IPUP T100L / EC100L Instruction Manual

http://www.toyota-industries.com/ TOYOTA INDUSTRIES CORPORATION

9

1. INTRODUCTION

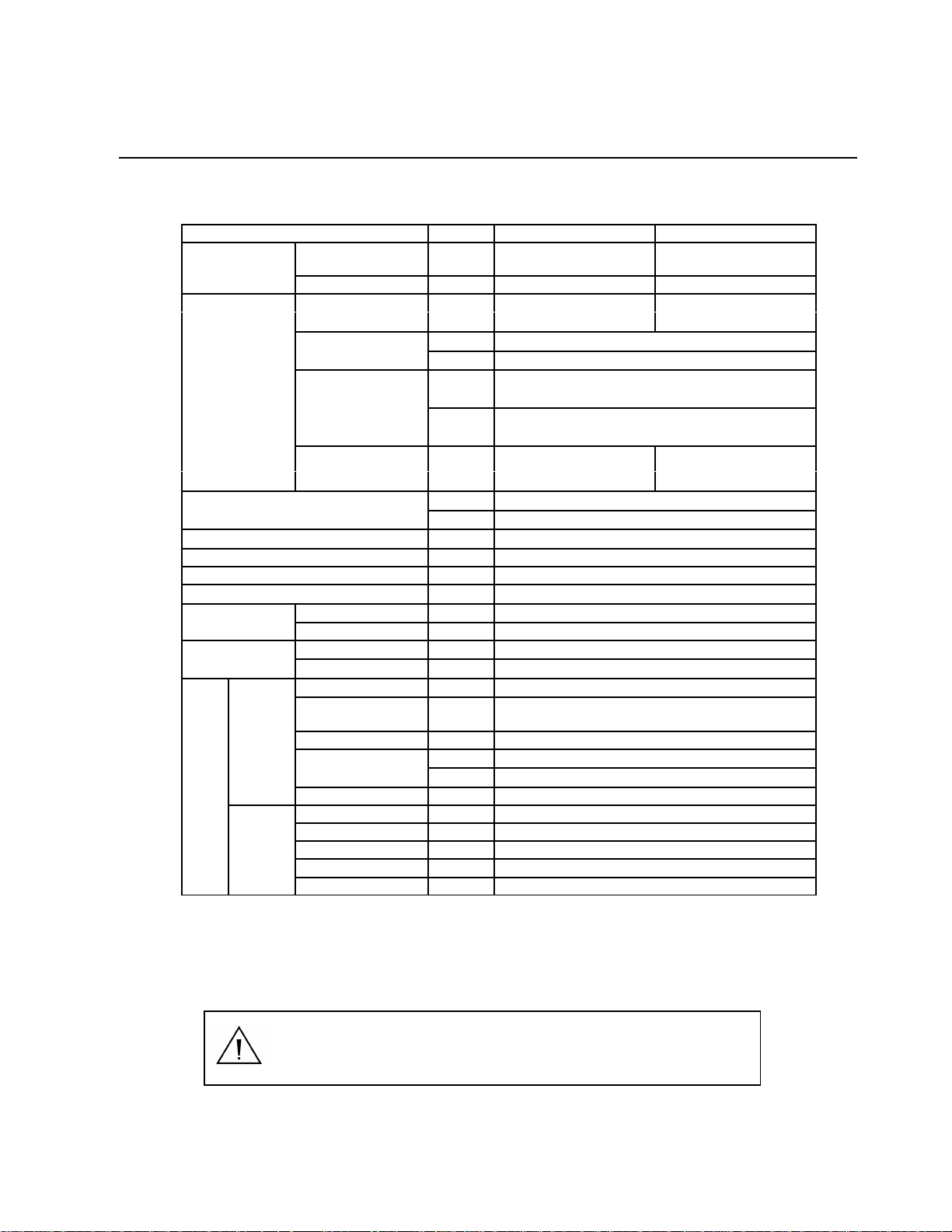

1-3. Technical Data

1-3-1. Technical data table

1) The lubricant is added to the appropriate level at the factory. Never change the lubricant

level.

2) Cooling water should satisfy water quality standard of Japan Refrigeration and Air

Conditioning Industry Association. Refer to “3-8-1characteristics of cooling water”

3) Voltage tolerance: ±10%

The above utilities are required for the pump. Be careful as

performance and reliability are not guaranteed unless the

requirements listed are satisfied.

Item Unit IPUP T100L EC100L

Dimensions

(LxHxW) mm 590×300×280 590×300×280

Dimensions and

weight Weight kg 105 104

Maximum revolution

(Default rpm setting)

r/min 5250 4650

m3/h 100

Peak

pumping speed l/min 1670

Pa 1.2

Ultimate pressure

(at Default rpm

setting) Torr 0.009

at ultimate pressure

kW 1.3 0.55

MPa 6.67×10-3Maximum continuous inlet pressure

(at Default rpm setting) Torr 50

Noise level (at ultimate pressure)dB(A) <55

Lubricant quantity cm3110(1)

Inlet flange NW50

Exhaust flange NW25

Ambient temperature

°C 15 to 30

Environment Humidity % Max 90 (no condensation)

Pollution degree 2

UL classification

Installation Category

II

Connector Inch 1/4

Type Non-corrosive industrial water or treated soft

water(2)

Flow Rate L/min Min. 1.5

kPaG Min300 Max700

Supply pressure Bar Min3.0 Max7.0

Cooling

water

Temperature °C 10 to 25

Number of phases

3

Input voltage V 208(3)

Frequency Hz 50/60

Full load current A 12

Power

supply

Max. power capacity

kVA 4.6