Tracon Tracon FPT-130 User manual

South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION GUIDE | PART NO. 25298 REV E

PACKING LIST

QTY. PART NO. DESCRIPTION

1 25169 TRACON MODEL FPT 130 Single-Point Freeze Protection Heat–Trace Control

1 25076 Temperature Sensor

1 25298 FPT 130 Quick-Reference Installation Guide (this document)

- 25165 TRACON MODEL FPT-130 Installation & Operation Manual

Available online at: networketi.com/product-manuals

PRIOR TO INSTALLATION

1. Read these installation instructions and manual prior

to beginning installation.

2. Install this device only if you are a qualied electrician

trained to perform such work.

3. Before beginning installation, lay out the system

components, the heat trace cable and the

temperature probe in their approximate locations to

visualize the system and evaluate exact component

and junction box placement, as well as required

cable and conduit lengths.

INSTALLATION

The FPT 130 Automatic Heat–Trace Control should be

installed by a qualied, licensed electrician. Installation

must conform to all applicable local and national electrical

codes and laws. The unit’s NEMA 4X IP66 enclosure allows

for indoor or outdoor applications.

The FPT 130 controller has an ambient operating

temperature range of −40 °F to 131 °F (−40 °C to 55 °C).

To avoid potential internal condensation mount the unit

out of direct sunlight.

Install the FPT on a xed, at, vertical surface using the unit’s

mounting anges. The mounting anges accommodate

1/4” or 6.3 mm fasteners.

The FPT 130’s nonmetallic enclosure has one 1.046” hole

for conduit entry; this can hold both power and load wiring.

Use only Listed Type 4X IP66 liquid–tight conduit hubs

or cable glands. Connect the hub to the conduit system

before connecting the hub to the enclosure.

The unit comes with two installed liquid–tight cable

glands. One of these ttings is for the temperature sensor

cable, and the other is for the alarm relay cable.

The cable glands can accommodate cable diameters

0.08” to 0.24” (2 mm to 6 mm). The temperature sensor

may be located up to 2,000’ (610m) from the FPT.

There is a removable electrical insulation divider that

must be in place when there is power applied to the unit.

All leads should be terminated; no unsecured leads

should be left inside the wiring compartment.

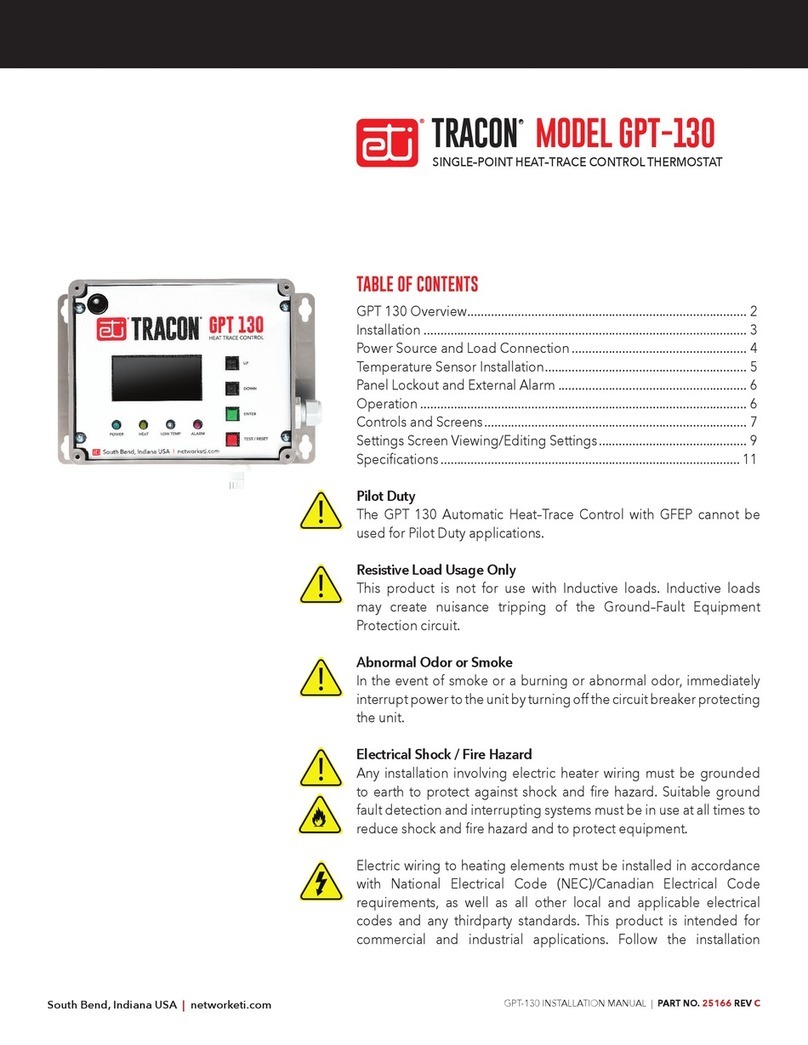

MODEL FPT-130TRACON

®

SINGLE–POINT FREEZE PROTECTION HEAT–TRACE CONTROL

South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION GUIDE | PART NO. 25298 REV E

2

FIGURE 1. The FPT 130 wiring layout.

Perform the following steps with the circuit breaker to the unit OFF. The TRACON FPT 130 is permanently

connected equipment and does not have an internal disconnect device. When power is applied, the system

will start.

NOTE:

1. INSTALL THE CONTROL BOX

Use the box itself as a template to determine the mounting

hole footprint. Install the box to a solid, stable surface

capable of supporting four times the weight of the box, or

about 20 pounds. Use all four mounting holes. Install the

control box to the wall using heavy-duty 1/4” or 6.3 mm

fasteners long enough to fasten the box securely. Do not

fully tighten mounting hardware at this time. Leave the

mounting hardware loose enough to work the conduit

into place. Hardware will be fully tightened following

installation of the conduit.

