Tractel Group altotir Manual

Operating and

maintenance instructions

Manual de empleo y

de mantenimiento

Istruzioni per l’uso e

la manutenzione

Instruções de uso e

de manutenção

GB

E

IT

P

altotir™

Powered drum winch

Torno eléctrico de tambor

Argano elettrico a tamburo

Guincho eléctrico de tambor

2

English

Español

italiano

Português

2

GB

CONTENTS Pages

1) Important safety information ............................................................................................ 3

2) Pictogram definitions ........................................................................................................ 4

3) Presentation

3.1 Conditions and composition of standard delivery ............................................ 4

3.2 Product definition ................................................................................... 4 and 5

3.3 Compliance with applicable regulations and standards .................................. 5

4) Description

4.1 Description of functions ................................................................................... 5

4.2 Altotir system components .............................................................................. 6

4.3 Dimensional specifications .............................................................................. 7

4.4 Functional specifications ................................................................................. 8

4.5 Electrical diagram ............................................................................................ 9

4.6 Control components ...................................................................................... 10

4.7 Safety devices ............................................................................................... 10

5) Wire rope ............................................................................................................ 10 and 11

6) Jib crane for scaffolding ................................................................................................. 11

7) Setup, installation

7.1 General checks before installation ........................................................ 11 to 13

7.2 Installation on jib crane ......................................................................... 13 to 15

7.3 Installation on frame ............................................................................. 15 to 18

7.4 Installation bearing on base tube ....................................................... 18 and 19

7.5 Commissioning .............................................................................................. 19

8) Maneuvers

8.1 Preliminary conditions ................................................................................... 19

8.2 Checks before use ........................................................................................ 19

8.3 Procedure ............................................................................................. 20 to 21

9) Emergency procedure in case of incident ...................................................................... 21

10) Unauthorized use of winch equipment ............................................................. 22 and 23

11) Malfunctions ..................................................................................................... 24 and 25

12) Temporary removal from service and deinstallation

12.1 Removal from service .................................................................................. 25

12.2 Checks before deinstallation ....................................................................... 26

12.3 Deinstallation procedure .................................................................. 26 and 27

13) Transport and Storage ................................................................................................. 27

14) Servicing, maintenance, periodic checks

14.1 Periodic checks required .................................................................... 27 to 29

14.2 Servicing, maintenance ............................................................................... 29

14.3 Spare parts ......................................................................................... 30 to 33

14.4 Inspection and maintenance sheet .............................................................. 33

15) Scrapping and protection of the environment .............................................................. 33

16) Markings on product and written instructions ............................................................... 33

Always concerned to improve the quality of its products, the TRACTEL Group reserves the right to modify

the specifications of the equipment described in this manual.

The companies of the TRACTEL Group and their agents or distributors will supply on request descriptive

documentation on the full range of TRACTEL products: lifting and pulling machines, permanent and

temporary access equipment, safety devices, electronic load indicators, accessories such as pulley blocks,

hooks, slings, ground anchors, etc… The TRACTEL network is able to supply an after-sales and regular

maintenance service.

3

GB

IMPORTANT SAFETY INFORMATION

1) Before installing and using your winch, be sure you are

perfectly familiar with the information contained in this manual;

you must comply with the utilization and safety instructions

given to ensure safe use of the winch. A copy of this manual

should be available to all winch users. Additional copies can

be provided on request.

2) Do not use the winch if any of the identication plates mounted

on the winch are damaged or illegible, or if any of the

markings, as indicated in section 16, are no longer legible. In

case of a damaged information plate, identical plates can be

supplied on request and should be fastened to the equipment

before continuing use of the equipment.

3) Make sure that any person to whom you have entrusted use

of the winch is perfectly familiar with the information contained

in this manual and is able to satisfy the safety requirements

involved by the purpose for which the equipment is used. This

manual should be in the user’s possession.

4) For all professional purposes, the winch must be placed under

the responsibility of a person who is perfectly familiar with the

applicable regulations and who has the necessary authority

to ensure application of these regulations by all users.

5) Any person using the winch for the first time must check, in a

risk-free environment, before applying the load, and on a

limited lifting height, that he has fully understood all the

requirements for safe, efficient operation of the equipment.

6) Set up and operation of the winch must only be performed

under conditions ensuring operator safety in compliance with

the regulations applicable to the equipment category.

7) Before use, systematically check that the winch and its

accessories are in good condition.

8) Tractel

®

shall not be held liable for use of the winch in any

setup configuration not described in this manual.

9) Any changes to the winch not supervised by Tractel, including

removal of parts, shall release Tractel

®

from all liability.

10) Any equipment assembly or disassembly not described in

this manual, or any repair performed without Tractel

®

authorization will release Tractel

®

from all liability, especially

where original parts are replaced by parts which are not

genuine Tractel

®

parts.

