Toyo VF66B User manual

TOYO INTELLIGENT INVERTER

CC66-Z Operating Manual

1

Foreword

Thank you for choosing optional circuit board for Toyo VF66B inverter.

This instruction manual contains information regarding the CC66-Z Optional Circuit Board for the

VF66B Inverter. For correct use, please carefully read this instruction manual prior to using the CC66-Z.

This instructions manual explains a setup of the function of CC66-Z, the wiring method, and a VF66B

inverter. Refer to a "CC66-Z communications protocol description" for CC-Link communication function.

In order to accommodate the many special functions to a wide variety of applications in addition to the

basic inverter functions, please thoroughly read the instruction manual of the inverter as well as any

other applicable specialized instruction manuals.

The communication specification of CC66-Z corresponds to CC-Link Ver1.1 and CC-Link Ver2.0.

2

Please read before use

For safety

Before installing, operating, maintaining and inspecting CC66-Z option, please read this manual and all other

appendices thoroughly in order to get familiarize with the feature of this option, safety information and

correct handling. For safe operation, be sure to also thoroughly read the instruction manual of the inverter. In

this instruction manual, the safety instructions are classified in to two levels: DANGER and CAUTION.

DANGER

Indicates a hazardous situation which may result in death or serious injury if it

is handled improperly.

CAUTION

Indicates a hazardous situation which may result in moderate or minor injury

or only in property damage if it is handled improperly. However, such a

situation may lead to serious consequences depending on circumstances.

CAUTION [Installation]

Do not use optional circuit board if you discover damage or deformation during unpacking.

Doing so may cause optional circuit board failure or malfunction.

Do not place any flammable materials near the optional circuit board.

Doing so may cause a fire.

Do not allow the optional circuit board to drop, fall over or sustain severe impacts.

Doing so may cause optional circuit board failure or damage.

Do not install or operate the optional circuit board if it is damaged or has any of its parts missing.

Doing so may lead to personal injury.

DANGER [Wiring]

Before wiring, make sure the power is OFF.

Failure to do so may cause an electric shock or fire.

Wait more than 10 minutes after turning the power OFF before opening the unit case lid.

Failure to do so may cause an electric shock or fire.

Make sure that the unit is correctly earthed.

Failure to do so may cause an electric shock or fire.

Wiring must be done by skilled technicians.

Failure to do so may cause an electric shock or fire.

Wire the unit after it is installed.

Failure to do so may cause an electric shock or fire.

CAUTION [Wiring]

Make sure that communication cables and connectors are properly installed and locked in place.

Failure to do so may cause optional circuit board failure or malfunction.

3

DANGER [Operation]

Turn the power ON after fitting the inverter front cover.

Do not remove the cover while the power is ON.

Failure to do so may cause an electric shock.

Do not operate any switch with wet hands.

Failure to do so may cause an electric shock.

Do not touch the inverter terminals while the power is ON, even if the inverter is in the idle state.

Failure to do so may cause an electric shock.

If the alarm is reset while the operation signal kept input, the inverter will suddenly restart. Reset the

alarm after making sure that the operation signal is OFF.

Failure to do so may lead to personal injury.

The inverter can be set to operate in a wide range of speed. Operate the inverter after sufficiently

checking the allowable range of the motor and equipment.

Failure to do so may cause personal injury, equipment failure or damage.

CAUTION [Operation]

The inverter radiating fin and the radiating resistance are hot. Do not touch them.

Failure to follow this warning may cause burns.

DANGER [Maintenance, inspection and parts replacement]

Always turn the power OFF before inspecting the inverter.

Failure to do so may cause an electric shock, personal injury or fire.

Unauthorized persons shall not perform maintenance, inspection or parts replacement.

Use insulated tools for maintenance and inspection.

Failure to do so may cause electric shock or personal injury.

DANGER [Other]

Never modify the unit.

Doing so may cause electric shock or personal injury.

CAUTION [General precautions]

Some illustrations given in this manual show the inverter from which the covers or safety shields have been

removed to illustrate the details. Before operating the inverter, reinstall the covers and shields to their

original positions and the inverter according to this manual.

These safety precautions and specifications stated in this manual are subject to change without notice.

4

Table of contents

Please read before use .......................................................................................................................................................2

For safety.........................................................................................................................................................................2

Chapter 1 Functional outline.........................................................................................................................................5

Chapter 2 Basic specification........................................................................................................................................6

2.1 Multifunctional input/output terminal specification..........................................................................6

2.2 Analog input/output terminal specification...........................................................................................7

2.3 PG input/output terminal specification....................................................................................................7

2.4 CC-Link communication terminal specifications..................................................................................7

2.5 CC-Link communication specification.......................................................................................................8

2.6 Other.......................................................................................................................................................................9

Chapter 3 Description of substrate......................................................................................................................... 10

3.1 Name of each part.......................................................................................................................................... 10

3.2 CC66-Z switches.............................................................................................................................................. 11

3.3 Installation of CC66-Z.................................................................................................................................... 12

3.4 LED operation................................................................................................................................................... 14

Chapter 4 Multifunction input/output specification........................................................................................... 15

4.1 Multifunction input ........................................................................................................................................ 15

4.2 Multifunction output ..................................................................................................................................... 17

Chapter 5 Analog input/output function................................................................................................................. 19

5.1 Analog input (2)............................................................................................................................................... 19

5.2 Analog input (2) input gain and offset adjustment.......................................................................... 20

5.3 Analog input (2) usage instructions........................................................................................................ 22

5.4 Analog output (2)............................................................................................................................................ 25

5.5 Analog output (2) gain offset adjustment............................................................................................ 26

Chapter 6 PG input/output function....................................................................................................................... 28

6.1 PG input signal................................................................................................................................................. 28

6.2 PG output signal.............................................................................................................................................. 30

Chapter 7 CC-Link communication function........................................................................................................ 31

7.1 Connection method of a communication cable.................................................................................. 31

7.2 Setup of CC-Link communication function........................................................................................... 31

5

Chapter 1 Functional outline

CC66-Z is remote device station apparatus corresponding to CC-Link Ver.2.0. CC66-Z is used connecting

with the PC board (VFC66-Z) in a VF66B inverter. CC66-Z is equipped with an analog input/output function,

multifunctional input/output function, and PG input/output function other than extended cyclic

transmission and the cable length relief between stations as CC-LinkVer.2.0 function.

CC-Link is the communication specification of the high-speed FA network developed in Japan, and realizes

the data communication network corresponding to a multi vendor.

By CC-Link communication function of CC66-Z, operation instructions, speed instructions, torque

instructions, etc. are inputted into a VF66B inverter, or a monitor can do the operational status and the

protection state of an inverter, current, voltage, etc. Moreover, the setting data of an inverter read-out/rewrites

and read-out of trace back data, read-out of a protection history, and read-out of monitor data can be

performed. Refer to a "CC66-Z communications protocol description" for CC-Link communication function.

Moreover, it can be used as an input/output signal of the built-in PLC function of VF66B inverter. Refer to the

description of VF66 PCTool for a built-in PLC function.

CAUTION [Safety precautions]

Carefully read the instruction manual before use, and use the inverter correctly.

Our inverter and optional circuit board are not designed or manufactured for the purpose of use in

life-support machines or systems.

If you intend to use the product stated in this document for special purposes, such as passenger cars,

medical devices, aerospace devices, nuclear energy controls and submarine relaying machines or systems,

consult our sales department.

This product is manufactured under strict quality control. However, if it is used in critical equipment in

which inverter and optional circuit board failure may result in death or serious damage, provide safeguard to

avoid serious accidents.

If you wish to use this inverter with loads other than three-phase AC traction, please contact us.

To use this product, electrical work is necessary. The electrical work must be done by qualified expert.

