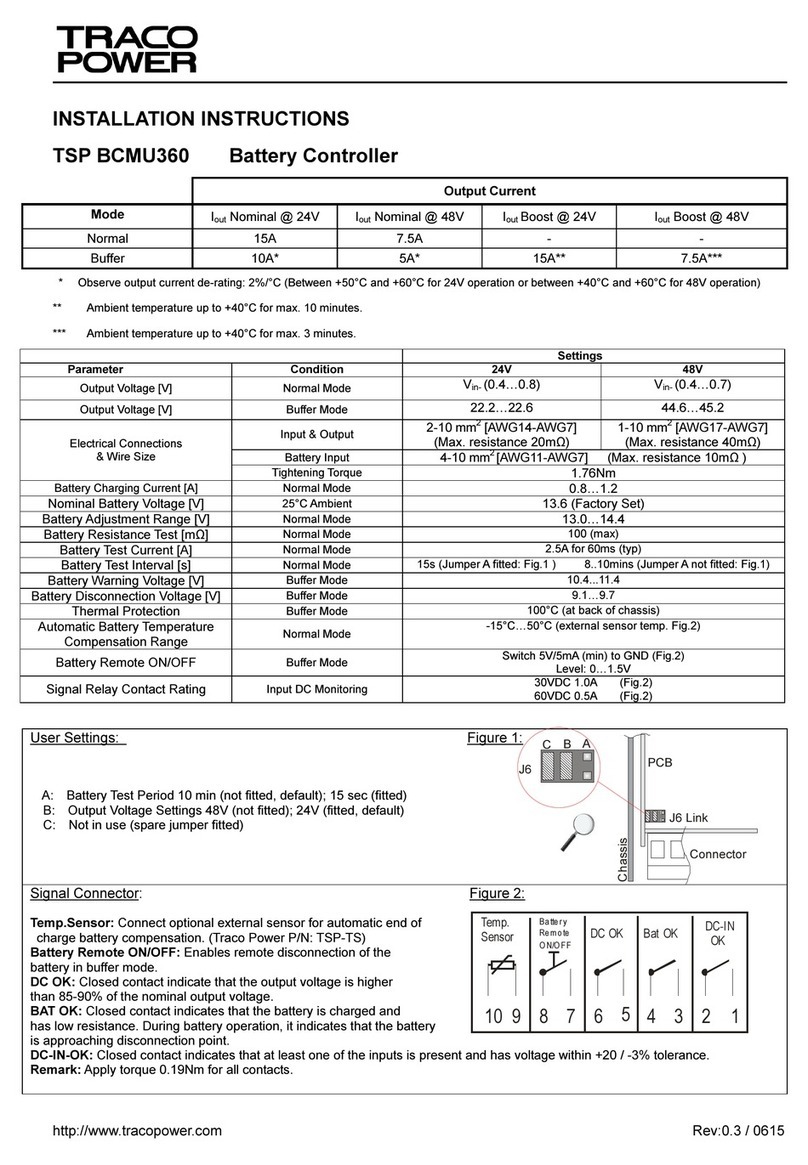

TracoPower TSP-BCM24 User manual

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 1

Jenatschstrasse 1

CH-8002 Zürich

Operating Instructions

BATTERY CONTROLLER MODULE TSP-BCM24

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 2

Jenatschstrasse 1

CH-8002 Zürich

Dimensions drawings:

TSP-BCM24

Note

This instruction cannot claim all details of possible equipment variations, nor in particular can they provide for

every possible example of installation, operation or maintenance. Further information is available from your local

distributor office or from the TSP industrial power supply data sheet. Subject to change without prior notice.

In order to guarantee safe operation of the TSP-BCM24 in combination with the TSP power supplies and

to be able to make use of all the functions, please read these instructions thoroughly!

Weight: 0.816lb

Gewicht: 0.37k

g

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 3

Jenatschstrasse 1

CH-8002 Zürich

English

1. Description and construction

The module TSP-BCM24 provides a professional battery management system to charge and monitor an external lead-acid battery (e.g.