11) The winch must never be used for any operations other than

those described in this manual. It should never be used with

loads exceeding the working load limit indicated on the

winch. The winch should never be used in an explosive

atmosphere.

12) To ensure safe use of the winch, it must be inspected and

serviced regularly to ensure that it is in a good, safe

operating condition. The winch should be inspected

periodically by a Tractel-approved repair agent as indicated

in this manual.

13) When the winch is not being used, it should be kept safety

out of reach of persons not authorized to use it.

14) For definitive removal from use of the winch, it should be

scrapped under conditions preventing any future use of the

winch. All environment protection regulations must be

observed.

15) The winch must be anchored to a structure which is

sufficiently strong to withstand the working load limit

indicated in this manual. If several units are used, the

strength of the structure and of the anchor point must be

consistent with the number of winches used in accordance

with their working load limit.

16) Never stand or circulate under the load. The area located

under the load should be indicated and access to this area

should be prohibited.

17) The winch must only be used in full compliance of applicable

safety regulations and standards relative to the installation,

use, maintenance and inspection of equipment lifting

devices.

18) It is strictly prohibited to use the winch for lifting or moving

persons.

19) During the lifting operations, when moving up or down, the

operator must always have a clear, uninterrupted view of the

load.

20) Before connecting the winch to its power source, check that

the power source complies with the characteristics of the

winch and that the electrical installation satisfies all the

necessary safety regulations.

21) Tractel

®

will only guaranty operation of the winch provided it

is equipped with a genuine Tractel

®

wire rope having the

characteristics specified in this manual.

22) Any intervention on the wire rope aimed at modifying or

repairing it outside Tractel

®

supervision will release Tractel

®

from any liability subsequent to the modification or repair

performed.

23) Keeping the wire rope in good condition is essential to safety

and correct operation of the machine. The condition of the

wire rope should be checked each time it is used as

indicated in the “wire rope” section. Any wire rope showing

any signs of damage must be immediately and definitively

removed from use.

24) During use, the operator must ensure that the wire rope is

constantly tensioned by the load and, in particular, that the

wire rope is not temporarily neutralized by an obstacle when

bringing a load down, as this could result in rupture of the

cable when the load comes free from its obstacle.

25) Before use, systematically check that the high limit stop is

properly positioned and operates correctly.

26) During lifting and lowering operations, the operator must

constantly observe the maneuver and the load to prevent

any risks of snagging.

IMPORTANT:

For all professional uses, especially when the machine

is to be used by employee personnel, you must

comply with all work regulations applicable to

installation, maintenance and use of the equipment, in

particular as concerns the required inspections:

inspection on first use by user, periodic inspections,

and inspections after disassembly or repair.

4

GB

2) Pictogram definitions

In this manual, the following terms are used:

“Operator”: Person or department in charge

of management and safe use of the product

for the purpose for which it is intended.

“Installer”: Person or department in charge of

assembly of the components of the product

received, installation of the product for use,

disassembly, dismantling, and transport for

storage and shelving.

“Technician”: Qualified person who is skilled

and familiar with the product, and who is in

charge of the maintenance operations

described in this manual.

“After-sales service”:

Company or department authorized by a

company of the Tractel®group for after-sales

service or repair operations on the product.

“DANGER”: Indicates remarks inten-

ded to avoid injury to persons which may be

mortal, serious or minor.

“IMPORTANT”: Indicates remarks

intended to avoid a failure or damage to the

product, equipment or environment, but not

directly endangering the life or health of the

operator or any other persons.

“NOTE”: Indicates remarks relative

to precautions to be followed to ensure

efficient and comfortable installation, use and

maintenance, with no implication of damage

or injury.

Read the user manual. This

symbol must be present on the product, and

indicated in the “Markings” section.

Enter the information in the

inspection and maintenance sheet.

3 Presentation

3.1 Conditions and composition of

standard delivery

The altotir™ winch standard delivery

comprises:

1. A plastic bag containing: 2 clamps for

mounting on tube (Fig. 1, item 8) and

4 clamping nuts (Fig. 1, item 14).

2. A plastic bag containing a CE statement

along with this user manual.

3. The winch, comprising:

• A control unit (Fig. 1, item 16)

• A power connector (Fig. 1, item 20)

• A lifting wire rope (Fig. 1, item 1)

equipped with its lifting hook (Fig. 1,

item 2)

NOTE: Any delivery not

comprising all the items of the standard

product composition must be compared

against the order.

3.2 Product definition

3.2.1 Definition of product and

intended use

The altotir™ winch is an electric drum winch.

It is designed for vertical load lifting by an

electric motor-driven winch. The winch is

designed to be manually transportable.

The winch is usually used as follows:

• Winch mounted on scaffolding jib crane,

itself secured to scaffolding (Fig. 10)

• Mounted on frame.