6

Chapter 2 Basic specification

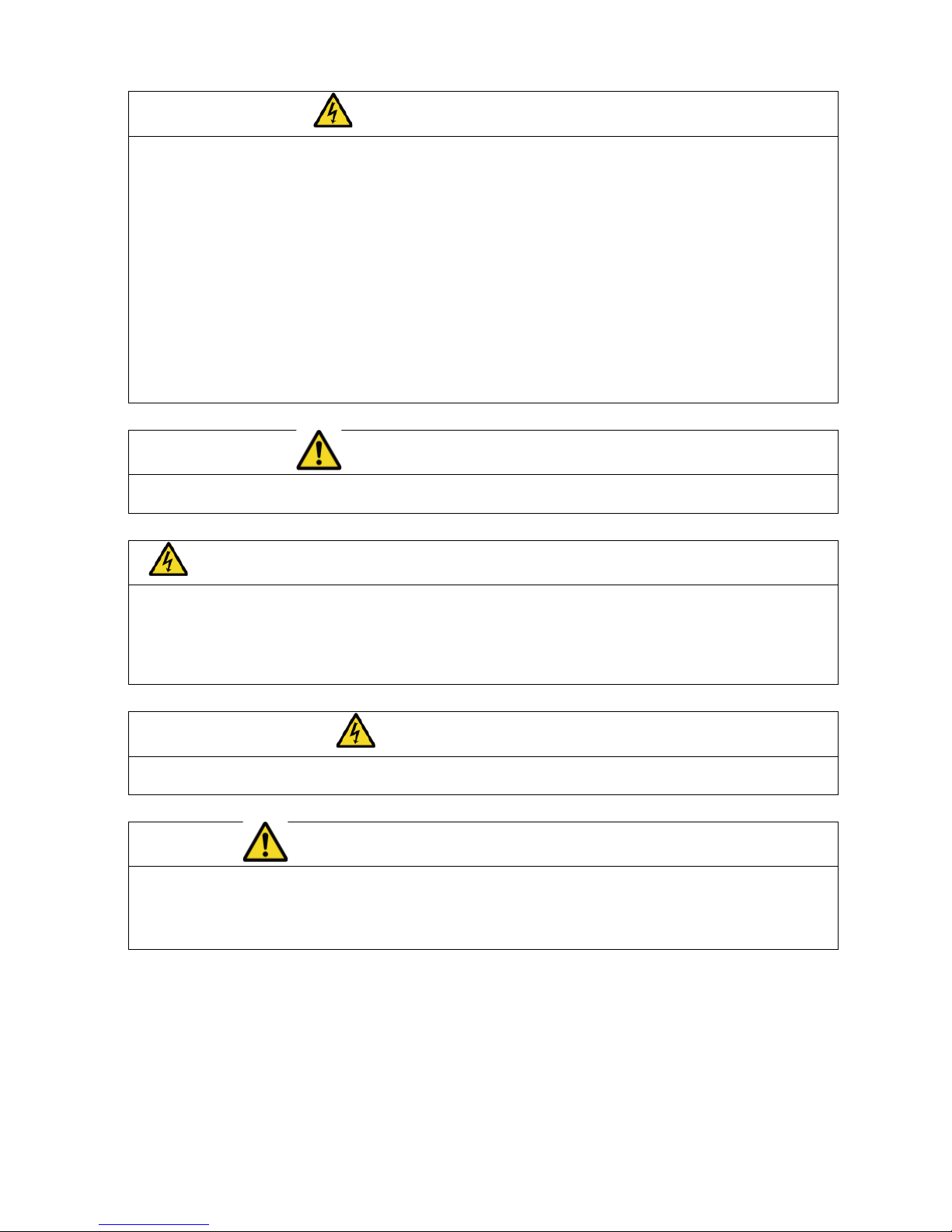

2.1Multifunctional input/output terminal specification

Multifunction input/output terminal

CC66-Z Terminal TB1

Terminal No.

Use

Description

PS

(2 Terminal)

Multifunction input

+12V power terminal

Output +12V of DC voltage

G

(2 Terminal)

GND terminal

Never connect GND terminal to the earth.

Never touch nor connect PS terminal and G terminal.

MI6

Multifunction input

terminal (6)

(Maximum input voltage DC24V/Maximum input current 3mA)

By input the signal in multifunction input terminal, the same

operation can be done as that of VF66B inverter console.

[In the initial condition, the VF66B inverter setting parameter for

the C area are set to:

・For multifunction input terminal (6), Preset speed selection 1

・For multifunction input terminal (7), Preset speed selection 2

・For multifunction input terminal (8), Preset speed selection 3

・For multifunction input terminal (9), Accel./decel time selection 1]

※See the instruction manual of the inverter for details of

multifunction input terminals.

MI7

Multifunction input

terminal (7)

MI8

Multifunction input

terminal (8)

MI9

Multifunction input

terminal (9)

P

Multifunction output

External power supply

connecting terminal

P terminal is connected to the external power supply(DC).

COM

Common potential

connection terminal

Never connect COM terminal to the earth.

MO3

Multifunction output

terminal (3)

(Max. voltage DC24V/Max. Output current 20mA)

Multifunction output terminal outputs the signal depends on the

situation of performance.

[In the initial condition, the followings are set by VF66 inverter

setting parameter:H area.

・For multifunction output terminal (3), not used.

・Multifunction output terminal (4), torque detected.]

※Refer to the instruction manual of the inverter for the details of a

multifunctional input terminal.

MO4

Multifunction output

terminal (4)

Multifunction input source mode/sink mode configuration jumper connector

CC66-Z Jumper

Connector

Connector

Use

Description

CN-SO

Source mode

・Setting source mode/sink mode is conducted by replacement of

jumper socket CN-SI, CN-SO.

・In replacement of jumper socket, please cut off the power supply.

[In the initial condition, the source mode is set.]

・In case of source mode, the switch etc. is connected between

multifunction input terminal (6) to (9) and PS terminal, and turn on/ off.

・In case of sink mode, the switch etc. is connected between multifunction

input terminal (6) to (9) and G terminal, and turn on / off.

For the detail information, please see the Chapter 4.

CN-SI

Sink mode

7

2.2 Analog input/output terminal specification

Analog input/output function

CC66-Z Terminal TB1

Terminal

No.

Use

Description

AIN2

Analog input/output

Analog input (2)

terminal

・Type of input can be selected from 0 to ±10V, 0 to 10V, 4 to 20mA by the

swift of SW1 and alternation of inverter setting parameter.

(Please refer to Chapter 5 for the change of the input range.)

・Input resistance is 150kΩin input analog voltage.

・Input resistance is 250Ωin input analog current.

[0 to 10V is set in the initial condition. ]

※See the instruction manual of the inverter for details of analog input

terminal(2).

AOT2

Analog output

(2) terminal

・By changing the VF66B inverter configuration parameters, the output range

of the analog output (2) terminal can be set to either 0 to 10V or 0 to ±10V

(max current 1mA).

[In the initial configuration, the inverter output current is set at “5V/inverter

rated current”.]

※See the instruction manual of the inverter for details of analog output

terminal (2).

G2

GND terminal

Never connect G2 terminal to the earth.

2.3PG input/output terminal specification

PG input/output function

CC66-Z Terminal TB2

Terminal No.

Use

Description

+12

+12V power terminal

Output +12V of DC voltage

G

(3 terminals)

GND terminal

Never connect GND terminal to the earth.

A

PG input terminal

Input A, B, U/Z, V, and W signal (complementary output) of 12 V power

PG respectively.

B

U/Z

V

W

PG-OUT

PG output terminal

Outputs a divided waveform of the PG A-signal.

2.4 CC-Link communication terminal specifications

CC-Link communication function

CC66-Z Terminal TB1

Terminal No.