YUASA NP batteries). Together with a power supply of the TSP series (TSP 090-124, TSP 180-124 and TSP 360-124) a perfect DC-UPS

system can be configured. The connected battery will be charged and held in charge mode by the power supply. In the event of a power

failure the battery will supply the output power until the battery is discharged. As a consequence, the output voltage of the system is

equivalent to the battery voltage.To avoid overcharging the battery, an external temperature sensor adjusts the battery voltage

automatically to the required end of charge voltage. This achieves a long battery life time.

The battery is protected against deep discharge. Mains power and the battery status are monitored regulary and failures indicated by

LED’s and signal outputs.

Before connecting the input, output and sense lines (see Fig. 2.1 and Fig 3.1; J1, J2 and J3) the potentiometer on the TSP power supply

has to be turned completely conterclockwise (Vout min). Afterwards the connection between the TSP (TSP xxx-124) and DC In on the TSP-

BCM24 (see Fig. 3,1, J1 and chapter 2.2.1) as well as the remote sensing between these two devices using the wire supplied with the

TSP-BCM module (see Fig. 2.1 and Fig. 3.1, J3). Before connecting the battery the battery charging voltage has to be adjusted as

recommended by the battery manufacturer. Further the Jumper J6 has to be set according to the TSP which is connected to the TSP-

BCM24 module (see Fig. 3.1 J6 and chapter 3.4). Than the battery can be connected to the Batt In connector (see Fig. 3.1, J1 and chapter

2.2.2). Now connect the load to DC-Out (see Fig. 3.1, J2 and chapter 2.2.3).

The TSP-BCM24 is a built-in device. The mounting position has to fulfil the requirements for fireproof case according to UL60950, IEC/EN

60950 or other appropriate national standard. The relevant UL regulations or equivalent national regulations must be observed during

installation.

The TSP-BCM24 is designed for mounting on a DIN rail TS35 (DIN EN 50022-35x15/7.5).

The output voltage of the TSP-BCM24 is protected against short circuit and open circuit conditions.

2. Installation

A sufficiently strong DIN-rail has to be provided. The correct mounting position for optimal cooling performance must be observed. Above

and below the TSP-BCM24 a minimum free space of 80mm [3.15in] is required and on each side of the TSP-BCM24 a minimum space of

50mm [1.97in] is required which allows air convection. The air temperature measured 10mm [0.39in] below the device must not exceed the

specified values in the data sheet. Observe same power derating above ambient temperatures of 40°C as specified for the TSP power

supplies.

Warning

The TSP-BCM24 is constructed in accordance with the safety requirements of IEC 60950, EN60950, UL60950,

UL508, IEC/EN60079-15 (Class I, Zone 2, AEX nC II C T4 U) and UL 1604 (Class I, Div. 2, Groups A, B, C and D).

The TSP-BCM24 fulfils the requirements for CE-compatibility and carries the CE-mark and is UL & cUL approved b

y

CSA.

The TSP-BCM24 built-in module is designed especially for use in process automation and other industrial

applications.

Components with dangerously high voltage and high stored energy are located in the device. However, these are

inaccessible. Failure to properly maintain the TSP-BCM24can result in death, severe personal injury or substantial

property damage. The TSP-BCM24 may only be installed and put into operation by qualified personnel. The

corresponding national regulations (e.g. UL, ANSI, VDE, DIN) must be observed. The successful and safe operation

of this module is dependent on proper storage, handling, installation and operation.

The potentiometer to adjust the output voltage is only allowed to be actuated using an insulated screwdriver, because

accidental contact may be made with parts inside the power supply carrying dangerous voltages.

Please observe following points before putting the device into operation:

• Read operating instructions thoroughly.

• That the input wiring is sufficiently dimensioned!

• That the output wiring is dimensioned according to the maximum output current or separately protected!

• Sufficient cooling is guaranteed!

• The temperature of the housing can become very high, depending on the ambient temperature and load.

