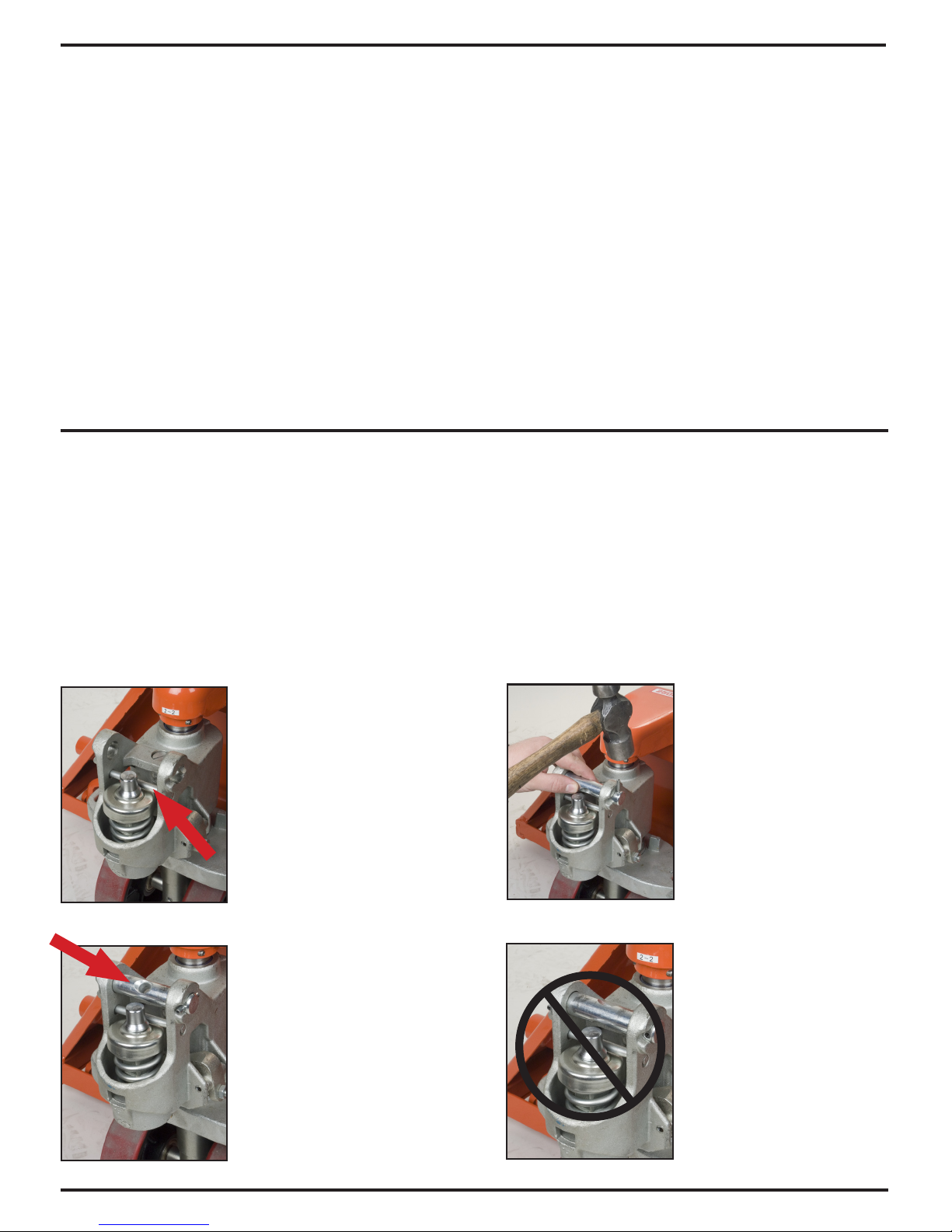

*** IMPORTANT - CHAIN****

Before this step, make sure to

feed the chain on the outside

of the piston stem roller (see

yellow arrow). If left in its proper

position, it will not be possible to

insert the handle pin and chain,

breakage may occur.

Align handle holes with pump

housing holes and push through

handle pin (see red arrow)

Make sure that handle pin is

completely through the handle

and resting on the other side.