Use

Description

DA

(2 terminals)

Communication signal

terminal

CC-Link communication terminal

Signal polarity of RS-485 (ISO/IEC8482)

DB

(2 terminals)

DG

Communication earth

terminal

RS-485(ISO/IEC8482)Signal line data earth terminal

SLD

Shield terminal of

communication cable

Connect the shield cable of a CC-Link communication cable

FG

Protective earth terminal

FG terminal is used when grounding all the station

8

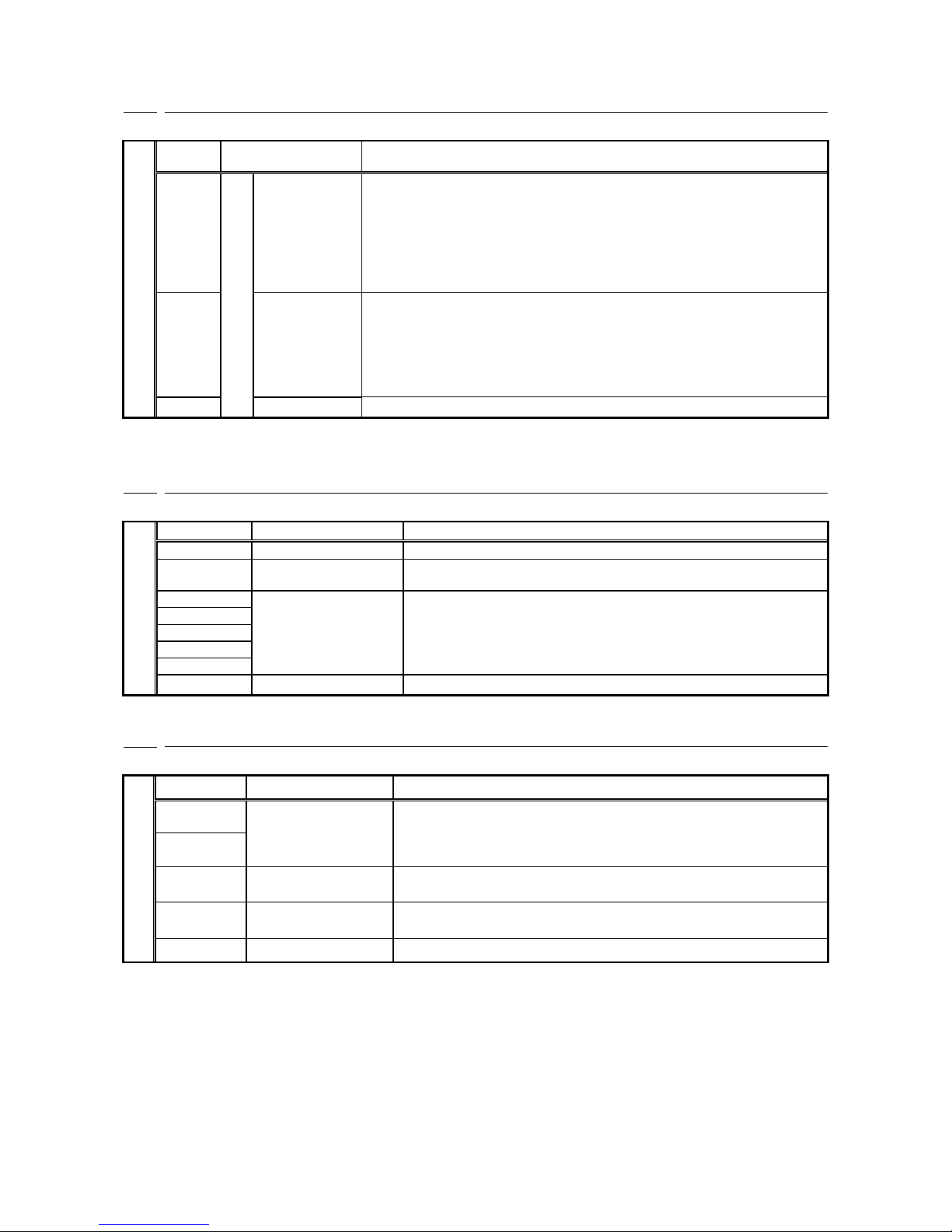

2.5 CC-Link communication specification

CC-Link communication specification of CC66-Z

Item

Specification

Communication protocol

CC-Link Ver1.1 CC-Link Ver2.0 Conformity

Station classification

Remote device station

Electrical charac-teristics of

physical layer

In conformity to RS-485(ISO/IEC8482)

+5V which insulated the power supply from the printed circuit board for inverter control

through the built-in DC/DC converter is supplied.

Maker code

0993H

The number of occupancy

sations, and a multiple

setup

Sets up by the console of the main part of a VF66B inverter.

(CC-Link Ver1.1 and CC-Link Ver2.0 change is possible)

At the time of CC-Link Ver1.1 selection Number of occupancy stations 1-4 station.

Multiple setup is twice, 4 times, and 8 times by the number one station fixation of occupancy

stations at the time of CC-LinkVer2.0 selection.

The number of statons of

a link

Ver1.1

One station occupancy

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:4 word

Two station occupancy

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:8 word

Three staion occupancy

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:12 word

Four station occupancy

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:16 word

Ver2.0

One-station occupancy

Twice

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:8 word

One-station occupancy

4 times

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:16 word

One-station occupancy

8 times

Remote input and output RX, RY: 32 points (fixation)

Remote register RWr, RWw:32 word

Transmission procedure

Half duplex transmission

Synchronization system

Frame synchronization

Modulation system

Base band system

Encoding system

NRZI (Non Return to Zero Inverted)method

Connection, wiring system

Terminal block 3 wires type

Connection cable

3 core twisted-pair cable with a shield with the cable only for CC-Link

Transmission speed and

transmission distance

To be set by built-in console of VF66B Inverter unit

156kpbs - A maximum of less than 1200m of the total extension of a cable

625kpbs -A maximum of less than 900m of the total extension of a cable

2.5Mpbs -A maximum of less than 400m of the total extension of a cable

5Mpbs -A maximum of less than 160m of the total extension of a cable

10Mbps -A maximum of less than 100m of the total extension of a cable

Cable length between stations of 20 cm or more

* The cable corresponding to CC-LinkVer1.1, 110ohms of terminator use

* Cable length between stations : Connection communication cable length between a master

station and a slave station or between slave stations

9

Number of connection

station

Number of connection is forming the following formula.

・(a+a2+a4+a8)+(b+b2+b4+b8)*2+(c+c2+c4+c8)*3+(d+d2+d4+d8)*4 ≦64

・(a*32+a2*32+a4*64+a8*128)+(b* 64+b2* 96+b4*192+b8*384)+

(c*96+c2*160+c4*320+c8*640)+(d*128+d2*224+d4*448+d8*896)≦8192

・(a* 4+a2* 8+a4* 16+ a8* 32)+(b* 8+b2* 16+b4* 32+b8* 64)+

(c*12+c2* 24+c4* 48+c8* 96)+(d*16+d2* 32+d4* 64+d8*128)≦2048

a : Number of a 1 time setup by one-station occupancy

b : Number of a 1 time setup by two-station occupancy

c : Number of a 1 time setup by three-station occupancy

d : Number of a 1 time setup by four-station occupancy

a2: Number of a 2 time setup by one-station occupancy

b2: Number of a 2 time setup by two-station occupancy

c2: Number of a 2 time setup by three-station occupancy

d2: Number of a 2 time setup by four-station occupancy

a4: Number of a 4 time setup by one-station occupancy

b4: Number of a 4 time setup by two-station occupancy

c4: Number of a 4 time setup by three-station occupancy

d4: Number of a 4 time setup by four-station occupancy

a8: Number of a 8 time setup by one-station occupancy

b8: Number of a 8 time setup by two-station occupancy

c8: Number of a 8 time setup by three-station occupancy

d8: Number of a 8 time setup by four-station occupancy

・16×A+54×B+88×C ≦2304

a:Number of offices of one-station occupancy

b:Number of offices of two-station occupancy

c: Number of offices of three-station occupancy

d: Number of offices of four-station occupancy

A: Number of a remote I/O station………………………………… Maximum of 64 sets

B: Number of a remote device station ……………………………… Maximum of 42 sets

C: Local station and the number of an intelligent device station…… Maximum of 26 sets

Setting of station number

1 to 64 : The number of offices is set up with the rotary switch on CC66-Z.

