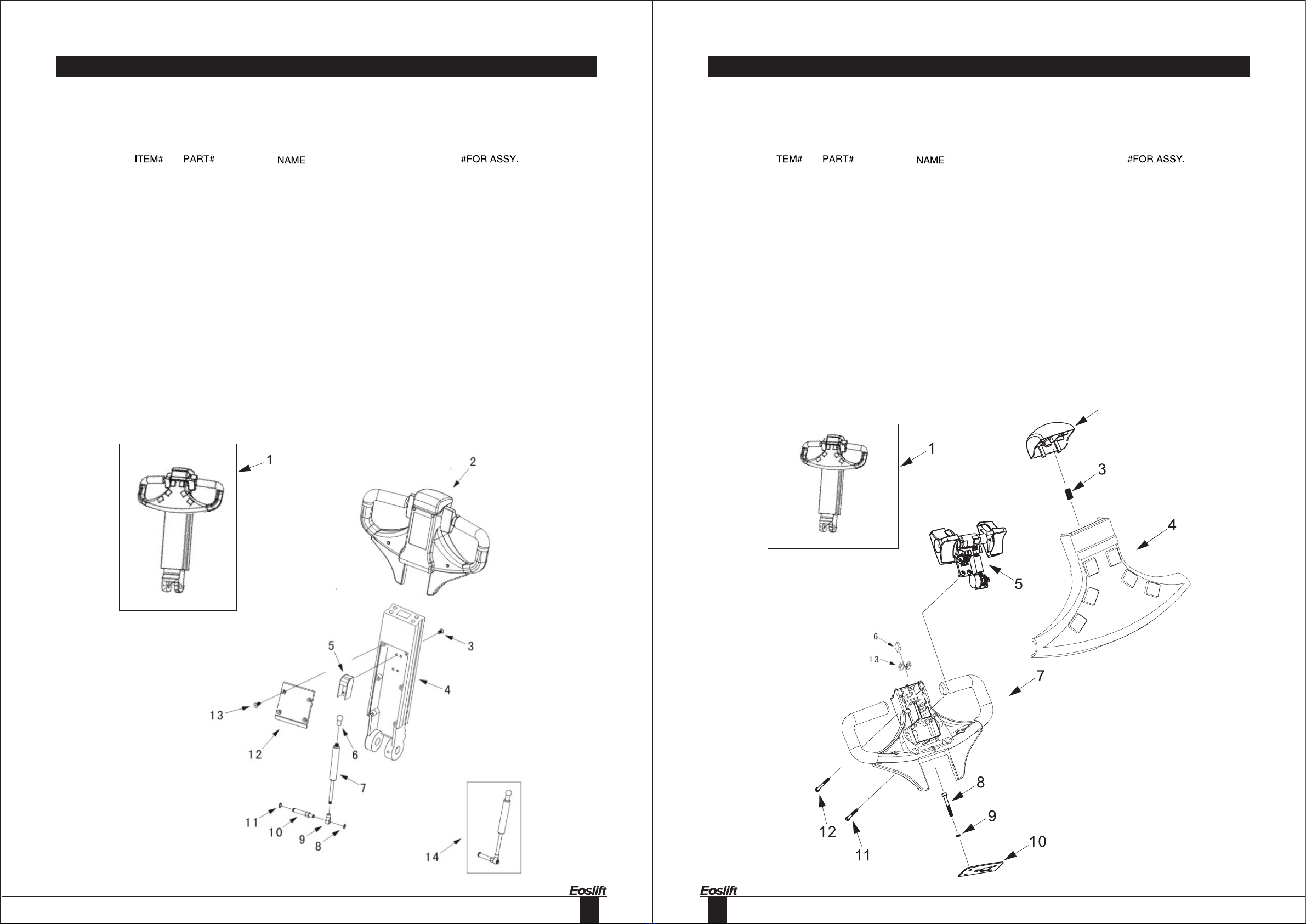

Fig.1 Steering control system

Steering control system

Handle assembly

Switch box assembly

Switch box assembly

Stepped switch assembly

Driving system

Gear box assembly

Driving system

Drive motor

Hydraulic system

Cylinder assembly

Hydraulic power unit

Valve assembly

Oil pump

Frame

Balance wheel assembly

Electric panel assembly

Forked frame

Electric panel assembly

Battery a ssembly

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

Fig.7

Fig.8

Fig.9

Fig.10

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Fig.18

Fig.19

Fig.20

ITEM# DENAME PAGE

1500500001

Lubricated bush

Pin shaft

Pin shaft

Sping pin

Rubber washer

Rubber sack

Rubber sleeve

Steel ball

2000507004

4300501001

Inner covering plate

Handle socket

Electron hanbgrip

32

33

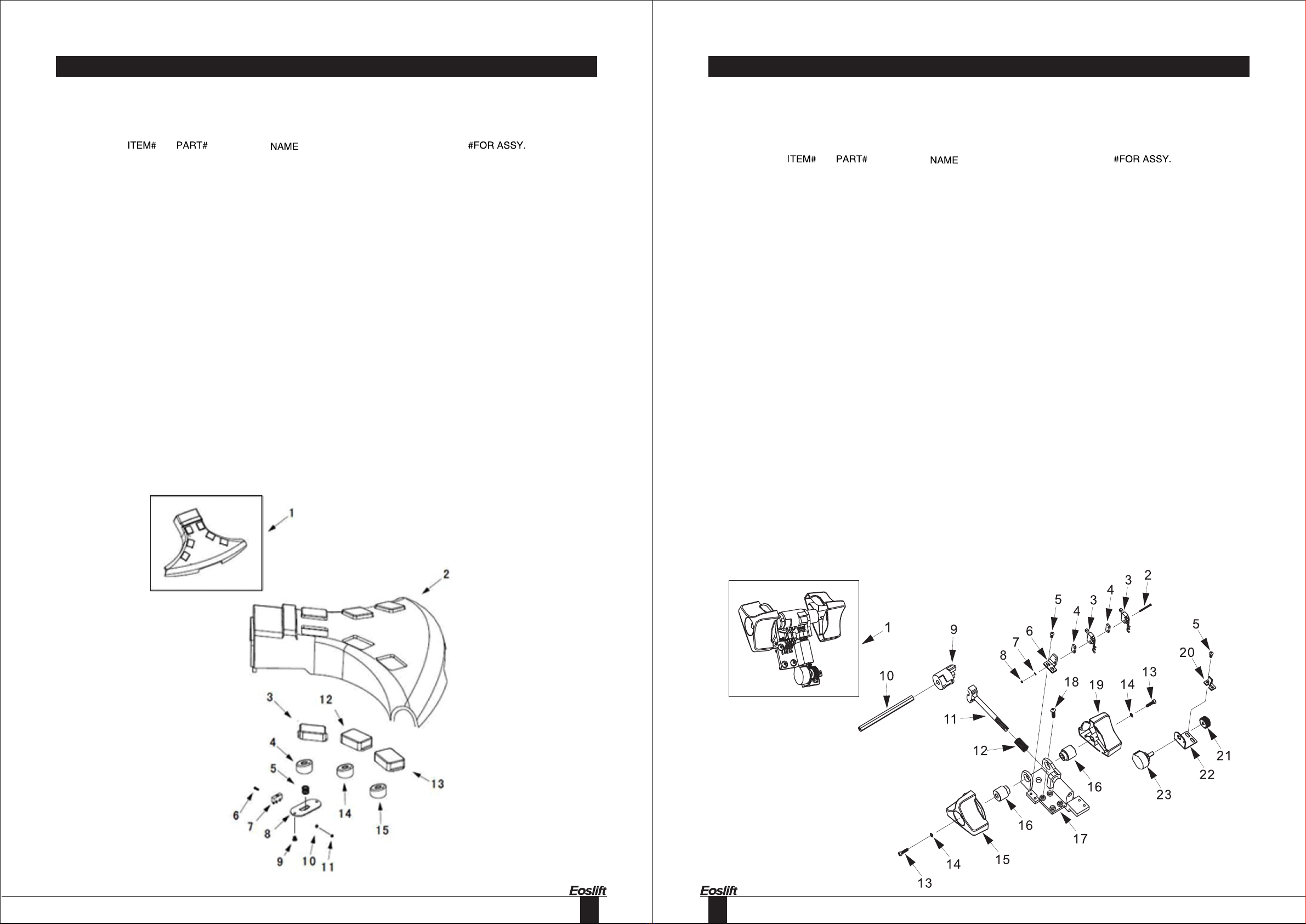

Fig.3 Switch box assembly

5300500002

5300518003

2000519004

5300500001

4300500004

2000507002

5300517002

6000131001

1001437003

1200518001

6000131006

4300531001

9300517001

1

2

3

4

5

6

7

8

9

10

11

12

13

Switch box assembly

Emergency reverser button cover

Spring

Cover assembly

Stepped switch assembly

Emergency reverser button

Handle

Screw

Washer

Supporting plate

Screw

Screw

Seat

1

1

1

1

1

1

1

4

4

1

2

2

1

Fig.2 Handle assembly

1500500001

5300500002

2000442001

4300501004

6000502002

2000525010

4000519004

2000527002

2000520003

2000525006

1000527001

4000517001

2000542001

4000500006

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Handle assembly

Switch box assembly

Screw

Handle tube

Pneumatic spring seat

