MAINTENANCE SCHEDULE

2-2 ©200515

Maintenance activities

4

ΛΦ45/55 series

2.2 OVERVIEW OF ANNUAL MAINTENANCE ACTIVITIES

ANNUAL MAINTENANCE ACTIVITIES (Y-SERVICE)

"Correct, if necessary, after inspection"

CAB AND ELECTRICAL SYSTEM

O Check pedal rubbers

O Check whether the latest version of the ITS manual is kept in the cab

O Replace the cab filter element - See note 1 Replaced O Yes O No

O Check the fluid level of the cab tilting pump

O Check cab fastening

ENGINE, COOLING SYSTEM AND FUEL SYSTEM

O Replace the air filter element

O Check the air inlet dust trapping valve

O Check the vibration damper (vulcanised version)

O Check/adjust the valve clearance - See note 4 Done O Yes O No

O Check the coolant freezing point

O Change the coolant - See note 5 Changed O Yes O No

O Remove the fuel fine filter

STEERING GEAR AND BRAKE SYSTEM

O Check the steering ball joints

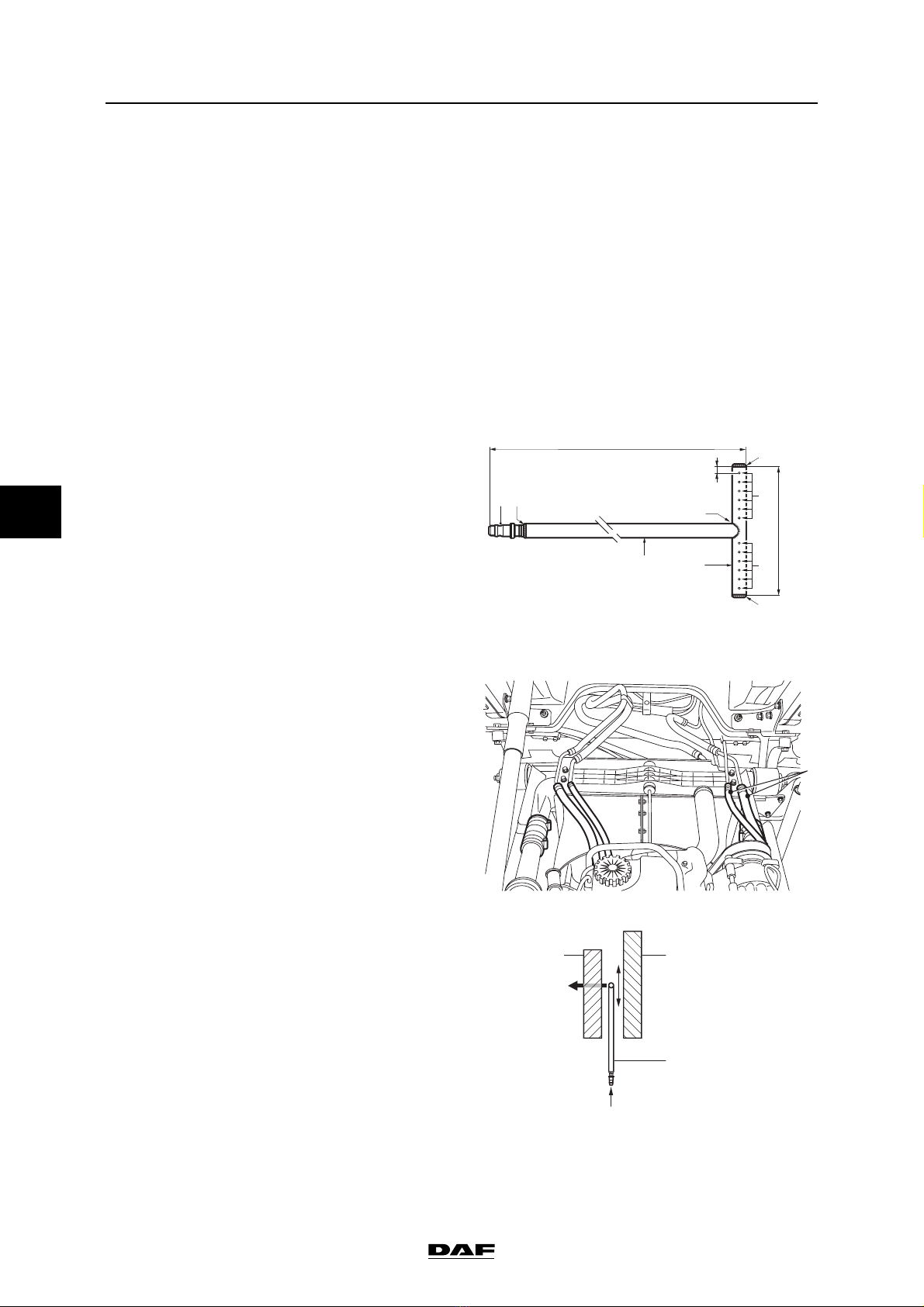

O Replace the air dryer filter element

O Check the brake cylinder fastening

O Check/adjust the load-dependent control valve

O Replace the steering gear filter element if the vehicle is equipped