Communication control

system

Broadcasting polling

Error check system

CRC(X16+X12+X5+1)

Correspondence service

Cyclic transmission

Extended cyclic transmission

Cable length relief between stations

2.6Other

Other standard specifications apply to VF66B inverter correspondingly. For more details, please refer to the

instruction manual of the inverter.

DANGER [Wiring]

Before wiring, make sure the power is OFF.

Failure to do so may cause an electric shock or a fire.

Substitution of Jumper socket is performed after certainly turning off an inverter.

Failure to do so may cause an electric shock, personal injury, equipment failure or malfunction.

CAUTION [Wiring]

G terminal, G terminal, and G2 terminal are not connected to a grounding by any means.

Doing so may cause equipment failure or damage.

Never connect or allow contact between the PS and G terminals.

Doing so may cause equipment failure or damage.

10

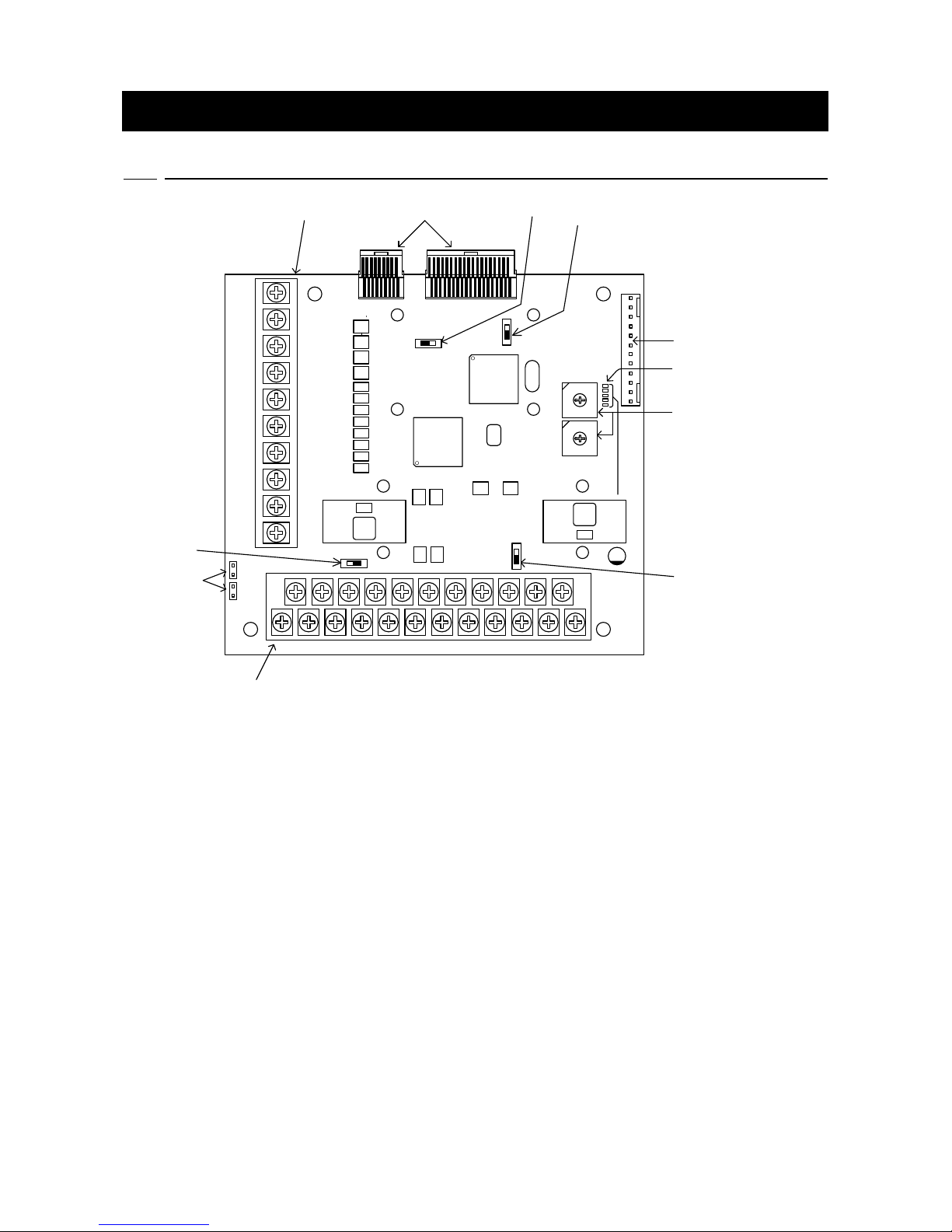

Chapter 3 Description of substrate

3.1 Name of each part

PSPSMI8GG2PCOMDADGSLDFG

MI6MI7MI9GAIN2AOT2MO3MO4DADBDB

CN-SI

CN-SO

PGOUTGWVU/ZGGBA+12

CC66-Z

TB1

TB2

SW1

SW3

SW2

SW4

LED1

LED3

LED5

LED6

LED4

CN3

CN1CN2

①

②

③

④

⑤

⑦

⑥

⑪,⑫,⑬,⑭,⑮

⑩

⑧

⑨

SW5

SW6

Figure3.1 CC66-Z substrate

①Connector to VFC66-Z (CN1,2)

②PG frequency dividing output switch (SW4)

③PG signal ON/OFF switch (SW2)

④Connector to external extension option“IOEXT66” (CN3)

⑤Multi function input/output, Analog input/output terminal block (TB1)

⑥Analog input(2) signal characteristic switching switch (SW1)

⑦Multi functional input signal characteristic switching jumper connector (CN-SI, CN-SO)

⑧PG input/output terminal block (TB2)

⑨Terminator (110ohms) changeover switch (SW3)

⑩CC-Link station number setting switch (SW5, SW6)

⑪Power supply LED for CC-Link commnucation (LED1, PWR, green)

⑫CC-Link communication operation LED (LED3, RUN, green)

⑬CC-Link communication transmitting LED (LED5, SD, green)

⑭CC-Link communication receiving LED (LED6, RD, green)

⑮CC-Link communication unusual LED (LED4, ERR, red)

As connector connecting to ④, please use housing :5051-12, terminal coated gold :2759G or 2759PBG

producted by Molex. For connection to CN3 and usage of CN3 and so on, refer to the instruction manual

about IOEXT66.

11

3.2 CC66-Z switches

The switch on CC66-Z can be switched and various functions can be changed.

Each kind of function of switch on CC66-Z

Name of

switch

Use

Description

SW1

Analog input(2) signal

characteristic switching

switch

Switch input signal characteristic of analog input (2) terminal.

・0 to 10V, 0 to ±10V input when the switch is OFF.

・4 to 20mA input when the switch is ON.

[In the initial condition, the switch is set to OFF.]

※When you switch input range, please change the parameter of VF66B inverter.

For more detail, please refer to chapter 5.

SW2

PG signal ON/OFF

switch

Switch ON/OFF PG signal.

・PG signal is no effect when the switch is OFF.

・PG signal is available when the switch is ON.

[In the initial condition, the switch is ON.]

