Tour Links Mini Link User guide

Mini Links Set Up Manual

Tools Required:

Phillips Screwdriver

1-866-92-1-PUTT

7888

www.tourlinks.net

English

MG-COIM-1

3

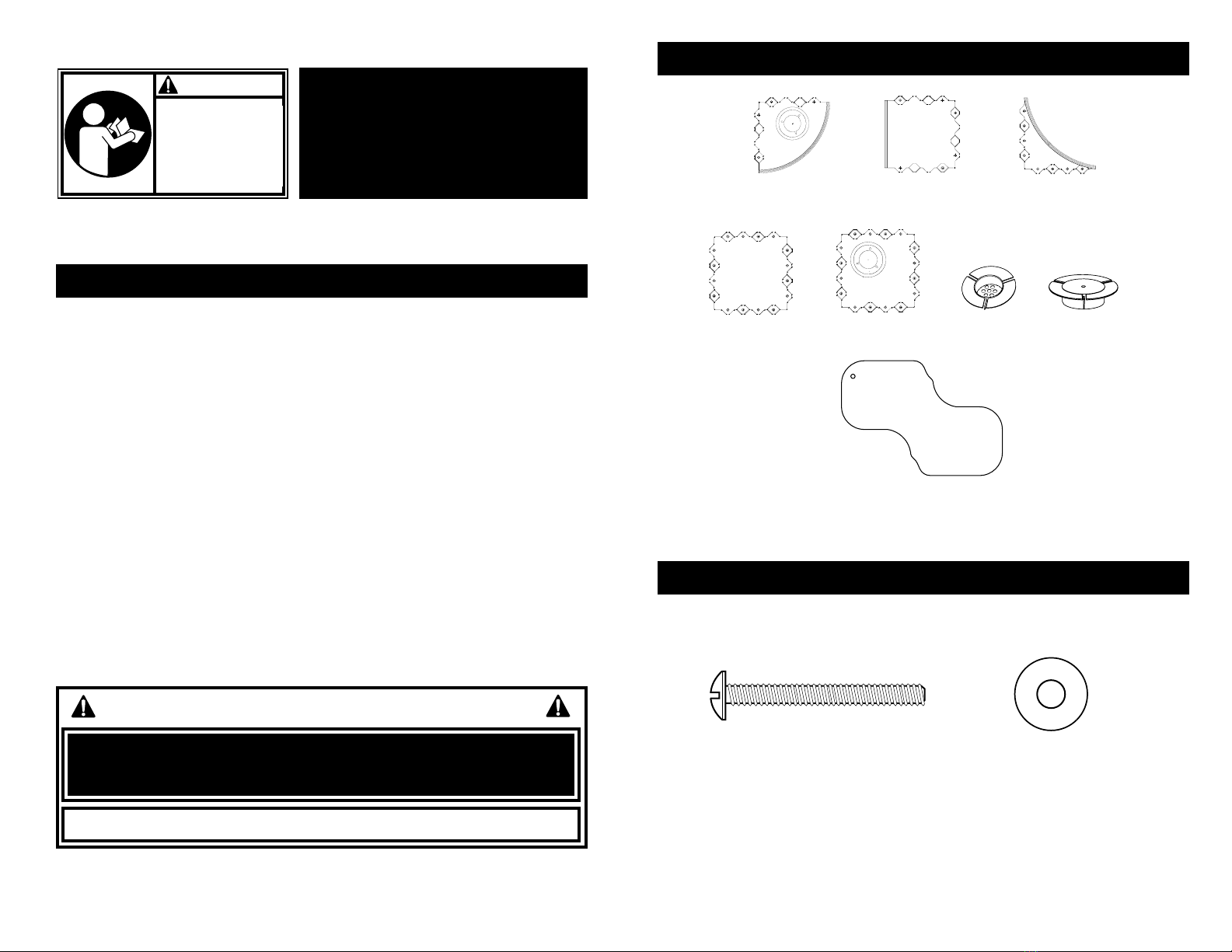

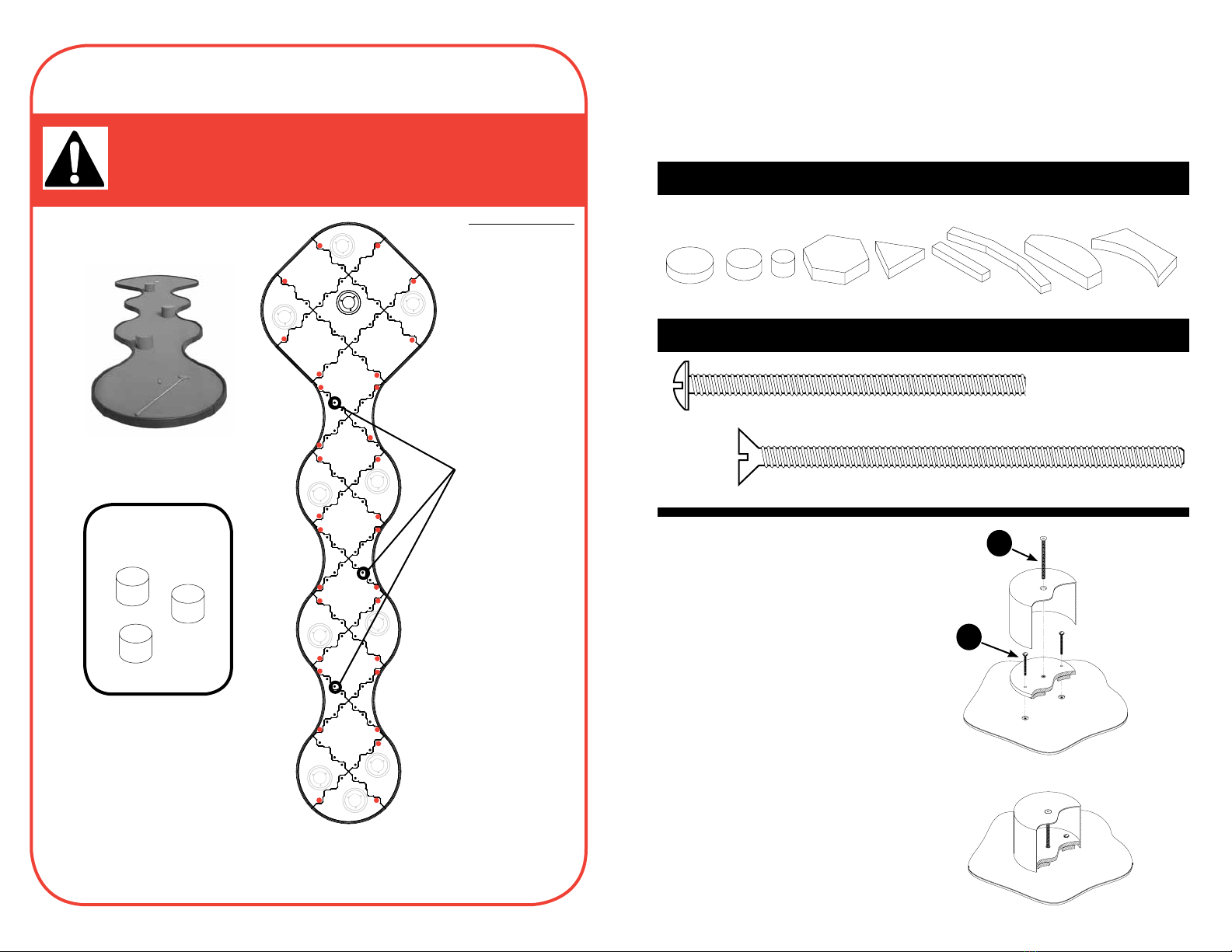

PARTS IDENTIFIER

HARDWARE IDENTIFIER (ACTUAL SIZE)

