TOTAL Lubmarine Tech'Care User manual

1

Introduction to the Rapid Oil Test Gauge

1. Product overview

2. Sub Assemblies description and location

3. Specifications

4. Unpacking and inspection

5. Initial start-up

6. Battery

7. Preserving the Rapid Oil Test Gauge

8. Maintenance

1. Power on / Main Run Screen / Power Off

2. Adjusting power off time

3. Adjusting the internal clock

4. Alarm function

4.1. Turning On and Off

4.2. Setting the maximum acceptable water content

4.3. Setting the minimum acceptable BN

5. Test history function

5.1. Viewing the test history

5.2. Downloading the test history to a computer

5.3. Erasing the test history

Power Strirrer

Water content measurement

Chlorides (salt water) detection

B.N. determination

Carbon matter determination

Spot test - Interpretation

Comparative viscosity

Guide to interpreting results

Safety data sheets

Replenishment of consumables

Pages

5

6

7

8

9

10

11

12

14

16

20

21

25

27

28

29

31

36

SUMMARY

3

Reference

Spots Chart

Safety

recommendations

Training

Videos

User Guide

Syringes

& Accessories

Syringes

Cotton Buds Rapid

Oil Test

Gauge

Reagent

WT1/NH

Test Kit

Cleaning

Solvent

Spot Test Kit

Solution E

ViscoTest

Reagent

BN1

Solution

WT/BN

Chlorides

Detection

Papers

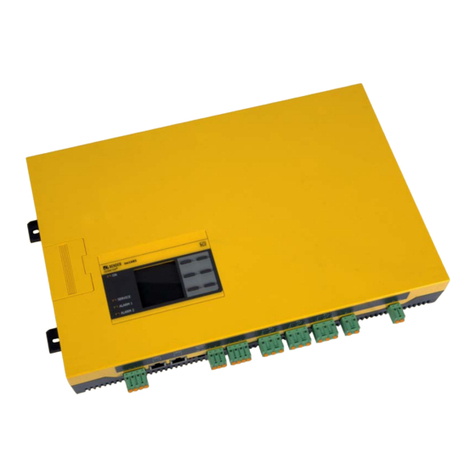

The Total Lubmarine Rapid Oil Test Gauge is a high precision battery operated digital lubricant testing gauge intended to measure and monitor

the water content of lubricants up to 1.5% H2O and/or the remaining alkaline reserve (BN) of lubricants up to 140 BN.

The gauge can be controlled locally by the operator using a front panel display and special function keys.

A USB communication port can be used to download test results to a computer.

5

1. Product overview

2. Sub Assemblies description and location

Keyboard

USB port

Reaction flask

Battery

Battery power indicator

Identification plate

Current function name

Main information display

Soft function keys

Keys

Vent groves

O’ring

Measuring port

LUBMARINE

TestConf Hist

RAPID

OIL TEST GAUGE

Rapid Oil Test Gauge

Product Overview

Power requirement :

Battery life :

Operating temperature :

Storage temperature :

Weight :

Dimensions :

Communication port :

Display :

Materials in contact with tested oil :

Test application :

Test memory :

Water Test

Water test reagent :

Water test solvent :

Required oil sample :

Measuring range* :

Display resolution :

Maximum allowable water content* :

Maximum water content without damage on measuring sensor* :

BN Test (optional)

BN test reagent :

BN test solvent :

Required oil sample :

Measuring range :

Display resolution :

1 off 9 volts 6LR61/PP3 battery

2½ years or 700 tests minimum

0 to 50 °C (32 to 122 °F)

- 20 to 65 °C (-4 to 149 °F)

0.25 kg (0.55 lb)

175 x 100 x 72 mm (6.89 x 3.94 x 2.84 in)

USB Mini-B

128 x 64 dots dot matrix LCD

PA, POM, NBR, AISI 316 stainless steel

(i) Water in oil content

(ii) Oil alkaline reserve (BN) (Option)