Pull down on the handle to

release the tension on the safety

pin. CAREFULLY remove the

safety pin.

Feed the chain and nut first back

inside the handle THROUGH the

handle pin’s center hole.

***IMPORTANT - TIP ***

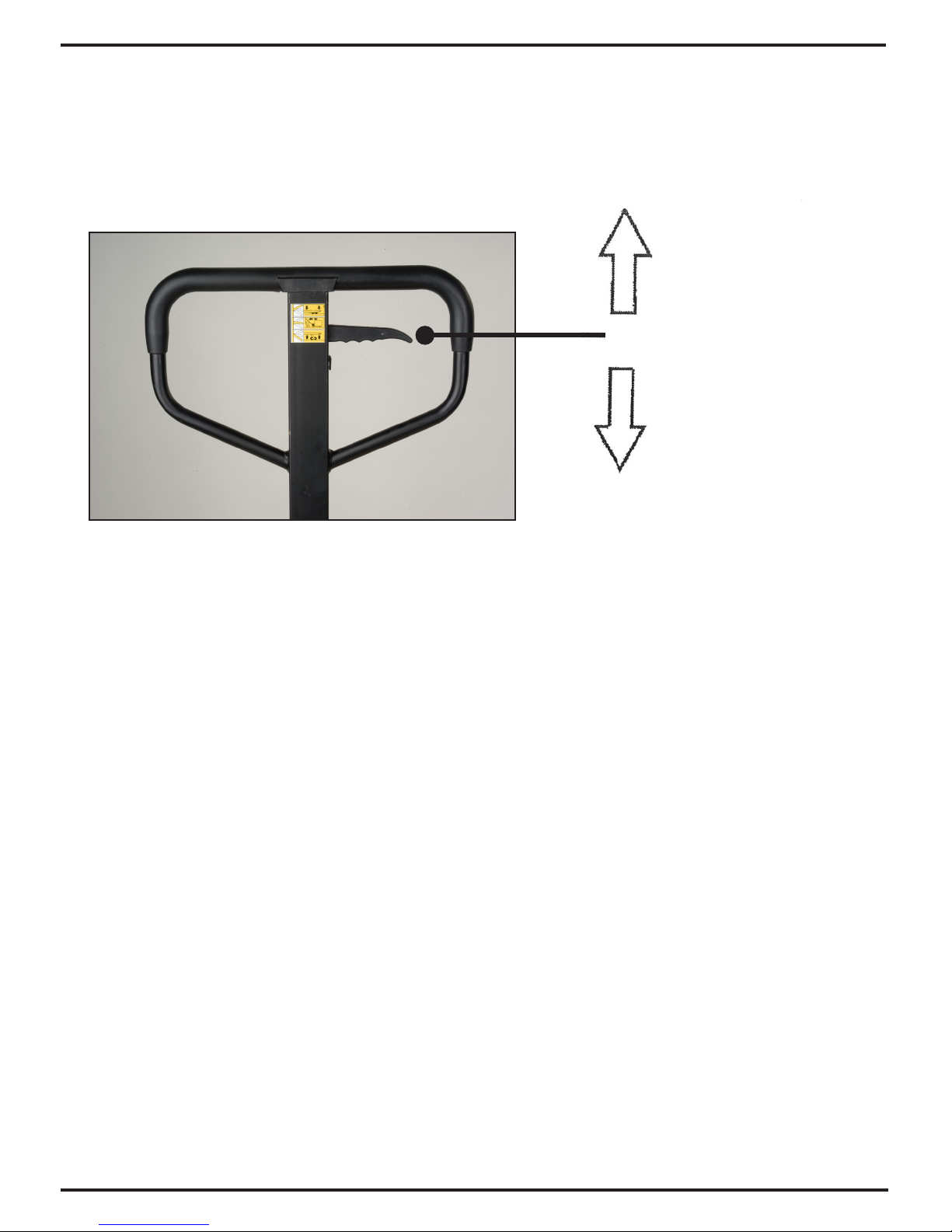

Release the up/down lever to

its lowest position to make the

process easier.