Joint

Pneumatic spring complete

Snap ring

Joint

Shaft

Snap ring

Covering plate

Screw

Pneumatic spring assembly

1

1

4

1

1

1

1

1

1

1

1

1

4

1

34

35

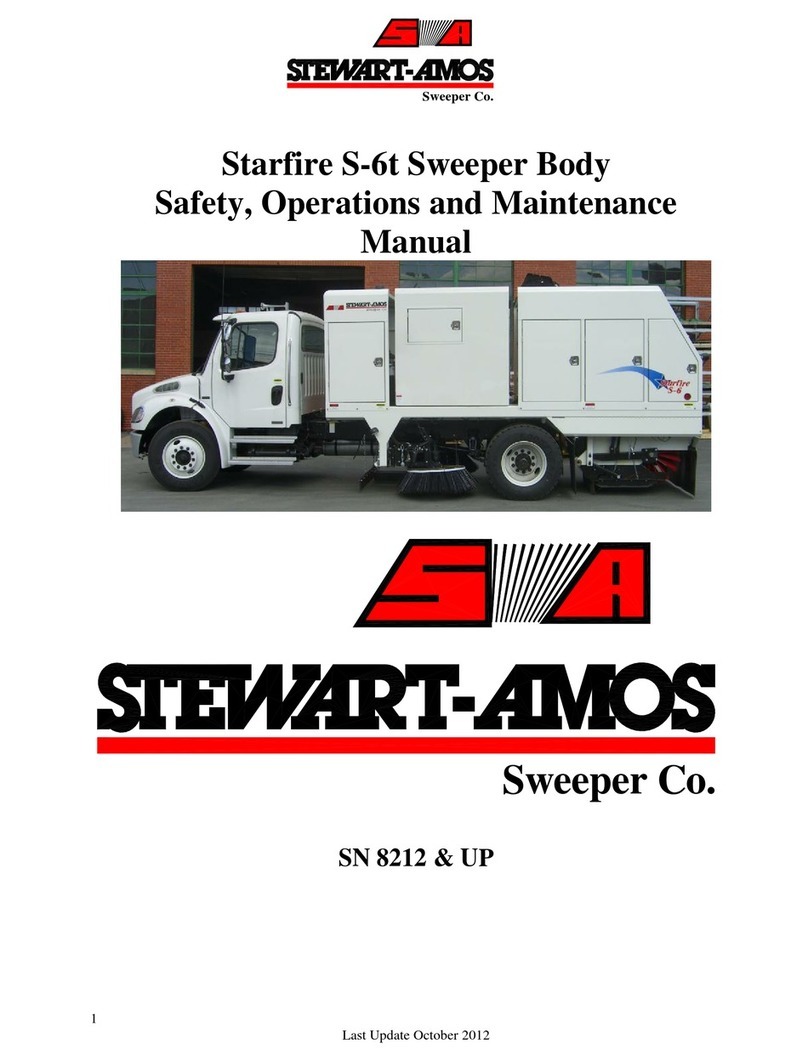

Fig.5 Stepped switch assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

4300500004

2000538005

2000507003

2000535001

2001141005

4300518003

1000504001

2000539002

4300501005

4300513001

1002343003

2000519004

4300900002

2001437005

4300540001

4300512001

4300535001

2000541004

4300540002

4300518004

2000521001

4700418001

4700400001

Stepped switch assembly

Screw

Inching switch

Isolate block

Screw

Fastening bracket

Washer

Nut

Cam

Cam shaft

Rack

Spring

Screw

Circlip

Right control knob

Shaft sleeve

Fastening bracket

Screw

Left control knob

Baffle

Gear

Fastening bracket

Potentiometer

1

2

2

2

2

1

2

2

1

1

1

1

2

2

1

2

1

4

1

1

1

1

1

Fig.4 Switch box assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

4300500007

4300508002

4300508003

4300540003

4300519001

4300541001

2000507002

4300518001

2000441002

1000504001

2000539002

4300508004

4300508005

4300540004

4300540005

Cover assembly

Cover

Button cover

Rubber contact

Spring

Screw

Inching switch

lsolate block

Screw

Washer

Nut

Button cover

Button cover

Rubber contact

Rubber contact

1

1

2

2

6

12

6

6

12

12

12

2

2

2

2

36

37

Fig.7 Gear box assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Screw

Gear

Nut

Gear

Bearing

Screw

Bolt

Washer

Side cover

O-ring

Bolt

Washer

Gear

Bearing

Washer

Washer

Gear

Flat

Circlip

Screw

Bearing

Seal washer

Spline shaft