1 000 tests minimum, including measured data, test evaluation,

date and time

Lubmarine reagent WT1/NH

Lubmarine solution WT/BN

5 ml

0 to 1.5 %H2O

0.05 %H2O

3.3 %H2O

9.9 %H2O

Lubmarine reagent BN1

Lubmarine solution WT/BN

10 ml

0 to 140 BN

1 BN

(*: Data valid for 5 ml oil sample only)

6

3. Specifications

Declaration of Conformity

We GESERCO SARL

16 RUE FRANCOIS ARAGO

33700 MERIGNAC

On behalf of TOTAL LUBRIFIANTS

Declare that

Product LUBMARINE RAPID OIL TEST GAUGE

Part Numbers WT1207, WT1208, WT1209, BN2106, BN2107, BN2108, BN2109,

BN2110, BN2111

Complies with the clauses of the Directive of the Council 2004/108/EC Electromagnetic Compatibility.

Standards : EN55022

EN61000-4-3

EN61000-4-11

EN61000-4-6

EN61000-4.4

EN61000-4-5

EN61000-4-2

Tests conditions and results are given in the CERE-ENSAM test report No. QC14 dated 04.01.2012.

Mérignac, August 8th, 2019

Luc DARGENT

Chief Executive

Rapid Oil Test Gauge

Product Overview

Check that all items are present and have no visible damage.

Delivery includes:

Description

Tech’Care/Std kit: Rapid Oil Test Gauge for water test only

or Tech’Care/Pro.2 kit: Rapid Oil Test Gauge for water and BN tests

Reaction flask

O’ring (installed in the test gauge)

9 volt 6LR61/PP3 battery (in battery compartment but not connected)

USB cable

For water test

Pack of sachets of reagent WT1/NH (50 sachets)

Flask of solution WT/BN (500 ml)

5 ml syringe (1)

10 ml syringe (1)

For BN test (optional)

Flask of reagent BN1 (500 ml)

Flask of solution WT/BN (500 ml)

10 ml syringe (3)

Part number

WT1209

BN2111

WT1154

DP6150

DP6151

DP6152

WT1203

WT1205

DP6106

DP6107

BN2200

WT1205

DP6107

7

4. Unpacking & inspection

5. Initial start-up

6. Battery

A battery power indicator is located in

the upper left corner of the

display screen.

When the battery power indicator

flashes, change the battery as

soon as possible.

Note:

When first powered on after the battery

has been replaced, the instrument

clock must be adjusted.

Upon delivery the battery of the Rapid Oil Test Gauge should be connected and the internal clock should be adjusted.

No other adjustment is required; the instrument is ready to be used.

The 9 volts 6LR6I/PP3 battery which powers your Rapid Oil Test Gauge should provide two years operation or more.

Installing the battery:

1- Remove the battery cover

from the back of the Rapid Oil

Test Gauge.

2- Insert the top of the

battery in the compartment

with terminals facing up,

observing proper polarity as

shown on the label .

3- Firmly push the battery

upwards, then swing its

bottom fully inside the

compartment.

4- Replace the cover.

Removing the battery:

1- Remove the battery cover

from the back of the Rapid Oil

Test Gauge.

2- Push the battery

downwards.

3- Swing the top of

the battery out of the

compartment, then take it

fully out.

4- Replace the cover.

LUBMARINE

TestConf Hist

RAPID

OIL TEST GAUGE

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

In order to ensure the accuracy of subsequent tests and to preserve the instrument over time, the Rapid Oil Test Gauge must always be kept

clean and dry :

7. Preserving the Rapid Oil Test Gauge

8. Maintenance

Any trace of oil, solutions or reagents

shall be removed from the gauge and

reaction flask after each use. Special

attention should be paid to the measuring

port which must be kept perfectly free,

and to the internal O’ring.

Use dedicated cleaning fabric or

absorbing paper for cleaning purpose.

Proper cleaning solvents include White

Spirit or Petroleum Distillates p/n DP6133.

Do not use petroleum ether or equivalent.

The Lubmarine Rapid Oil Test Gauge was designed for maintenance free operation.