Other utilization configurations are detailed in

the sections which follow:

GB

3.2.2 Operating principle

Using the two control buttons on the control

unit (Fig. 1, item 21), the operator controls

lifting and lowering of the load secured to the

lifting hook (Fig. 1, item 2). To stop an up or

down movement, the operator simply

releases the control button used.

3.2.3 Characteristics of host structure

IMPORTANT: Before using the hoist,

the operator must make sure that the

scaffolding is sufficiently strong and stable to

handle the working load limit of the winch, to

which the weight of the unit and its

accessories must be added, in compliance

with applicable rules and regulations.

3.2.4 Complementary product

required (see Section 7)

When using the altotir™ winch on scaffolding,

a scaffolding jib crane (Fig.8) is required. The

altotir™ winch must be secured on the jib

crane tube (Fig. 10, item 11) by its mounting

clamps (Fig. 10, item 8).

The assembly formed by the altotir™ winch

and the jib crane must be secured to a

vertical tube of the scaffolding using clamps

and a pivot (Fig. 8, items 3 and 4).

3.3 Compliance with applicable

regulations and standards

The altotir™ winch satisfies the requirements

of machinery directive 98/37/CE and outdoor

directive 2000/14/CE.

4 Description

4.1 Description of functions

The altotir™ winch is formed by a frame and

a geared motor assembly coupled to the wire

rope warping drum.

The frame ensures the following functions:

• Enables setting the winch on the ground in

a stable position on its base tube (Fig. 1,

item 12)

• Allows 2 persons to carry the winch by its

carrying handle (Fig. 1, item 11).

• Protects the assembly formed by the

geared motor and drum (Fig. 1, items 3, 4,

5) against projections and impacts when

installing and during use, transport and

storage of the unit.

• Ensures protection of the electrical unit

(Fig. 1, item 6) against projections, impacts

and weather when installing and during use,

transport and storage of the unit.

• Facilitates storage by its rectangular shape.

• Provides access to the electrical unit (Fig.

1, item 6) by an access plate covering the

electrical unit (Fig. 1, item 18).

• Ensures storage of the control unit (Fig. 1,

item 15) and the power connector (Fig. 1,

item 20) during transport and storage of the

unit.

• Enables securing the unit in its working

position by means of clamp fastening studs

(Fig.1, item 13) and clamp fastening cross-

members (Fig. 1, item 7).

• Enables use of the winch seated on the

ground (Fig. 12).

The geared motor ensures the following

functions:

• Lifting and lowering of a load by a single

phase electric motor (Fig. 1, item 4) driving

a reduction gear (Fig. 1, item 22), itself

driving a drum on which the wire rope winds

and unwinds.

• Enables maintaining the load in a stopped,

stationary position during an up or down

cycle by the spring-applied break.

5

6

GB

4.2 Altotir system components

The altotir™ winch is formed by the following components, shown in Fig. 1.

13

22 311 14 7

8

17

9

12

5

4

19

18

6

16

21

15

10

2

20

1

1) Lifting wire rope

2) Lifting hook

3) Wire rope warping drum.

4) Electric motor

5) Spring-applied brake

6) Electrical unit

7) Fastening crossmembers

8) Tube mounting clamps

9) Limit stop lever

10) Limit stop

11) Carrying handle

12) Base tube

13) Clamp fastening studs

14) Clamp fastening nuts.

15) Control unit.

16) Emergency stop button

17) Protective casing

18) Electrical unit access cover

19) Motor compartment access cover

20) Power connector

21) Load up-down control buttons

22) Reduction gear

The equipped wire rope is formed by the

lifting wire rope (Fig. 1, item 1), the lifting

hook (Fig. 1, item 2), and the limit stop

(Fig. 1, item 10).

The dimensions indicated on the figures in

this manual are expressed in millimeters

(mm).

NOTE: Each altotir™ winch is

tested before shipping to 110 % of its

working load limit (WLL) on a lifting height

of 1m, and to 125% of its working load limit

in static utilization mode.

4.3 Dimensional specifications

The dimensional specifications (in millimeters) of the winch are indicated in Figures 2a and

2b below.

7

GB

320

19

314

651

Ø 110

98

889

222

89

4xM10

309

Ø28

280

Figure 2a: Dimensional characteristics of winch, side view

Figure 2b: Dimensional characteristics of winch, front view

4.4 Functional specifications

The functional specifications of the winch are listed in the table below.

