Jegs 41492 User manual

1

1-800-345-4545 jegs.com

Installation Instructions for 41492

2D Analog 6 Gauge Panel Kit w/Chrome Billet

* Always disconnect the battery before attempting any electrical work on your vehicle. *

KIT COMPONENTS

◊One (1) Assembled Analog Circuit Board (with Speedometer, Tachometer, Voltmeter, Water

Temp., Fuel Level and Oil Pressure Gauges –with lens and two attached mounting

brackets.

◊One (1) Temperature Sending Unit (41690)

* 1/8” NPT, 0-255 Deg., 1/2” NPT Bushing

◊One (1) Pressure Sending Unit (41608)

* 1/8” NPT, 0-100 PSI Oil Pressure

◊One (1) Universal Speedometer Sensor (41610)

* 7/8” NPT Industry Standard threads

PANEL MOUNTING INSTRUCTIONS

Carefully remove existing gauges. You may need to alter the dashboard in your vehicle to accommodate

this new Analog panel. Remove the two mounting brackets from the back of the new panel and reinstall

them on the backside of your vehicle’s dashboard.

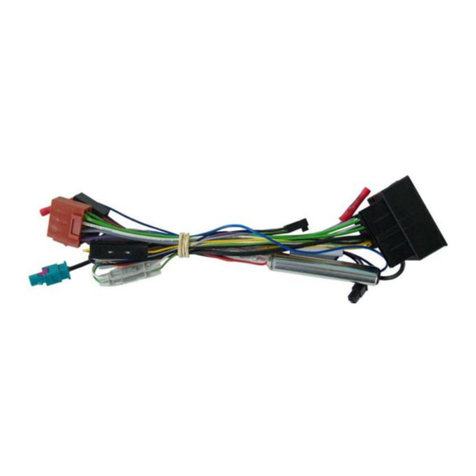

WIRING INSTRUCTIONS

Note: Automotive circuit connectors are the preferred method of connecting wires. However, you may

solder if you prefer.

Ground –Black--This is the main ground for the display system. A wire should be run from this

board to the vehicle engine block for the best ground. Use 18 or 14 AWG or larger wire to ensure

sufficient grounding. Proper vehicle grounding is extremely important for any gauges (or electronics) to

operate correctly. The engine block should have heavy ground cables to the battery, frame, and firewall.

Failure to properly ground the engine block, senders, or digital dash can cause incorrect or erratic

operation.

Power –Pink--Connect the power terminal to accessory +12V power from the fuse panel or vehicle wiring

harness. Using a 5-amp fuse or an inline 5-amp fuse holder. This terminal should have power when the key

is on or in accessory position. Use 18 AWG wire to ensure the system receives a sufficient power feed.

Power - Red--Connect the power terminal to accessory +12V power from the fuse panel or vehicle wiring

harness. Using a 5-amp fuse or an inline 5-amp fuse holder This terminal should have power when the key

is on or in accessory position. Use 18 AWG wire to ensure the system receives a sufficient power feed.

2

1-800-345-4545 jegs.com

Dimmer–Purple Connect to the parking lights to dim the LEDs 50% when the headlights are on. However, *DO NOT

* connect to the headlight rheostat control wire, or the dimming feature will not work properly and may cause damage

to Unit.

Turn Signals - Grey Two 18-gauge wires, one for each signal. Each wire is labeled on the printed circuit

board as ‘LEFT’ and ‘RIGHT’. Connect each wire to its corresponding indicator circuit.

OR

Right Turn Signals - Grey with White strip 18-gauge wire is the - RIGHT turn signal

Left Turn Signals - Grey with Black strip 18-gauge wire is the –Left turn signal. Each wire is also labeled

on the printed circuit board as ‘LEFT’ or ‘RIGHT’. Connect each wire to its corresponding indicator circuit.

Voltage Gauge –This Gauge Requires no wire hookup. Volt Gauge is built into the dash panel

and is powered by the main power and ground connection of the dash. It does have an Adjuster

to fine tune the voltage. Note: you will need to adjust it before fully installing the dash

Brake –Tan - Connect to the parking brake wire from the dash to negative side of parking brake light

switch. NOTE: If you are using a one wire switch you may need to switch to a two-wire switch. This wire is

an optional wire some vehicles may not require

High-Beam –Brown - Connect the brown wire on the Dash unit to your high beam headlight circuit. This

wire is powered on when the high beam is turned on.

