Trackunit TU600-x Supplement

NOTE: Model ID TU600-x (LTE Cat M1 /Cat NB1 / 2G)

Short guide : TU600-x

Version

0

.

3

,

January 2020

45,5 mm (W)

17,9

mm (

H

)

122,3 mm (L)

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 2

Index

Practical Advice .......................................................................................... 3

Machine and vehicle guidelines for correct wiring ....................................... 4

Installation example .................................................................................... 5

Functionality check: LED on the unit ........................................................... 6

Installation check and update using “Verify my Trackunit” .......................... 7

Input filtering (INFILT) ................................................................................. 8

CAN bus termination resistor ...................................................................... 9

Troubleshooting ........................................................................................ 10

Product specifications ............................................................................... 11

Temperature range ................................................................................... 12

Mechanical specifications ......................................................................... 12

Regulatory information and precautions.................................................... 13

Approvals and Certifications ..................................................................... 15

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020

3

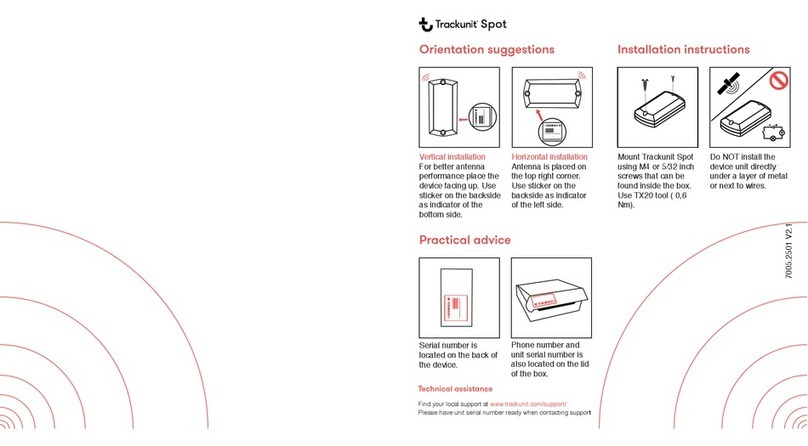

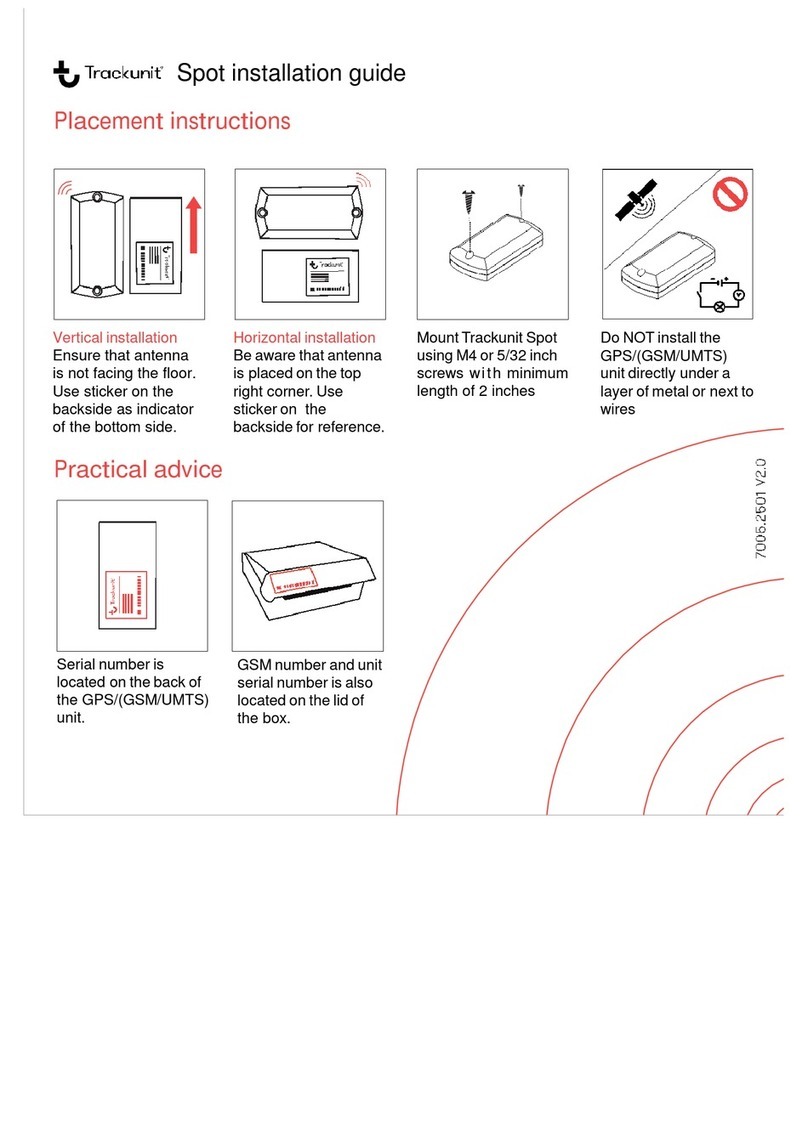

Practical Advice

1. Save important number

2. In tallation i be t done out ide

3. Correct po itioning of the unit

The serial number is

located on the unit.

The mobile number

and unit serial number

are located on the box

label. It can be peeled

off and saved for later

use.

Do not perform

installation inside a

building.

Install the unit outside

for better PS and

SM/UMTS signal.

Position the unit as

shown for optimal

signal conditions.

Avoid installing the unit

directly under a layer of

metal or next to wires.

S/N xxxxxx

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 4

Machine and vehicle guideline for correct wiring

Wire color

Description

Power Connect to machine battery through a fuse (mandatory)1

round Connect to ground (mandatory)