SW3

Terminator changeover

switch

ON/OFF of a terminator can be switched.

・A terminator is separated for a switch in OFF.

・A terminator is connected for a switch by ON.

SW4

PG frequency dividing

output switch

Switch output of PG frequency dividing signal.

・1/4 frequency dividing signal is output when the switch is side of 3.

・1/2 frequency dividing signal is output when the switch is side of 1.

[In the initial condition, the switch is set to position “3”.]

SW5,SW6

CC-Link station number

setting switch

Station number of CC-Link is set up.

・Please set up a station number by the decimal number of double figures, and it

is SW5 about a low ranking beam, and set up the beam of a higher rank in

SW6.

・A station number should set up 01-64.

DANGER [Switch]

Change of a switch is performed by certainly turning off the inverter.

Failure to do so may cause an electric shock, personal injury, equipment failure or malfunction.

12

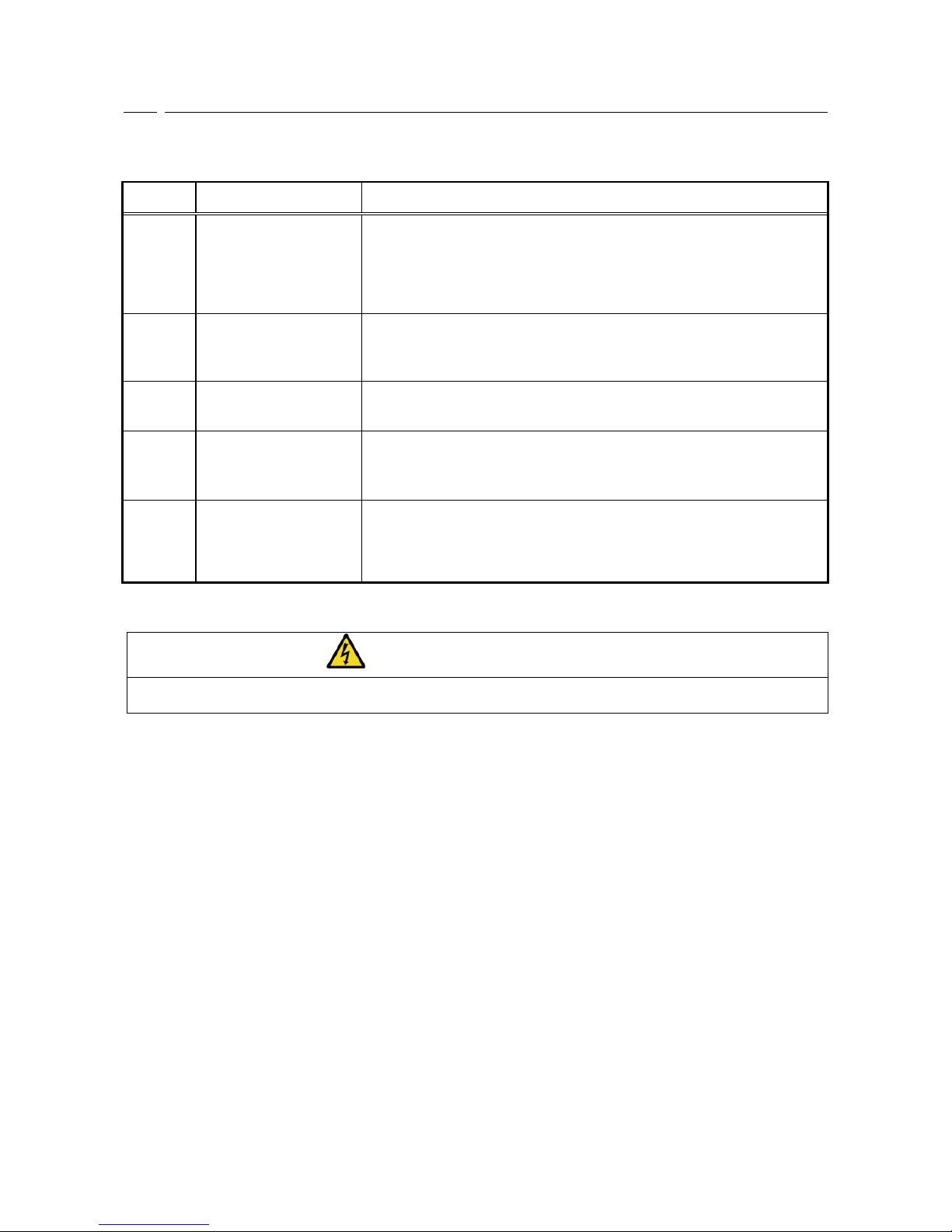

3.3 Installation of CC66-Z

サポート

オプション基板

コネクタ

SET66-Z基板

VFC66-Z基板

Figure 3.2 CC66-Z installation position (VF66B-2R222)

*For information about opening and closing the front cover, please refer to the instruction manual of the

inverter.

(1) Confirm that the power is off before performing any work.

(2) Install the CC66-Z board in the location designated by the dotted lines shown in Figure 3.2. (The figure

shows the VF66B-2R222 model, however, the installation location is the same for other models.)If another

optional circuit board is already installed, remove it by following the procedure described below.If another

optional circuit board is not already installed, skip to (6).

