TOTAL Lubmarine Tech'Care User manual

1

Introduction to the Rapid Optical Oil Tester

1. Product overview

2. Sub Assemblies description and location

3. Specifications

4. Unpacking and inspection

5. Initial start-up

6. Battery

7. Preserving the Rapid Optical Oil Tester

8. Maintenance

Operating the Rapid Optical Oil Tester

1. Power on / Main Run Screen / Power Of

2. Adjusting power off time

3. Adjusting the internal clock

4. Alarm function

4.1. Turning the oil monitoring function On or Off

4.2. Setting the maximum acceptable level of iron in oil

5. Test history function

5.1. Viewing the test history

5.2. Downloading the test history to a computer

5.3. Erasing the test history

100μl precision pipette

Iron Test

Safety data sheets

Replenishment of consumables

Pages

4

5

6

7

8

9

10

11

13

19

21

Overview :

The Lubmarine Tech’Care/Tcc kit is a high efficiency oil monitoring kit

designed to give a rapid and accurate measurement of the iron content*

in cylinder oils of modern low speed engines.

The use of such equipment is recommended by marine engine

makers to quickly evaluate the iron content*

and adjust cylinder lubrication.

The Lubmarine Tech’Care/Tcc kit includes any accessories and

consumables for performing 50 cylinder oil tests.

*Iron content measured by Tech’Care/TCC is correlated to the total iron content

as defined by ICP measurement ASTM D5185 and recommended by OEMs.