Digital input 1 Can be connected to hour counter. Optional input2

Digital input 2 Connect to the ignition signal (mandatory for vehicles and machines)1

Digital input 3 Optional input1

Digital input 4 Can be used for INFILT function. Optional input2

Digital output 1 Can be used to control a relay3/4

CAN High Connect to CAN High

CAN Low Connect to CAN Low

1 – Wire input M8 connector for access control and temperature sensor

1: Supply voltage range 12–48V

2: Active/high when min. 9,5V DC at input

3: Max. load 200 mA

4: Do NOT use this output to switch off vehicles and machines during operation or driving

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 5

In tallation example

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 6

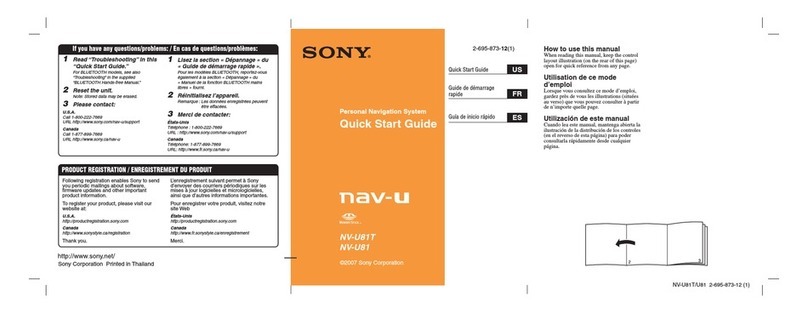

Functionality check: LED on the unit

Status

LED mode

LED color

Status indication

Red flashing light and constant

green light in LED

- Mobile network is OK and PS

has valid satellite position

!

No light in LED

- No power supply

!

Constant red light and no green

light in LED

- Power supply is OK, but NO mobile network

- PS has NO satellite position

!

Red flashing light and no green

light in LED

- Mobile network is OK

- PS has NO satellite position

!

Constant red and green light in

LED

- Power supply is OK, but NO mobile network

- PS has valid satellite position

LED

LED

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 7

In tallation check and update u ing

“Verify my Trackunit”

Step 1: Login

- o to

http://verify.trackunit.com

- Enter user name and

password

Step 2: Find unit

- Enter serial number and

then click “Find”

Step 3: Review

status

- Time of last received data

- PS and mobile signal

- Mobile number

- Power supply voltage

- Internal battery voltage

- Status of inputs 1-4

(on/off)

- Click “Find” again to

refresh status

Step 4: Basic

configuration

options

- Enter a device name

- Enter engine hours

- Enter start distance

- Select category

- Connect up to multiple

groups

- Add a note (visible in

Trackunit Manager)

Step 5: Logout

- Click “Update” to save

- Click “Logout”

Note

- Prior to verification, make

sure the unit is installed

and active in an area with

sufficient PS and mobile

coverage.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 8

Input filtering (INFILT)

In case the main breaker is on the negative

wire (ground wire from the machine battery),

the inputs may register a voltage level and

start counting operating hours.

