TracRac TracONE User manual

Installation Instructions

SKU#

PACKAGED BY:

DATE:

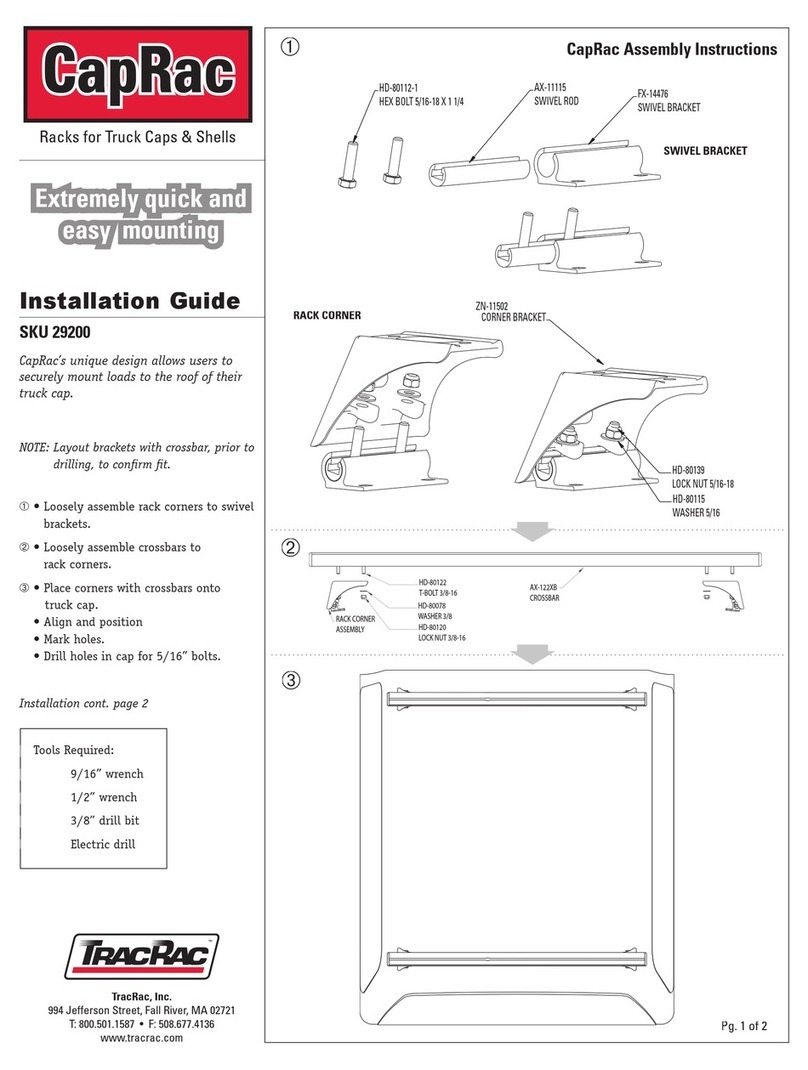

A

B

5

9

1

00-27000-01

4

4

44

44

4

4

10

10

10

10

DETAIL A

6

6

DETAIL B

3

2

77

7

7

8

8

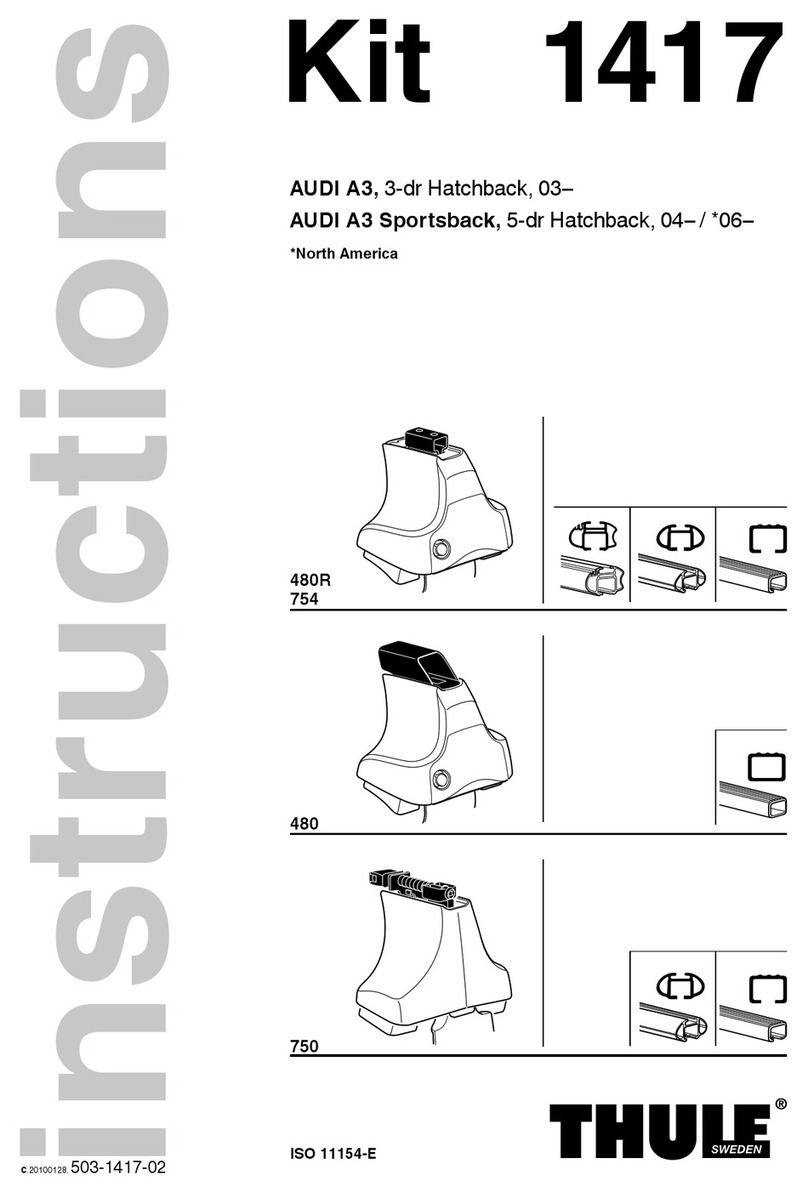

ITEM NO.

PART NUMBER

00-27000-01/QTY.

1

01-27021-01

2

2

01-27023

4

3

01-27012

4

4

01-27006

8

5

RX-11034-3

4

6

01-27015

1

7