8

GB

Winch technical data

Winch altotir™ 200

Weight kg 49

Working load limit (WLL) kg 200

Power supply

Voltage V230 ± 12

Frequency Hz 50

Type -Single phase

Motor power kW 0.87

Startup current A11

Rated current A 8

Control voltage V230

Rated lifting speed m/min 21

Maximum working height m25

Guarantied sound power LwA dB (A) 81

Level of weighted equivalent continuous acoustic

pressure A LAeq

dB (A) 68

Level of weighted equivalent instantaneous acoustic

pressure Lp

dB (C) 85

Outline dimensions for packaging (LxlxH) mm 690 x 280 x 320

Classification mechanism per FEM -1Cm

Protection degree

Control unit -IP65

Power connector -IP44

Electric motor -IP55

Electrical unit -IP55

Length of power cable m 1

Length of control cable m 1,5

Wire rope technical data

Unit altotir™ 200

Diameter mm 4

Tensile strength kN 13

Composition -19 x 7

Treatment -Galvanized

Length m25

4.5 Electrical diagram

DANGER:

Access to the control unit, electrical unit and motor is strictly limited to qualified electricians.

The electrical diagram of the winch is given in Figure 3.

9

GB

Figure 3: Electrical diagram of winch

4.6 Control components

The winch is operated by pressing either the

“Up” or “Down” button on the control unit

(Fig. 1, item 16); The control unit must

always be held in a vertical position by which

it hangs from its control cable. Never place

the control unit in the upside-down position

(control cable down) as this could result in

erroneous maneuvers.

When the “Up” or “Down” button is released,

the movement stops.

NOTE: “Up” and “Down” is indica-

ted on the corresponding control button by

an arrow pointing in the direction of

movement controlled, with the control unit

held upright and the control cable leading

upward (Fig. 1, item 16).

4.7 Safety devices

The altotir™ winch has the following safety

devices:

• Spring-applied brake (Fig.1, item 5).

• Red emergency stop button on control unit

(Fig. 1, item 16).

• Mechanical interlocking, inhibiting simulta-

neous action of the Up and Down controls

(integrated in control unit).

• Limit stop lever on winch (Fig. 1, item 9)

which functions with the limit stop (Fig. 1,

item 10), which can either be fixed or

adjustable, to meet the installation needs.

• Safety latch on hook (Fig. 4, item 2 ).

• Electrical protection of control unit: class 2.

The emergency stop is obtained by pressing

the red emergency stop button (Fig. 1,

item 16). In order to restart the winch after an

emergency stop, the emergency stop button

must be released by turning it in the direction

of the arrows marked on the button, after you

have made sure that the emergency

condition has been eliminated.

The hook with safety latch is shown in

figure 4.

Composition :

1) Lifting hook

2) Safety latch

NOTE: The 230V single phase

motor is protected against overheating by a

temperature sensor in the winding. The

sensor inhibits operation and interrupts the

control circuit when the temperature in the

winding is not below the trigger threshold

value.

5 Wire rope

The lifting wire rope, equipped, is shown in

figure 5.

Composition :

1) Lifting wire rope

2) High locking sleeve for limit stop

3) Limit stop

4) Low locking sleeve for limit stop

5) Loop with thimble

6) Lifting hook

IMPORTANT: To ensure safe use of

the altotir™ winch, only the altotir™ wire

rope, specially designed for this winch,

should be used.

DANGER: 1. Use of the winch with

a damaged wire rope or with a wire rope

which is not appropriate for the winch

represents a major risk of accident and

failure. The wire rope must be checked

regularly on an on-going basis to ensure that

it is in good condition. Should the wire rope

show any signs of damage, such as

deformation, bending, broken wires (Fig. 6),

it should be immediately replaced. Any wire

rope for which the nominal diameter has

been reduced, due to wear, by 10%, or which

10

GB

has more than 10 broken wires along a

length of 200mm should be eliminated.

Standard ISO 4309 (Lifting devices for

suspended loads – Wire ropes – Servicing,

maintenance, installation, inspection and

removal).

• Measure as indicated (Fig. 7).

Do not expose the wire rope to temperatures

exceeding 100°C or to aggression by

mechanical or chemical agents.

At one end, the wire rope of the altotir™

winch is equipped with a hook with safety

latch mounted on a wire rope loop equipped

with a thimble and a swaged sleeve. At this

end, it is also equipped with a limit stop

located between two specific sleeves. The

other end is fastened to the drum by a wedge

socket system (Fig. 14).

Check regularly that there are no signs of

damage where the wire rope is fastened to

the drum and to the lifting hook.

If any damage is observed, immediately

replace the complete wire rope.

6 Additional accessories

Optionally, Tractel®can also supply:

• A jib crane for mounting on scaffolding

(Fig. 8).

• An adjustable limit stop (Fig. 9).

6.1 Jib crane for scaffolding

This jib crane is particularly suited for use of

the altotir™ winch with tubular scaffolding of

diameter 49mm.

The jib crane is secured to a vertical tube of

the scaffolding and the altotir™ winch is

anchored to the anchoring tube (Fig. 8,

item 11).

The jib crane for scaffolding is shown in

figure 8.