To avoid this situation, the digital input 4

(pink wire) should be connected to the

chassis/ground on the machine.

The infilt function should be activated via

“Verify my Trackunit”

Activation of input filtering

o to: http://verify.trackunit.com/

NB! Enabling the filtering function will

disable inputs 1 to 3 when input 4 is

on/active. This can prevent all digital input

alarms. It will also disable the use of any

alarm function on digital input 4.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 9

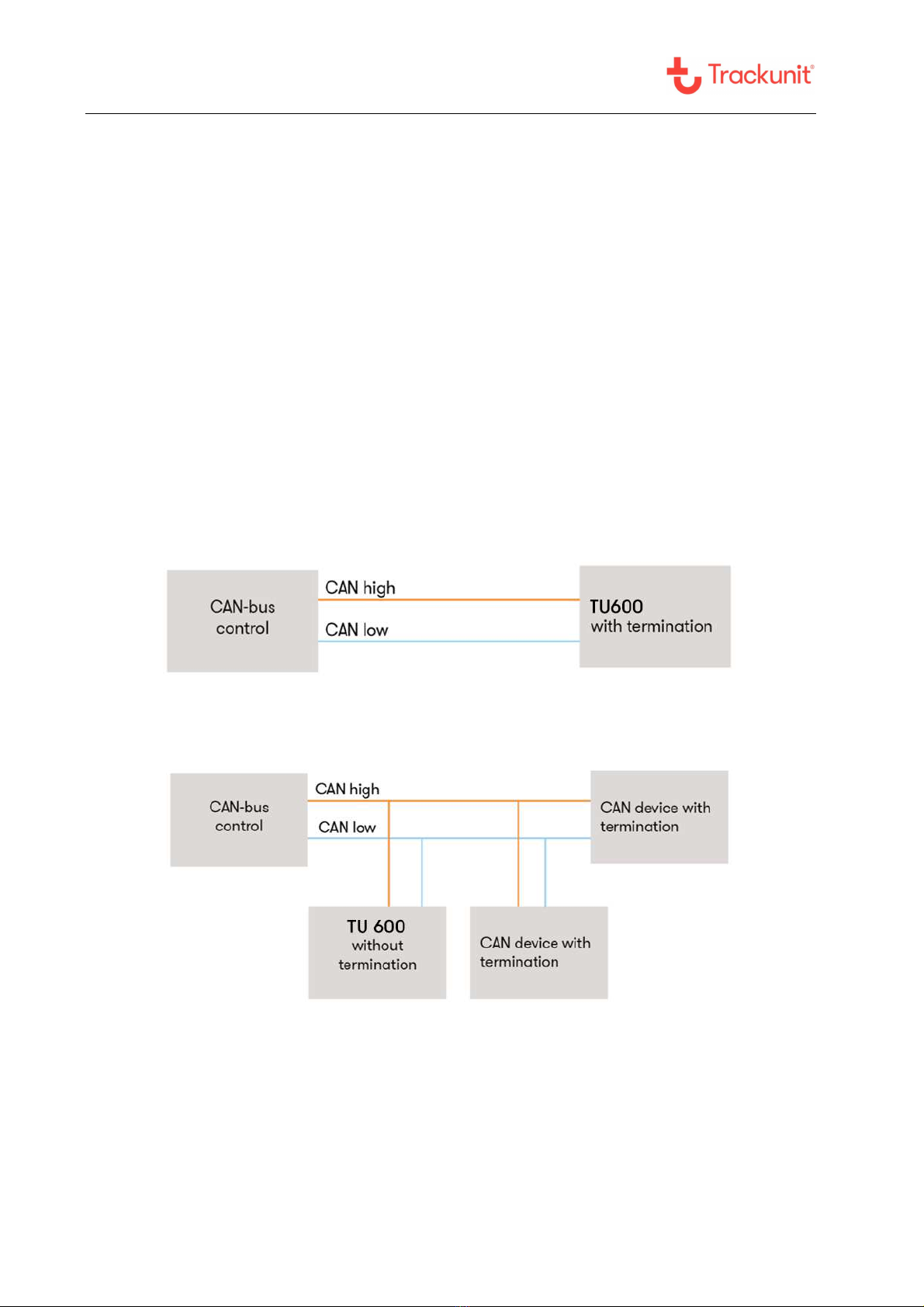

CAN bu termination re i tor

When installing the TU600 on a J1939 CAN-bus, it is very important to determine if the

installation is on a “private” CAN-bus directly to the CAN controller, or if the TU600 is to be

installed as a stub on a CAN-bus with multiple CAN devices already attached.