2. Straight Edge Panel

P2-SE

1. Single Curve Panel

P2-ORSCE

8. Turf

7. Filler Plate

A2-CFPA

3. Inside Radius Panel

P2-IRSCE

4. Panel-Center

P2-IC

6. Cup

A2-FCA

5. Panel-Center-With Cup

P2-ICC

2

INDOOR/OUTDOOR PLAY

Different outdoor and indoor environment elements will cause possible expansion and

contraction of the turf and the base. This putting green was designed to be used for play

both indoors and outdoors.

Assemble on level surface: For optimal play, assemble on a hard, flat surface. The base

is made of a strong material but over a long period of time will relax to conform to the

level of the surface underneath. The green will only be as level as the surface below. If

the surface is not level, measures may be taken to construct a level playing surface.

Portability: All of the panels interlock for ease of assembly and disassembly. To move or

store the putting green you must disassemble EACH interlocking panel from each other

for safety in moving. Two people are required for safe assembly and disassembly.

Moving cup: The mobility of the cup was designed so the cup could always be lined up

under the hole cut outs of the turf. The cup will not move during play.

Drainage: Spacing between the joints of the panels allows the drainage of water off the

deck when used outdoors.

IMPORTANT! Remove all contents from boxes.

NOTICE TO ASSEMBLERS

ALL Tour Links Putting Green Systems,

including those used for DISPLAYS, MUST

be assembled with fasteners according

to the instructions. Failure to follow

instructions could result in INJURY.

READ AND UNDERSTAND

OPERATOR’S MANUAL

BEFORE USING THIS UNIT.

FAILURE TO FOLLOW

OPERATING INSTRUCTIONS

COULD RESULT IN INJURY

OR DAMAGE TO PROPERTY.

WARNING!

Please register this product online at www.tourlinks.net

SAFETY INSTRUCTIONS

• Two(2)peoplearerecommendedforthisoperation.

• Thelifeofyourputtinggreendependsonmanyconditions.Theclimate,placementofthe

green,exposuretocorrosivessuchaspesticides,herbicides,orsaltsareallimportantfactors.

• IftechnicalassistanceisrequiredcontactTourLinks.

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this system.

9. Stainless Steel Screw 10. Stainless Steel Washer

54

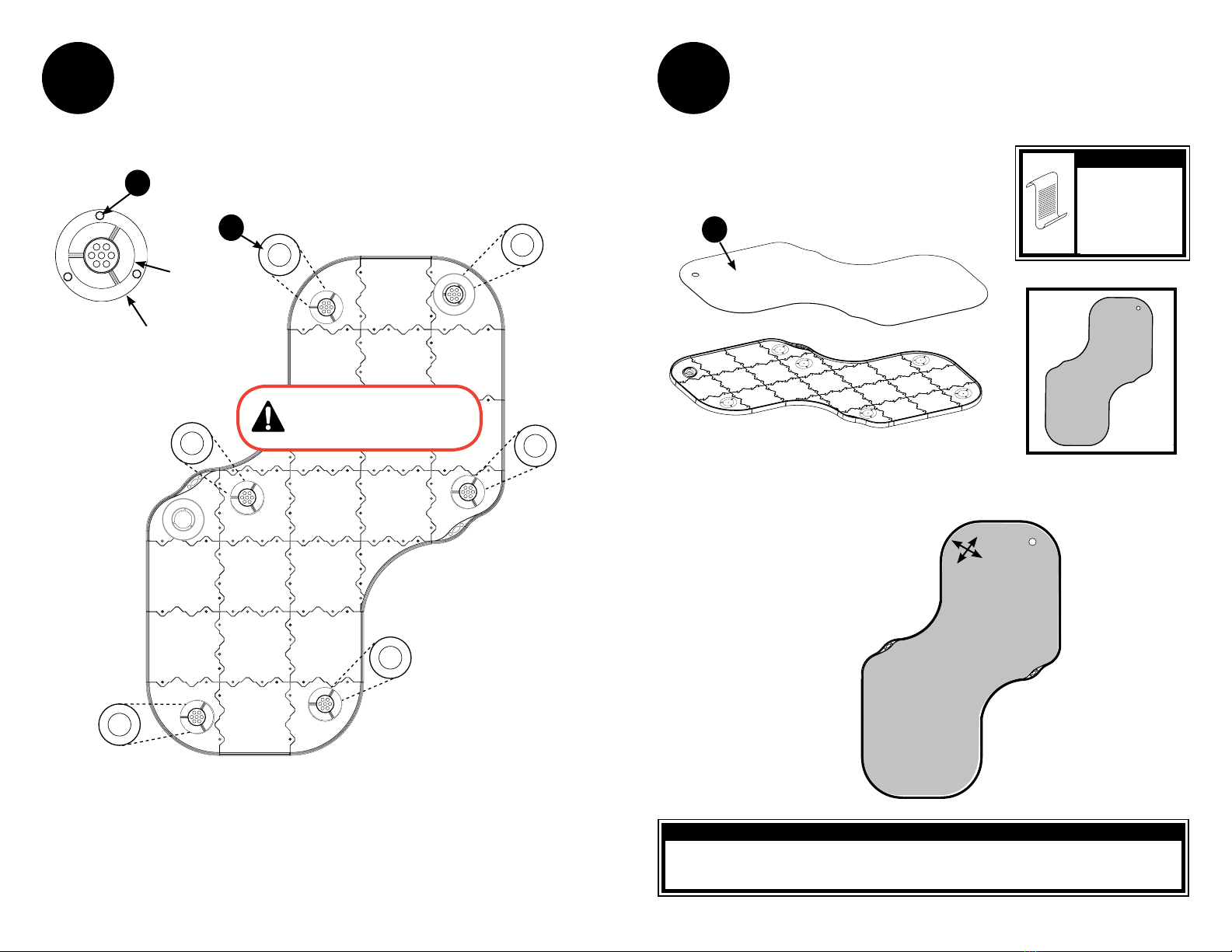

IMPORTANT: Refer to THE PRODUCT IDENTIFICATION PAGE

IMPORTANT: Refer to THE PRODUCT IDENTIFICATION

PAGE

on page 3 of this manual to insure proper panel layout.