Composition:

1) Male pivot clamp fastening nuts

2) Washers under male pivot clamp

fastening nuts

3) Male pivot clamp

4) Male pivot

5) Washer enabling sliding of female pivot

on male pivot

6) Locking pin securing male pivot on

female pivot

7) Locking screw securing male pivot and

clamp on scaffolding tube

8) Jib crane

9) Female pivot

10) Nut and locknut for adjustment and

locking of female pivot on jib crane

11) Anchoring tube

6.2 Adjustable limit stop

The adjustable limit stop is specially

designed to limit the load lifting height.

The adjustable limit stop is shown in

Figure 9.

Composition:

1) Adjustable limit stop plate

2) Wire rope clamp

3) Clamping screw

4) Hex key to tighten screws

7 Setup, installation

7.1 General checks before installation

These checks are applicable to all the winch

utilization configurations described in this

manual.

7.1.1 Host structure checks

• The mechanical strength of the host

structure to which the altotir™ winch will

be anchored, and the strength of the

pulleys, must be compatible with the

WLL of the winch, with its own weight

added.

11

GB

12

GB

7.1.2 Environment checks

Before installing, check that:

• The electrical power source is

compatible with the altotir™ winch (230

V / 50 Hz single phase) ; refer to the

nameplate and technical data table for

the altotir™ winch.

• The electrical power source is protected

in compliance with the applicable

regulations by a differential circuit-

breaker and a ground link, protecting the

operator, the altotir™ winch and its

equipment.

• The length of the electrical control cable

is sufficient to connect the winch in the

location defined by the operator under

satisfactory safety conditions.

• The operator has uninterrupted eye

contact on the equipment load along the

entire lifting height.

• The work area is secured in compliance

with applicable regulations.

• The installer has the necessary fastening

(slings) and lifting means to safely

position the altotir™ winch next to the

opening of the seating plane (Fig. 12,

item 2).

• The anchoring point for installation lifting

device is compatible with the weight of

the altotir™ winch, in compliance with

the applicable regulations.

• The location for lifting or setting the

equipment loads to be handled by the

altotir™ winch are compatible as

concerns access, strength, horizontality,

and adhesion of loads considered.

• There are no obstacles against which the

load or wire rope may bear or rub

laterally, or against which the load may

snag.

7.1.3 Winch check

Before installing, you must check that:

• The altotir™ winch is compliant with the

standard delivery as detained in this

manual.

• The length of the wire rope is sufficient

for the path to be covered by the load.

Add an additional 1 m to ensure two

remaining windings on the drum when

the load is in the lowered position.

• All of the safety systems on the altotir™

winch operate (see § 4.7).

• The wire rope passes through the

opening provided on the limit stop lever.

If not, proceed as follows:

- Switch off the winch and disconnect the

electrical power supply

- Insert the lifting hook (Fig. 1 item 2)

through the opening provided on the limit

stop lever (Fig. 1, item 9).

- Place the limit stop in a skewed position

in order to insert it in the opening

provided on the limit stop lever.

• If an extension cord is used for the electrical

power supply, it must have the following

technical characteristics:

• 230 V single phase: 3 wires (1 phase,

1 neutral, 1 ground) with section of

2.5 mm².

These characteristics are valid up to 50 m

of electrical cable. Beyond this length,

contact the Tractel®network.

• The connection of the electrical

extension cord is reinforced by an

accessory (“sleeve”) so that the

connectors do not have to support the

weight of the extension cord.

• If an electric power generator is used as

power source, that it delivers, at the

least, the voltage and power required for

startup, i.e. 6 kVA.

IMPORTANT: It is prohibited to use

the winch for pulling, slanted lifting, pulling

along a slanted plane or any other

configuration other than those described in

this manual.

DANGER: If the winch is to be

installed in a location which is dangerous for

the operator, all safety precautions required

by the applicable work regulations must be

taken to eliminate any uncontrolled hazard

during the operation.

• Check that:

- The installation conditions have been

carefully analyzed to limit, to the

maximum, any risk of falling of a person,

the equipment used or the winch.

- The operator can safely access the

altotir™ winch control unit under safety

conditions compliant with applicable

regulations.

- The installer has all the necessary

personal protection equipment (fall-

arrest harness, gloves, safety shoes,

helmet) to safely carry out the

installation.

- If the installer is required to use a fall-

arrest system as defined by directive

89/656/CEE, he must check that the

anchor point to which the fall arrest

system is anchored is sufficiently strong.

- The environment in which the winch is

used is not explosive (ATEX Directive).

- The environment in which the winch is

used is not abnormally corrosive, such

as a marine environment or other.

IMPORTANT: The load must be

secured to the wire rope by the hook.

The load must be secured by a sling of

appropriate capacity, dimensions and type

for the object to be handled (Fig.18).