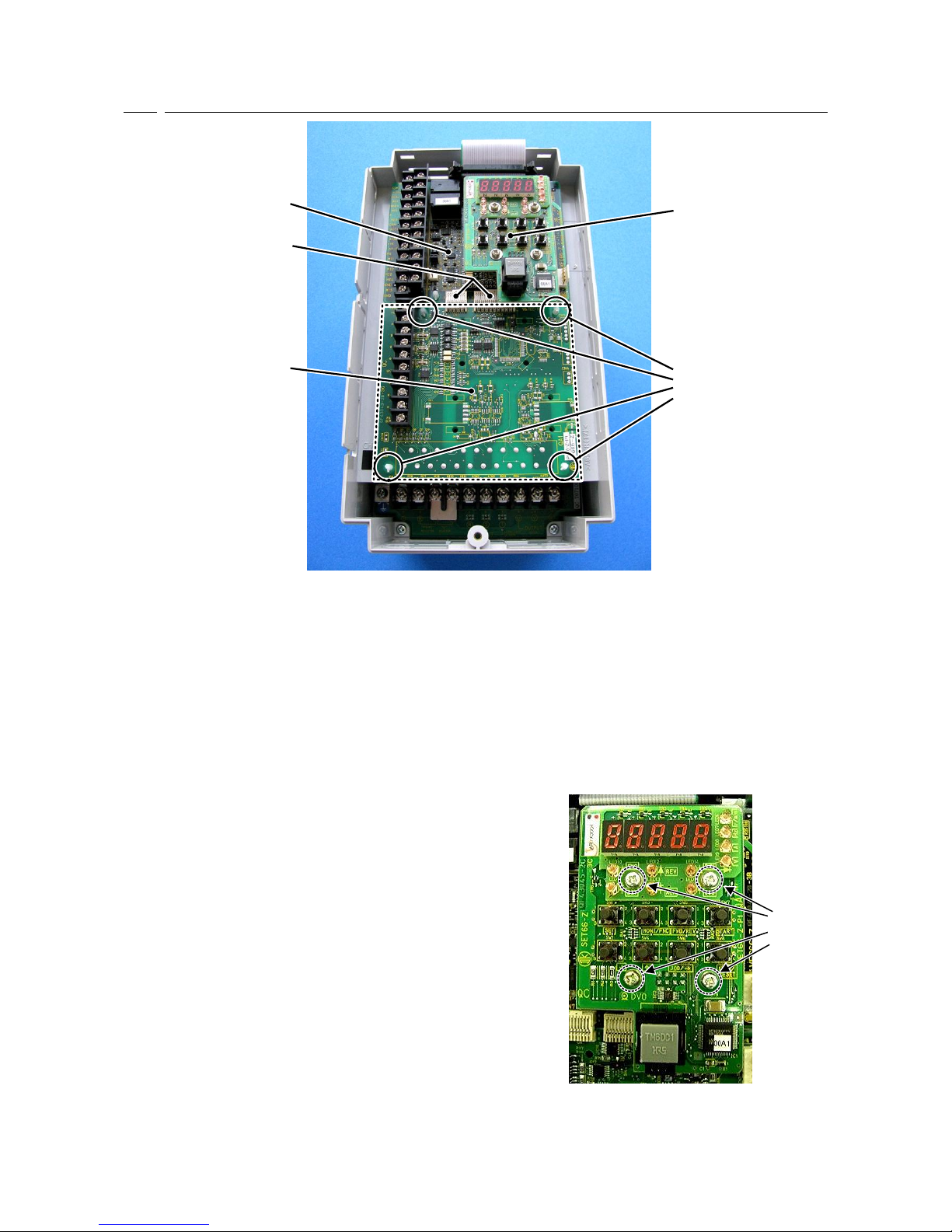

(3) In order to safely remove the optional circuit board, first

remove the SET66-Z board. Remove the 4 screws

indicated by the circles in the figure on the right. Pull the

SET66-Z board away from the VFC66-Z board in order to

detach it.

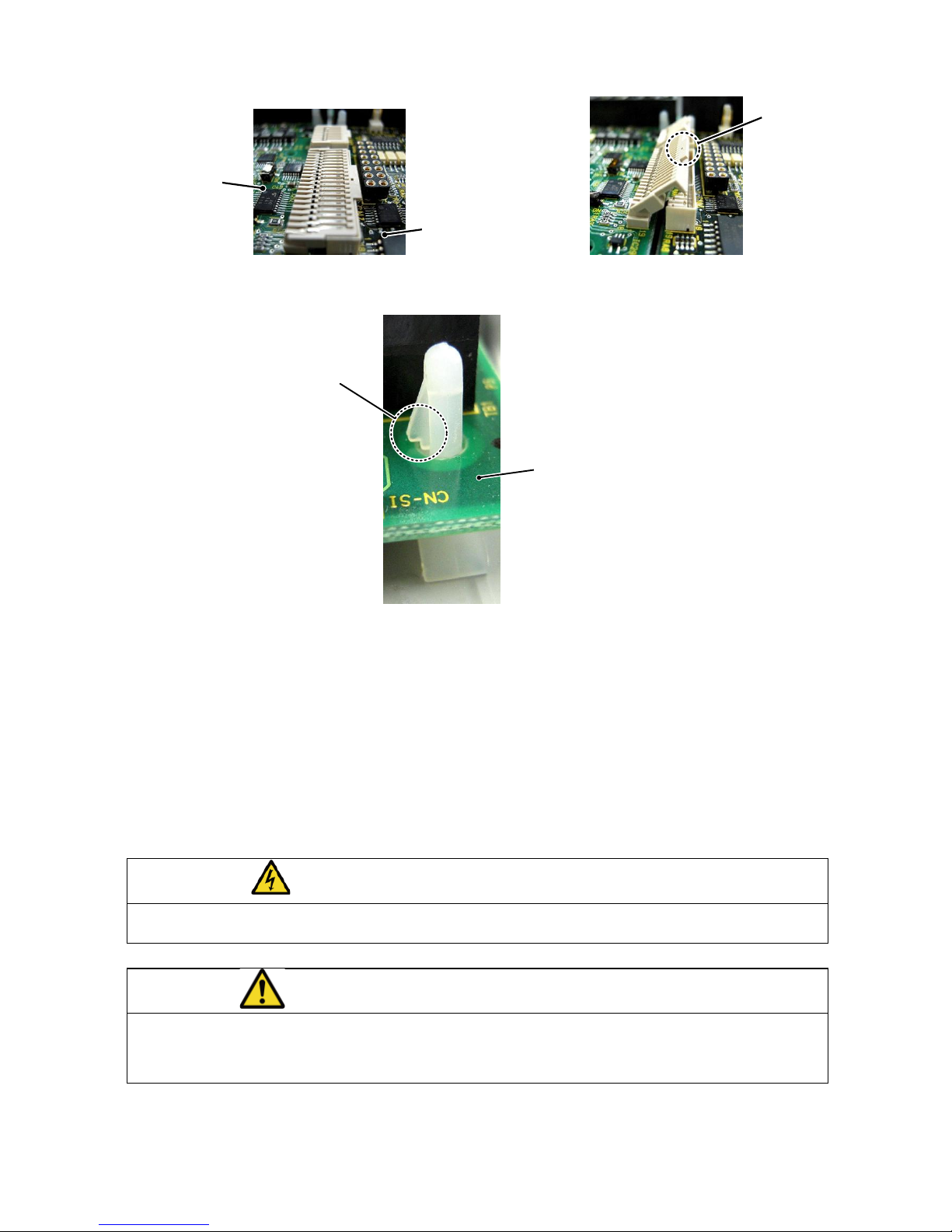

(4) Next, release the two connectors between the VFC66-Z

board and the optional circuit board.Figure 3.4 (a) shows

the connector in its engaged position.Pull up the tab to

release the connector as shown in Figure 3.4 (b).

(5) 4 board supports are included to mount the optional

circuit board to the inverter housing, as indicated by the

circles in Figure 3.2. Press down on the board support

locking hooks as shown in Figure 3.5 to remove the

optional circuit board.

ねじ

Figure 3.3 SET66-Z circuit board

Screws

VFC66-Z circuit board

Connectors

Optional circuit board

SET66-Z circuit board

Supports

13

つまみ

オプション基板

VFC66基板

(a) Locked connector (b) Connector tab

Figure 3.4 Connector

爪

オプション基板

Figure 3.5 Support locking hook

(6) Align the four holes of the CC66-Z board with the 4 board supports indicated by the circles in Figure 3.2.

Push down on the board until the support locking hooks snap into place as shown in Figure 3.5.

(7) Align the tabs (shown in Figure 3.4 (b)) of the CC66-Z board connectors CN1 and CN2 with the VFC66-Z

board connectors CN7 and CN4. Press down on the tabs to engage with the connectors. Once the

connectors are correctly joined, it will look like Figure 3.4 (a).The movable part of the connector has some

elasticity and if the joint is weak, it may become disconnected. Ensure that is it properly locked in place.

(8) Install the SET66-Z board to its original position.

(9) Return the front cover to its original position.

DANGER [Installation/Removal]

Always confirm that the power is off before installing/removing any circuit boards.

Failure to do so may cause an electric shock, personal injury, equipment failure or malfunction.

CAUTION [Installation/Removal]

Avoid excess connection and disconnection of the connectors.

The connector mounting area may become loose, leading to problems such as poor connections.

Do not attempt to insert any object other than a compatible connector.

The connector mounting area may deform, leading to problems such as poor connections.

Optional circuit board

VFC66-Z circuit board

Optional circuit board

Locking hook

Tab

14

3.4 LED operation

・LED1 operation

When operation of CC66-Z of an inverter during a stop or operation is normal, LED1 blinks at intervals of

about 1 second. Even if it switches on a power supply, when LED1 does not blink normally, failure of CC66-Z

can be considered.

・LED3 operation

When normal reception of the refreshment & polling from a master station is carried out normally, LED3

turns on CC66-Z. Refreshment & polling is data periodically transmitted to a slave station from a master

station, and if this communication breaks off fixed time, LED3 will go out.

・LED4 operation

The light is put out when LED4 has normal CC-Link communication. The light is switched on at the case

where CC-Link communication has abnormalities, and the time of a setup of the inaccurate station by SW5

and SW6 (a station number 0 and the station number containing the number of occupancy stations are 65 or

more).

