45

ŸRemove all packing materials and protective film, where used

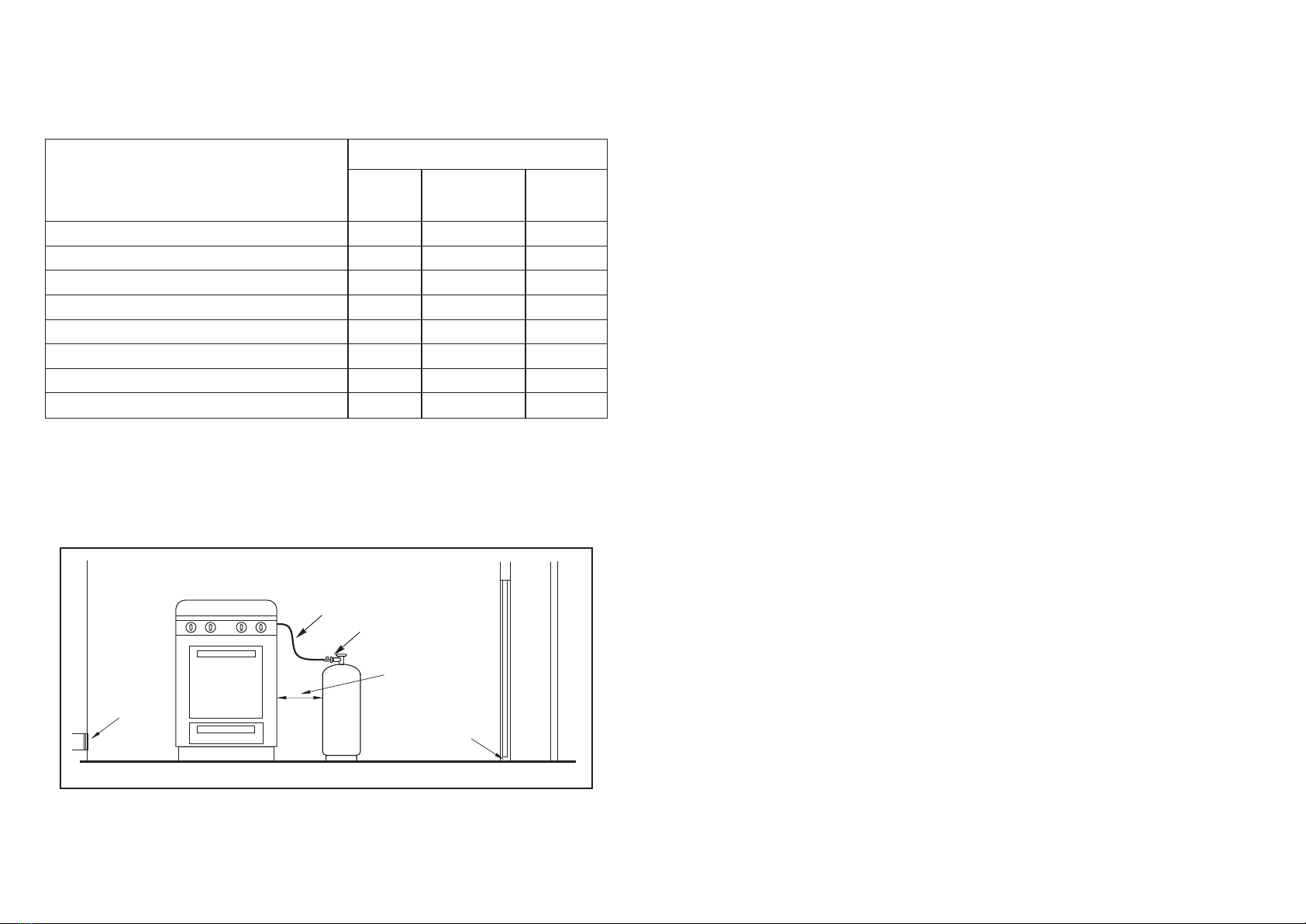

ŸMake sure that the area behind the stove is kept clear and that there are no flammable

materials above the stove. At the back of the stove is a flue for the oven burner and hot air

will rise from this area. It is best to keep the stove about 150 mm away from the wall.

ŸEnsure that the top burners and burner caps are correctly fitted into their specific locations

ŸCheck that the pot support grids are in place.

3. Preparing the appliance for use

pot lid or a wet towel. Never throw water onto the flames as this will not extinguish

them and may even cause the flames to spread.

ŸMake sure that flammable materials are not place closer than 500 mm to the stove.

ŸWhere the stove is placed adjacent to work tops or cupboards, keep a minimum clearance

of 50 mm between the sides of the stove and the work tops or cupboards.

ŸThis stove is equipped with battery powered semi automatic ignition.(see Fig 5) The battery is

housed in a recessed box at the back of the stove on the right hand side towards to bottom It is

protected by a removable cover plate. To fit or change the battery remove the cover plate. When

fitting or changing a battery ensure the battery is a Type D LR20 (1,5v). Once the battery, is fitted

remember to replace and secure the cover plate (see Fig 6).