No maintenance is required apart from:

• Keeping the instrument clean with its O’ring greased as described in §7.

• Replacing the battery when necessary.

• In line with your Quality Assurance system: recalibrating the instrument at regular intervals.

From time to time check the state of the reaction flask and look for potential mechanical or chemical fatigue (cracks, wear…).

Never use a reaction flask which shows signs of mechanical or chemical fatigue as it may break under the high pressure generated by the

water and/or BN test.

It is recommended to grease from time to

time the internal O’ring using silicon free

grease p/n DP6108.

The battery compartment cap and USB

port cap should be kept in place at all

times in order to protect the internal

electronics of the instrument.

8

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

Press any of the 4 front panel keys to

switch the Rapid Oil Test Gauge on.

The instrument initializes and displays its

serial number and embedded software

version for a few seconds.

The instrument then displays the Main

Run Screen which offers three functions:

[Conf],[Test] and [Hist]

1 - Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2 - Press the [Conf] key.

3 - Press the [Other] key.

4 - Press the [Pwr Off] key

Press the key corresponding to the

function you want to run:

Select [Conf] to adjust the internal clock,

the oil monitoring function and the power

off time of your instrument.

Select [Test] to run a water test or a BN

test (optional)

Select [Hist] to view the test history

Refer to the appropriate section of this

manual for details on each function.

In order to preserve battery life the instru-

ment turns off automatically if not used for

a period of time. Refer to section 2 below

for instructions for setting power off time.

The user may also press the key for

2 seconds at any time to switch off the

Rapid Oil Test Gauge

Note: When first powered on after the

battery has been replaced, the instrument

accesses automatically the clock adjust-

ment function.

Alarm OtherTime

Config

Pwr Off

Config

Save

2 minute

Set Power Off

LUBMARINE

TestConf Hist

RAPID

OIL TEST GAUGE

9

The Rapid Oil Test Gauge shows the

current Power Off time.

1 - Press the [▲] key to increase the value.

Press the [▼] key to decrease the value.

2 - Press [Save] when done

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

1 Power on / Main run screen / Power off

2 Adjusting power off time

The Rapid Oil Test Gauge has an internal clock which is used to time stamp test results when they are stored in the instrument memory.

To adjust the internal clock:

The Lubmarine Rapid Oil Test Gauge has an alarm function which can warn the operator in case of:

- Excessive water in oil content

- Insufficient oil alkaline reserve (low BN)*

If the function is On, the water in oil content or the BN value* is evaluated at the end of each test and the instrument shows if the test result is

acceptable or not. The information is also stored in the instrument memory with the test result.

The default settings of the function are:

- Function status: Off

- Water content alarm set to 1.5 %H2O

- BN alarm* set to 1 BN

5- The year is displayed.

Press the [▲] key to increment the year.

Press the [▼] key to decrement the year.

Press [Next] when done.

Alarm OtherTime

Config

Next

Year : 2019

Set Date

Save

Minute : 30

Set Time

9

(* The BN monitoring function is available only for Lubmarine

Rapid Oil Test Gauges having the BN Test option).

1- Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2- Press the [Conf] key.

3- Press the [Time] key.

Note:

When first powered on after the battery has been replaced,

the instrument accesses automatically the clock adjustment function.

6- Adjust the month and press [Next]

when done.

7 - Adjust the day and press [Next] when done.

8- Adjust the hour and press [Next]

when done.

9- Adjust the minutes and press [Save]

to store the data and return to the main

run screen.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

4 Alarm Function

10

4.1 Turning the alarm function On or Off

1- Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2- Press the [Conf] key.

3- Press the [Alarm] key.

The instrument shows the current status

of the function.

4- Press the [On/Off] key.

5- Confirm the desired status by pressing

the [Yes] key.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

3 Adjusting the internal clock

Config

Alarm TimeOther

Alarm is : On

H2O : 0.5 % H2O

BN : 60 BN

Config Alarm

H2O BN On/Off

Yes No

Confirm alarm : off

Config Alarm

4.2 Setting the maximum acceptable level of water in the oil

4.3 Setting the minimum acceptable level of alkaline reserve (BN) of the oil*

1- Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2- Press the [Conf] key.