SUMMARY

3

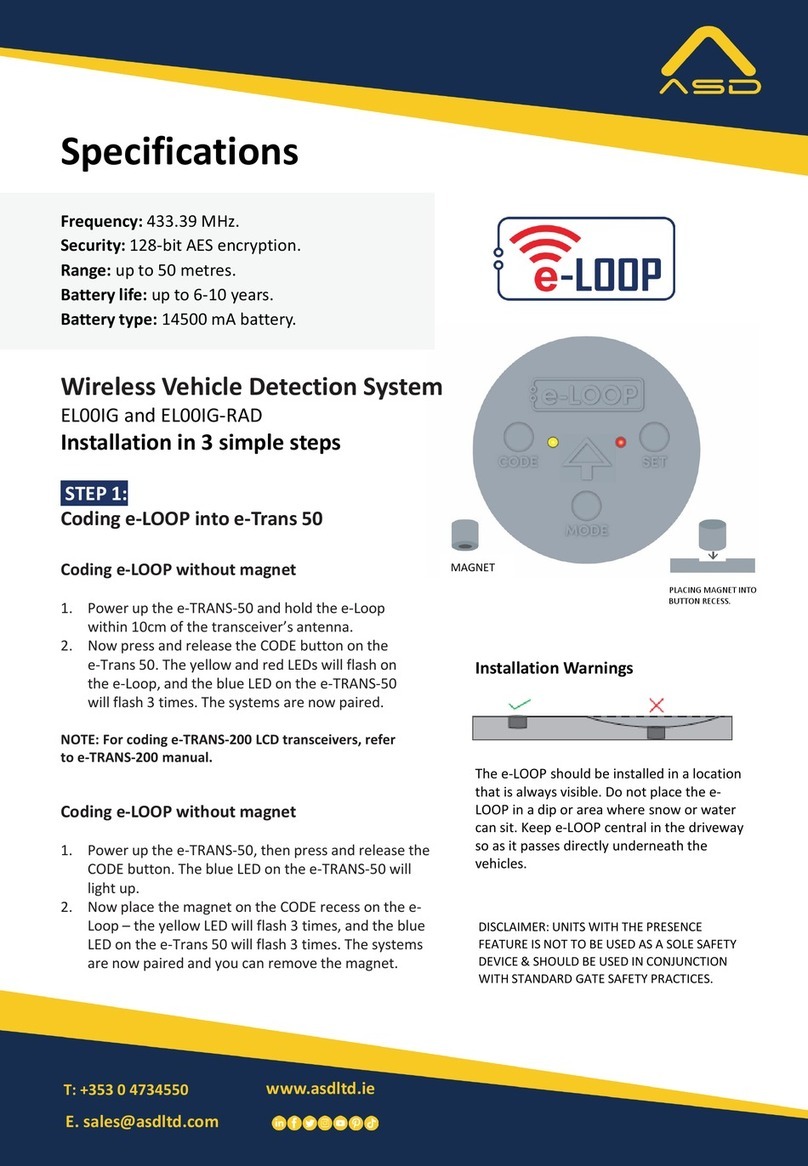

Training

Videos

User Guide

Pen

Syringes

Magnetic

rack

Wipe

felt pad

100 μl

precision

pipette

Pipetting

level adjuster

Rapid Optical

Oil tester

Mini USB

cable Vial caps

Reagent

IT1

Solvent

IT2

Vials

Solution

IT3

Spare

capillaries

The Total Lubmarine Rapid Optical Oil Tester is a high precision battery operated digital lubricant testing gauge intended to measure and

monitor the iron content of lubricants up to 800 ppm iron.

The gauge can be controlled locally by the operator using a front panel display and special function keys.

A USB communication port can be used to download test results to a computer.

4

1. Product overview

2. Sub Assemblies description and location

Keyboard

Test port cap

Test port

USB port

Battery

Battery power indicator

Current function name

Main information display

Soft function keys

Keys

Identification

plate

LUBMARINE

TestConf Hist

RAPID OPTICAL

OIL TESTER

Rapid Optical Oil Tester

Product Overview

Power requirement :

Battery life :

Operating temperature :

Storage temperature :

Weight :

Dimensions :

Communication port :

Display :

Materials in contact with tested oil :

Test application :

Test memory :

Iron Test

Iron test reagent :

Required oil sample :

Measuring range* :

Display resolution :

1 off 9 volts 6LR61/PP3 battery

2½ years or 700 tests minimum

15 to 35 °C (59 to 95 °F)

- 20 to 65 °C (-4 to 149 °F)

500 g

190 x 150 x 86 mm (7.48 x 5,90 x 3,38 in)

USB Mini-B

128 x 64 dots dot matrix LCD with backlight

Glass

Iron in oil content

1 000 tests, including measured data, test evaluation, date and time

Lubmarine reagents IT1, IT2 & IT3

100 μl (3 drops)

60 to 800 ppm iron

1 ppm

* : Data valid for a 100 μl oil sample -3 drops- only)

5

Declaration of Conformity

We GESERCO SARL

16 RUE FRANCOIS ARAGO

33700 MERIGNAC

On behalf of TOTAL LUBRIFIANTS

Declare that

Product LUBMARINE RAPID OPTICAL OIL TESTER

Part Numbers IT 9111

Complies with the clauses of the Directive of the Council 2004/108/EC Electromagnetic Compatibility.

Standards : EN55022

EN61000-4-3

EN61000-4-11

EN61000-4-6

EN61000-4.4

EN61000-4-5

EN61000-4-2

Tests conditions and results are given in the CERE-ENSAM test report No. QC14 dated 04.01.2012.

Mérignac, August 8th, 2019

Luc DARGENT

Chief Executive

Rapid Optical Oil Tester

Product Overview

3. Specifications

Check that all items are present and have no visible damage.

Delivery includes:

Description

Tech’Care/Tcc kit: Rapid Optical Oil Tester for iron test only

9 volt 6LR61/PP3 battery (in battery compartment but not connected)

Magnetic sample preparation rack

Pack of 50 test tubes

100 μl Precision pipette

Pipetting level adjuster

6 x 5 ml syringes

Flask of solution IT1 (250 ml)

Flask of solvent IT2 (250 ml)

Flask of reagent IT3 (250 ml)

USB cable

Wipe felt pad

Part number

IT9111

DP9151

IT9102

IT9103

IT9103

IT9110

SER05

IT9200

IT9201

IT9202

DP6152

IT9105

6

4. Unpacking & inspection

5. Initial start-up

6. Battery

Upon delivery the battery of the Rapid Oil Test Gauge should be connected and the internal clock should be adjusted.