Slide deck panels together piece by piece.

After the first few panels have been locked together, the best method

for sliding the remaining panels together is to kneel on the assembled

section and pull the next panel in towards you to engage the teeth.

Pulling the panels into place is far easier then trying to push them into

place. Please see drawing #3 on page 6 which indicates the angle to pull

a new panel into position when surrounded by locked panels. Use your

pre-cut turf as the template to gauge whether or not the panels need to

be pushed tighter or spread apart. It is important that the turf be allowed

to lay flat in a warm environment for several hours prior to installation to

achieve a relaxed state in the fibers. This will allow the turf to return to

its proper size.

After all the panels have been installed in their proper configuration lay

the relaxed turf on to the panels to check turf fit and slide the panels

together or pull them apart to create a gap of around 1/16 inch between

the turf edge and the panel bump rail. Please note that with time the turf

will tend to shrink a bit due to the natural tendencies of textiles. We have

attempted to make the turf fit in all conditions, but due to manufacturer

allowed tolerances, it may be necessary to trim the carpet to achieve

proper fit. This trimming should only be done if the panels have all been

spread to their maximum adjustability and the turf is still tight. After the

panels have been adjusted to the turf size, temporarily remove the turf.

Insert the self tapping screws and washers into the locations indicated

on page 3. Hand start each screw and then tighten with a screwdriver or

power driver. DO NOT OVER TIGHTEN. Once tight, back the screws off by

one-quarter turn to allow the panels to move freely during expansion and

contraction. Some models come with additional screws and washers to

be used at the installers discretion. See attached layout sheets for screw

locations. Our experience shows that the number of screws indicated

achieves the best results.

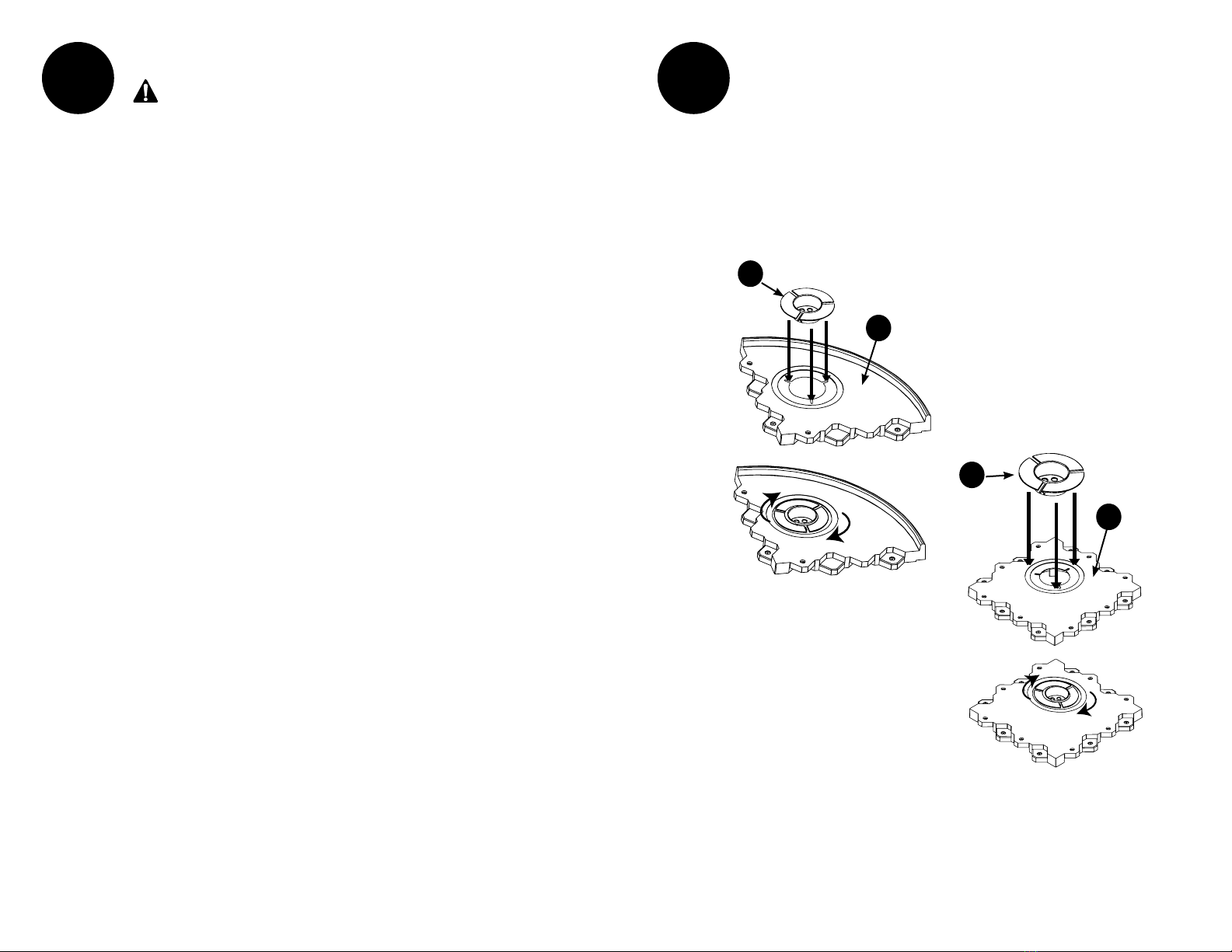

1Install the cup assemblies in all the panels that are indicated having cups.

Insert the cups into the panels and twist. The cup is now able to move in a

complete circular orbit to allow for expansion and contraction of both the

panels and the turf.

Locate any corner panels that do not have a cup assembly and insert a filler

plate. Install using the same method as described with the cups.

2

6

1

6

5

6 7

Position deck washers (11) around cups and into the circular indent on the

deck using the double sided deck washer tape (19) as shown.

NOTE: Filler plates do not require deck washers.

3

Cup

Circular indention

on the deck panel

19

11

This illustration is representative only.

Refer to The Product Identification

page on page 5 of this manual to

insure proper panel layout.

Unroll and Install the relaxed turf (8) as shown.

Make sure hole in turf lines up with the cup.

4

8

Use care when

installing or moving

tUrf. never crease

tUrf.

when assembled, it is

sUggested to allow 24

hoUrs for assembled

Unit to settle

NOTE:

TOP VIEW

Cups can be moved in

any direction to line

up with holes in turf.