Water –Blue - This gauge is incompatible with other sending units, so you must replace the existing water

temperature sending unit with the included sender. Do not use Teflon tape or other sealer on the new

sending unit’s threads to avoid inaccurate readings. Connect the blue wire to the sending unit. For best

results we suggest running a new wire.

Oil Pressure –Orange - Replace the existing oil pressure sending unit with the unit included. Do not use

Teflon tape or other sealer on the new sending unit’s threads. This will avoid inaccurate ground connections

as the sending units get their ground from the threads. The oil sender gets its ground from the threading

into the engine block, thus proper grounding is crucial. Connect to the sending unit.

Fuel –Yellow The fuel gauge sending unit is not normally supplied because the display system can use

the existing fuel level sending unit in the tank in most cases. If your wiring harness already has a single

wire routed through the vehicle for the fuel sender, then it may be used. If using a wire from an external

harness, make sure that the wire does not have power. Fuel senders reference their ground from the

sender mounting plate. Connect the yellow wire to the factory sending unit. Be sure the toggle settings on

the switch match those displayed on the panel, as illustrated. NOTE: If the switch is on the back of the

circuit board the position is UPSIDE DOWN!

Both switches in the ON position for Ford/Chrysler

For GM - #1 toggle is ON

# 2 toggle is OFF.

Both switches in the OFF position for VDO

For Universal/Stewart Warner

#1 toggle is OFF

3

1-800-345-4545 jegs.com

Note: If doing a LS engine swap, pick up the tach signal wire from the ECM/ECU and then set the tach

switch to 4-cylinders. You may also need to order the Intellitronix LS Engine Swap Adapter Kit –for Series

1, 2 and 3 engines. The part number is 555-41614. If you are getting the tach signal from the ECU, the

resistor in the adapter kit will help pull a stronger signal for the tachometer.

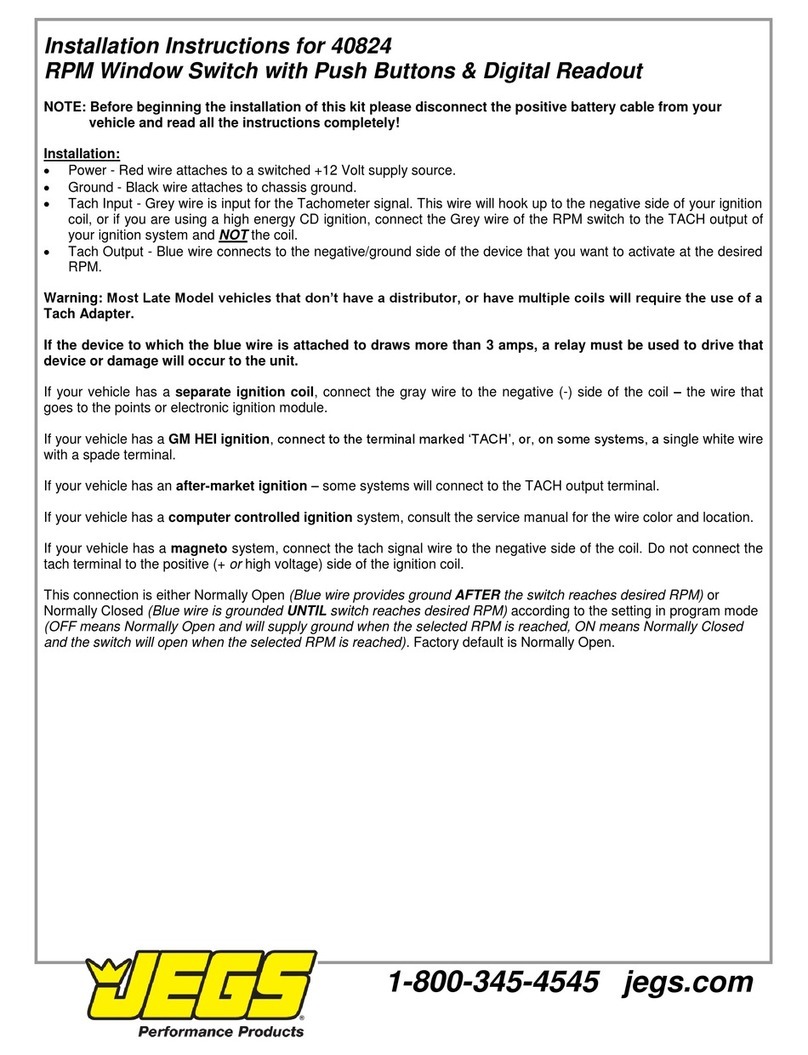

Tachometer –Green If your vehicle has a separate ignition coil, connect the green wire to the negative

(-) side of the coil –the wire that goes to the points or electronic ignition module.

