Printed in the Federal Republic of Germany TR-Electronic GmbH 2017, All Rights Reserved

06/26/2018 TR - ELA - BA - GB - 0021 - 04 Page 3 of 26

Table of contents

Table of contents................................................................................................................................ 3

Amendment-index.............................................................................................................................. 5

1 General ............................................................................................................................................. 6

1.1 Scope...................................................................................................................................... 6

1.2 Relevant directives and standards ......................................................................................... 7

1.3 Used abbreviations / Terms.................................................................................................... 8

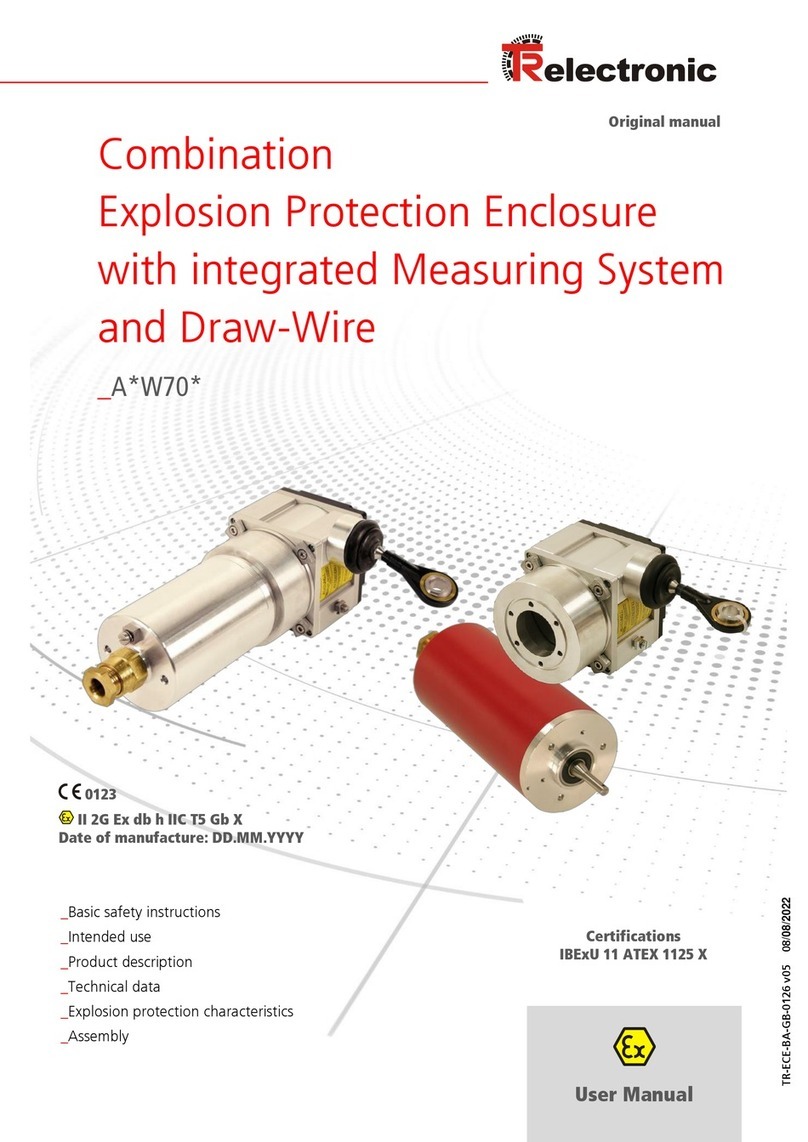

1.4 Product description................................................................................................................. 8

2 Basic safety instructions................................................................................................................ 9

2.1 Symbol- and note definition.................................................................................................... 9

2.2 Obligation of the operator prior to commissioning.................................................................. 10

2.3 General dangers with the use of this product......................................................................... 10

2.4 Intended use........................................................................................................................... 11

2.5 Non-intended use ................................................................................................................... 11

2.6 Warranty and liability .............................................................................................................. 12

2.7 Organizational measures........................................................................................................ 12

2.8 Personnel selection and -qualification; basic obligations....................................................... 13

2.8.1 Electrical installations design, device selection and erection................................. 13

2.8.2 Inspection, maintenance and repair ....................................................................... 13

2.9 First commissioning / Commissioning.................................................................................... 14

2.10 Assembly, installation and dismantling................................................................................. 14

2.11 Inspection, maintenance and repair..................................................................................... 15

2.12 Special conditions for safe use, marking "X"........................................................................ 16

3 Transport / Storage ......................................................................................................................... 17

4 Technical data.................................................................................................................................. 18

4.1 Power supply.......................................................................................................................... 18

4.2 Mechanical characteristics ..................................................................................................... 18

4.3 Environmental conditions........................................................................................................ 18

4.4 Enclosure materials................................................................................................................ 19

4.5 Explosion protection characteristics....................................................................................... 20

4.5.1 Ex-labeling, gas ...................................................................................................... 20

4.5.2 Ex-labeling, dust ..................................................................................................... 21

5 Assembly.......................................................................................................................................... 22

5.1 Mechanics profile- housing design......................................................................................... 22