CupAdjustment:

for Permanant installation of mini linKs follow the

“toUr linKs Permanant installation gUide”

NOTE

8 9

BACKYARD INSTALLATION

If you are installing the green in the backyard, or other natural outdoor areas,

we have a few techniques that will speed up the installation. The Tour Links®

panels are designed to flow over the existing ground slope that is naturally

created in the earth.

If a particular valley is too severe then some filling with finely crushed stone

in these areas is recommended. If a hill is too severe, a little digging may be

required.

Remember most golf greens are not dead flat.

1. Place your pre cut turf, green side up, on the grass in the desired location.

It is important that your turf be allowed to relax in a warm environment

for several hours to assure the best fit.

2. Walk around the edge of the turf with a bottle of baby powder or chalk

and mark the grass around the pre cut turf creating an outline of the

green.

3. Remove the synthetic turf.

4. Use a weed whacker to scalp the grass as low as possible within the

outline of the green. This will give you a great base to start with.

5. Now follow your “Tour Links Design Sheet” and begin to layout the

panels.

6. Assemble the panels per the Tour Links Assembly Instruction Manual. Be

sure to build your panels to the dimensions of the pre-cut turf, due to the

natural shrinkage that occurs in all textiles. There should be about 1/16”

gap around the edge. This gap will vary as temperatures and natural

shrinkage occur. You must only use the provided screws & washers for all

INSTALLATION TIPS

When placed on sloped ground, Tour Links panels are designed to flex

and mimic the underlying sloped ground creating a realistic putting

green. When placed on a flat and level surface, Tour Links panels will

remain flat and level.

The easiest method of installation of the Tour Links®system is indoor

or outdoor on a hard surface. Whether it is tile, carpet, or a wooden

deck, this installation requires nothing more than sliding the panels

together and tightening the provided screws and washers. Almost

immediately the space is transformed into a professional putting

green.

installations and DO NOT over tighten the screws. Use just enough force

to snug the screws down and then back off a quarter turn. You will only

need to insert the screws in the holes of the outer panel as shown on

page 3. There are a few additional screws provided to be used in areas

of the green that are following a severe contour. Use these screws to

insure proper alignment in necessary. If you are installing over sand or

soil areas a layer of commercial polyester fabric weed barrier cloth should

be laid out under the panels to prevent sand or dirt from interfering with

assembly of the panels. This weed barrier cloth should also be used if you

are installing over grass. It is believed that this cloth will help minimize

any uneven settling of the panels. Be sure to either weed wack the

grass down to bare dirt or kill the grass with a liquid weed killer prior to

installation of the weed control cloth and the panels.

7. As you are laying out the panels and you come to a panel with a hole

make sure the hole is positioned in the correct location. The center panel

is designed to allow for 4 different hole locations depending on which

way the panel is installed.

8. If you are installing on a contoured surface, water may tend to settle in

some low areas along the bump rails of the curved panels.

9. Locate the low areas by flowing water over the panels and watch where

it collects. Rolling a golf ball on the panels will also indicate the low

areas.

10. At the identified low area, 1/2” away from the bump rail, drill a 3/8”

hole through the deck material. This will allow any collected water to

funnel out of the low area. Repeat the drilling at all identified low water

collection areas. This step may not be necessary depending on your

location.

11. Your green may seem a little spongy at first, but as the panels settle,

the green will become very stable. A solid base could be achieved

immediately by spreading and compacting a 1” layer of finely crushed

rock, such as decomposed granite or crushed limestone. Pack down the

rock and lay out the panels. This is where a layer of commercial polyester

fabric weed barrier cloth is required to keep the new gravel or sand

from getting caught in the panel teeth, disrupting the expansion and

contraction of the panels. NOTE: Polyester weed barrier cloth is available

at most home centers.

12. Install the turf as described in step 4 on page 9 of this manual.

13. Periodic vacuuming of the turf is recommended, as well as washing the

bump rails. To clean the bump rails, use any automotive black bumper

conditioner found in any auto parts store.