The winch wire rope must not be used, under

any circumstances, as a sling by running it

around an object with the hook attached to

the wire rope (Fig.17).

7.2 Installation on jib crane

This is the most frequently used installation

configuration (Fig. 10).

For this installation, the installer must have:

• 1 altotir™ winch, standard delivery.

• 1 jib crane, with mechanical strength

verified by a qualified technician to

ensure it can handle the forces to be

applied.

7.2.1 Checks before installation

7.2.1.1 Host structure checks

IMPORTANT:

Before installing, you must check that:

• The scaffolding is sufficiently stable and

strong for use with the altotir™ winch.

• The scaffolding tube (Fig. 10, item 24) is

sufficiently strong. In particular, the

scaffolding tube must be made of steel

and have a diameter of 49 to 50 mm.

It must not show any apparent deterio-

ration such as corrosion, bending,

cracks, rupture or impact marks.

7.2.1.2 Environment checks

• Perform the general checks detailed in

section 7.1.2.

Check the following:

• Check that the assembly formed by the

jib crane and the altotir™ winch will not

interfere with any obstacle along the

entire angular working range of the jib

crane.

• Check that the operator can safety

access the jib crane to pivot it along the

necessary working range under safety

conditions satisfying the applicable

regulations.

7.2.1.3 Winch check

Perform the general checks detailed in

section 7.1.3 and check that the jib crane

complies with the standard delivery as

described in this manual.

13

GB

14

GB

7.2.2 Assembly of jib crane on

altotir™ winch and installation

on scaffolding

The altotir™ winch, equipped with the jib

crane, is shown in figure 10.

Composition:

7) Fastening crossmembers

8) Tube mounting clamps

11) Anchoring tube

13) Clamp fastening studs

14) Clamp fastening nut

24) Cylindrical scaffolding tube.

Proceed as follows when securing the

altotir™ winch on a jib crane:

Tools required:

• 1 open end wrench, 17 mm

• 1 open end wrench, 19 mm

The installation procedure comprises

3 phases:

Phase 1: Assembling the altotir™ winch and

the jib crane (Fig. 10).

• Position the anchoring tube (Fig. 10,

item 11) of the jib crane in the slots

provided for this purpose on the

fastening crossmember (Fig. 10 , item 7).

• Fit the mounting clamps (Fig. 10, item 8)

on the studs (Fig. 10, item 13).

• Manually screw on the 4 clamp fastening

nuts (Fig. 10, item 14) uniformly.

• Using the 17mm open end wrench,

moderately tighten the 4 nuts.

• Check that the mounting clamps (Fig. 10,

item 8 ) and the fastening crossmember

(Fig. 10, item7) are in contact with the

anchoring tube of the jib crane (Fig. 10,

item 11).

• Check that the jib crane is rigidly secured

to the altotir™ winch.

Phase 2: Installing the jib crane pivot on the

scaffolding tube.

• Couple the male pivot clamps (Fig. 8,

item 3) with the male pivots (Fig. 8,

item 4) using the screws, nuts and

washers (Fig. 8, items 7, 1, 2).

• Place the assembly formed by the male

pivot on the scaffolding tube (Fig. 10,

item 24); if necessary, slightly loosen the

clamp mounting nuts to facilitate

installation.

• Close the male pivot clamp (Fig. 8,

item 3) on the scaffolding tube then

manually tighten the mounting nuts (Fig.

8, item 1) symmetrically on each pivot.

• Before you lock the mounting nuts using

the 19 mm open end wrench, check that

the distance between pivots is 320 +/-

1 mm (Figure 2b) and that the pivots are

positioned in line with each other.

• Firmly lock the pivot clamp fastening nuts

using the 19 mm open end wrench.

Phase 3: Installing the altotir™ winch equip-

ped with the jib crane on the

scaffolding

• Position the jib crane equipped with the

altotir™ winch on the male pivots as

shown in figure 8.

• Using the 19 mm open end wrench,

horizontally adjust the anchoring tube

(Fig. 8, item 11) by tightening or

loosening the adjustment locknut (Fig. 8,

item 10). Once the jib crane tube is

horizontal, lock the pivot by tightening

the locknut (Fig. 8, item 10 ).

• Check that the assembly formed by the

altotir™ winch and the jib crane pivots

with no sticking points or grabbing over

the pivot working range.

• Connect the altotir™ winch to the

electrical power supply.

GB

15

7.2.3 Checks after installation

7.2.3.1 Checks without load

After completing the installation, check that:

• The winch is correctly connected

electrically.

• The electric power cable and the control

cable are not subject to any pulling or to

any risk of grabbing when the jib crane is

rotated along its travel range.

• The winch control unit is within arm’s

reach of the operator over the jib crane’s

entire travel range.

• The operator can manually pivot the jib

crane.