01-27016

1

8

01-27043

1

9

01-27013

2

10

01-27035

4

11

01-27014

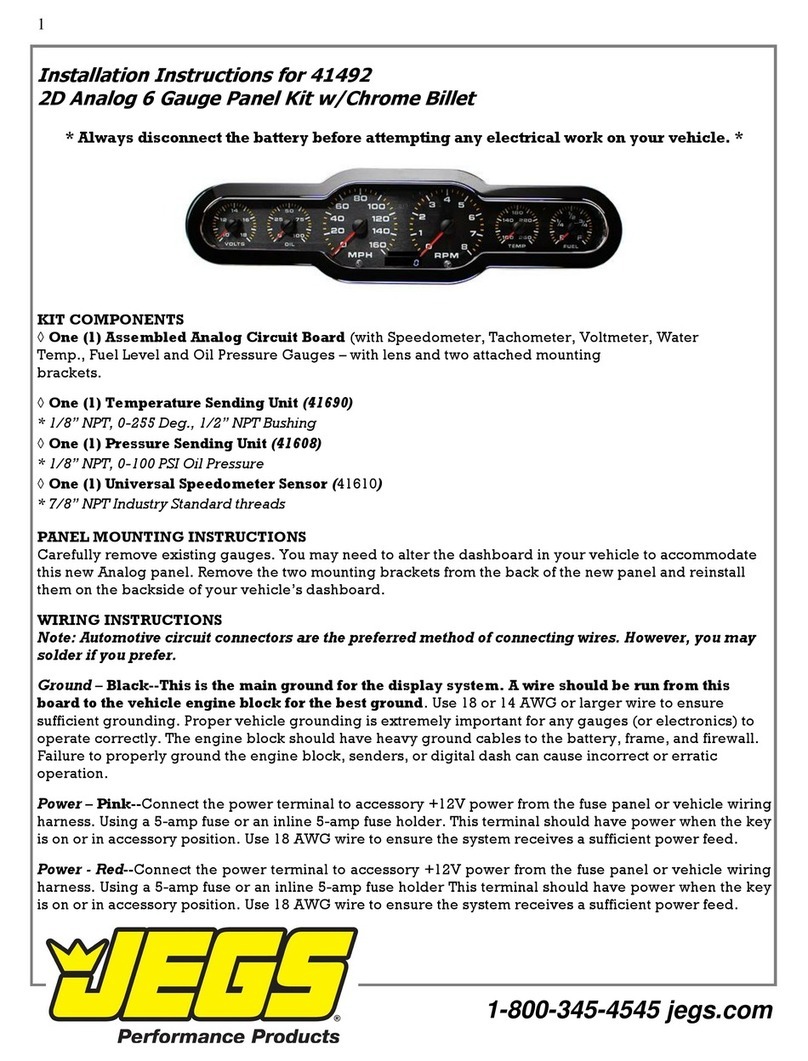

DESCRIPTION

P/C, DOUBLE T SLOT CROSSBAR

P/C, DOUBLE/TRIPLE CROSSBAR ENDCAP

P/C, MODULAR SADDLE

P/C MODULAR CLAMP

SHIM, ROUNDED

HARDWARE BAG - CLAMPS

HARDWARE

BAG - UPRIGHT/SADDLE

HARDWARE BAG

- PLASTIC TIEDOWNS

P/C, UPRIGH BASE

LF/RR

ASM, MODULAR UPRIGHT

P/C UPRIGHT BASE RF/LR

2

Fall River Mass.