3- Press the [Alarm] key.

1- Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2- Press the [Conf] key.

3- Press the [Alarm] key.

The instrument shows the current

maximum acceptable level of water in

the oil.

4- Press the [H2O] key.

The instrument shows the current

minimum acceptable alkaline reserve

of the oil.

4- Press the [BN] key.

5 - Press the [▲] key to increase the value.

Press the [▼] key to decrease the value.

7- Press [Ok] when done.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

5- Press the [▲] key to increase the value.

Press the [▼] key to decrease the value.

6- Press [Ok] when done.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

11

(* The BN monitoring function is available only

for Lubmarine Rapid Oil Test Gauges having the BN Test option).

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

Config

Alarm TimeOther

Config

Alarm TimeOther

Alarm is : On

H2O : 0.5 % H2O

BN : 60 BN

Config Alarm

H2O BN On/Off

Alarm is : On

H2O : 0.5 % H2O

BN : 60 BN

Config Alarm

H2O BN On/Off

0,5% H2O

Config Alarm

Ok

50 BN

Config Alarm

Ok

5.3 Erasing the test history

1- Remove the USB port cover of the Rapid Oil Test Gauge and

connect a Mini-USB cable to the port.

2 - Connect the USB cable to the USB port of the computer.

3- Open the file explorer of the computer.

4- The Rapid Oil Test Gauge shows as a removable USB drive

named OILTSTR.

5-The OILTSTR drive contains a file named DATALOG.CSV which

is the test results file.

6- Delete the DATALOG.CSV file.

5 Test history function

5.1 Viewing test history

5.2 Downloading the test history to a computer

The Lubmarine Rapid Oil Test Gauge has a test history function which

automatically stores the result of each test.

Stored data include :

Test tag number

Date

Time

Test identifier

Measured value

If the alarm function was turned on at time of test, the Rapid Oil Test

Gauge will also store the test result evaluation (“OK” or“Fail”)

The test history can be viewed on the Rapid Oil Test Gauge local

display using the [Hist] function or downloaded to a computer via the

USB communication port for subsequent processing.

The test history function can store up to 1 000 test results. When the

instrument memory is full, a “History full” message shows and the

instrument will not store any additional data unless the memory is

cleared.

3- The instrument shows the result of the

last test performed. Use the [▲] and [▼]

keys to browse test results.

4- The Rapid Oil Test Gauge shows as a

removable USB drive named OILTSTR.

The OILTSTR drive contains a file named

DATALOG.CSV which is the test results file.

Copy and paste the DATALOG.CSV file on

your hard drive to save it.

LUBMARINE

TestConf Hist

RAPID

OIL TEST GAUGE

History

Test 4 / 4

06/08/2019 - 15:44

Test Id:TU100

0.00 %H2O - OK

History

Test 4 / 4

06/08/2019 - 15:44

Test Id:TU100

0.00 %H2O - OK

12

1- Press any of the 4 front panel keys to

turn the Rapid Oil Test Gauge on.

2- Press the [Hist] key.

1- Remove the USB port cover of the

Rapid Oil Test Gauge and connect a Mini-

USB cable to the port.

2- Connect the USB cable to the USB

port of the computer.

3- Open the file explorer of the computer.

4- When done, press briefly the key

to exit function and return to the Main

Run Screen.

5- Use Microsoft Excel™ or equivalent

to view and process the test history data

contained in the DATALOG.CSV file.

Rapid Oil Test Gauge

Operating the Rapid Oil Test Gauge

The Lubmarine Power Stirrer is a high efficiency miniature magnetic stirrer facilitating Water and BN tests.

It is delivered with a special pyramidal stir bar which provides optimum stirring efficiency.

The Power Stirrer operates on mains (100 - 240 VAC / 50 - 60 Hz) and is controlled via a front pannel knob.