Default etup without 120-ohm bu termination.

The 120-ohm termination resister is a software-controlled resistor, so make sure to use and

select the correct TU600 CAN-bus profile.

CAN-bu profile i elected in Trackunit Manager and oftware control the re i tor etup.

With 120-ohm bu termination (directly connected)

Without 120-ohm bu termination ( tub connected)

NB! When the unit is stub connected, the wire length must be minimized to avoid CAN-bus noise and

error ratio.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 10

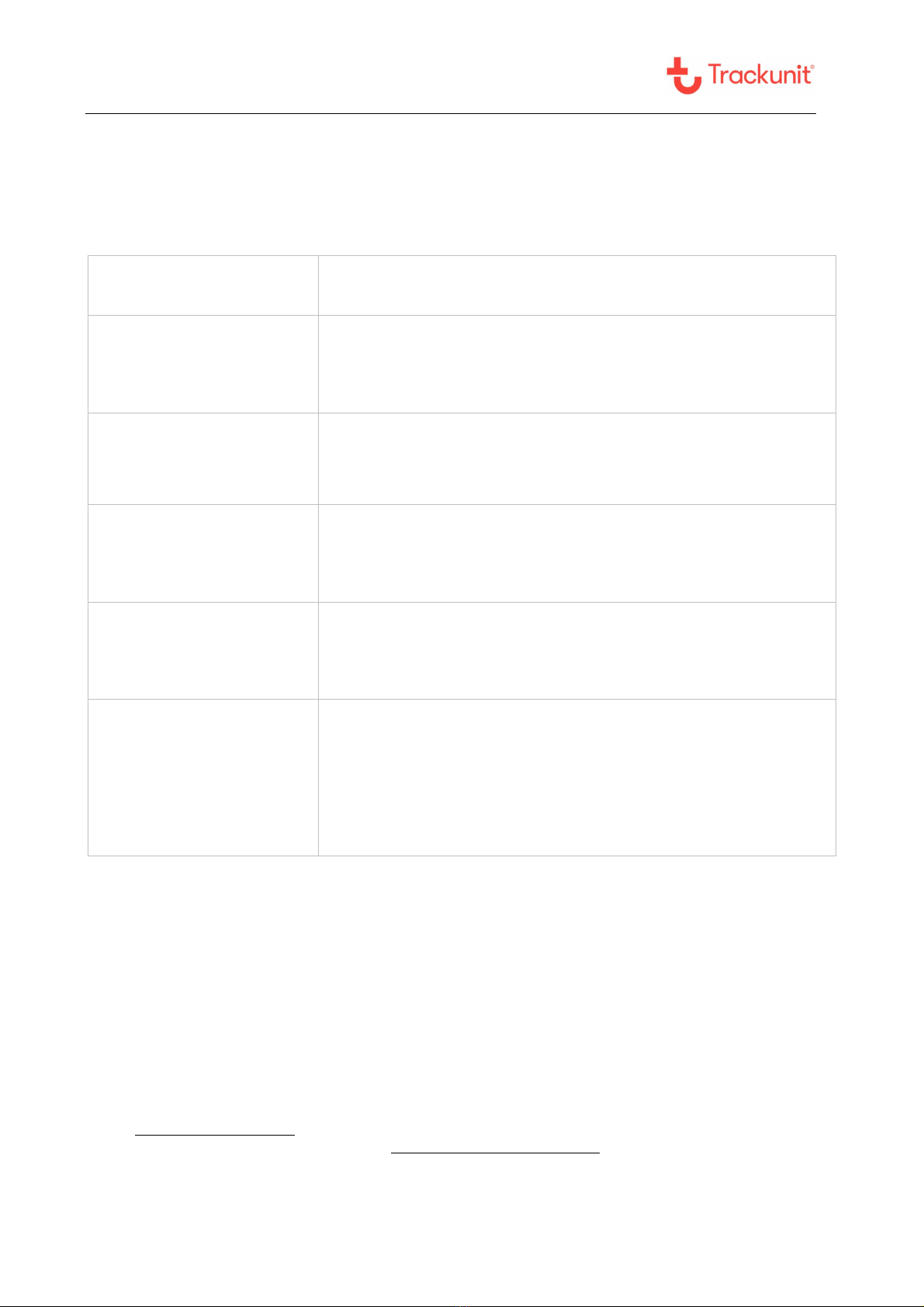

Trouble hooting

Error description

Possible solutions

No reply on SMS command

Verify correct SM number

Check LED status – see page 6

No light in LED

Check if the red and blue wires are installed correctly or

if the fuse is blown

Constant red light

in LED

Verify location of the unit – see page 3

Move machine or vehicle for better SM signal

No green light in LED

Verify location of the unit – see page 3

Move machine or vehicle for better PS reception

Inputs counting operating

hours when machine is off

Possibly due to the main breaker being on the negative wire (ground

wire from the machine battery). When off, the inputs may register a

voltage level and start counting operating hours.

To avoid this situation, the digital input 4 (pink wire) should be

connected to the chassis/ground on the machine.

See Input filtering (INFILT) section, page 8.

Technical A i tance

If you experience an issue and cannot find the information you need in the product documentation, please

contact Trackunit.

Spare part lists:

Spare battery PN 4233.0002

HW shield for harsh environments PN. 7402.9551 and 7402.9552.

Fuse kits (30V/1A) for 12V-24V operations or (80V/3A) for 12V-48V operation.

Trackunit support: +45 96 73 74 00

Email: support@trackunit.com

The guides can also be downloaded online: www.trackunit.com/downloads

NB! When contacting technical support, please have the unit serial number ready.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 11