Once the chain is in the proper

position, check to see that it

moves freely and that it is not

obstructed.

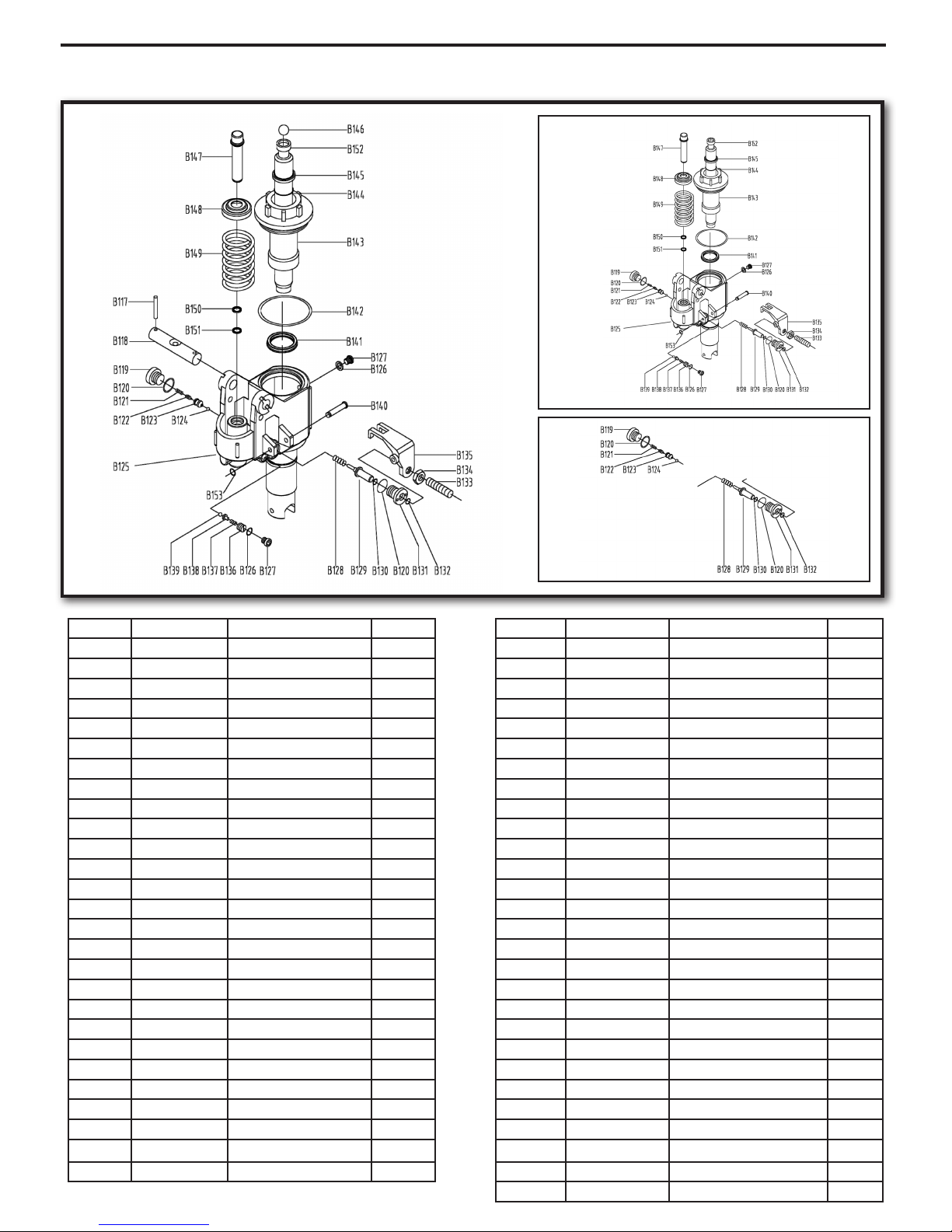

Using both hands,

push on the valve

cam to raise the

hook inside the

housing and feed

the end of the

chain in the cam.