1. Product overview

2. Description & Technical Data

3. Safety Instructions

Rated voltage :

Rated frequency :

Absorbed power :

Power input :

Speed (adjustable) :

Operating time :

Ambient temperature :

Ambient humidity (relative :

EN 60529 protection class :

Pollution degree :

Overvoltage category :

Protection class :

Transport temperature :

Storage temperature :

Operation at altitude :

Test tube size (max.) :

Stir bar (max.) :

Max. stirring quantity :

Dimensions :

Weight

100 - 240 Vac

50/60 Hz

10 W

7.2 W

0 / 300...1800 rpm ±25%

100 %

+5 to +40 °C

80 %

IP 21

2

II

III

-25 to +70 °C

-10 to +70 °C

max. 2000 m above sea level

ø 70 mm

ø 6 x 30 mm

250 ml

95 x 116 x 40 mm

0.32 kg

DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product corresponds to the regulations 89/336/EC, 92/31/EC,

94/9/EC and 73/23/EC and conforms with the standards or standardized documents EN 61010-1(IEC/CEI 61010-1),

EN 61326-1(IEC 61326-1), EN 50021 and EN 61326-1(IEC 61326-1).

• Read the operating instructions in full before starting up and follow the safety instructions.

• Keep the operating instructions in a place where they can be accessed by everyone.

• Ensure that only trained staff work with the appliance.

• Follow the safety instructions, guidelines, occupational health and safety and accident prevention regulations.

• Caution - Magnetism! Effects of the magnetic field have to be taken into account (e.g. data storage media, cardiac pacemakers...).

• Wear your personal protective equipment in accordance with the hazard category of the media to be processed and avoid risks from:

- splashing and evaporation of liquids

- ejection of parts

• The appliance is not suitable for manual operation.

• Set up the appliance in a spacious area on an even, stable, clean, non-slip, dry and fireproof surface.

• The feet of the appliance must be clean and undamaged.

• Check the appliance and accessories beforehand for damage.

• Position the knob at the left stop before starting up.

• Gradually increase the speed. Reduce the speed if

- the medium splashes out of the vessel because the speed is too high

- the appliance is not running smoothly

- the container moves on the base plate.

• Do not used damaged components. Only replace damaged parts with spare parts identical to the original in function and quality.

14

Power Supply Unit

Stir bar

Pliers

Power On/Off & Control

OPTION

Power Stirrer

Product Overview

Beware of and avoid hazards due to :

- flammable materials

- glass breakage

- incorrect container size

- overfilling of media

- unsafe condition of container or of the complete assembly.

•Only process media that will not react dangerously to the extra energy produced through processing. This also applies to any energy

produced in other ways, e.g. through light irradiation.

• It may be possible for wear debris from rotating accessory parts to reach the material being processed.

• Do not operate the appliance in explosive atmospheres, with hazardous substances or under water.

• The appliance must only be disconnected from the mains supply by pulling out the plug-in power supply unit

• Safe operation is only guarnateed with the accessories described in the “Technical data” chapter.

• The centre of gravity of the assembly must lie within the the surface on which it is set up.

• The device will automatically restart following any interruption to the power supply.

• The appliance may heat up when in use.

• The voltage stated on the type plate must correspond to the mains voltage.

• Protect the appliance and accessories from bumps and impacts.

• The appliance and the power supply unit are maintenance - free and must not be opened.

1. Product overview

5. Operation

6. Maintenance

• Starting up

- Connect the appliance to a socket (the voltage stated on the nameplate must correspond to the mains voltage).

- Set the knob to the left stop (you will hear and feel it clicking into place).

- Place the stir bar in the Rapid Oil Test Gauge reaction flask.

(Refer to the appropriate section of the manual for Water Test and BN Test instructions).

- Place the Rapid Oil Test Gauge on the very centre of the Power Stirrer plate.

- Set the speed using the knob:

Turn to right to increase speed

Turn to left to reduce speed

- Allways try to achieve the maximum speed delivering maximum fluctuations.