・LED5 operation

LED5 is turned on when CC66-Z has taken out CC-Link communication transmitting data.

・LED6 operation

LED6 is turned on when CC66-Z has detected CC-Link communication receiving data.

CAUTION [SafetyPrecautions]

If LED1 is not operating normally, the CC66-Z or VFC66-Z board may be malfunctioning.

If this is the case, please contact us immediately.

15

Chapter 4 Multifunction input/output specification

4.1 Multifunction input

CC66-Z

TB1

PS

4.7kΩ

MI7

MI6

4.7kΩ

MI8

4.7kΩ

MI9

4.7kΩ

G

CN-SO

CN-SI

Multifunction

input 6

Multifunction

input 7

Multifunction

input 8

Multifunction

input 9

External power source

(+12~+24V)

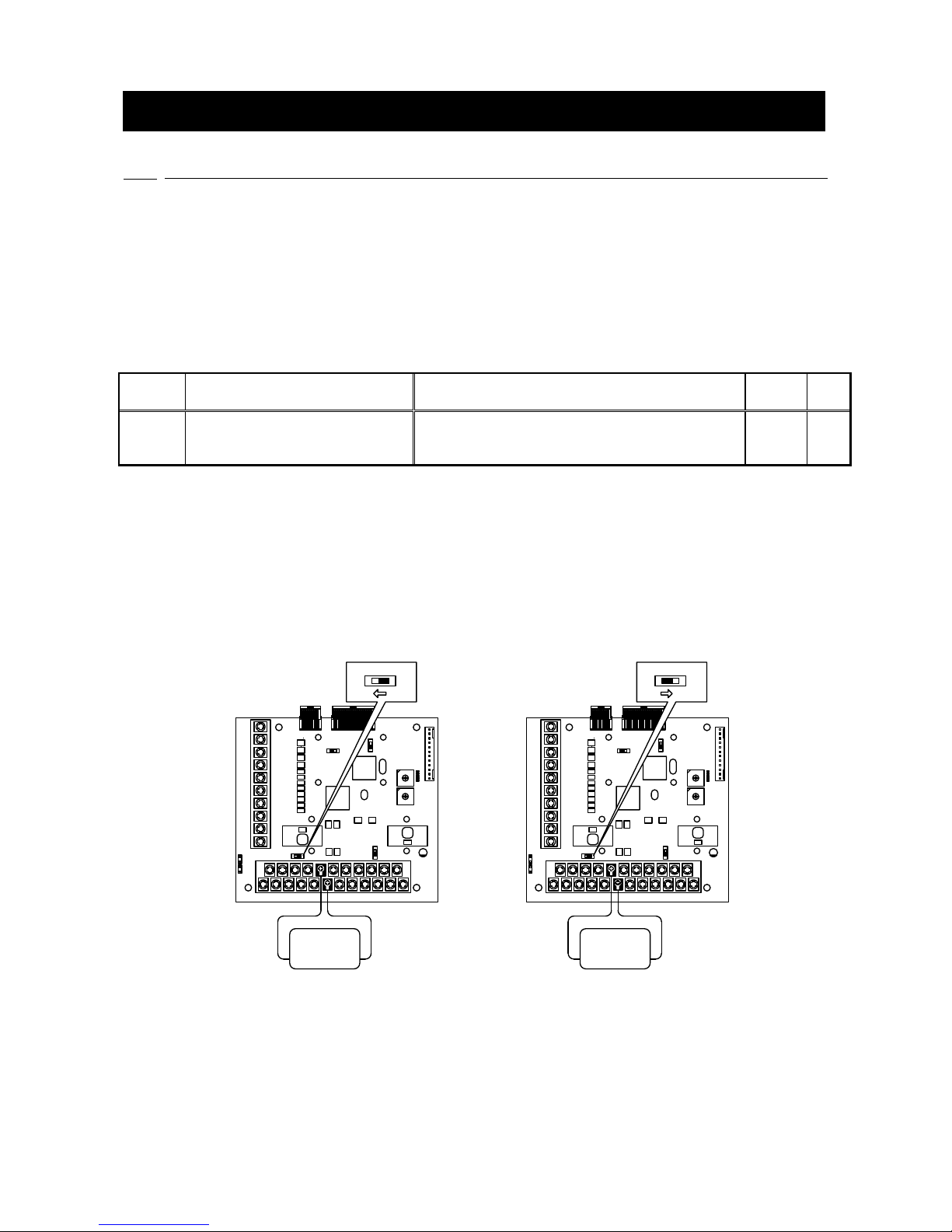

1. Source mode (with internal power source) 2. Source mode (with external power source)

TB1

PS

4.7kΩ

MI7

MI6

4.7kΩ

MI8

4.7kΩ

MI9

4.7kΩ

G

CN-SO

CN-SI

Multifunction

input6

Multifunction

input7

Multifunction

input8

Multifunction

input9

Externalpowersource

(+12~+24V)

CC66-Z

3. Sink mode (with internal power source) 4. Sink mode (with external power source)

Figure 4.1 Multifunction input connections

The CC66-Z can use the VF66B inverter multifunction input. The above figures show typical multifunction

input signal connection methods. The maximum allowable voltage is 24V and the maximum allowable

current for any one terminal is 3mA. For more information about the functions of the individual

multifunction input terminals, please refer to the instruction manual of the inverter.

The multifunction input signal can be set to either source mode or sink mode and an internal power source

or external power source can be chosen for the inverter. In the initial configuration, it is set to source mode.

To switch between source mode and sink mode, place a jumper shunt on either the CC66-Z jumper connector

CN-SO (source mode) or CN-SI (sink mode).

CC66-Z

TB1

PS

4.7kΩ

MI7

MI6

4.7kΩ

MI8

4.7kΩ

MI9

4.7kΩ

G

Internal power source

(12V)

CN-SO

CN-SI

Multifunction

input 6

Multifunction

input 7

Multifunction

input 8

Multifunction

input 9

TB1

PS

4.7kΩ

MI7

MI6

4.7kΩ

MI8

4.7kΩ

MI9

4.7kΩ

G

Internal power source

(12V)

CN-SO

CN-SI

Multifunction

input 6

Multifunction

input 7

Multifunction

input 8

Multifunction

input 9

CC66-Z

16

Multifunction input related inverter parameters

Display

Items

Item Selection

Default Data

Unit

c-00

Multifunction input

place selection

0: Terminal block

1: Digital communication option

0: Terminal block

-

c-06

Multifunction input

terminal (6)

function selection

0: Preset frequency selection 1 (V/f mode)

Preset rotation speed selection 1 (vector mode)

1: Preset frequency selection 2 (V/f mode)

Preset rotation speed selection 2 (vector mode)

2: Preset frequency selection 3 (V/f mode)

Preset rotation speed selection 3 (vector mode)

3: Acceleration/deceleration time selection 1

4: Acceleration/deceleration time selection 2

5: Frequency UP command (MRH mode) (V/f mode)

Rotation speed UP command (MRH mode) (vector

mode)

6: Frequency DOWN command (MRH mode) (V/f mode)

Rotation speed DOWN command (MRH mode) (vector

mode)

7: Frequency hold (V/f mode)

Rotation speed hold (vector mode)

8: S-pattern acceleration/deceleration prohibition

9: Max. frequency reduction (V/f mode)

Max. rotation speed reduction (vector mode)

10: Droop control disabled

11: No function (V/f mode)

Speed/torque control selection (vector mode)

12: Forward/reverse operation command selection

13: DC brake command

14: No function (V/f mode)

Initial excitation command (vector mode)

15: External failure signal 1 (protection relay 86A enable)

16: External failure signal 2 (protection relay 86A enable)