BACKYARD INSTALLATION

10 11

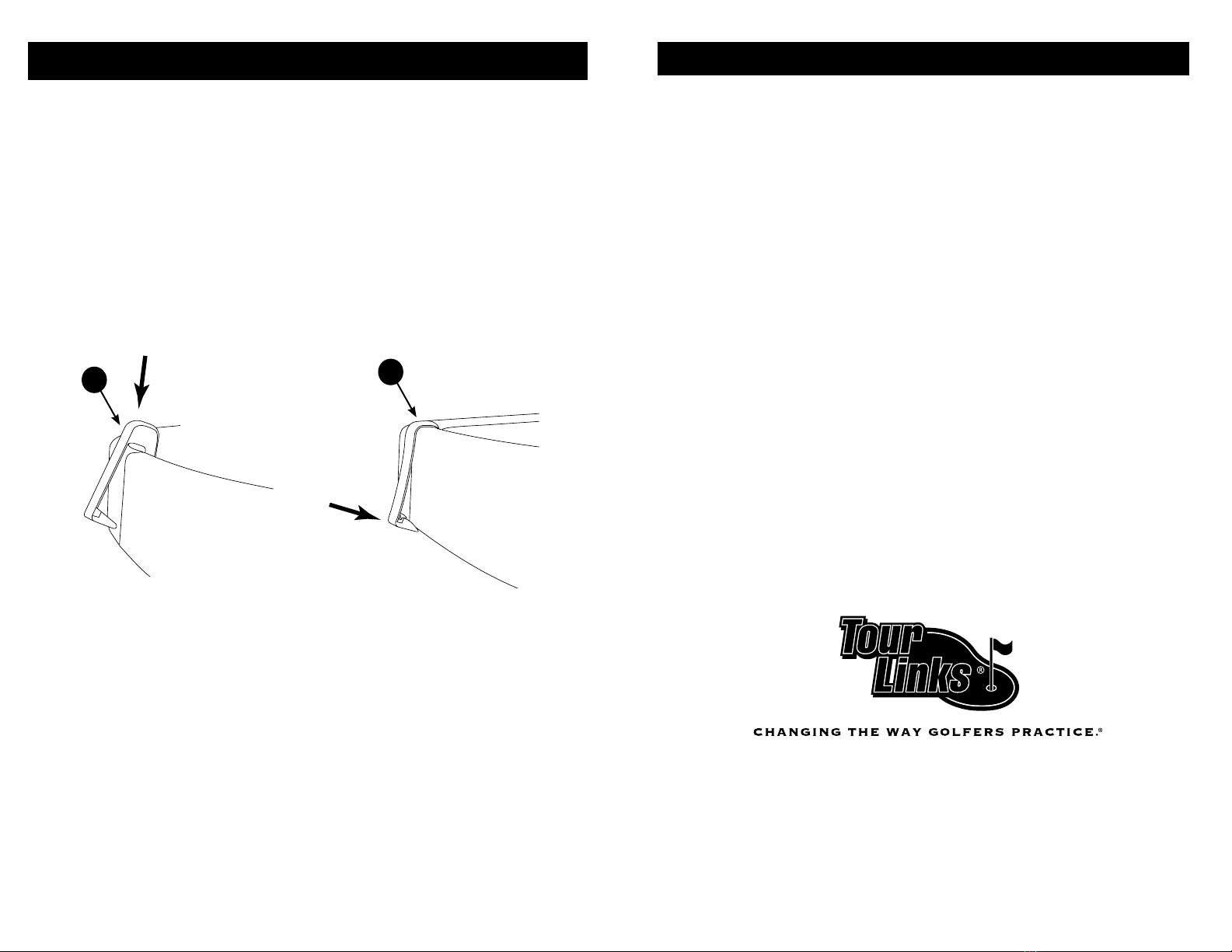

BUMP RAIL CLIP INSTALLATION

Once the entire green has been assembled, with the turf fitting 1/6-inch

away from the bump rail, it’s time to install the bumper clips. The small black

plastic clips are designed to attach over the bump rails at the seams. This is

an aesthetic feature that hides the gaps that may have been created during

installation in order to ensure proper turf fit. Place the clips over the bump

rail and push down on top of the clip until it follows the contour of the bump

rail and then push the clip into the side of the bumper rail. There is a small

molded prong on the bottom of the clip which will attach to the lower edge

of the panel. The clip is designed to slide back and forth in the seam during

expansion and contraction. To remove the clip simply lift up the panel and

disengage the prong.

20 20

GENERAL CARE AND MAINTENANCE

• Cleanpanelswithasoftdampcloth.Carefullysweep

or vacuum turf. To clean the bump rails, use any

automotive black bumper conditioner found in any

auto parts store.

• Whenrollingupturfforstorage,alwaysrollloosely

with green-side out.

• Donotcreaseturf.

• Foroutdoorapplication:Ifunitwillnotbeinusefor

an extended period of time, roll turf with green side

out and store turf and accessory pieces indoors.

• Disassembleunitbeforemoving.

1-866-92-1-PUTT

7888

www.tourlinks.net

131212

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Use the diagrams on the following pages for proper individual hole set up .