Caution:

Risk of electrical shock and electrical discharge. The TSP-BCM24 nor the power supply must not be opened until a

t

least 5 minutes after complete disconnection of the mains and battery.

Electrostatic sensitive device. Qualified and trained personnel only may open the TSP-BCM24 or the powe

r

A

ttention: In case of non-observance or exceeding the mentioned limiting value of the data sheet, the function

and electrical safety can be impaired and can destroy the TSP-BCM24 and/or the power supply.

Danger: Never work on the TSP-BCM24 or power supplies if power is applied

or if the batter

y

is still connected!

Before installation ensure that the main switch is switched off and prevented from being

switched on again. In case of non-observance, touching of any live components or imprope

r

dealing with this TSP-BCM24 or power supply can result in death or fatal injury.

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 4

Jenatschstrasse 1

CH-8002 Zürich

English

2.1 Assembly

To fix device on the DIN-rail, hook top part of clip on DIN-rail, push down and inward until you hear a clipping sound.

To remove the device, pull the latch of the clip with the aid of an insulated flat head screwdriver. When clip has cleared bottom

DIN rail remove the screwdriver from recess. Lift the device off DIN-rail.

Wall mounting or chassis mounting can be achieved by use of optional mounting bracket TSP-WMK01 (1 bracket, see Fig. 4.1).

Remove the DIN-clips by removing the screw and place the mounting brackets in the same place as the DIN-clips. Use the

countersink screws, which are included with the wall mounting kit (1 countersink screw with TSP-WMK01) to fix the mounting

brackets on the TSP-BCM24 (tightening torque 0.8-0.9Nm).

2.2 Connecting cable

Only qualified personnel may carry out the installation. The device is equipped with COMBICON connector. This reliable

and easy-to-assemble connection method enables a fast connection of the device.

2.2.1 DC- Input (Fig. 3.1 ÎConnector J1, pin 1 & pin 2):

The 24Vdc connection is made by using the –Vin (-DC In) and +Vin (+DC In) connections and has to be carried out in

accordance with the local regulations. Sufficiently dimensioned wiring has to be ensured (see 2.2.1.1).

To achieve a reliable and shockproof connection strip the connecting ends according 2.2.1.1. If flexible wires are used the wires

have to be terminated. (e.g. by using ferrules)

2.2.1.1 Connections and terminal assignment

Solid or stranded wires Torque Stripping length

Device Terminals

Function [mm2][AWG] [Nm] [mm]

+

Vin &

-

Vin

Input Voltage (24Vdc

)

0.5 … 2.5

24 … 12

0.5

–

0.6

7.0

+Bat & -Bat Battery Voltage (24Vdc) 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

+Vout & - Output Voltage (24Vdc) 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

TSP 090-124

TSP 180-124

Signal Relay inputs and relay outputs 0.2 … 2.5 32 … 12 0.5 – 0.6 7.0

+

Vin &

-

Vin

Input Voltage (24Vdc)

1.0 … 2.5

18 … 12

0.5

–

0.6

7.0

+Bat & -Bat Battery Voltage (24Vdc) 1.0 … 2.5 18 … 12 0.5 – 0.6 7.0

+Vout & - Output Voltage (24Vdc) 1.0 … 2.5 18 … 12 0.5 – 0.6 7.0

TSP 360-124

Signal Relay inputs and relay outputs 0.2 … 2.5 32 … 12 0.5 – 0.6 7.0

2.2.1.2 Internal Fuse

2.2.2 Battery In (Fig. 3.1ÎConnector J1, pin 3 and pin 4):

The battery connection is made using the “+Bat In” and “-Bat In“ connections. Make sure that the battery lines are dimensioned

according to the maximum output current (see 2.2.1.1) or are separately protected! The wires on the secondary side should

have large cross sections in order to keep the voltage drops on these lines as low as possible. To achieve a reliable and

shockproof connection strip the connecting ends according 2.2.1.1. If flexible wires are used the wires have to be terminated.