No other adjustment is required; the instrument is ready to be used.

The 9 volts 6LR6I/PP3 battery which powers your Rapid Oil Test Gauge should provide two years operation or more.

LUBMARINE

TestConf Hist

RAPID OPTICAL

OIL TESTER

Rapid Optical Oil Tester

Product Overwiew

A battery power indicator is located in

the upper left corner of the

display screen.

When the battery power indicator

flashes, change the battery as

soon as possible.

Note:

When first powered on after the battery

has been replaced, the instrument

clock must be adjusted.

Installing the battery:

1- Remove the battery cover

from the back of the Rapid Oil

Test Gauge.

2- Insert the top of the

battery in the compartment

with terminals facing up,

observing proper polarity as

shown on the label .

3- Firmly push the battery

upwards, then swing its

bottom fully inside the

compartment.

4- Replace the cover.

Removing the battery:

1- Remove the battery cover

from the back of the Rapid Oil

Test Gauge.

2- Push the battery

downwards.

3- Swing the top of

the battery out of the

compartment, then take it

fully out.

4- Replace the cover.

8. Maintenance

7. Preserving the Rapid Optical Oil Tester

Any trace of oil, solutions or reagents

should be removed from the test tube

prior to inserting it into the Rapid Optical

Oil Tester.

Use only dedicated cleaning fabric or

absorbing paper to wipe the tube.

Do not use any cleaning solvents.

Regularly check the cleanliness of the

vial wipe felt pad which is located inside

the test port.

Change the wipe felt pad as soon as it

is spoiled.

To change the vial wipe felt pad :

1. Unscrew the tip of the test port.

2. Remove the spoiled pad and dispose of it.

3. Take a new felt pad and roll it.

4. Insert the rolled felt pad into the test

port tip.

In order to ensure the accuracy of subsequent tests and to preserve the instrument over time, the Rapid Optical Oil Tester must always be

kept clean and dry :

The test port cap should be replaced

when the Rapid Optical Oil Tester is not

being used in order to protect the internal

electronics of the instrument.

5. Replace the tip on the test port and

screw it.

6. Insert a vial in the test port and slide

it gently a few times in order to hone the

positioning of the pad.

The battery compartment cap and USB

port cap should be kept in place at all

times in order to protect the internal

electronics of the instrument.

7

Rapid Optical Oil Tester

Product Overwiew

The Lubmarine Rapid Optical Oil Tester was designed for maintenance free operation.

No maintenance is required apart from:

• Keeping the instrument clean as described in §7.

• Replacing the battery when necessary.

• In line with your Quality Assurance system: recalibrating the instrument at regular intervals.

The Rapid Oil Test Gauge has an internal clock which is used to time stamp test results when they are stored in the instrument memory.

To adjust the internal clock:

8

Press any of the 4 front panel keys to

switch the Rapid Optical Oil Tester on.

The instrument initializes and displays its

serial number and embedded software

version for a few seconds.

The instrument then displays the Main

Run Screen which offers three functions:

[Conf],[Test] and [Hist]

5- The year is displayed.

Press the [▲] key to increment the year.

Press the [▼] key to decrement the year.

Press [Next] when done.

1 - Press any of the 4 front panel keys to

turn the Rapid Optical Oil Tester on.

2 - Press the [Conf] key.

3 - Press the [Pwr Off] key.

Press the key corresponding to the

function you want to run:

Select [Conf] to adjust the internal clock,

the oil monitoring function and the power

off time of your instrument.

Select [Test] to run a water test or a BN

test (optional)

Select [Hist] to view the test history.

Refer to the appropriate section of this

manual for details on each function.

In order to preserve battery life the instru-

ment turns off automatically if not used for

a period of time. Refer to section 2 below

for instructions for setting power off time.