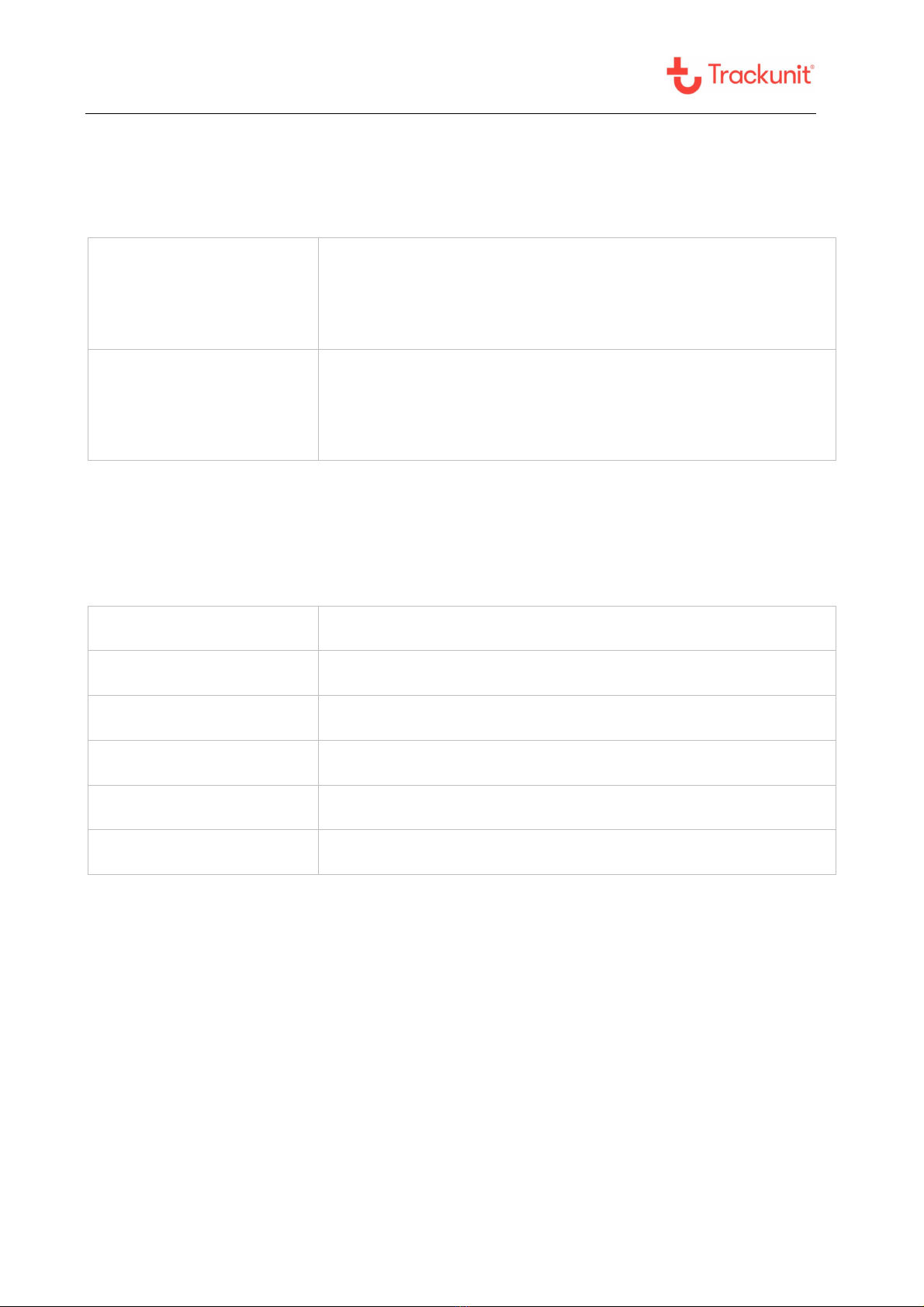

Product pecification

Product

TU600

2 SM

Yes

LTE M1 / NB1 IOT

Yes

Operational voltage

(supply voltage)

12-48 V DC

Absolute maximum voltage

range

8-58 V DC continuous

Standby consumption

( SM-receiver active)

10 mA / 7 mA (avg. at 12V/24V)

Consumption during

charging an empty battery

225 mA / 115 mA (max at 12V/24V)

Charging time for an empty

backup-battery

4 hours at 25ºC / 77ºF)

Digital inputs

4

Digital outputs

1

CAN inputs (High / Low)

2

Access control input

M8 connector

1

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 12

Temperature range

In active running mode

-

20ºC to +55ºC/60ºC

Limited by the Li-Ion backup battery when the unit is either machinery or

battery powered.

Storage

-40ºC to +70ºC

Shorter battery lifetime must be expected when storage and operation

occur at extreme temperatures.

Mechanical pecification

Length 122,3 mm (4.8 in.)

Width 45.5 mm (1.8 in.) (50,1 mm incl. cradle) (1.9 in.)

Height 17.9 mm (0.7 in.) (22,7 mm incl. cradle) (0.9 in.)

Cable length 170 cm (5.6 ft.)

Environmental class IP67 (With HW Shield IP66k & IP69k – PN. 7402.9551 and 7402.9552)

Weight 66 g (excluding cable) (2.3 oz.)

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 13

Regulatory information and precaution

Use location

This equipment design applies to commercial or industrial equipment

expected to be installed in locations where only adults are normally present

Terms of use

Use only Trackunit approved accessories and/or batteries. Do not connect

incompatible products

New battery

In case of battery malfunction, expiration or any other situation where a new

battery might be needed, replacement batteries can be ordered through

support@trackunit.com

CE mark