17: External failure signal 3 (protection relay 86A enable)

18: External failure signal 4 (protection relay 86A enable)

19: External failure signal 1 (protection relay 86A disabled)

20: External failure signal 2 (protection relay 86A disabled)

21: External failure signal 3 (protection relay 86A disabled)

22: External failure signal 4 (protection relay 86A disabled)

23: Trace back external trigger

24: Second set-up block selection

25: Emergency stop (B contact)

26: No function

27: Frequency commanding terminal block selection (V/f

mode)

Rotation speed commanding terminal block selection

(vector mode)

28: No function

29: Operation command [reverse] (STARTR)

30: Jog command [forward] (JOGF)

31: Jog command [reverse] (JOGR)

32: Emergency stop (A contact)

33: Protection reset (RESET)

34: External signal input 1

35: External signal input 2

36: External signal input 3

37: External signal input 4

0:Preset frequency

selection 1

-

c-07

Multifunction input

terminal (7)

function selection

1:Preset frequency

selection 2

c-08

Multifunction input

terminal (8)

function selection

2:Preset frequency

selection 3

c-09

Multifunction input

terminal (9)

function selection

3:Acceleration/

deceleration time

selection 1

The multifunctional input of CC66-Z besides the input from a terminal block can be inputted from

CC-Link communication. Either can be chosen with the inverter setting parameter c-00. Refer to a

"CC66-Z communications protocol description" for the details of the multifunctional input by

communication.

Moreover, the multifunctional input signal of CC66-Z can be used as an input relay of the built-in PLC

function of VF66B inverter. For more information, refer to a "CC66-Z communications protocol description"

and the instruction manual of the inverter, and the description of VF66 PCTool.

17

DANGER [Wiring]

Before wiring, make sure the power is OFF.

Failure to do so may cause an electric shock or a fire.

Substitution of Jumper socket is performed after certainly turning off an inverter.

Failure to do so may cause an electric shock, personal injury, equipment failure or malfunction.

CAUTION [Wiring]

G terminal and G2terminal are not connected to a grounding by any means.

Doing so may cause equipment failure or damage.

Never connect or allow contact between the PS and G terminals.

Doing so may cause equipment failure or damage.

4.2 Multifunction output

1. Connection with PLC (Source mode)

CC66-Z

Power source

(+24V max) TB1

PLC input unit

COM

MO4

MO3

P

2.ConnectionwithPLC(Sinkmode)

CC66-Z

Powersource

(+24Vmax)

TB1

PLCinputunit

COM

MO4

MO3

P

3. Connection with Relay

CC66-Z

Power source

(+24V max) TB1

COM

MO4

MO3

P

RY

RY

+

+

Figure 4.2 Multifunction output connections

The CC66-Z can use the VF66B inverter multifunction output. The above figures show typical multifunction

output signal connection methods. Multifunction output is open corrector output of transistor. In order to use it,

DC power supply are required for the exterior. The maximum allowable voltage is 24V and the maximum

allowable current for any one terminal is 20mA. For more information about the functions of the individual

multifunction output terminals, please refer to the instruction manual of the inverter.

18

Multifunction output related inverter parameters

Display

Items

Item Selection

Default Data

Unit

H-02

Multifunction output

terminal (3)

function selection

0: not used

1: Frequency detection (1) (V/f mode)

( Frequency = detection setting )

Motor speed detection (1) (vector mode)

( Motor speed = detection setting )

2: Frequency detection (1) (V/f mode)

( Frequency ≧detection setting )

Motor speed detection (1) (vector mode)

( Motor speed ≧detection setting )

3: Frequency detection (1) (V/f mode)

( Frequency ≦detection setting )

Motor speed detection (1) (vector mode)

( Motor speed ≦detection setting )

4: Frequency detection (2) (V/f mode)

( Frequency = detection setting )

Motor speed detection (2) (vector mode)

( Motor speed = detection setting )

5: Frequency detection (2) (V/f mode)

( Frequency ≧detection setting )

Motor speed detection (2) (vector mode)

( Motor speed ≧detection setting )

6: Frequency detection (2) (V/f mode)

( Frequency ≦detection setting )

Motor speed detection (2) (vector mode)

( Motor speed ≦detection setting )

7: Reach setting

8: Torque detection

9: Torque detection (absolute value)

10: Power failure

11: Overload pre-alarm

12: Restart mode

13: In reverse operation

14: Protection operation code

15: not used

16: In operation

17: Extended schedule function(Usually, not set up)

18: Timer 1 setup time passes

19: Timer 2 setup time passes)

20: 2nd set-up block selected

21: Cooling fan failed

23: DB abnormal state

0:not used

-

H-03

Multifunction output

terminal (4)

function selection

1:Torque

detection

When connecting a PLC input unit outside, CC66-Z can choose a connection in sink mode and source mode.

Recommends using a twist line to a product line of PLC and CC66-Z. When connecting a relay externally, a coil

uses a relay of a D.C. operation (for example, OMRON: G7T-112S-DC24V etc.). Since CC66-Z builds in the

reflux diode which controls surge voltage, it certainly connects the + side terminal of external power source to

P terminal of a terminal block in CC66-Z.

The CC66-Z multifunction output signal can also be used as the VF66B inverter built-in PLC function output

relay. For more information, refer to a "CC66-Z communications protocol description" and the instruction

manual of the inverter, and the description of VF66 PCTool.

CAUTION [Wiring]

Before wiring, make sure the power is OFF.

Failure to do so may cause an electric shock or a fire.

COM terminal and G terminal in terminal block 1 are not connected to a grounding by any means.

Doing so may cause equipment failure or damage.

19

5.1 Analog input (2)

The analog input (2) to the terminals on CC66-Z can be used as the input value to the rotation speed

command value (or frequency command value), torque command value, and built–in PLC function by analog

input (2) function.

For usage of analog input(2) function correctly, the correct VF66B inverter parameter setting as mentioned

below is required. Refer the instruction manual of the inverter together. Furthermore, for the built-in PLC

function, please refer VF66 PC Tool manual.

Before usage of analog input(2), please conduct the adjustment of gain as mentioned below.

Inverter setting parameter of analog input (2) input characteristics

Display

Item

Set-up range

(Item selection)

Default

Data

Unit

G-03

Analog input(2) characteristics

selection

0:0 to ±10V

1:0 to 10V

2:4 to 20mA

1

―

* If setting the torque command value as analog input (2), set this to “0”. Only the 0 to ±10V voltage input characteristic can

be used.

The analog signal input into analog input (2) should be connected between the [AIN2] and [G2] terminals of

the CC66-Z terminal block TB1, as shown in the following figures. The input analog signal characteristics can

be chosen as either “voltage input 0 to ±10V”, “voltage input 0 to 10V” or “current input 4 to 20mA”, as shown

in the above table. Choose an appropriate setting that matches the characteristics of the input signal. Also set

the SW1 switch as shown in the following figures.

AIN2 G2

CC66-Z

TB1

Variable

voltage

source

SW1

O

N

OFF

SW1

AIN2

G2

CC66-Z

TB1

Variable

current

source

SW1

O

N

ON

SW1

(a) Voltage input (b) Current input

Figure 5.1 Connection of analog input (2)

Chapter 5 Analog input/output function

Table of contents

Popular Inverter manuals by other brands

INHENERGY

INHENERGY HI-3K-SL user manual

Growatt

Growatt SPF 4KT HVM user manual

Northern Lights

Northern Lights IM1000 installation manual

GE

GE VAT300 Series quick guide

Kohler

Kohler l654 Service manual

Generac Power Systems

Generac Power Systems 004090-2, 004091-2, 004092-2, 004093-2, 004094-2, 004095-2, 004096-2, 004097-2, 004474-0, 004124-1, 004125-1, 004126-1... owner's manual