The user may also press the key for

2 seconds at any time to switch off the

Rapid Optical Oil Tester

Note: When first powered on after the

battery has been replaced, the instrument

accesses automatically the clock adjust-

ment function.

1- Press any of the 4 front panel keys to

turn the Rapid Optical Oil Tester on.

2- Press the [Conf] key.

3- Press the [Time] key.

Note:

When first powered on after the battery has been replaced,

the instrument accesses automatically the clock adjustment function.

6- Adjust the month and press [Next]

when done.

7 - Adjust the day and press [Next] when done.

8- Adjust the hour and press [Next]

when done.

9- Adjust the minutes and press [Save]

to store the data and return to the main

run screen.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

The Rapid Optical Oil Tester shows the current Power Off time.

1 - Press the [▲] key to increase the value.

Press the [▼] key to decrease the value.

2 - Press [Save] when done

At any time press briefly the key to exit function and return

to the Main Run Screen. Modifications will not be saved.

Alarm Pwr OffTime

Config

Next

Year : 2019

Set Date

Save

Minute : 30

Set Time

Alarm Pwr OffTime

Config

Save

2 minute

Set Power Off

LUBMARINE

TestConf Hist

RAPID OPTICAL

OIL TESTER

Rapid Optical Oil Tester

Operating the Rapid Optical Oil tester

3 Adjusting the internal clock

1 Power on / Main run screen / Power off

2 Adjusting power off time

The Lubmarine Rapid Optical Oil Tester has an alarm function which can warn the operator in case of excessive iron content in the oil.

If the function is On, the iron content is evaluated at the end of each test and the instrument shows if the test result is acceptable or not.

The information is also stored in the instrument memory with the test result.

The default settings of the function are:

- Function status: Off

- Iron content alarm set to 300 ppm

9

1- Press any of the 4 front panel keys to

turn the Rapid Optical Oil Tester on.

2- Press the [Conf] key.

3- Press the [Alarm] key.

1- Press any of the 4 front panel keys to

turn the Rapid Optical Oil Tester on.

2- Press the [Conf] key.

3- Press the [Alarm] key.

The instrument shows the current status

of the function.

4- Press the [On/Off] key.

5- Confirm the desired status by pressing

the [Save] key.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

The instrument shows the current

maximum acceptable level of water in

the oil.

4- Press the [Set] key.

5- Press the [Iron] key.

6 - Press the [▲] key to increase the value.

Press the [▼] key to decrease the value.

7- Press [Save] when done.

At any time press briefly the key to

exit function and return to the Main Run

Screen. Modifications will not be saved.

Config

Alarm TimePwr Off

Alarm is : On

Iron 300 ppm

Config Alarm

Set On/Off Save

Config

Alarm TimePwr Off

Alarm is : On

Iron 300 ppm

Config Alarm

Set On/Off Save

Iron

300 ppm

Config Alarm

Save

Rapid Optical Oil Tester

Operating the Rapid Optical Oil tester

4.1 Turning the alarm function On or Off

4.2 Setting the maximum acceptable level of iron in the oil

4 Alarm Function

5.3 Erasing the test history

1- Remove the USB port cover of the Rapid Optical Oil Tester and

connect a Mini-USB cable to the port.

2 - Connect the USB cable to the USB port of the computer.

3- Open the file explorer of the computer.

4- The Rapid Optical Oil Tester shows as a removable USB drive

named OILTSTR.

5- The OILTSTR drive contains a file named DATALOG.CSV which

is the test results file.

6- Delete the DATALOG.CSV file.

5 Test history function

5.1 Viewing test history

5.2 Downloading the test history to a computer

The Lubmarine Rapid Optical Oil Tester has a test history function

which

automatically stores the result of each test.

Stored data include :

Test tag number

Date

Time

Test identifier

Measured value

If the alarm function was turned on at time of test, the Rapid Optical

Oil Tester will also store the test result evaluation (“OK” or“Fail”)

The test history can be viewed on the Rapid Optical Oil Tester local

display using the [Hist] function or downloaded to a computer via the

USB communication port for subsequent processing.