To ensure that the ignition system does not interfere with any other dashboard functions, do not run the

tachometer wire alongside any other sender or input wires. Do not use solid core spark plug wires with this

dashboard system. Solid core ignition wires cause a large amount of electromagnetic and radio frequency

interference which can disrupt the system’s operation.

If your vehicle has a GM HEI ignition, connect to the terminal marked ‘TACH’, or, on some systems, a single

white wire with a spade terminal.

If your vehicle has an after-market ignition –some systems will connect to the TACH output terminal.

If your vehicle has a Computer controlled ignition system, consult the service manual for the wire color

and location.

If your vehicle has a magneto system, connect the tach signal wire to the negative side of the coil. Do not

connect the tach terminal to the positive (+ or high voltage) side of the ignition coil. Many tachometers,

shift lights or RPM-activated switches will not read directly from a Magneto, so your installation may need

a Magneto Signal Converter to function properly.

The default setting for the tachometer is for an 8-cylinder engine.

To set the cylinder selection: With the ignition off, hold in the right button and power the dash on.

The tach will then enter a setup mode where the needle will move (between the zero and one on the face

of the instrument) to indicate 400 (4 cylinder), 600 (6 cylinder) or 800 (8 Cylinder) continuously.

When the needle gets to the desired setting, tap the right button once more. It is now set and will enter

normal operating mode. To see the high RPM/tach setting, hold down the right button. It will reset after

five seconds.

Digital Performance Speedometer

Speedometer –White - (Factory sender with Powertrain Control Module) When using a LS engine

swap, you will need to pick up the Speedometer signal wire from the PCM Pin 50 on the red connector.

(This pin may Differ. Refer to your vehicles Pinout Chart for accuracy). Any other Computer based engine

will need to use to use the PCM/ECM to run the speed signal for the Speedometer.(Consults Pinout Chart)

Speedometer –White - (Factory two wire sender no PCM) - Most vehicles built after 1984 have an

electronic transmission sender. If your vehicle is already equipped with an electronic transmission, then

the electronic vehicle sender will usually have Two wires attached to it. One connects to the Signal wire on

dash (we prefer this to be high output). The other wire (Low output) Ground at the Engine block. To find

High and Low output wire color or pin location will need to be looked up by Vehicle vin or Model and year

or (Consults Pinout Chart).

4

1-800-345-4545 jegs.com

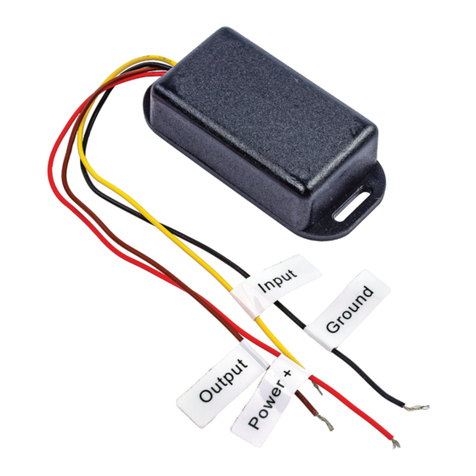

Speedometer -White (JEGS- Speed Sender) - Disconnect the mechanical speedometer cable from the

transmission and thread the new electronic sensor onto the transmission. This panel comes with a 3-wire

sensor. If you are using this sensor, the white wire is the speed signal; connect this to the speed signal

wire on your gauge. The red and black wires in the cable are switch power (12VDC) and ground,

respectively. NOTE:(Twist all Three wires together and this will provide an additional level of interference

protection.) The speed signal wire should not be routed alongside the tachometer, ignition, or any other

high-current or high-voltage wires. NOTE: When using in a FORD you will need a 555-41611

The recall button on the speedometer operates as follows:

Once –cycles between Trip Mode, Odometer Mode and the clock.

Clock –To set the clock push quickly push both buttons simultaneously and release. Use the buttons to

scroll to the correct setting.

While in Odometer Mode:

1. Hold LEFT to enter Recall/Setting Mode

2. ¼ Mile Recall

3. 60 Second Time Recall

4. Odometer Setting

5. Calibration

CALIBRATION

The speedometer leaves the factory with a pre-set industry standard setting of 8,000 pulses per mile.