ŸRepeat the above process to ignite the other burners as required.

ŸTurning the control knob in a clockwise direction from the mid position will again reduce the

flame level and it the knob is turn fully in a clockwise direction it will shut down the burner.

ŸTo adjust the flame to the required level, turn the burner control knob further in an anti clockwise

direction to reduce the flame. If turned to fully in this direction the flame will continue to burn at

the simmer position. Turning the control knob back to the mid position will give the maximum

flame level.

ŸThe flame height of the oven burner can be adjusted by turning in an anti clockwise direction to

ŸTo light the oven burner, open the oven door and with the light a match or hand held igniter torch.

Turn the Oven control knob to the high position (See Figs.2 & 5) and then place the lit match or

igniter torch to the hole in the centre front of the oven floor(see Fig. 6). This will ignite the oven

burner.

ŸTo light the cooker burners. Push in and turn the control knob of the burner you wish to light in an

anti clockwise direction to the mid position (see Figs. 2 & 3) and then press the ignitor button(See

Fig.2). This will create the ignitor spark to all burners at the same time but only the burner you

have activated will ignite. Once the burner is ignited, continue to hold the control knob in the

pushed in position for about 10 seconds to allow the flame failure sensor (see Fig.5) to recognise

that the burner is alight and then release the knob. The burner flame should remain lit. If it does

not, repeat the above process and hold the knob in for a few more seconds once the flame is lit.

ŸIf for any reason the ignition system does not function - e.g. in the case of a flat ignitor battery,

then hold a lit match or igniter torch to the selected burner with the control knob at the ignite

position and pushed in. The burner will then ignite.

ŸIt is not necessary or desired to put the lit match or igniter through the hole. All that is required is

to offer it up to the hole and that will ignite the oven burner.

ŸNote that each burner is fitted with a flame failure sensor which will shut off the gas supply if the

burner flame goes out (see Fig. 5). After lighting the burner hold the control knob in the pressed

in position for 5-10 seconds to allow the flame failure sensor to function correctly, If the fame

goes out when the knob is released, repeat the light procedure and hold the control knob in for a

few more seconds

4. Lighting the Burners

ŸTo clean the enameled and stainless steel surfaces of the appliance use a wet cloth or non

abrasive sponge and a mild soapy detergent. Abrasive cleaners and scourers should not be

used as this may permanently damage the surface.

ŸTo turn off the oven burner turn the oven control knob fully in a clockwise direction.

ŸThe pot support grids may be immersed in a soapy solution in order to clean them. Take note of

the locations for the pot supports to make sure they are firmly in place once refitted.

ŸWhen placing food in the oven, always place the food on the wire grid supplied with the stove.

Best results will be obtained with the grid in the middle position.

ŸWhen cooking using the top burner always use the burner that suits the pot size. For pots

smaller that 200 mm diameter use the medium burners. For larger pots use the large burner This

will ensure that you will achieve the best cooking efficiency. If the flame appears to extend up the

sides of the pot either place the pot on a smaller burner or reduce the flame height by adjusting

the required burner control knob.

ŸNever let water dry or evaporate on the cleaned surfaces as this may cause stains . It is best to

dry the cleaned surfaces immediately after cleaning.

ŸPre heat the oven for 10 minutes on a medium heat before placing any food in the oven.

ŸWhen cleaning the area around the burners never let water get into the burner ports as this may

prevent them from igniting or operating correctly.

ŸNever place any food or container on the oven floor.

ŸTo remove the burners from the stove top, firstly remove the pot support grids an place them to

one side. Lift off the burner caps from the burners and then lit out the burners from the stove top,

noting the relative positions of the medium and large burners.(See Figs. 2 & 3)

ŸIn the event that water does get into the burner ports, remove the burners from the stove and

shake them dry. Also blow through them to make sure that no water remains in the burners

before placing them back on the stove.

ŸWhilst it is acceptable to wash the burner caps in a soapy water solution it is best to simply wipe

the burners wit a damp cloth soaked in a detergent solution rather than to immerse them. Be

sure to make sure the burners and burner caps are dry before replacing them in their original

positions.

ŸClean the stove top and oven afer every use to prevent the build up of fat or food particles which if

left may be difficult to remove.

ŸAvoid opening the oven door during cooking as this will affect the cooking time. Examine the

food through the window in the oven door.

increase the flame and in a clockwise direction to decrease it.

ŸWhen using the oven, always open or close the oven door slowly to avoid air movement

which could affect the flame.

ŸFor details of the oven temperature settings refer to the Table and Fig. 7 below

6. Cleaning and Maintenance

5. Using the stove

ŸThere are no preset maintenance periods for this appliance but it is recommend that the stove

be examined by a qualified technician on and annual basis.. This will ensure continued effective

and safe operation of the appliance.

ŸBe careful when using proprietary oven cleaners as these may damage the oven surface. A

soapy detergent is the best option .