The test history function can store up to 1 000 test results. When the

instrument memory is full, a “History full” message shows and the

instrument will not store any additional data unless the memory

is cleared.

3- The instrument shows the result of the

last test performed. Use the [▲] and [▼]

keys to browse test results.

4- The Rapid Optical Oil Tester shows as a

removable USB drive named OILTSTR.

The OILTSTR drive contains a file named

DATALOG.CSV which is the test results file.

Copy and paste the DATALOG.CSV file on

your hard drive to save it.

10

1- Press any of the 4 front panel keys to

turn the Rapid Optical Oil Tester on.

2- Press the [Hist] key.

1- Remove the USB port cover of the

Rapid Optical Oil Tester and connect a

Mini-USB cable to the port.

2- Connect the USB cable to the USB

port of the computer.

3- Open the file explorer of the computer.

4- When done, press briefly the key

to exit function and to return to the Main

Run Screen.

5- Use Microsoft Excel™ or equivalent

to view and process the test history data

contained in the DATALOG.CSV file.

LUBMARINE

TestConf Hist

RAPID OPTICAL

OIL TESTER

History

Test 4 / 4

06/08/2019 - 15:44

Test Id:Cyl 1

115 ppm iron - OK

History

Test 4 / 4

06/08/2019 - 15:44

Test Id:Cyl 1

115 ppm iron - OK

Rapid Optical Oil Tester

Operating the Rapid Optical Oil tester

To discharge the oil into the vial :

To draw in the oil sample :

Push the pipetting knob down

to the stop.

Carefully wipe the outside of the

capillary with a lint-free cloth

or swab. Take care not to touch

the capillary orifice because

this would cause liquid to be

sucked out.

Dip the capillary into the

reagents until the pipetting

level adjuster comes to a stop.

Push the pipetting knob down

to its stop.

Dip the capillary into the oil

until the pipetting level adjuster

comes to a stop. Slowly release

the pipette plunger.

Make sure that the pipetting

level adjuster is mounted on to

the precision pipette and locked.

Remove the pipette tip from

the vial.

Release the pipette plunger.

2

45

31

6

11

Viewing window

Shaft

Collet

Plunger

Capillary

Protection tube

Pipetting level

adjuster

Pipetting knob

100μl Precision Pipette

For Iron Test

-Loosen the collet (half a turn).

-Pull the capillary off the piston rod.

-Pull the remaining pieces out

of the capillary mounting.

-Check through the viewing

window that the capillary is

correctly located/pushed

1 fully home.

- Wrap them in a cloth, and

crush them with pliers.

To remove an old capillary : To remove a damaged capillary :

Cleaning :

- Dip the capillary into a beaker

containing p/n DP6133 cleaning solvent.

- Press and depress the pipetting knob

several times in order to flush solvent

into the capillary, until the capillary and

plunger are clean.

- Remove the capillary from the solvent

and allow to dry completely.

To fit a new capillary :

- Slide the capillary to lock

position (A).

- Screw the collet by hand

into place.

Checking for tightness (Daily) :

- Draw in some oil.

- Hold the pipette upright for 10 sec

with capillary down.

- If a drop forms, see «Trouble Shooting».

and allow to dry completely.

Contact GESERCO for

technical support :

Any other trouble.

Pipette leaks.

Pipetted volume too

large / Air bubbles in the oil

drawn in.

Capillary not properly seated.

Damaged capillary. Change capillary.

(See «Changing the Capillary»).

Unscrew collet, push capillary

fully home, and

finger-tighten collet again.

(See «To fit a new capillary»).

Problem Possible Cause Corrective Action

The instrument is dirty. Clean the instrument.

1

1

2

2

12

Trouble Shooting

A

100μl Precision Pipette

For Iron Test

Make sure that the apparatus and accessories are perfectly clean before starting the test.

In order to maximize accuracy, Lubmarine recommends that the Iron Test is performed within 2 hours after

the cylinder oil samples have been drawn.