PRODUCT IDENTIFICATION PAGE

1 - Straight Shot page 13

2 - Off the Wall page 14

3 - Big Blue page 15

4 - Between the Yellow Lines page 16

5 - Zig Zag page 17

6 - Take Dead Aim page 18

7 - Narrow Path page 19

8 - Gum Drop Lane page 20

9 - Around the Corner page 21

10 - Take Your Pick page 22

11 - The Snake page 23

12 - Tight Squeeze page 24

13 - Stop and Go page 25

14 - Keep to the Left page 26

15 - Landing Zone page 27

16 - Point to Point page 28

17 - Tight Turn page 29

18 - Hold Your Breath page 30

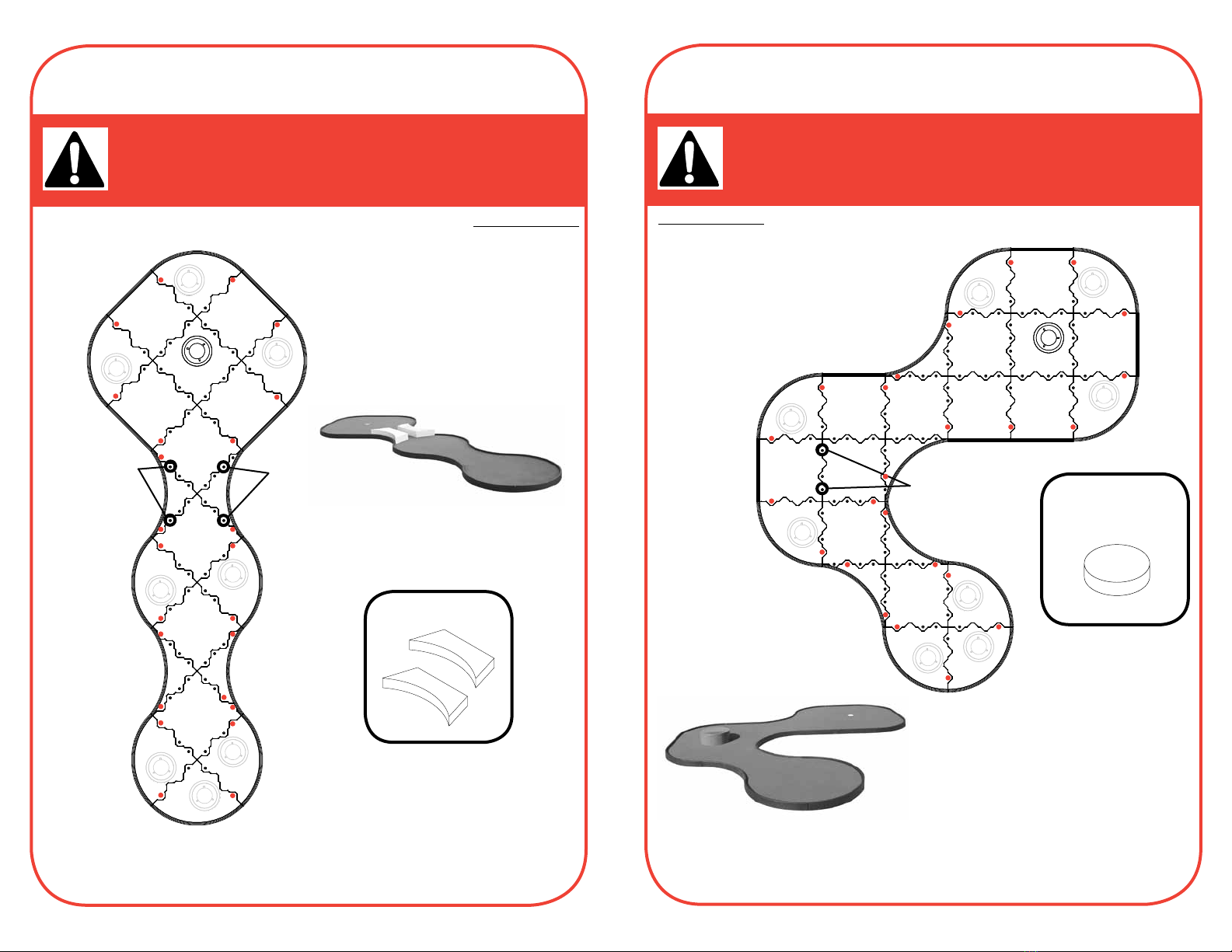

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 1 - Straight Shot

Parts List

4 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

1514

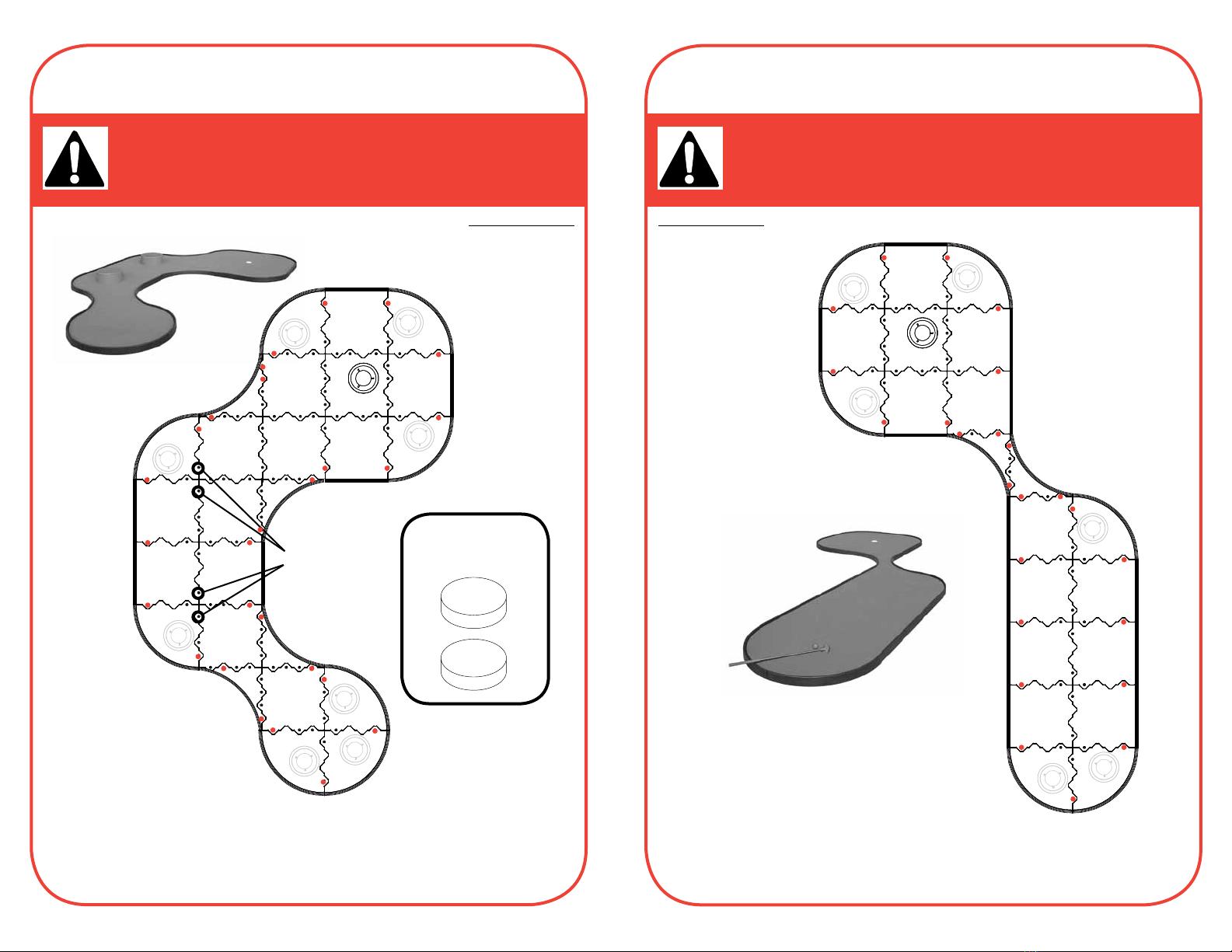

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 2 - Off the Wall

Prop Mounting Points

Optional Prop

Parts List

12 Straight Edge Panels

2 Center Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

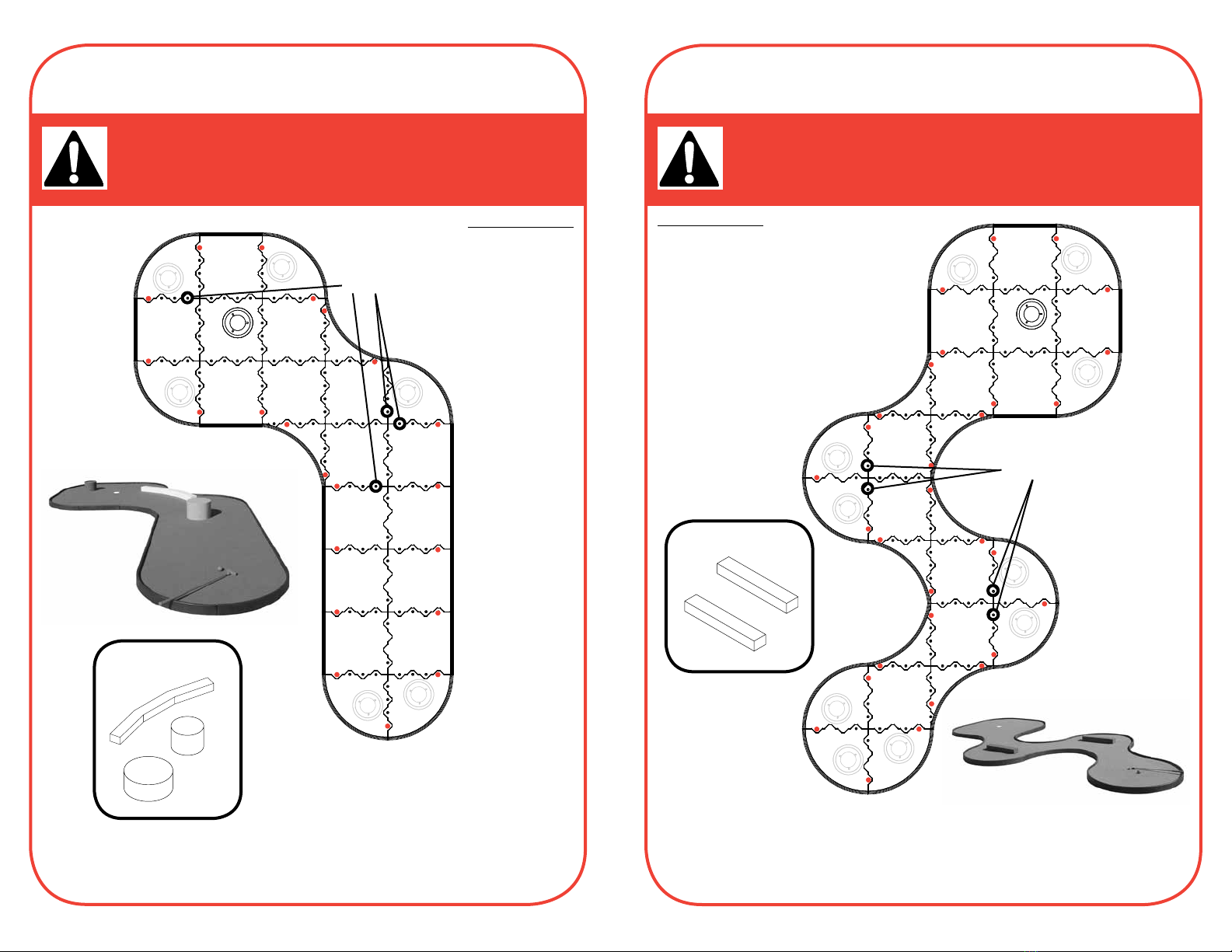

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 3 - Big Blue

Prop Mounting Points

Prop Mounting Points

Parts List

14 Straight Edge Panels

2 Center Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

Optional Props

1716

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 4 - Between the Yellow Lines