(see image at

right)

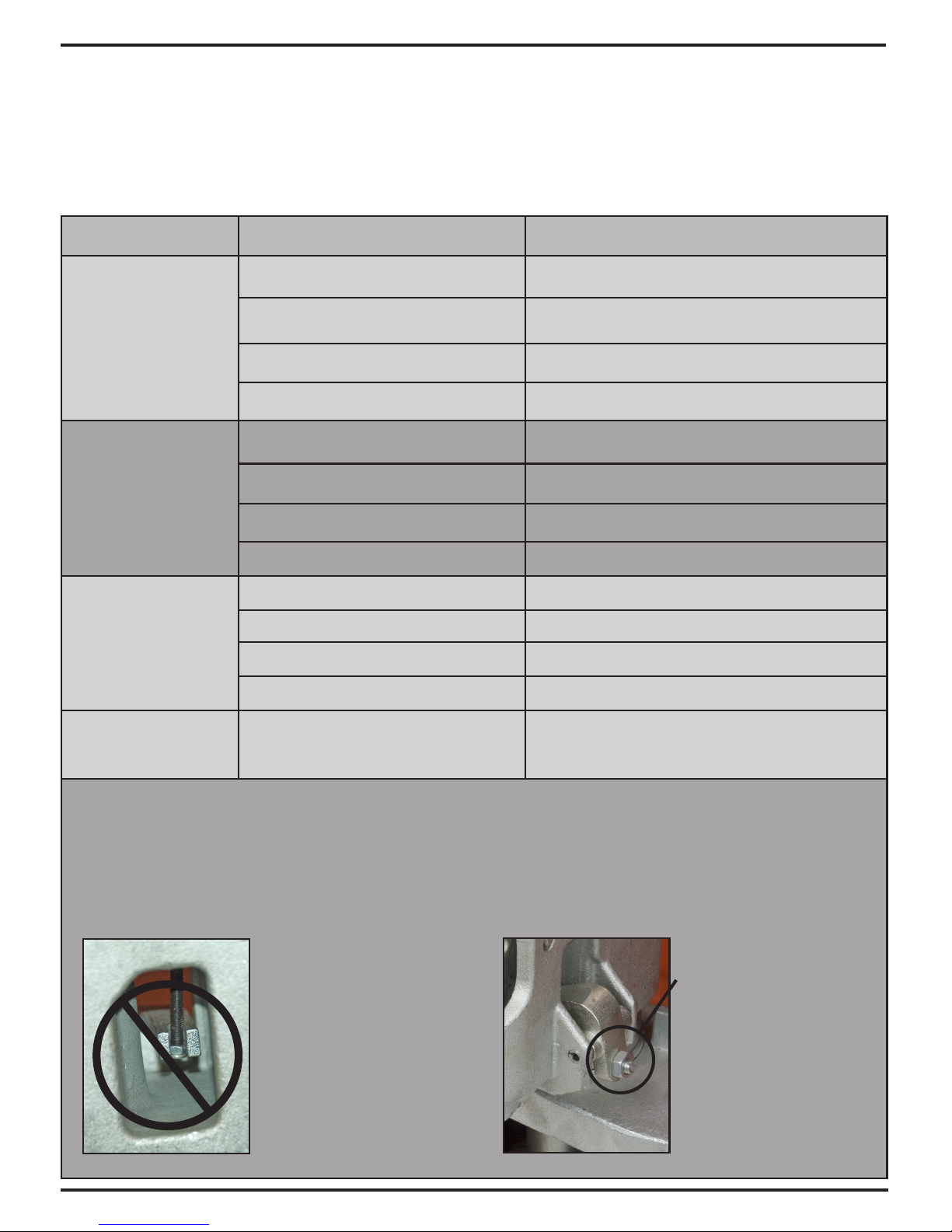

Pump the lever a few times to

raise the forks. Put the up/down

lever to its NEUTRAL position.

Using a 14mm wrench and a

flat screwdriver, adjust the valve

cam so that the forks don’t lower

or rise (if handle is pumped) at

this position.