with the RAS-EC system - See note 6 Replaced O Yes O No

O Replace the steering gear high-pressure filter if the vehicle is

equipped with the RAS-EC system - See note 6 Replaced O Yes O No

DRIVE AND CHASSIS

O Change the differential oil - See note 2 Changed O Yes O No

O Change the hub oil - See note 2 Changed O Yes O No

O Check operation of the differential lock

O Check the drive shaft play

O Check attachment of the clamp of the drive shaft universal joint

O Adjust the crown wheel guide bolt in case of a 5.12 rear axle

O Check for noticeable wheel bearing play in case of a 5.10, 5.12,

5.14 and 8.20 rear axle - See note 1 Done O Yes O No

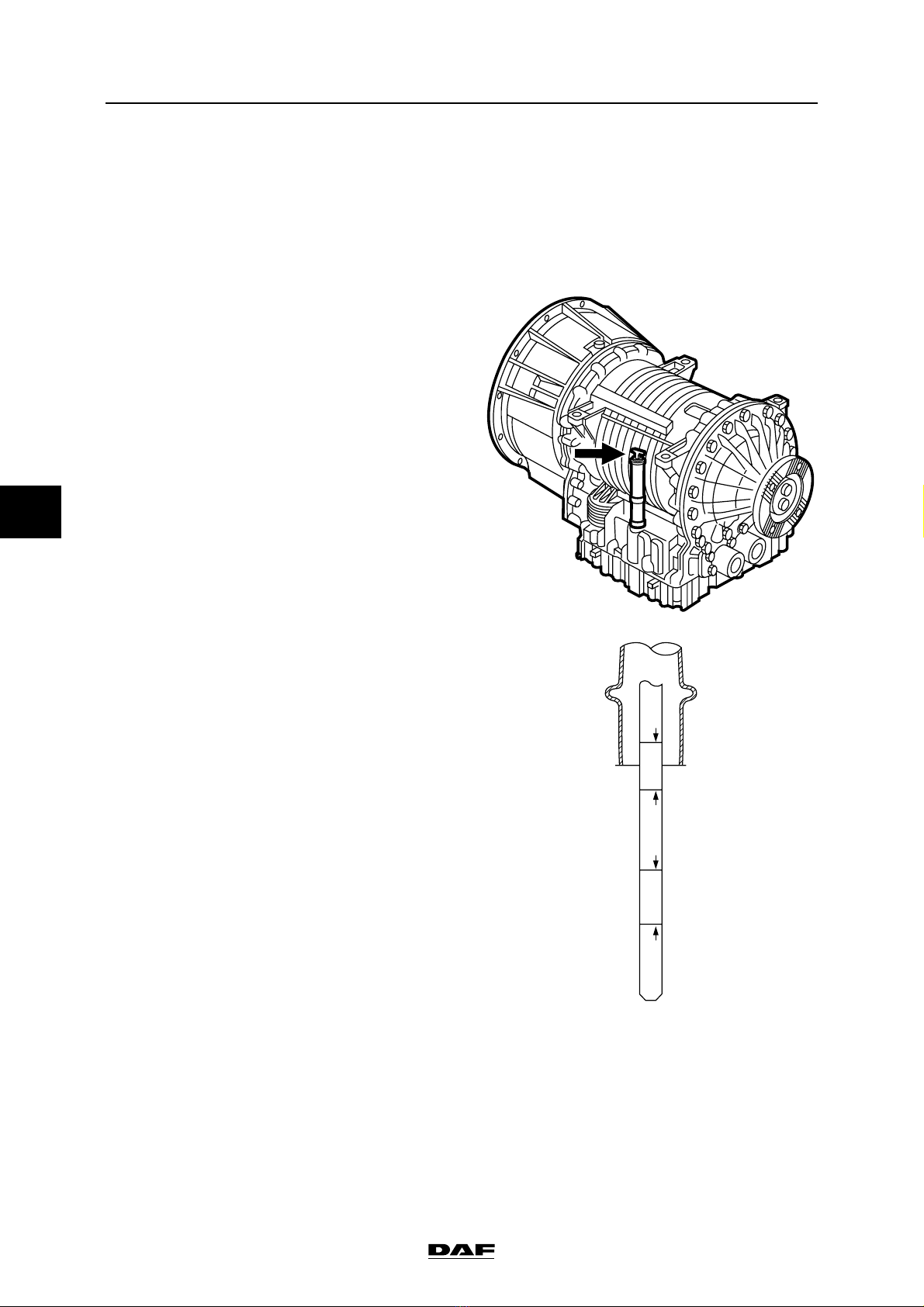

O Change the gearbox oil - See note 3 Changed O Yes O No

O Replace the grease of grease-lubricated hubs, F36 and F48 front

axles - See note 1 Replaced O Yes O No

O Check the fifth wheel

O Check the trailer coupling

O Check superstructure attachment

O Lubricate according to Y-service lubrication schedule

OTHER ACTIVITIES

O Check whether there are any field actions that still need to be performed on the vehicle