Gear box body

Gear box assembly

2000130002

7800321001

2000125001

2000121006

2000120003

2000141001

2000625001

2000603010

2000111002

2000128002

2000130001

2000135001

2000121002

2000120002

2000137001

2000137002

4000201001

4000101001

2001037001

2000731003

2000120001

2000105001

2000121003

2000126001

7800300003

4

1

1

1

2

8

2

2

1

1

1

1

1

1

2

2

1

1

8

8

1

1

1

1

1

Fig.6 Driving system

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

7800300001

1000131001

2001037001

7800300002

5501221004

7800337001

7800330002

1500318001

0300320001

7800300003

2000325001

4000332001

2000325002

8700406001

9300312002

1

4

4

1

1

1

1

1

1

1

5

1

5

1

1

Electromotor

Screw

Washer

Electromotor

Gear

Washer

Screw

Flange

Axletree

Gear box assembly

Double-head bolt

Drive wheel assembly

Nut

Limittation Switch

Sleeve

38

39

Fig.9 Drive motor

1

2

3

4

5

6

7

8

9

0301415001

0301408001

4300900002

0301411001

2001420001

2001427002

0301412001

0301400002

0301400001

3

1

2

1

1

1

1

1

1

Tie-in

Plastic mantle

Screw

Cover

Bearing

Snapring

Spring

Rotor

Drive motor

Fig.8 Driving system

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Brake assembly

Spline

Snap ring

Sleeve

0-ring

Flat key

Moto r

Screw

Position sleeve

Dus t ring

O-ring

Bearing

Snap ring

Snap ring

Gea r

Semicircle key

Nu t

0301000001

2001021001

2001427001

4301412002

2000628005

2001021001

0301400001

0301431001

2001212003

2001405001

2001228001

2001420001

2001427001

2001227003

2000121005

2001435001

2001425002

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