Prop Mounting Points Prop Mounting Points

Optional Props

Parts List

4 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

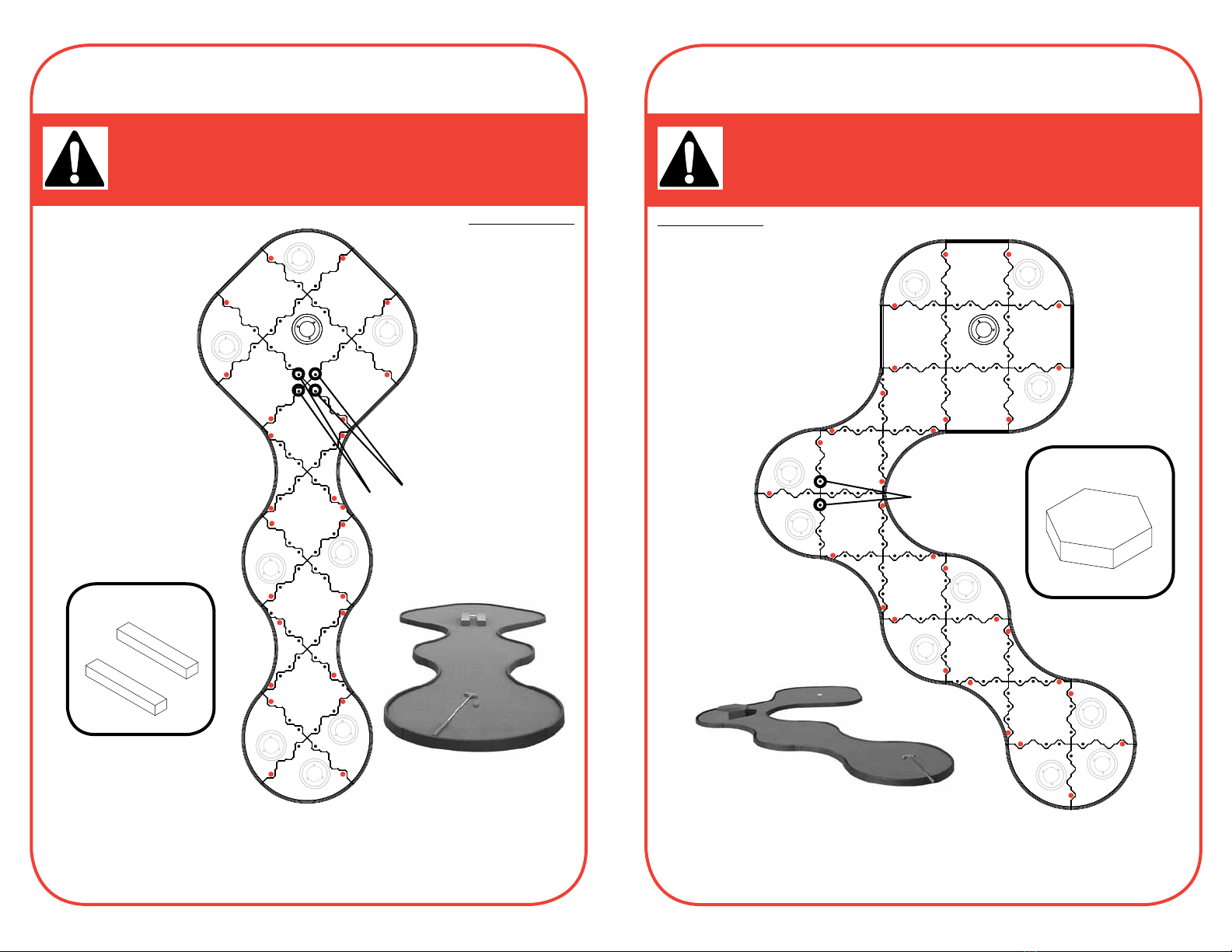

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 5 - Zig Zag

Optional Prop

16” Cylinder

Prop Mounting Points

Parts List

6 Straight Edge Panels

5 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

1918

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 6 - Take Dead Aim

Prop Mounting Points

Optional Props

2 - 12” Cylinders

Parts List

4 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

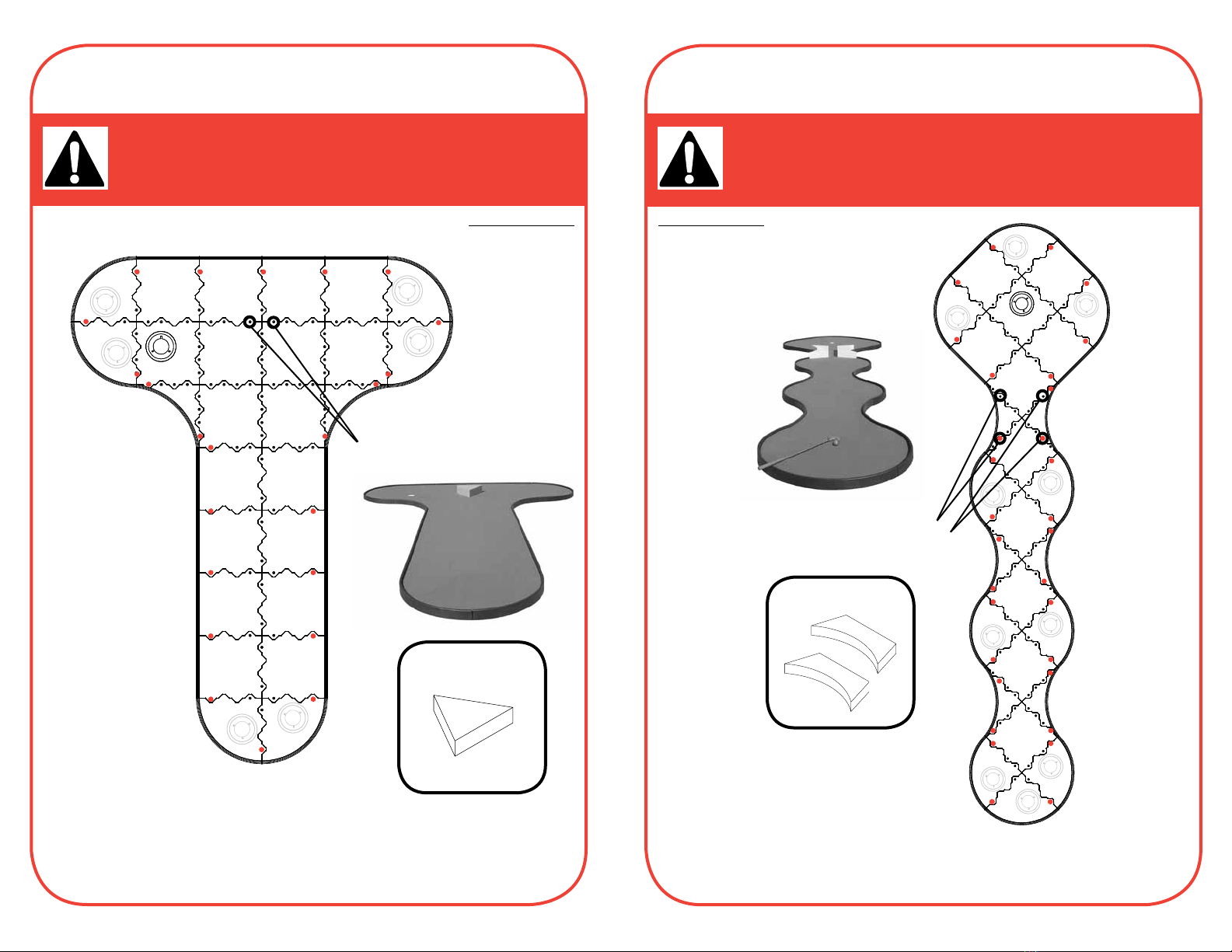

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 7 - Narrow Path

Optional Prop

Prop Mounting Points

Parts List

12 Straight Edge Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

2120

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 8 - Gum Drop Lane

Optional Props

12” Cylinder

16” Cylinder

8” Cylinder

Prop Mounting Points

Parts List

14 Straight Edge Panels

2 Center Panels

1 Center Panel with hole

5 Single Curve Panels

1 Inside Radius Panel

1 Cup

5 Filler Plates

Bolts and Washers

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 9 - Around the Corner

Optional Props

Prop Mounting Points

Prop Mounting Points

Parts List

10 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

2322

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 10 - Take Your Pick

Prop Mounting Points

Optional Props

Parts List

10 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 11 - The Snake

Optional Props

Prop Mounting Points

Parts List

4 Straight Edge Panels

6 Center Panels

1 Center Panel with hole

10 Single Curve Panels

6 Inside Radius Panels

1 Cup

10 Filler Plates

Bolts and Washers

2524

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 12 - Tight Squeeze

Optional Props

Prop Mounting Points

Parts List

4 Straight Edge Panels

4 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 13 - Stop and Go

Prop Mounting Points

Optional Prop

Parts List

4 Straight Edge Panels

6 Center Panels

1 Center Panel with hole

10 Single Curve Panels

6 Inside Radius Panels

1 Cup

10 Filler Plates

Bolts and Washers

2726

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 14 - Keep to the Left

Optional Prop

Prop Mounting Points

Parts List

12 Straight Edge Panels

5 Center Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 15 - Landing Zone

Prop Mounting Points

Optional Props

Parts List

4 Straight Edge Panels

6 Center Panels

1 Center Panel with hole

10 Single Curve Panels

6 Inside Radius Panels

1 Cup

10 Filler Plates

Bolts and Washers

2928

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 16 - Point to Point

Prop Mounting Points

Optional Props

2 - 16” Cylinders

Parts List

6 Straight Edge Panels

6 Center Panels

1 Center Panel with hole

8 Single Curve Panels

4 Inside Radius Panels

1 Cup

8 Filler Plates

Bolts and Washers

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 17 - Tight Turn

Parts List

12 Straight Edge Panels

1 Center Panel with hole

6 Single Curve Panels

2 Inside Radius Panels