• The jib crane pivots with no sticking

points or grabbing over the entire

working travel.

• No interference is observed between the

wire rope, equipped with its hook and its

limit stop, and the environment over the

entire load lifting length.

• There remains at least 2 wire rope coils

on the drum when the wire rope is fully

extended to the low limit stop.

7.2.3.2 Checks with load

• Secure the maximum working load to the

lifting hook (Fig. 1, item 2).

• When the load lifts off the ground, check

that:

- The scaffolding remains stable.

If not, immediately stop the up

movement, remove the load, and take

the necessary steps to stabilize the

scaffolding.

- There is no deformation, cracks or

rupture on the scaffolding tube (Fig.10,

item 24) or in the immediate

environment.

If any problem is observed, immediately

stop the up movement and dismantle

the altotir™ winch.

- There is no slippage between the pivots

(Fig. 8, items 3 and 4) and the scaffol-

ding tube (Fig. 10, item 24).

If slippage is observed, immediately stop

the up movement, remove the load, and

re-tighten the nuts (Fig. 8, item 1) using

the 19 mm open end wrench.

- No interference is observed between the

load and the environment over the entire

load lifting height, using the control unit.

- The jib crane with load in the up position

pivots with no excess effort required on

the part of the operator.

- When pivoting the jib crane along its

travel range, no rotation slippage occurs

between the pivots (Fig. 8, items 3 and

4) and the scaffolding tube (Fig. 10,

item 24)

If slippage is observed, immediately stop

the jib crane rotation, lower the load to

the ground, reposition the pivot and

properly tighten them on the scaffolding

tube.

- No deformation on the ground or on the

working platform is observed when the

load is set down.

7.3 Installation on frame

This installation configuration is used when

the lost height of the winch is not compatible

with the lifting height (Fig. 11). For this

installation, the installer must have:

• 1 altotir™ winch, standard delivery,

• 1 adjustable limit stop (Fig. 9),

• 2 idler pulleys,

• 1 tubular anchoring structure with

diameter of 49 to 50 mm (Fig. 11) and

whose mechanical strength has been

verified by a qualified technician

For this installation configuration, the winch

is turned over; the mounting clamps, for

mounting on tube, are under the winch and

the lifting wire rope comes out toward the top

in the direction of the pulley located directly

in line with the winch.

7.3.1 Checks before installation

7.3.1.1 Host structure checks

IMPORTANT:

Before installing, check that:

• The altotir™ winch anchoring tube

(Fig. 11, item 2), is sufficiently strong. In

particular, the anchoring tube must be

made of steel and have a diameter of 49

to 50 mm. It must not show any visible

signs of corrosion, bending, cracks,

rupture or impact marks.

• The host structure next to the idler pulley

rigging (Fig. 11, items 4 and 5) complies

with the applicable regulations as

concerns stability and mechanical

strength.

• The working load limit of the idler pulleys

is compatible with the installation

configuration and the working load limit

of the winch (Fig. 11, items 4 and 5)

in compliance with the applicable regu-

lations.

• The idler pulleys are compatible with the

diameter of the winch wire rope in

compliance with the applicable regu-

lations.

• The idler pulley anchoring point, winch

side (Fig. 11, item 4) is properly situated

in line with the warping drum of the

altotir™ winch (Fig. 1, item 3).

7.3.1.2 Environment checks

Before conducting any installation, perform

the general checks detailed in section 7.1.2.

7.3.1.3 Winch checks

• Perform the general checks detailed in

section 7.1.3.

• Check that the adjustable limit stop

complies with the standard delivery

characteristics as described in this

manual.

7.3.2 Installing the altotir™ winch

Tools required:

• 1 open end wrench, 17 mm

• One hex key, 8 mm

The installation procedure comprises 3

phases:

Phase 1: Assembling the altotir™ winch on

the frame (Fig.11).

• Position the anchoring tube (Fig.11,

item 2) of the frame in the slots provided

for this purpose on the fastening

crossmember (Fig.10, item 7).

• Fit the clamps (Fig.10, item 8) on the

studs (Fig.10, item 13).

• Manually tighten the 4 clamp fastening

nuts (Fig.10, item 14) uniformly.

• Using the 17 mm open end wrench,

moderately tighten the 4 nuts.

• Check that the mounting clamps (Fig.10,

item 8) and the fastening crossmember

(Fig. 10, item 7) are in contact with the

frame anchoring tube (Fig.11, item 2).

• Check that the altotir™ winch cannot

pivot around the frame anchoring tube.

Phase 2: Installing the wire rope in pulleys

• Using the control unit, unwind the wire

rope, keeping it tensioned while

unwinding. Insert the wire rope in the

idler pulley, winch side (Fig. 11, item 4).

Using the control unit, unwind the wire

rope again, keeping the wire rope

tensioned. Insert the wire rope in the

idler pulley, load side (Fig. 11, item 5).