(e.g. by using ferrules)

2.2.3 Output (Fig. 3.1ÎConnector J2, pin 1, pin 2, pin 3 & pin 4):

The 24VDC connection is made using the “+Vout” and “-Vout“ connections. All output terminals should be connected to the load.

Make sure that all output lines are dimensioned according to the maximum output current (see 2.2.1.1) or are separately

protected! The wires on the secondary side should have large cross sections in order to keep the voltage drops on these lines

as low as possible.

To achieve a reliable and shockproof connection strip the connecting ends according 2.2.1.1. If flexible wires are used the wires

have to be terminated. (e.g. by using ferrules)

At the time of delivery, the output voltage is 24VDC. The output voltage can be set (using an insulated screwdriver) from 24 to

28VDC on the potentiometer (see Fig. 3.1).

The device is protected against overload and short circuit.

2.2.4 Signalling (Fig. 3.1ÎConnector J5, pin 1, pin 2, pin 3, pin 4, pin 5 & pin 6):

The AC OK, Bat OK and DC OK outputs are for enabling monitoring of the functions of the TSP-BCM24, mains and battery. The

floating AC OK signal contacts (see Fig. 3.1 ÎConnector J5, pin 1 & pin 2) is monitoring if the mains is present. If mains is

present the relay contact (30Vdc / 1A) is closed. It is detected by measuring the input at DC In.

The floating Bat OK signal contacts (see Fig. 3.1 ÎConnector J5, pin 3 & pin 4) is monitoring if the battery can supply enough

current for a given time.

The floating DC OK (see Fig. 3.1 ÎConnector J5, pin 5 & pin 6) is available to monitor if the TSP-BCM provides an output

voltage. If the output voltage of the TSP-BCM24 is present the relay contact (30Vdc / 1A) is closed. It is detected by measuring

the TSP-BCM24 output voltage.

Three LED’s also enables a visual evaluation of the functions of TSP-BCM, mains and battery directly on site and are in parallel

to the signal relay contacts.

Model Ratings Marking

TSP-BCM24 15.0 A / 60V F1 Î15A

CAUTION: For continued protection against risk of fire replace with same type

and rating of fuse! Only authorised and trained personnel should change

this fuse.

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 5

Jenatschstrasse 1

CH-8002 Zürich

English

2.2.4.1 AC-OK LED:

The AC-OK LED is a green colour LED that indicates the status of the TSP-BCM24 input and enables visual evaluation of the

function locally in the control cabinet. AC-OK LED green on – DC input present. DC-OK LED green off – DC input failure.

2.2.4.2 Bat-OK LED:

The DC-OK LED is a green colour LED that indicates the status of the battery and enables visual evaluation of the function

locally in the control cabinet. DC-OK LED green – battery can supply enough current. DC-OK LED green off – battery failure and

should be changed to ensure a proper and reliable operation of the battery in the event of mains fail.

2.2.4.3 DC-OK LED:

The DC-OK LED is a green colour LED that indicates the status of the output and enables visual evaluation of the function

locally in the control cabinet. DC-OK LED green on – normal operation. DC-OK LED green off – output failure.

3. Function

3.1 Remote ON/OFF:

The TSP-BCM24 device provides an external remote on/off function by use of pin 7 and pin 8 at connector J5 (see Fig. 3.1). To

switch off the power supply and TSP-BCM24 a connection between Connector J5 pin 7 and Connector J5, pin 8 by use of a

switch has to be made. At open connection between J5 pin 7 and J5 pin 8 the device is providing the adjusted output voltage.

On the TSP-BCM24 a switch is available to switch off the system on site (in the control cabinet).

3.2 Battery test:

The TSP-BCM24 device is designed to monitor the batteries condition. The battery is loaded with a sudden current

pulse as long as the mains is present to monitor the batteries condition. The time between the current pulses can

be set either to 15 seconds (see Fig. 3.1, J4, Pin 1 & 2) or to 10 minutes (see Fig. 3.1, J4, Pin 2 & 3)

3.3 Temperature sensing (optional):

The TSP-BCM24 device is designed to operate with temperature compensation required for proper operation of the battery. The

temperature is detected using an external NTC sensor (10kΩ) connected to the signal connector (J5 pin 9 and pin 10). If the

sensor is not connected the device automatically switches to +25°C constant temperature operation mode.