TITLE:

SCALE:

1:10

TracONE

-

REV:

R

DESIGN:

EBB

TracONETM Accessories

Part # Description

25250 TracBox - Full Size, Crossover, Powder Coated Toolbox

41000 Toolbox Mount Kit

25110 Aluminum Crossbar Tiedowns (Qty: 2)

44400 Plastic Loop Crossbar Tiedowns ( qty: 4)

44300 Kayak Mount Kit

25411 Bike Mount Kit

34000 Tacoma Mount Kit

41500 Tacoma Mount Kit with Toolbox Mount Kit

TracONE Toolbox Mount Kit - The toolbox mount kit

includes Aluminum Shims & Hardware to mount any

crossover toolbox that will fit your truck.

TracBox - Full size, Silver Powder Coated, Crossover

Toolbox.

Features:

Weatherproof Seals•

Dual Push Button•

Shocks

Heavy Duty Gas•

Shocks

2 Stage Rotary Latch•

Foam Filled Lid•

5 Compartment Sliding•

Tray

L: 70 in. W: 20 in. H 20 in.•

Kayak Rack Kit - Complete with all of the mounting

hardware. The Kayak Kit has felt lined rear saddles and

rubber front saddles for easy loading and a secure fit.

Bike Mount - mount your bikes to the crossbar safely and

securely.

Aluminium Die-Case

CrossBar Tiedowns

Qty: 2 Tiedowns

Plastic Loop Tiedowns

Qty: 2 Tiedowns

Toyota Tacoma Mount Kit- These replacement clamps

work with your existing hardware to mount your TracONE into

the Tacoma Deck Rail System.

Tiedown Options-

These instructions will guide you through the 3 main component assemblies:

Upright units1.

Cross bars2.

Clamp units3.

Please reference the drawing below for a general overview.

Tool you will need:

3/16” Allen Key•

7/32” Allen Key•

Tape Measure•

9/16” Socket and Socket Wrench•

Recommended:•

Torque Wrench

7/32” Allen Drive Bit

Non-Impact Drill

Installation Instructions

A

B

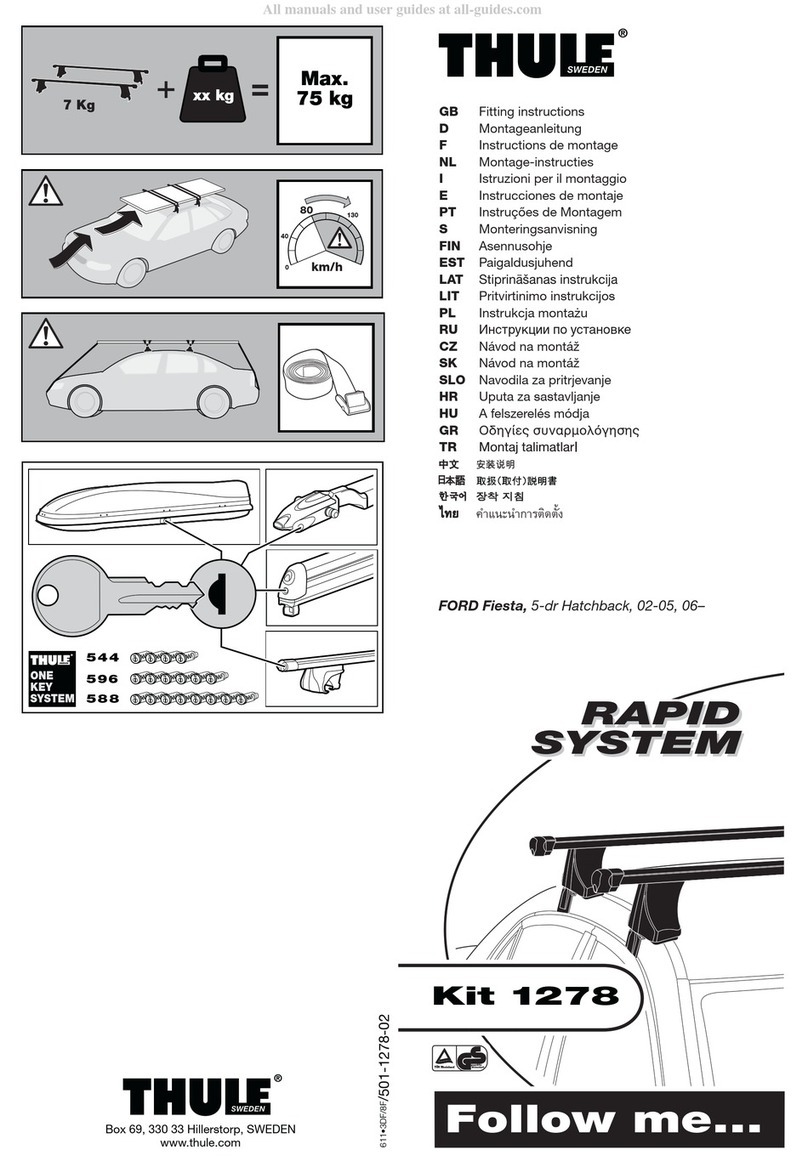

Hardware Bag Contents

01-27016 Hardware Bag-1

Upright/Saddle Hardware

01-27015 Hardware Bag-2

Clamp Hardware

01-27043 Hardware Bag-3

Plastic Tie-down Hardware

Item # 12

3/8 - 16 x 1.5”

Flat Head Cap Screw

Qty - 16

Item # 13

3/8 - 16 x .625”

Button Head Cap

Screw

Qty - 8

Item # 14

3/8 - 16

Square Nut

Qty - 8

Item # 15

M6-1

Socket Head Cap

Screw

Qty - 4

Item # 18

3/8 - 16 x 2.5”

Hex Head Cap Screw

Qty - 8

Item # 19

3.0”

U - Channel

Qty - 8

Item # 20

Plastic Tiedown

Qty - 4

Item # 21

3/8 - 16 x 1.125”