Wear goggles. Wear protective gloves. Read the instructions

and MSDS contained

in this manual.

Before each test, look after your own safety

and the environement.

Wash thoroughly and obtain medical advice if a reagent

or solution come into contact with your eyes or skin.

1

13

Iron Test

With Rapid Optical Oil Tester

Enter a test label.

Use the [▲] and [▼] keys to

scroll and press [Next]

to select.

Select empty space to store

label and go to the next screen.

6

Place the oil sample contained in a

Diagomar Plus bottle on the magnetic

rack. Beware: in order to separate

iron from particulate iron and ensure

test accuracy, the bottle must remain

on the rack for 5 minutes prior to

testing.

Press the [Iron] key.

Up to 7 vials containing

reagents can be prepared in

advance as soon as they are

used within 2 hours.

Press any of the 4 front panel

keys to turn the Rapid Optical

Oil Tester on.

Then press the [Test] key.

Follow the test instructions

displayed by the instrument.

Press the [▼] key for more

instructions.

Close the vial with a new cap

and flip it over once smoothly

to mix the contents.

After mixing, it is normal

that the reagents remain in

two phases.

When the instrument memory

is full, a “History Full” message

shows. Press [Go] to confirm test

(result will not be stored) or

[Abort] to cancel.

Using 1 clean syringe per

reagent, inject into the vial:

5 ml of Solution IT1

5 ml of Solvent IT2

5 ml of Reagent IT3

2

5

9

3

7

10

4

8

14

DO NOT SHAKE

Iron

RUN TEST

LUBMARINE

Zero

5° Homogenize mix gently

6° Insert vial into Tester

7° Press ZERO

Run Iron Test

Next

Enter Test id

……

Run Iron Test

LUBMARINE

TestConf Hist

RAPID OPTICAL

OIL TESTER

AbortGo

History Full

Iron Test

With Rapid Optical Oil Tester

Check that the vial wipe felt pad

which is located inside the test

port is clean.

Change it in case it is spoiled.

(See section 7 on page 7

for instructions).

11

Press the [Zero] key.

In case the Tester shows ‘Zero

Error’, press [Ok] to repeat the

zeroing process or to stop.

Using absorbing paper, wipe

excess oil from the exterior of

the pipette.

Plug the vial.

Flip the vial over smoothly

10 times.

Insert the vial into the Rapid

Optical Oil Tester.

Make sure that the red line on

the vial is visible through the

slot of the Rapid Optical Oil

Tester test port.

Make sure that the pipetting

level adjuster is mounted on to

the precision pipette and locked.

Return the vial to the magnetic

rack and remove the cap.

Inject oil into the vial.

Make sure the oil drops go into

the reagents and not on the

vial walls.

Using the precision pipette, draw

some oil from the sample bottle.

Make sure the oil is drawn from

the surface of the oil, not to

suck up any iron particles from

the bottom.

Insert the vial into the Rapid

Optical Oil Tester in order to set

the Tester zero.

Make sure that the red line on

the vial is visible through the

slot of the Rapid Optical Oil

Tester test port.

13

16

18 19

14

17

15

12

15

DO NOT SHAKE

Zero

5° Homogenize mix gently

6° Insert vial into Tester

7° Press ZERO

Run Iron Test

Iron Test

With Rapid Optical Oil Tester

The Rapid Optical Oil Tester

counts down the time required

to complete the test.

(300 seconds)

When the test is complete,

the instrument beeps, shows

and logs the iron content of

the oil sample. If the alarm is

activated, the instrument

shows if the test result is

acceptable according to the

function settings.

Dispose of the vial and cap in an

appropriate waste container.

Do not use them for another test

as results may be biased.

Do not dispose of the residues in

the drainage system.

Carefully clean the tip of the

precision pipette.

21

22

16

Press the [Go] key.