The TU600 products complies with the essential requirements

of the RED Directive 2014/53/EU directive with respect to the EMC

requirements, safety and radio spectrum matters

FCC mark

The TU600 products contains radio transmitters and complies with the

essential requirements of Part 2.1091, 15.247, 22, 24, 27 and 90 of the FCC

rules, and with RSS- EN, RSS- 102, RSS-130, RSS-132, RSS-133, RSS-

139, and RSS247 of the Industry Canada requirements

Environmental

The TU600 products complies with the SAE J1455 environmental conditions

for heavy trucks when mounted in the vehicles. Additionally, compliance to

shock and acceleration by IEC 61373. The product protection covers IP67

(standalone) and IP66k &IP69k (With HW shield).

Charging

The battery will recharge as long as its temperature range is within 0ºC to

+45ºC and the vehicle to which the unit is mounted is running. In case of

temperatures outside this range the internal battery will not recharge.

Operating

conditions

The internal battery will operate in temperature ranges from -20ºC to +60ºC.

In case of temperatures outside of this range the internal battery will be

disabled by the device. Battery lifetime is expected to be 3 years under

normal operating conditions.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 14

Fuse

Recommended fuse holders and fuses for installation up to 48V supply

voltages (can be ordered at Trackunit A/S):

a. Supply voltage 12V/24V (Max 30A)

i. ATO blade fuses (Max 32V/1A) used with Littelfuse FHAC0002SXJ fuse

holder (standard).

ii. ATP blade fuse (Max 32V/1A - ATO style) used with TaiTek FH-

006WR-12R-12-U fuse holder (standard).

b. Supply voltage 12V - 48V (Max 30A)

i. FKS blade fuse (Max 80V/3A - ATO style) used with Littelfuse FH2 fuse

holder (recommended).