- Excessive stirring power may cause a loss of the magnetic connection between the Power Stirrer and the Stir Bar.

If such loss occurs, reduce stirring power by turning the knob to the left until the magnetic connection between the

Power Stirrer and the Stir Bar is recovered making the Stir Bar rotating again, then increase stirring speed.

• Shutting down

- Set the knob to the left stop (you will hear and feel it clicking into place), the motor is switched off.

- Disconnect appliance from mains when not in use

Unpack the device carefully and check that all items are present and have no visible damage.

In case of any damage a detailed report must be set immediately (post, rail or forwarder).

Delivery includes: 1 ea. Power Stirrer, 2 ea. stir bars, 1 ea. Power supply unit, 1 ea. plastic pliers.

The device is maintenance-free.

For cleaning disconnect the plug-in power supply unit.

Only use cleansing agents which have been recommended by GESERCO or LUBMARINE.

isopropyl alcohol

isopropyl alcohol/water containing surfactant

isopropyl alcohol/water containing surfactant

water containing surfactant

water containing surfactant

Do not allow moisture to get into the appliance when cleaning.

Wear protective gloves when cleaning the device.

Please consult with GESERCO before using any cleaning

or decontaination methods, other than those recommended here.

Use to remove:

Dyes :

Construction materials :

Cosmetics :

Foodstuffs :

Fuels :

15

OPTION

Power Stirrer

Product Overview

Make sure that the apparatus and accessories are perfectly clean before starting the test.

Wear goggles. Wear protective gloves. Read the instructions

and MSDS contained

in this manual.

Before each test, look after your own safety

and the environement.

Wash thoroughly and obtain medical advice if a reagent

or solution come into contact with your eyes or skin.

1

16

OPTION

Water Content Measurement

With Reagent WT1/NH & Rapid Oil Test Gauge

Grease the thread and O’ring of

the Rapid Oil Test Gauge.

Press the [H2O] key then follow

the test instructions displayed

by the instrument.

Enter a test label.

Use the [▲] and [▼] keys to

scroll and press [Next]

to select.

Select empty space to store

label and go to the next screen.

Using the 10 ml syringe, inject

10 ml of solution WT/BN in the

reaction flask.

Do not shake.

Press any of the 3 front panel

keys to turn the Rapid Oil Test

Gauge on.

Then press the [Test] key.

Press the [▼] key for more

instructions.

Homogenize the oil to be tested,

then introduce 5 ml of oil to be

tested into the reaction flask

using the syringe provided.

Do not shake.

When the instrument memory

is full, a “History Full” message

shows. Press [Go] to confirm test

(result will not be stored) or

[Abort] to cancel.

Drain a full sachet of reagent

WT1/NH in the reaction flask.

2

5 6

9

3

7

10

4

8

17

LUBMARINE

TestConf Hist

RAPID

OIL TEST GAUGE

AbortGo

Run Water Test

History Full

H2OBN

RUN TEST

Next

Enter Test id

……

Run Water Test

Start

1° Add full WT REAGENT

2° Add 10ml of SOLUTION

3° Add 5ml of OIL

Run Water Test

Water Content Measurement

With Reagent WT1/NH & Rapid Oil Test Gauge

18

Hold the reaction flask on a

stable surface then close

and tighten the Rapid Oil

Test Gauge.

Shake vigorously 10 seconds

to start the reaction.

If NOT using

the Power Stirrer option :

Keep on shaking vigorously

throughout the test.

The Rapid Oil Test Gauge

counts down the time required

to complete the test.

Press the [Start] key.

If using the Power Stirrer option :

Place the Rapid oil Test Gauge

on the very centre of the

Power Stirrer.

Adjust the stirring speed of the

bar to the highest possible speed

which ensures a smooth rotation.

If the overpressure alarm sounds

and flashes, stop the test immediately

and open to release pressure.

Press the [Go] key.

When the test is complete, the

instrument beeps, shows and

logs the water content of the

oil sample. If the oil monitoring

function is activated, the

instrument shows if the test

result is acceptable according

to the function settings.