Chances are that you may not need to recalibrate your speedometer, unless you have changed the

original tire size or the rear end gear ratio.

Note: Do not attempt to recalibrate your speedometer until after it is working properly, and you have

determined that the speed is incorrect. The calibration procedure will NOT correct a faulty installation or

improper wiring. If you attempt to recalibrate your speedometer without making sure the speedometer is

receiving pulses from the sending unit, the speedometer will display ‘Err’ and default back to the factory

settings.

To calibrate:

Locate a measured mile where you can safely start and stop your vehicle. By running the vehicle over

this measured distance, the speedometer will learn the number of pulses outputted by the speedometer

sensor during a specific measured distance. It will then use this acquired data to calibrate itself for

accurate reading.

1. There is a small recall push-button in the center of the panel used to calibrate and read all of the data

stored in the speedometer. After installing your speedometer according to the wiring instructions, when

the ignition is on it should immediately display the default screen of 0 MPH, if the vehicle is not moving.

NOTE: You will now need to drive your vehicle to the predetermined measured mile. During this trip, the

speedometer should read something other than 0 MPH. If it does not change, return and locate the

problem before continuing. Otherwise, proceed with the calibration.

5

1-800-345-4545 jegs.com

2. Stop at the beginning of the measured mile with your vehicle running and in odometer mode (NOT trip

mode), press and hold the push-button until the odometer displays ‘HI-SP’. On its own, the gauge will then

cycle through the recorded performance in the following order: ‘0 – 60’, ‘1/4’, ‘ODO’, and ‘CAL’.

3. While ’CAL’ is displayed, quickly tap the push-button once. This will put the speedometer in Program

Mode. If you did not tap while ‘CAL’ is displayed, the pulses per mile will be displayed on the odometer

and the display will go back to MPH mode. Otherwise, you will now see ‘CAL’ displayed along with the

number ‘0’. This indicates that the microprocessor is now ready for calibration.

4. When you are ready, begin driving on the metered mile. You will notice that the reading will start

counting up. The odometer will begin to display the incoming pulse count. Drive the vehicle through the

measured mile (speed is not important, only the distance traveled).

5. At the end of the mile, stop and press the push-button again. The odometer will now display the new

number of speedometer pulses that were registered over the distance. The odometer will continue to

display the pulse reading for a few seconds. Once it reverts to the default mode, you have successfully

calibrated your speedometer.

Warning: If, while in ‘CAL’ mode, you do not move the vehicle but press the button again, the

microprocessor will NOT have received any data and the unit will display ‘Err’ and will revert to the

factory settings. At a minimum, drive some distance and return to the start if necessary. If you miss

stopping the display at ‘CAL’, simply repeat the steps.

Setting the Odometer

While scrolling through ‘CAL’ mode you will see ‘ODO’ appear. This will allow you to enter the vehicle’s

actual mileage. Press the trip button again at this point and you will enter the odometer set up mode. Press

quickly to change the number of the digit on the right. Press and hold to advance to the next digit. Do this

for all 5 digits.

For Example: To enter the mileage 23456 into the odometer, at the ‘ODO’ prompt, tap the small black

button (quickly) two times, until the number 2 is displayed. Then press and hold the button until the

numbers 20 are displayed. Tap the button 3 times until 23 is displayed. Press and hold

the button until 230 is displayed and continue in this manner until 23456 is displayed. The speedometer

will advance to the home screen, five seconds after the last number is entered.

Recording and Viewing Performance Data

Follow these steps to record and recall Performance Data (high speed, ¼mile ET, and 0- 60 time):

1. Before each run, your car must be at a complete stop at the starting position. Press and hold the push-

button as it cycles through the performance data. At the end, the odometer will reset, and all performance

data will be cleared. This will not affect your stored calibration value or the odometer reading.

2. Press the push-button until ‘HI-SP’ is displayed. The gauge will automatically cycle through the

performance data.

3. Start the run, pass, session, etc., as mentioned above.

4. When finished, repeat Step 2 to view the data gathered from the run. While stopped, you can view this

data as often as you wish. However, once it finishes scrolling one time, the memory is ready to record new

data and will begin recording again once the vehicle starts to move. The highest speed measured over

multiple runs will be retained in memory.

Table of contents

Other Jegs Automobile Accessories manuals