2. CONNECT THE SUPPLY AND LOAD

Feed the Input Supply (Input Power) and the Load (Heater

Cable) through the Conduit Entry Hole in the enclosure as

shown, then connect the leads, as shown in the Figure 3.

Line is black; neutral is white; ground is green.

Note: Both the power and the load require a #10 AWG wire.

3. INSTALL THE TEMPERATURE SENSOR

The FPT 130 comes with a thermistor temperature sensor

with a 20 ft. jacketed cable that has an operating range of

−40 °F to 230 °F (−40 ˚C to 110 ˚C). Refer to Figure 4.

FIGURE 3.

Contractor connections.

JP1

JP2

FPT130

Thermistor

Fault FPT130

Set

Point

GPT

Heat On

Fire Prot Lock

Heat Off

1

01

1

0

0

1

0

0

1

50F

45F

30F

38F

INPUT POWER HEATER CABLE

TEMPERATURE SENSOR

ALARM RELAY

Figure 1

Thermistor

The FPT 130 wiring layout

Line:

Neutral:

Ground:

BLACK / Line 1

WHITE / Line 2

GREEN

Line:

Neutral:

Ground:

BLACK / Line 1

WHITE / Line 2

GREEN

South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION GUIDE | PART NO. 25298 REV E

3

4. INSTALL THE EXTERNAL ALARM

An alarm or power–off condition can be communicated

by either opening or closing a relay contact. It is important

to make the proper alarm relay connections to achieve

the desired result. The middle terminal labeled COM

(Common) is used in both wiring congurations. Connect

one alarm relay lead to the COM terminal. If the system

needs a contact to close to signal an alarm or power–off

condition, connect the other alarm relay lead to the NC

(Normally Closed) terminal.

If the system needs a contact to open to signal an alarm

or power–off condition, then connect the other alarm

relay lead to the NO (Normally Open) terminal.

If the unit has power, and there are no alarm conditions

then the NO and COM terminals will be connected. If

the unit loses power or an alarm condition occurs then

the NC and COM terminals will be connected. Refer to

Figure 5.

5. INSTALL THE CONDUIT AND FULLY

TIGHTEN HARDWARE

Install the conduit runs to the control box. Use only Listed

Type 4X IP66 liquid–tight conduit hubs. With cabling

routed through conduit and conduit is secure, fully tighten

the control box mounting hardware and re-assemble

control box panels and cover in their original location.

Note: At this point the circuit breaker to the unit can be

turned on providing power to the unit.

6. SETUP AND SETTINGS EDITING

Please refer to the FPT 130 Manual for comprehensive

instructions for Setup and Settings Editing.

FIGURE 4. Thermistor sensor connection FIGURE 5. External alarm connection

Wiring to

Normally Closed

alarm contact

South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION GUIDE | PART NO. 25298 REV E

4

Pilot Duty

The FPT 130 Automatic Heat–Trace Control

with GFEP cannot be used for Pilot Duty

applications.

Resistive Load Usage Only

This product is not for use with Inductive loads.

Inductive loads may create nuisance tripping

of the Ground–Fault Equipment Protection

circuit.

Abnormal Odor or Smoke

In the event of smoke or a burning or abnormal

odor, immediately interrupt power to the unit

by turning off the circuit breaker protecting the

unit.

Electrical Shock / Fire Hazard

Any installation involving electric heater wiring

must be grounded to earth to protect against

shock and re hazard. Suitable ground fault

detection and interrupting systems must be in

use at all times to reduce shock and re hazard

and to protect equipment.

Electric wiring to heating elements must

be installed in accordance with National

Electrical Code (NEC)/Canadian Electrical

Code requirements, as well as all other local

and applicable electrical codes and any

thirdparty standards. This product is intended

for commercial and industrial applications.

Follow the installation instructions contained in

this manual and those provided by the heater

manufacturer.

Size the circuit breaker appropriately for

the expected load and inrush current. The

maximum rated current for the FPT 130 is 30

amps with resistive load.

Heater loads and their controls should not

share a circuit branch with other types of

equipment. A shared circuit may result in

electromagnetic interference that can affect

system operation.

Make certain that the heater shield is properly grounded.

Failure to do so may result in damage to the equipment

or re.

Following installation and prior to beginning system

operation, refer to and perform the Post-Installation Test

described in this manual.

CONTACTING CUSTOMER SERVICE

For assistance, contact Customer Service. Ofce hours are

from 8:00 AM until 5:00 PM ET.

Email: [email protected]

Web: networketi.com

Mail: ETI

1850 North Sheridan Street

South Bend, IN 46628

LIMITED WARRANTY

ETI’s two year limited warranty covering defects in

workmanship and materials applies. Contact Customer

Service for complete warranty information.

DISCLAIMER

ETI makes no representations or warranties, either

expressed or implied, with respect to the contents

of this publication or the products that it describes,

and specically disclaims any implied warranties of

merchantability or tness for any particular purpose. ETI

reserves the right to revise this publication, and to make

changes and improvements to the products described

in this publication, without the obligation of ETI to notify

any person or organization of such revisions, changes or

improvements.

South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION GUIDE | PART NO. 25298 REV E

5

Note: The DIP switches are read

at power-up. If any DIP switch

is changed while the unit is

on, then the power needs to be

turned off and on again for the

new setting to take effect.

FPT130

Thermistor

Fault FPT130

Set

Point

GPT

Heat On

Fire Prot Lock

Heat Off

1

01

1

0

0

1

0

0

1

50F

45F

30F

38F

Other manuals for Tracon FPT-130

3

This manual suits for next models

1

Table of contents

Other Tracon Thermostat manuals