Open the flask to release pressure.

12

15

17

13

1614

18

OPTION

If using the Power Stirrer option :

Put the stir bar provided into

the mixture.

Make sure that the stir bar

lays flat on the bottom of

the reaction flask.

11

OPTION

Start

4° Close and tighten

5° Press START

Run Water Test

Go

Shake Gauge well

until count is down to 0

Run Water Test

80

Run Water Test

RELEASE PRESSURE

Run Water Test

Ok

0.45%H2O

Water Content

OK

Water Content Measurement

With Reagent WT1/NH & Rapid Oil Test Gauge

Other manuals for Tech'Care

1

This manual suits for next models

1

Table of contents

Other TOTAL Lubmarine Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bender

Bender ISOMETER isoHR1685DW-925 manual

Eastron

Eastron SDM72DM user manual

Bosch

Bosch LR20 Operating/safety instructions

Technische Alternative

Technische Alternative CAN-EZ3 General information, Installation and connection, Relevant functions

Conrad

Conrad SB-090 Safety instruction

ARJAY ENGINEERING

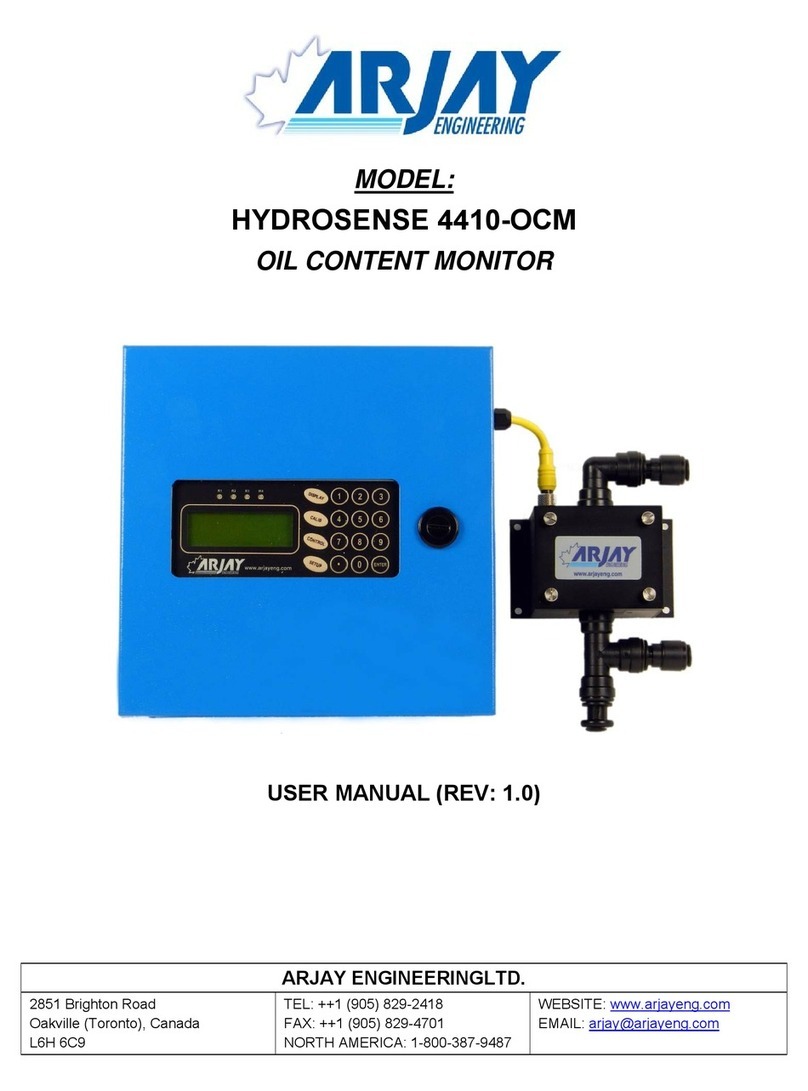

ARJAY ENGINEERING HYDROSENSE 4410-OCM user manual