1 Cup

6 Filler Plates

Bolts and Washers

3130

IMPORTANT: IDENTIFY PROPER HOLE BEFORE PROCEEDING WITH ASSEMBLY.

Follow the diagram below for proper hole set up .

PRODUCT IDENTIFICATION PAGE

Hole 18 - Hold Your Breath

Prop Mounting Points

Optional Props

3 - 8” Cylinders

Parts List

4 Straight Edge Panels

6 Center Panels

1 Center Panel with hole

10 Single Curve Panels

6 Inside Radius Panels

1 Cup

10 Filler Plates

Bolts and Washers

Each Mini Links prop is designed with

an interior plate that aligns to existing

mounting points of the panels. (See each

hole layout for exact location of mounting

points) Locate the prop style and placement

of the props for each hole and attach the

proper mounting plate to the panel system

using the 1/4” bolts. You will see that the

mounting holes have been pre-cut into the

turf to insure proper placement .

Once the interior plates are secured,

simply slide the prop over the plate

and attach with the 3/8” mounting bolt

PROPS IDENTIFIER

HARDWARE IDENTIFIER

2. Extra Long 3/8” Mounting Bolt (1)

Bolt length is different for each prop

1. Stainless Steel 1/4” x 3” Screw (2)

MiniLinks props are manufactured in aluminum to our exact specifications

and powder coated with a tough finish which will last for years of outdoor fun.

Prop Installation

2

1

32

Warranty

Seller warrants that the equipment delivered by seller will be of the kind

and quality described in the order or contract and will be free of defects in

workmanship or material. Should any failure to conform to this warranty appear

within three years seller shall,on notification, correct such nonconformity,

including nonconformance with the specifications, at its option, either by

repairing any defective part or parts, or by making available F.O.B. sellers plant,

a repaired or replacement part.

This warranty is in lieu of all warranties of merchantability, fitness for purpose

or other warranties, express or implied, except of title and against patent

infringement. Correction of nonconformitys, in the manner and for the period

of time provided above, shall constitute fulfillment of all liabilities of seller to

buyer, whether based on contract, negligence or otherwise with respect to, or

arising out of such equipment.

Neither party shall be liable for special, indirect, or consequential damages. The

remedies set forth in this instrument are exclusive, and the liability of seller with

respect to any contract or sale or anything done in connection with the same,

whether in contract, in tort, under any warranty, or otherwise, shall not, except

as expressly provided in this instrument, exceed the price of the equipment or

part on which such liability is based.

Any controversy relating to this agreement or any modification or extension of it

allowed by its terms shall be resolved by arbitration in the city of St. Petersburg,

Florida, administered by the American Arbitration Association under the then

prevailing Commercial Arbitration Rules.

1-866-92-1-PUTT

7888

www.tourlinks.net

MG-COIM-1

This manual suits for next models

1

Table of contents