Machinery

The TU600 product complies with the essential requirements of the Directive

2006/42/EC and EU regulation 167/2013 when integrated as intended:

I) ISO 13766-1 Earth-moving machinery and construction machinery

II) EN/ISO 14982 Agricultural and forestry machines.

III) EN 12895 Industrial trucks – Electromagnetic compatibility.

IV) UN regulative ECE R10 EMC rev. 5 in accordance with EU regulation

661/2009 for Electronic Sub-Assembly (ESA).

NOTE: Harmonized standards under the directive 2014/30/EU have been

applied.

Statement for ISO 13849-1:

The TU600-x are when installed not a vital part in the machine safety system,

but it can be used as access control/immobilizer if paired with a keypad (e.g.

DualID II) or Ibutton or by Bluetooth LE. This function depends on correct

installation (see installation guide) and requires that the output wire is

connected to a relay to control the starter motor, see installation diagram.

When the emergency stop on the machine is activated, the unit and keypad

functions will be disabled. The internal battery ensures that a PS position

still can be acquired on an hourly basis.

PRECAUTION: Trackunit recommend only mounting Output1 to tarter

motor through a relay and under no circum tance hould Output1 be

u ed to control the engine hutdown during operation or any moving

part on the machinery.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 15

Approval and Certification

FCC/IC part 15.19

Notice

This device complies with Part 15 of the FCC Rules and with Industry

Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

IC RSS- EN

Notice

Le présent appareil est conforme aux CNR d'Industrie Canada applicables

aux appareils radio exempts de licence. L'exploitation est autorisée aux

deux conditions suivantes: (1) l'appareil ne doit pas produire de brouillage,

et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

FCC part 15.21

Notice

Changes or modifications made to this equipment not expressly approved

by Trackunit may void the FCC authorization to operate this equipment.

FCC/IC

Radiofrequency

radiation exposure

Information

This equipment complies with FCC/IC radiation exposure limits set forth for

an uncontrolled environment. This equipment may be installed and

operated with minimum distance of 20 cm between the radiator and your

body.

This transmitter must not be co-located or operating in conjunction with any

other antenna or transmitter.

Environmental

compliance

SAE J1455 EN/IEC 60068-2-1:2007 Cold

SAE J1455 EN/IEC 60068-2-2:2006 Dry Heat

SAE J1455, IEC 61373 EN/IEC 60068-2-27:2010 Shock

SAE J1455 EN/IEC 60068-2-31:2008 Drop

SAE J1455, IEC 61373 EN/IEC 60068-2-64:2008 Random vibration

and acceleration

SAE J1455 EN/IEC 60068-2-78:2001 Damp heat steady state

SAE J1455 (IEC 60529+A1+A2)CSV:2013 Degrees of protection

(IPcode): IP67 and With HW hield: IP66k & IP69k

NOTE A:

The TU600 is not to be mounted in areas with presence of Motor oil,

asoline, Diesel fuel, Hydraulic fluid, Brake fluid, Transmission fluid,

lycol and water mixture etc.

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020

16

NOTE B:

The housing not designed to withstand high pressure cleaning. Only use

the TU600 when mounted inside the designated Trackunit protection cap

(7402.9551 and 7402.9552 Trackunit Raw – Hardware Shield, can be

ordered at Trackunit A/S) in mounting areas where high pressure cleaning

is common procedure.

Regulatory

labeling

The TU600-x product family are regulatory compliant to the following

regulation:

PTCRB

certification for

interoperability

with mobile

networks

Selected variants of the TU600 products series under FCC ID: ZMF-TU600

and IC: 9746A-TU600 are certified for PTCRB interoperability with mobile

networks:

#77390: Trackunit TU600-5, HW 1.000, SW 60.012, SVN 7

Japan

The TU600-x model is certified for Japan under ID n°: [R] 003-180062, [R]

209-J00306, [T] D180034003

This device is granted pursuant to the Japanese Radio Law (電波法)

=

当該機器には電波法に基づく、技術基準適合証明等を受けた特定無線設備を装着して

いる

This device should not be modified (otherwise the granted designation

number will become invalid)

本製品の改造は禁止されています。(適合証明番号などが無効となります。)

Chile

Este equipo cumple con la Resolución No 403 de 2008, de la

Subsecretaria de telecomunicaciones, relativa a radiaciones

electromagnéticas.