40

41

Fig.11 Cylinder assembly

1

2

3

4

4700613001

2800605002

4700612001

2800605001

1

1

2

1

Pistonrid

Dustring

Supporting tach

Seal washer

Fig.10 Hydraulic system

1

2

3

4

5

Joint

O-ring

Hydraulic power unit

Washer

Joint

8700615004

6000637001

4000600007

1500617001

1500615001

1

2

1

1

1

42

43

Fig.13Valve assembly

Fig.12 Hydraulic power unit

1

2

3

4

5

6

7

8

9

10

11

12

13

1001400001

2000612004

4000600006

1000628001

1000600007

2000631003

2000631001

1000626001

1000609001

1000741001

1000635002

1000605005

1000605006

1

1

1

1

1

2

2

1

4

4

1

1

1

Hydraulic motor

Connecting bearing sleeve

Valve assembly

O-ring

Oil pump

Screw

Screw

Oil tank

Washer

Screw

Joint

Oil plug

Cover

44

45

Fig.14 Oil pump

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

2000628001

2000605006

2000628002

4000611001

2000628016

2000628017

2000605002

2000612002

1000621005

1000621006

2000633001

1000603006

2000611006

2000628019

4000625002

1

1

1

1

2

2

2

2

1

1

4

1

1

1

1

O-ring

Seal washer

O-ring

Oil out cover

O-ring

O-ring

O-ring protection washer

Oil discharge block

Drive gear

Driven gear

Pin

Pump body

Oil feed cover

O-ring

Oil suction pipe

Fig.13 Valve assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

2

2

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2000630001

2000637001

2000625003

2000628014

2000619004

2000614008

4000603010

2000619001

2000613003

2000628007

2000612006

2000628015

2000610001

2000628001

2000603018

1000603003

2000628018

2000637005

2000634002

1000603012

2000628009