Before connecting the sensor it is required to set the battery voltage as recommended for +25°C ambient using the

potentiometer (see Fig. 5,1). E.g. for YUASA NP batteries it is: 2,26Vdc x 12 cells = 27,12Vdc. When the sensor is connected

the device will automatically detect it and will start adjusting the correct voltage for the battery.

3.4 Jumper setting of TSP supplying the TSP-BCM24:

The TSP-BCM24 device is designed to provide the remaining output current for battery charging current in maximum 15A. To

ensure that the TSP which is supplying the TSP-BCM24 is not used in overload even if a descharged battery is connected, the

jumper J6 has to be set (see Fig. 3.1). The factory setting (position 1) is for the use of a TSP 360-124. The jumper J6 has to be

set to position 2 if a TSP 180-124 is used and to position 3 if a TSP 090-124 is used.

4. Compliance to UL508C

The TSP-BCM24 is a built-in device and to comply with UL508C the device must be installed in a cabinet with minimum

dimensions of: 400mm (Width) x 500mm (Height) x 200mm (Depth)

4.1 Operating Temperature Ranges and load derating:

Depends on the TSP supplying the TSP-BCM24. Please see operating temperature range and load derating at the TSP power

supply datasheet or TSP operating instructions.

5. Technical Specifications

5.1 Input Specifications

Order code

Model

Input voltage max. Input Power * Output Voltage **max. Output Current

TSP-BCM24 24Vdc power supply and

24Vdc battery 360 Watt 24 Vdc 15.0 A

* Output voltage adjustable

** Maximum current at Vout nom.

5.2 Output Specifications

Output Voltage adjustable Range with Potentiometer 24 - 28 Vdc

Ripple and Noise (20MHz Bandwidth) at Vin nom und Iout max 200mV pk-pk max

Max. Capacitive Load unlimited

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 6

Jenatschstrasse 1

CH-8002 Zürich

English

5.3 General Specifications

Operating Temperature Range -25°C … +70°C

-13°F … +158°F

Cooling Convection cooling; no internal fan

Storage Temperature Range -25°C … +85°C

-13°F … +185°F

Load Derating above +40°C (104°F) 1.5%/K

Battery protection Over voltage, deep discharge, short circuit and revers connection

(built-in fuse)

Status signal DC-OK input, DC-OK output, BAT OK

All relay contact closed at status OK

Humidity (non condensing) 95% rel H max.

Pollution Degree 2

Temperature Coefficient 0.02%/K

Reliability, calculated MTBF in accordance to IEC 61709 >350'000 hours

Remote ON/OFF see Fig. 3.1 2 pin connector (see Fig. 3.1; J5 pin 7 and pin 8)

connect via a switch ÎContact closed = Device off

Signal Relay Contacts 30Vdc / 1A

Remote link cable (0.5m) 1 cable included with TSP-BCM24 module

Case protection in accordance to IEC 529 IP20

Isolation See Safety Standards

Safety Standards

according to

- Information Technology Equipment

- Industrial Control Equipment

IEC / UL / EN 60950-1

UL 508C

Electromagnetic compatibility

(EMC) Emissions

in correspondence to connected units (no internal switching device

Electromagnetic compatibility

(EMC) Immunity

in correspondence to connected units (no internal switching device

Environment Vibration

Shock

IEC 60068-2-6 3 axis, sine sweep, 10 … 55Hz, 1g, 1oct/min.