Regulatory

accessed

countries

The regulatory accessed countries are countries without local registrations

or approvals. A manufacturer declaration of conformity assessment to the

national rules are applied for:

10R - 05 8766

FCC ID: ZMF-TU600

IC: 9746A-TU600

TU600-x

Short uide TU600-x v0.2, January 2020, ©Trackunit 2020 17

Americas: Chile (Regulatory label)

Asia: Myanmar

Certified countries

The TU600-5 model is additionally certified for countries that has no

regulatory label requirements:

India, Kuwait, Qatar, Saudi Arabia.

The certificates can be requested at Trackunit A/S for use for import

declarations.

Table of contents

Other Trackunit GPS manuals

Popular GPS manuals by other brands

Eagle

Eagle IntelliMap 502C iGPS Installation and operation instructions

Garmin

Garmin Rino 120 Owner's manual and reference guide

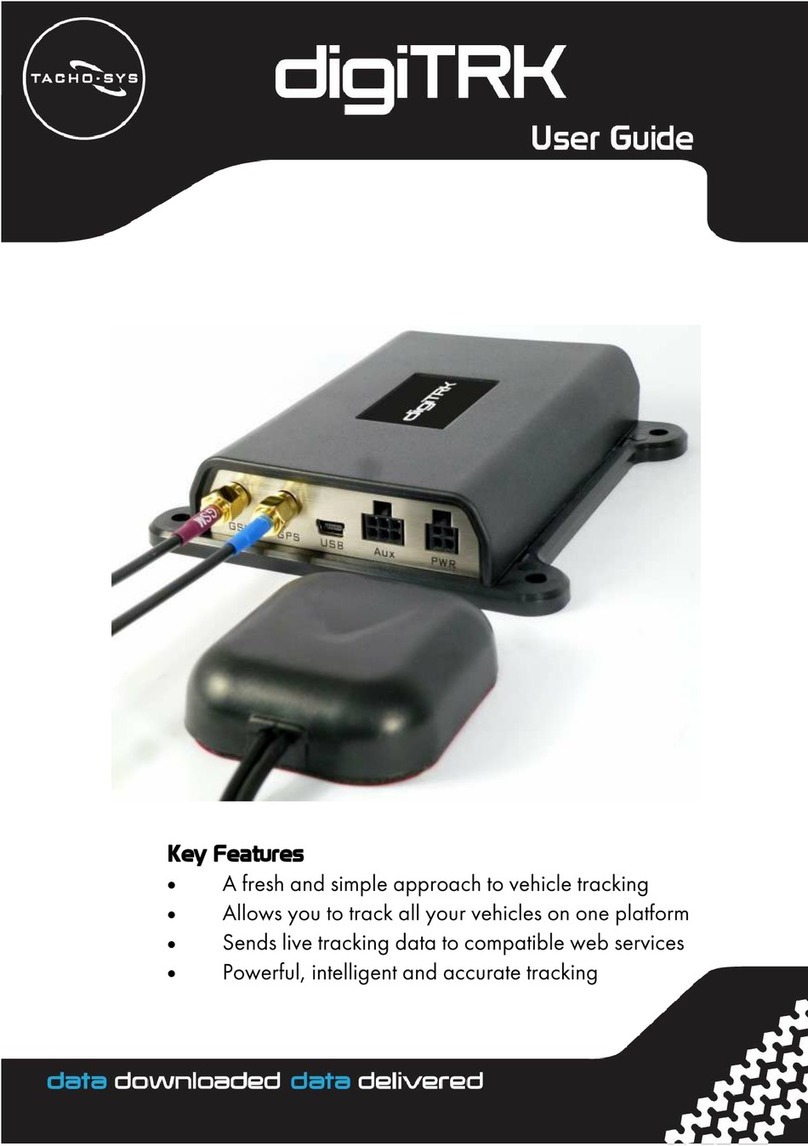

Tachosys

Tachosys digiTRK user guide

SkyGolf

SkyGolf SkyCaddie LX5 quick start guide

ACR Electronics

ACR Electronics GYPSI 406 PLB Product support manual

Aspenta

Aspenta Vectu owner's manual