20

GO

11° Turn vial upside down

10 times

12° Insert vial into tester

and press Go

Run Iron Test

Wait

until count down to 0

300

Run Iron Test

Ok

120 ppm

(comment)

Iron Content

Iron Test

With Rapid Optical Oil Tester

Solution IT1

Solvent IT2

Reagent IT3

17

Health Safety

&

Environmental Data

PHYSICAL CHARACTERISTICS

Appearance : Colorless limpid liquid. Density at 20°C, kg/l : 0.823. Flash Point, °C : 73. Viscosity at 20°C, mm2/s : 8.26

CHEMICAL COMPOSITION

Mixture

HAZARDOUS COMPONENTS

Heptan-1-ol, CAS: 111-70-6

REACTIVITY DATA

Thermal Stability : Stable at ambient temperature.

Hazardous Decomposition Components : Carbon oxides (CO, CO2) various hydrocarbons, aldehydes and soot.

POTENTIAL HAZARDS Heptan-1-ol, CAS: 111-70-6

Eye and skin contact : Produces eye damage after contact.

TOXICITY

Oral : LD50 > 6200 mg/kg bw (rat - OECD 401)

EXPOSURE LIMITS

DNEL (Workers) : Long Exposure: Dermal, Systemic 5.8 mg/kg, Inhalation, Systemic 20.6 mg/m3.

DNEL (Population) : Long Exposure: Oral, Systemic 2.9 mg/m3.

PNEC : STP 10 mg/l, Soil 0.0396 mg/l, Intermittent 0.38 mg/l, Fresh water 0.038 mg/l, Marine water 0.0038 mg/l,

Sediment (Fresh Water) 0.31 mg/l, Sediment (Marine Water) 0.031 mg/l.

PRECAUTIONS

Health : Avoid contact with eyes. Avoid contact with skin and observe good personal hygiene. Change heavily contaminated clothing.

Ensure good ventilation. Wash hands thoroughly after use, and always wash hands before eating, drinking or using the toilet.

Use single use disposable clothes and discard when soiled.

Safety : Store under cover away from heat and sources of irritation. Containers must be properly labelled and kept closed when not

in use. Clean up spilled material immediately.

Environmental : Take all necessary precautions against accidental spillage in to soil or water.

PROTECTIVE CLOTHING

Protective clothing, including impervious gloves, should be worn if skin contact is anticipated. Wear face visor or goggles if eye contact can

accidentally occur. Protective clothing should be regularly inspected and maintained; overalls should be dry cleaned and laundered.

FIRST AID / ACTION ON CONTACT

Skin : Clean the affected area thoroughly with water and neutral soap. In case of modifications on the skin (stinging, redness, rashes,

blisters…), seek medical advice with this Security Data Sheet.

Inhalation : Not an anticipated route of exposure. However, in case of symptoms of intoxication remove the person affected from the expo

sure area and provide with fresh air. Seek medical attention if the symptoms get worse or persist.

Eyes : Rinse eyes thoroughly with luke warm water for at least 15 minutes. Do not allow the person affected to rub or close their eyes.

If the injured person uses contact lenses, these should be removed unless they are stuck to the eyes, as this could cause further

damage. In all cases, after cleaning, a doctor should be consulted as quickly as possible with the MSDS of the product.

Ingestion : In case of consumption, seek immediate medical assistance showing the MSDS of this product.

MEDICAL ADVICE

There are no specific antidotes or therapeutic measures – treat symptomatically.

EMERGENCY ACTION

Fire : Product is non-flammable under normal conditions of storage, manipulation and use. In the case of inflammation as a result of

improper manipulation, storage or use preferably use polyvalent powder extinguishers (ABC powder), in accordance with the

Regulation on fire protection systems. DO NOT to use tap water as an extinguishing agent.

Spillage : Isolate leaks provided that there is no additional risk for the people performing this task. Evacuate the area and keep out those

without protection. Personal protection equipment must be used against potential contact with the spilt product. Absorb the

spillage using sand or inert absorbent and move it to a safe place. Do not absorb in sawdust or other combustible absorbents.