IEC 60068-2-27 3 axis, 15g, half sine, 11ms

Enclosure Material Aluminium (Chassis) / Zinc plated Steel (Cover)

Mounting DIN-Rail mounting

Wall mounting

For DIN-Rails as per EN 50022-35 x 15 / 7.5

(snap-on self-locking spring)

With wall mounting bracket option TSP-WMK01

(see datasheet page 9)

Connection Screw terminals

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 7

Jenatschstrasse 1

CH-8002 Zürich

6.1 Block diagram TSP-BCM24

6.2 Connection of TSP-BCM24

Fig.: 2.1

Fig. 1.1

Remote Link

J3.1

J3.2

J1.2

J1.1

J2.3

J2.4

J2.1

J2.2

J1.4

J1.3

J5.1 J5.2 J5.3 J5.4 J5.5 J5.6 J5.7 J5.8 J5.9 J5.10

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 8

Jenatschstrasse 1

CH-8002 Zürich

6.3 Connectors of TSP-BCM24

J1 J2 J3 J4 J5 J6

Pin 1 -Vin (DC In) GND (-) S+ 15 sec test AC-OK Signal TSP 360-124 (Factory setting)

Pin 2 +Vin (DC In) GND (-) S- Com AC-OK Relay contact TSP 180-124

Pin 3 -Bat in Vout (+) - 10 min test Bat-OK Signal TSP 090-124

Pin 4 +Bat in Vout (+) - - Bat-OK Relay contact

Pin 5 - - - - DC-OK Signal

Pin 6 - - - - DC-OK Relay contact

Pin 7 - - - - Remote ON/OFF

Pin 8 - - - - Remote ON/OFF

Pin 9 - - - - Temperature Sensing

Pin 10 - - - - Temperature Sensing

Fig.: 3.1

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 9

Jenatschstrasse 1

CH-8002 Zürich

55.0

(2.16)

6.4 Wall mounting brackets (TSP-WMK01) for TSP-BCM24

7. TSP-BAT Battery Pack

7.1 Description

The battery packs are designed to built, in connection with the TSP-BCM24 battery

controller module, a complete DC-UPS system. The entire range utilizes 12V

maintanance free VRLA (valve regulated lead acid) batteries made by Panasonic.

These are not spillable lead gel type batteries. Two 12V batteries are connected in

series and assembled inot a stainless steel enclosure, with integrated connector and

connection cable.

8. Technical Specifications

8.1 Input Specifications

Order code Model

(includes mating

connector)

Nominal voltage Charge current

recommended

Nominal capacity

(at +25°C, 77°F)

TSP-BAT-034

TSP-BAT-072

TSP-BAT-120

24Vdc

0.80 A

1.75 A

3.00 A

3.4 Ah

7.2 Ah

12.0 Ah

8.2 General Specifications

Temperature range (max) - during discharge

- when charging / charged

- storage

-15°C - +50°C max (+5°F - +122°F)

0°C - +40°C max (+32°F - +104°F)

-15°C - +40°C max. (+5°F - +104°F)

Battery lifetime 3 - 5 years

Remote link cable 1 cable (0.5m) included

Weight

TSP-BAT-034

TSP-BAT-072

TSP-BAT-120

3.2kg (7.1lb.)

5.8kg (12.9lb.)

9.0kg (20.0lb.)

Fig.: 4.1

Tel: +41 43 311 4511

Fax: +41 43 311 4545

www.tracopower.com

Date: 19 October 2006

Issue: 1.3

Page

Seite 10

Jenatschstrasse 1

CH-8002 Zürich

8.3 Dimensions

8.3.1 TSP-BAT-034

8.3.2 TSP-BAT-072

8.3.2 TSP-BAT-120

Other manuals for TSP-BCM24

1

Table of contents

Other TracoPower Controllers manuals

Popular Controllers manuals by other brands

Hanyoung

Hanyoung NP200 instruction manual

FujiFilm

FujiFilm FRONTIER 350 instruction manual

Outback Power Systems

Outback Power Systems FLEXnet DC user guide

Siemens

Siemens SIRIUS ACT 3SU18 Original operating instructions

Unitronics

Unitronics Vision V130-TR6 installation guide

EVSE

EVSE Viridian EV EPC20 Series manual