*** IMPORTANT - FINAL CHECK ***

Test all the features of the pallet

truck before this step. The handle

should be pumped with full strokes

to prime and eliminate air in the

system. The up/down lever should be

checked at the handle’s lowest posi-

tion for this puts the most tension

on the chain. Once the pallet truck is

adjusted properly and is performing

well, drive in the second spring pin

using a hammer.

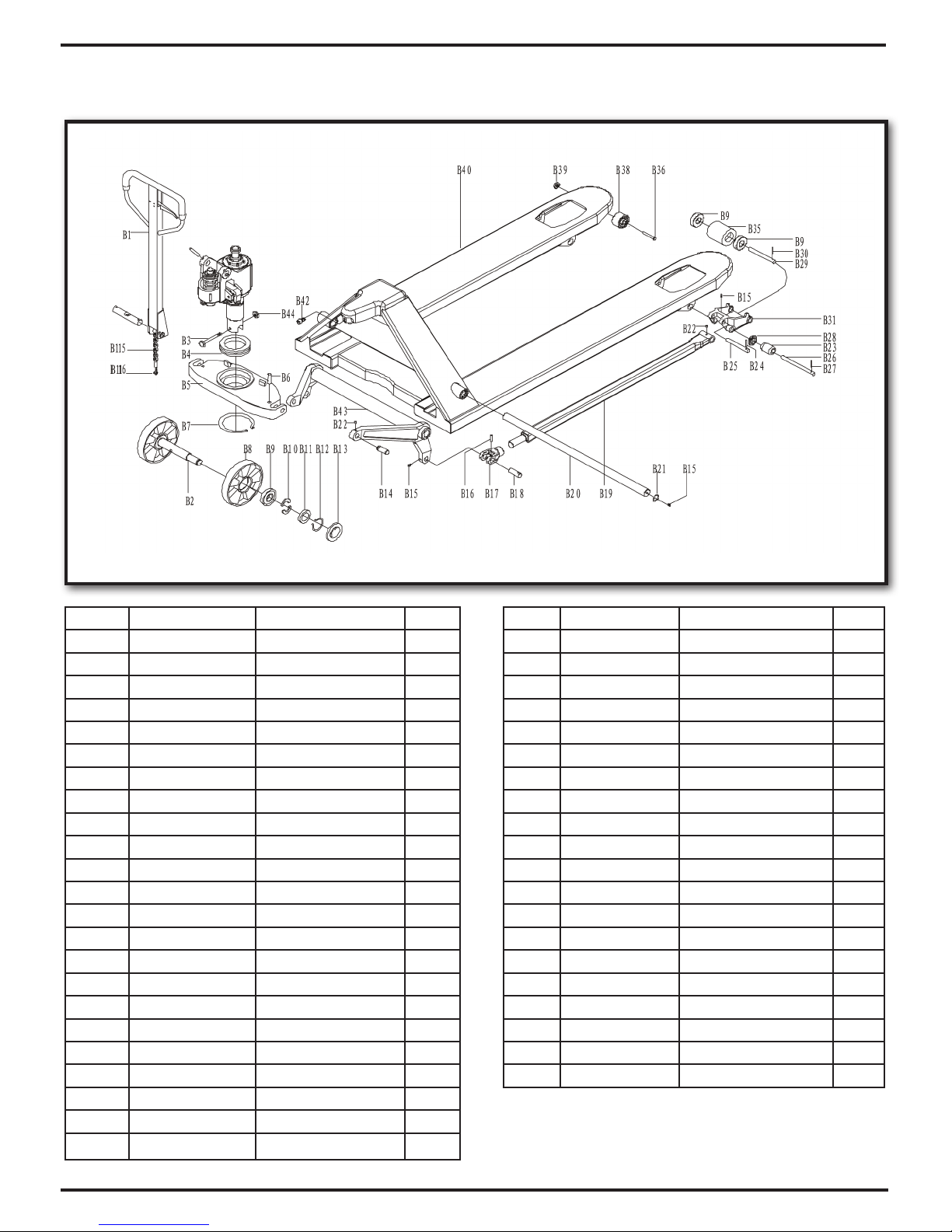

5. 6.

7. 8.

9. 10.

11. 12.