T-Bolt

Qty - 4

Hardware

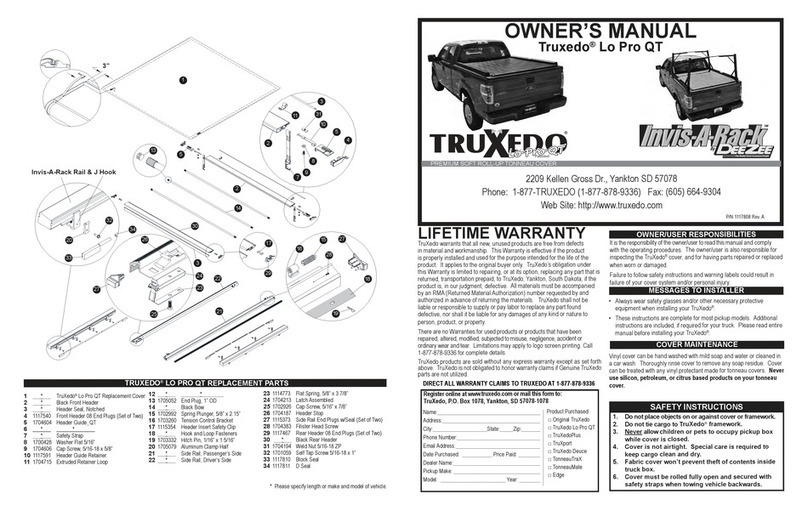

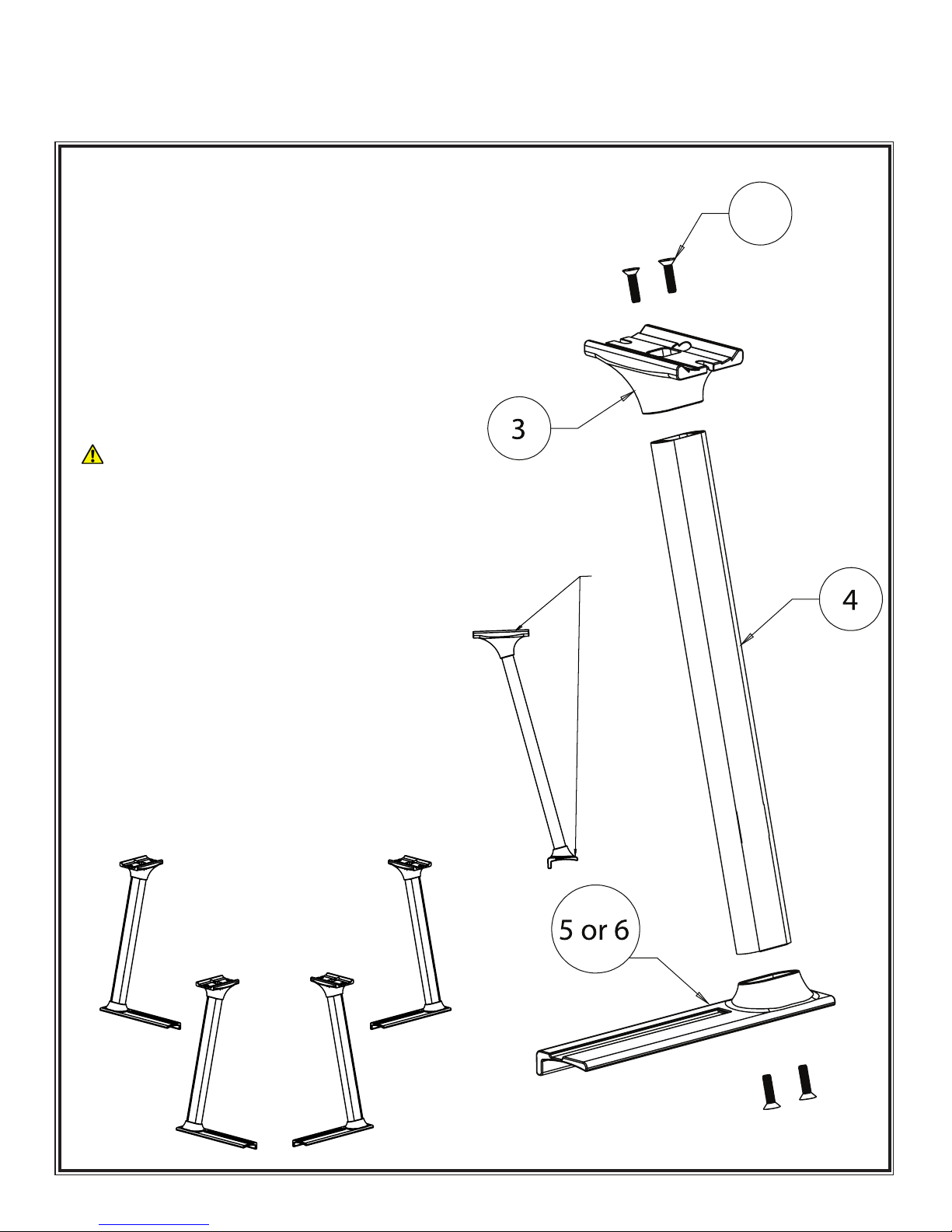

1.1 Upright Assembly

First take the upright (Item 4) and insert it into a1.

modular saddle (Item 3).

Bolt the saddle through the top by using two 3/8”-162.

flat head cap screws (Item 12) and tighten using

an 7/32” Allen Wrench (or 7/32” Allen Drive Bit).

Torque the 3/8” -16 FHCS to 32 ft-lbs. We recom-

mend threading both flat head cap screw initially by

hand to ensure that you don’t cross thread the bolt.

1.1.1 When tightening the 3/8” flat head cap screws

ensure that the allen key is fully seated in the bolt so

that it will not strip

Now take the upright and saddle and bolt it to the

3.

modular base (Item 5)

Bolt the base through the bottom by using two4.

3/8”-16 flat head cap screws (Item 12) and tighten

usingan 7/32” Allen Wrench (or 7/32” Allen Drive

Bit.) Torque the 3/8” -16 FHCS to 32 ft-lbs.

For the other front upright repeat steps one through

5.

four, except use (Item 6) in step three.

Repeat Steps 1-5 on each of the uprights6.

1.1.2 NOTE: Item 5 and Item 6 are mirror images of each

other. Reference the packing checklist to confirm what

part to use.

Step 1

Part 1 - Uprights

12

Figure 1.1

Note:

Both

surfaces

must be

parallel

with each

other

Part 2 - Cross Bars

Step 2

Step 3

Figure 3.1

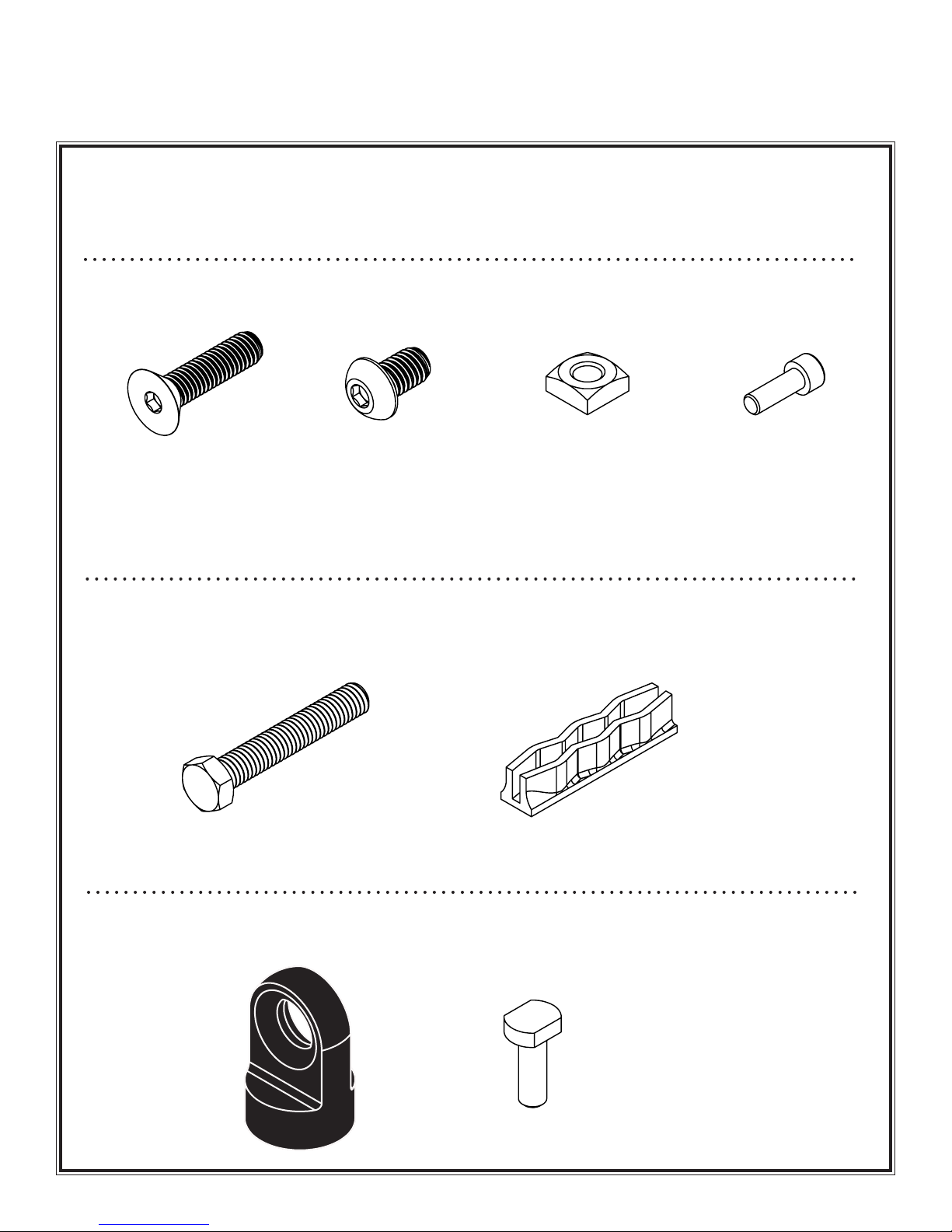

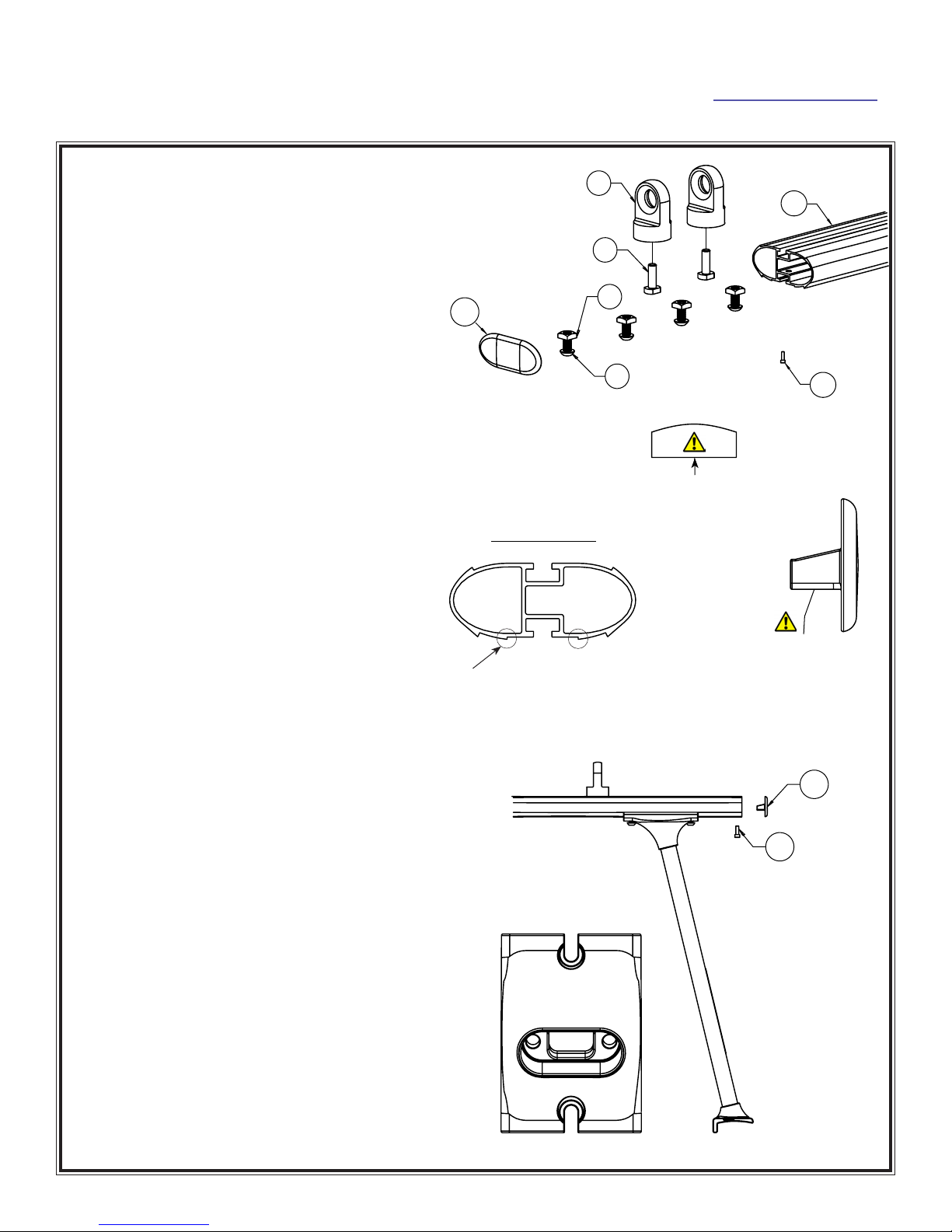

2.1 Crossbar Assembly

Take the double T-Slot crossbar (Item 1) and

1.

insert four square nuts (Item 14) into the bot-

tom T-Slot. Reference Figure 2.1, 2.2 & 2.3

Insert a T-bolt (Item 21) through the bottom of

2.

the cross bar tie-down (Item 20) and slide the

unit into the top track of the crossbar so that

both the bolt and the tiedown are locked into

the t-track.

Insert the Crossbar End Cap with the flat3.

mounting surface facing down into the end

of the crossbar. Using the clearance hole on

the bottom of the crossbar and the M6 SHCS

(Item 15). Tighten down the M6 SHCS using a

3/16” Allen Key. Repeat on the opposite side.

Reference Figure 3.1

Repeat steps 1-3 for the remaining crossbar.4.

3.1 Front & Rear Crossbar Installation

Now place the assembled crossbar on top1.

of the assembled uprights. Make sure the

crossbar is right side up. Reference Figure 2.3

Slide the Square Nuts (Item 14) so that they

2.

are directly above the slotted hole in the

saddle. Insert the 3/8 BHCS (Item 13) into

the Square Nuts (Item 14) and tighten the

cap screws, using an 7/32” Allen Wrench (or

7/32” Allen Drive Bit) Do not fully torque the

screws until Step 8 of the Truck Installation

3.1.1 Note: Make sure that the BHCS sits completely

within the recessed area of the saddle casting. See

Figure 3.2

Repeat Steps 1 and 2 for the opposite upright.3.

Repeat Steps 1-3 for the remaining crossbar.4.