2000619003

2000613001

2000504001

2000603004

2000628010

2000634001

1000604001

1000603013

1000619001

1000303014

2000637002

1000603016

Bolt

Washer

Bolt

O-ring

Spring

Core of slide valve

Valve body

Spring

Core of slide valve

O-ring

Slide valve sleeve

O-ring

Washer

O-ring

Electromagnetic coil

Plug

O-ring

Washer

Filter net

Valve holder

O-ring

Spring

Spring socket

Steel ball

Valve holder

O-ring

O-ring protection washer

Steel ball

Spring socket

Spring

Pressure adjusting bolt

Washer

Nut

46

47

Fig.16 Banlance wheel assembly

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

4300327001

7300712002

7300320001

7300218001

1001031003

7301218001

1000339001

2000737003

2000305001

2300312001

1000320002

4000312002

2700332001

7300330001

7300300001

4300304001

4300720002

7300305001

1

1

1

1

6

1

1

1

2

2

2

1

1

1

1

1

1

1

Mat

Mat

Bearing

Wheel seat

Screw

Wheel bracket

Nut

Circlip

Dust ring

Bush

Bearing

Wheel sleeve

Balance wheel

Screw

Balance wheel assembly

Nut

Bearing

Pressurize circle

Fig.15 Frame

1

2

3

4

1500724001

1500724002

7300300001

1500400001

1

1

1

1

Frame

Bracket

Balance wheel assembly

Electric panel assembly

Table of contents

Other Eoslift Truck manuals

Popular Truck manuals by other brands

EP Equipment

EP Equipment CQD15S-E Operation manual

Sealey

Sealey Premier CST990HD quick start guide

Eagle

Eagle TT Series Parts and service manual

STEWART-AMOS

STEWART-AMOS Starfire S-6t 2012 Operation and maintenance manual

Komatsu

Komatsu 210M Operation & maintenance manual

Dawson

Dawson Truck Mate Operator's manual