Series 248-2 Assembly Instructions Dated 11/2021 Previous instructions become invalid. 3 / 12

•To ensure water cannot penetrate the assembled box body, the

sealing cords in the profiles must not show any signs of damage.

•Connect the components directly using the screws supplied.

The assembly contact surfaces must be free from dirt.

•Use the original screws and bolts, and use them only once (even for

repairs). Third party / used screws and bolts endanger operational

safety. Screws must not tilt. Never position the screws or bolts at an

angle and keep to the specified torques (2.3). A torque lower than

specified weakens the strength and tightness of the body, a signifi-

cant exceedance can cause damage to components!

•The body is not designed for docking operations! Set out the un-

derbody so that forces acting through rear bumper guards are trans-

ferred into the auxiliary frames or the chassis.

•The fastenings between the longitudinal chassis beams and chassis

frame must be made as described in the body guidelines of the

respective chassis manufacturer. The two front fastenings at least

must be spring-mounted. Otherwise, forces that occur, e.g. in case of

cornering, load changes or non-uniform loading, are transferred onto

the body and can cause cracks in the body structure.

1.3 Safety instructions

Pay attention to your own safety and to that of your employees.

Working with kits involves hazards. Therefore, caution is always

necessary, in particular, you should definitely:

... Wear safety gloves. Wear safety footwear, as heavy parts can fall.

Wear hearing protectionas well as safety goggles when working

with air screwdrivers, grills, grinding equipment, etc. Wear a helmet

when working with or near a crane.

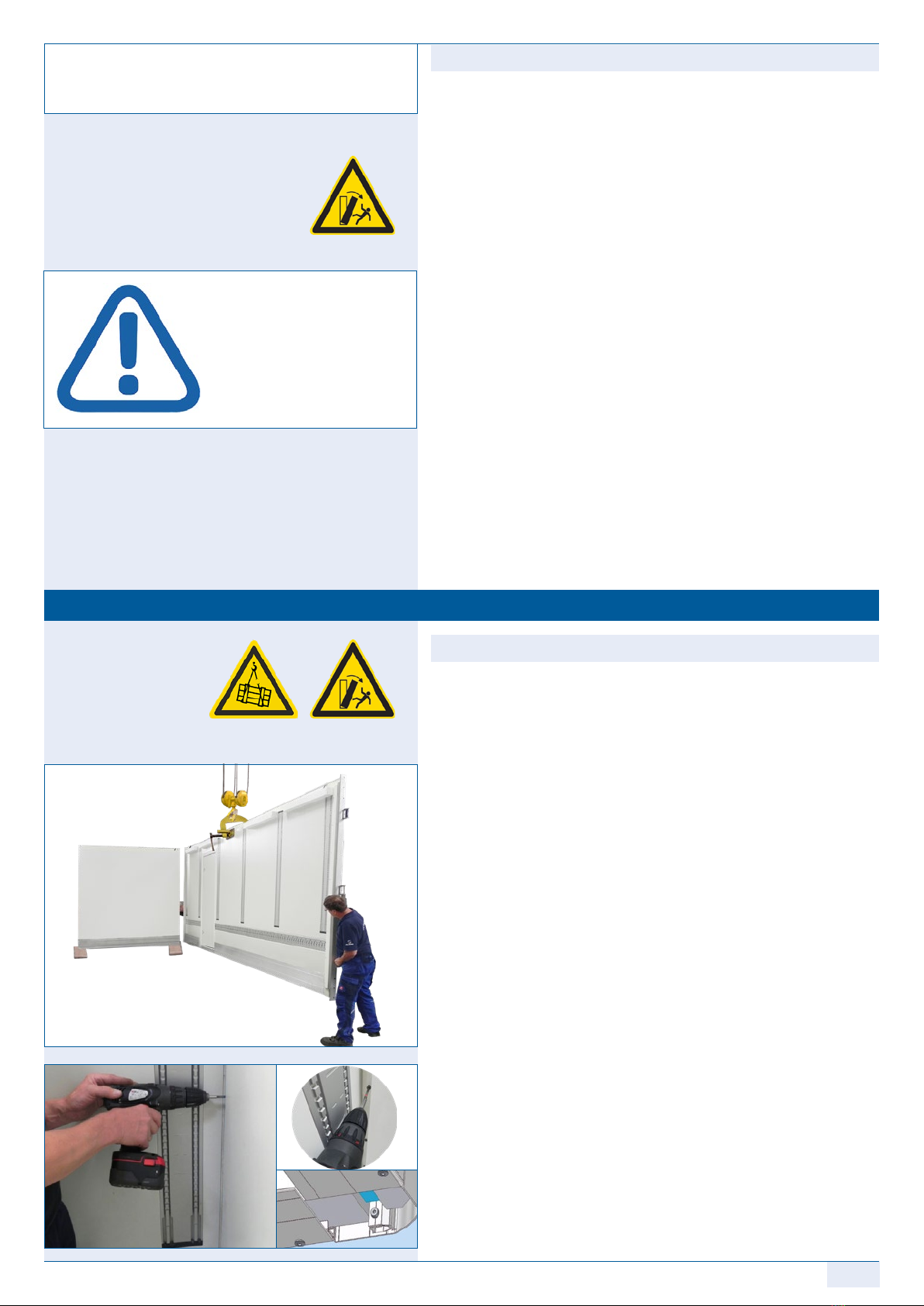

... when unloading /transporting the kit in the transport rack using a

crane, use a suitable lifting beam. If using a forklift truck, push the

transport rack completely onto the fork arms.

... Place transport racks on level surfaces only and secure them against

tilting and toppling, secure any assembly dollies against rolling

away.

... Always lift assemblies vertically, not at an angle! Never step under

raised loads! The suspension point/anchorage in the crane must al-

ways be above the assembly’s centre of gravity!

... remove all packing straps in the specified order during assembly,

always remove the white packing straps first. The individual compo-

nents and assemblies are held by a red packing strap. Secure the part

to be removed against toppling before cutting the packing strap.

... lift the roof with a lifting beam or vacuum lifter only! The roof

mounting strips (airline rails) are used as an assembly aid only. They

must not be used to lift assembled box bodies. Risk of pulling out!

... comply with all relevant legal requirements in your country, such

as laws, regulations, etc. regarding road traffic and goods transport,

as well as all relevant occupational health and safety regulations.

This is the responsibility of the body builder.

... ensure adequate ventilation when cleaning and sealing and follow

the use, safety and disposal instructions of the adhesive / sealant

manufacturer. Request the safety sheet and the instructions for

use from the manufacturer as printed on the cartridge or contact

+49 (0)521 4173 -1110.

1

2

suspended

loads on the

crane

Risk due to

high-pressure

cleaners

falling

objects

Risk of

scalding

hazardous

materials

toppling parts

or assemblies