2.4.1 t h i s f a c e d o w n

2.2.1 no t e : f l at

f a c e o f t h es q u a r e

n u t m u s t f a c e t h e

o p e n s l o t o f t h e

c h a n n e l

Figure 2.2

Crossbar End View

Top

Bottom

2.3.1 g r o v e f i t s i n t o s a d d l e

Figure 2.3 Figure 2.4

13

14

21

20

2

15

2

15

Figure 3.2

Figure 2.1 1

Part 3 - Clamps & Truck Installation

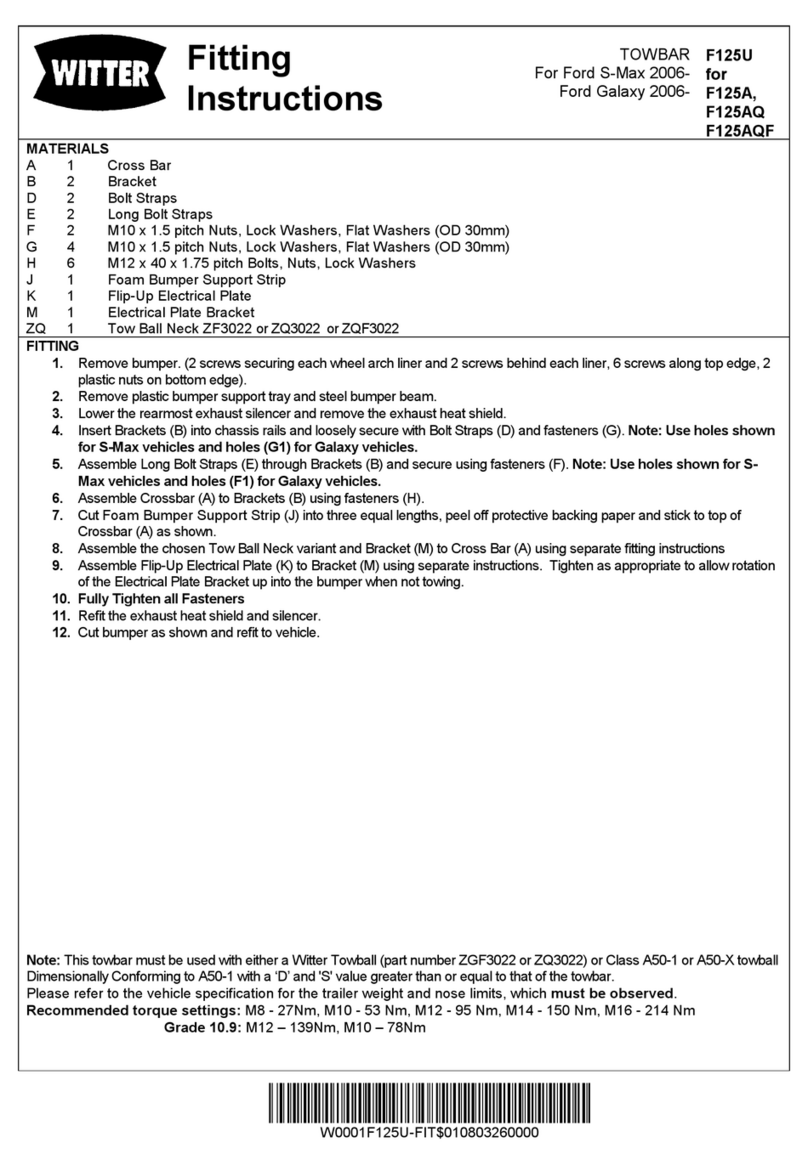

4.1 Base Clamp Assembly

Take a modular clamp (Item 7) and thread a 3/8”-161.

hex head cap screw (Item 18) through the bottom

as shown. (See note about Loc-Tite)

Now take a C channel clamp foot (Item 19) and2.

place it on top of the 3/8” hex head cap screw as

shown.

Repeat steps one and two for the remaining seven3.

clamps.

Step 4

Step 5

4.1.1 Note: Clamp feet must be used to ensure proper clamping

force distribution between the rack and the truck bed and

prevent damage

5.1 Front Upright and Base Clamp Assembly

Now take the rounded shims (Item 8) and place1.

them on the sidewalls of you truck approximately

where the uprights will sit.

The front uprights will be directly behind the rear win-

dow. Place the unit as far forward as possible

Place the front uprights on top of the rounded2.

shims (Item 8) making sure that the rubber shims

are completely under the bases.

With one pair of uprights now on the truck, they3.

must be secured using two Modular Clamps (Step

4). When positioning the clamps make sure they

are spaced as far apart as possible.

First torque the clamps on either side of the rack4.

towards the cab, then follow with the other two

clamps towards the rear of the truck

Torque down the HHCS to 14 lb-ft using a 9/16”5.

socket and a torque wrench.

5.2 Rear Upright and Base Clamp Assembly

The rear uprights should sit as far towards the tailgate

as possible without the base hanging off the back of

the bed rail, while maximizing the distance between the

clamps (Figure 5.2)

Place the rear uprights on top of the rounded shims

6.

(Item 8) making sure that the rubber shims are

completely under the bases.

With the second pair of uprights now on the truck7.

they must be secured using two of the previously

assembled (Step 4) clamps (2 per upright). When

positioning the clamps make sure they are spaced

at least 7 5/16 inches apart. Any less of a distance

will reduce the load capacity of the rack. You may

adjust the position of the rack on the bed to ensure

that this distance can be achieved

Repeat Steps 3-5 on the rear rack.8.

Finally with the uprights secured you now want to9.

take a measuring tape and center your crossbars.

Once centered use your 7/32” Allen Wrench (or

7/32” Allen Drive Bit) to fully secure your crossbars.

Torque the BHCS to 27 ft-lbs.

5.1.1 no t e : Bes u r e t o k e e p t h er u B B e r

s h i m u n d e r t h eB a s ew h e n t i g h t e n i n g t h e

c l a m p s

5.1.2 maximize distance

Figure 5.1

5.2.1 When tightening the 3/8” flat head cap

screws ensure that the allen key is fully

seated in the bolt so that it will not strip

75/16 In.

4.1.2 We recommend

that you apply Loc-Tite

(red) to any thread that is

engaged with the clamp.

4.1.3 HHCS (Item 18)

should be re-torqued every

5000 miles.

Figure 5.2

19

18

7

Apply Loc-Tite

within this area

Table of contents

Other TracRac Automobile Accessories manuals