DISPOSAL

Dispose of by incineration or other suitable means under conditions approved of by the controlling authority. At sea, unwanted product should

be stored for eventual discharge into a shore based approved disposal facility.

SUPPLYING CLASSIFICATION AND LABELLING EEC Labelling (CLP)

Eye Irrit. 2: H319 - Causes serious eye irritation • P264: Wash thoroughly after use • P280: Wear protective gloves/protective clothing/eye protec-

tion/face protection • P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy

to do. Continue rinsing • P337+P313: If eye irritation persists: Get medical advice/attention

TRANSPORT CLASSIFICATION AND LABELLING

Not classified as dangerous for transportation

18

Solution IT1

Other manuals for Tech'Care

1

Table of contents

Other TOTAL Lubmarine Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

CARLO GAVAZZI

CARLO GAVAZZI WM23-96 - PROGRAMMING user manual

PCE Instruments

PCE Instruments PCE-CT 80 user manual

TSI Instruments

TSI Instruments AIRASSURE PM2.5 Firmware update instructions

Laser Technology

Laser Technology TruPulse 200X manual

vinmetrica

vinmetrica SC-50 quick guide

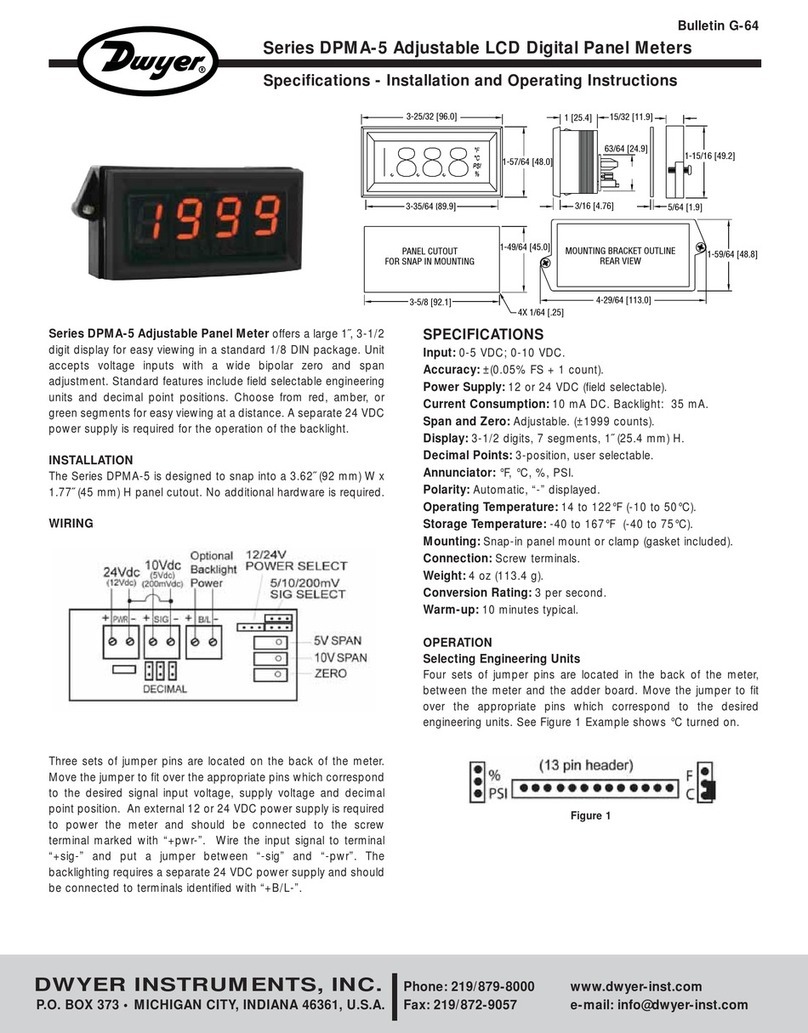

Dwyer Instruments

Dwyer Instruments DPMA-5 Series Installation and operating instructions