NOTE: Tractel®recommendation:

Two persons required when installing wire

rope on pulleys.

• Allow the lifting hook and the limit stop

to hang (Fig. 1, items 2 and 10).

• Lower the assembly formed by the lifting

hook and limit stop (Fig. 1, items 2

and 10) by acting on the control unit.

• At the end of the wire rope travel, check

that two coils of wire rope remain on the

winch warping drum.

16

GB

Phase 3: Installing the adjustable limit stop

IMPORTANT: The adjustable limit

stop must be installed on the section of lifting

wire rope located between the altotir™ winch

and the idler pulley, winch side (Fig. 11,

item 4).

• Install the adjustable limit stop as

detailed in the procedure given in

section. 14.3

• Position the adjustable limit stop to

ensure that:

• When the lifting hook is at the low limit,

the adjustable limit stop (Fig. 11, item 6)

does not interfere with the idler pulley,

winch side (Fig. 11, item 4).

• When the adjustable limit stop is in

contact with the limit stop lever (Fig. 11,

item 9), the limit stop (Fig. 11, item 10)

does not interfere with the idler pulley,

load side (Fig. 11, item 5).

• Manually check that the adjustable limit

stop is locked on the wire rope.

7.3.3 Checks after installation

7.3.3.1 Checks without load

Check that:

• There is no interference between the

adjustable limit stop (Fig. 11, item 6) and

the idler pulley, winch side (Fig.11,

item 4) when the lifting hook is at the low

limit.

• There is no interference between the

limit stop (Fig. 11, item 10) and the idler

pulley, load side (Fig. 11, item 5) when

the limit stop lever (Fig. 11, item 9) is

actuated by the adjustable limit stop

(Fig. 11, item 6).

• No interference is observed between the

wire rope, equipped with its hook and

limit stop, and the environment along the

entire load lifting height.

• No interference is observed between

the wire rope equipped with its

adjustable limit stop, and the environ-

ment along the entire load lifting height.

• The winch stops, on an up-movement

cycle, when the adjustable limit stop

(Fig. 11, item 6) comes into contact with

the limit stop lever (Fig. 11, item 9).

If this is not the case, immediately stop the

up-movement and have the limit stop lever

checked by a qualified technician.

• There are at least two coils of wire rope

remaining in the warping drum at the low

unwinding limit.

• No slack wire rope is observed while the

lifting hook is being lowered, in particular

between the 2 idler pulleys. If any slack

wire rope is observed, fit a weight on the

lifting hook to ensure that the wire rope

remains tensioned (2 kg max.).

7.3.3.2 Checks with load

• Fasten the maximum working load to the

lifting hook (Fig. 1, item 2).

• When the load lifts off the ground, check

that:

- There are no signs of deformation,

cracks or rupture on the anchoring tube

(Fig. 11, item 2) or in the immediate

environment.

If any problem is observed, immediately

stop the up-movement, remove the

weight on the ground, and have the

installation checked by a qualified

technician.

- There are no signs of deformation,

cracks or rupture next to the idler pulley

rigging point (Fig. 11, items 4 and 5) or in

the immediate environment.

If any problem is observed, immediately

stop the up-movement, set the load on

the ground and have the idler pulley

rigging point checked by a qualified

technician.

- No interference is observed between the

load and the environment along the

entire load lifting height, by acting on the

control unit.

- No deformation on the ground or on the

working platform is observed when the

load is set down.

17

GB

The inverted assembly configuration on

structure is shown in figure 11.

Composition:

1) Wire rope

2) Anchoring tube

3) Host structure

4) Idler pulley, winch side.

5) Idler pulley, load side

6) Adjustable limit stop

9) Limit stop lever

10) Limit stop.

7.4 Installation bearing on base tube

This installation configuration is used when

the installer does not have an anchoring point

for the idler pulley under the structure. For

this installation, the installer must have a

standard altotir™ winch.

7.4.1 Checks before installation

7.4.1.1 Host structure checks

IMPORTANT:

Before installing, you must check that:

• The seating plane for the altotir™ winch

(Fig.12, item 2), is sufficiently strong.

• The seating plane for the altotir™ winch

is horizontal and smooth.

• The wire rope opening under the altotir™

winch observes the dimensions require-

ments specified in Figure 12.

• The winch is properly wedged on the

seating plane to avoid any movements of

the winch when operating.

7.4.1.2 Environment checks

Before installing, perform the general checks

detailed in section 7.1.2.

7.4.1.3 Winch checks

Before installing, perform the general checks

detailed in section 7.1.3.

7.4.2 Installing the altotir™ winch

Proceed as detailed below for installation of

the altotir™ winch on the base tube.

No special tools are required.

• Run the wire rope, equipped with hook

and limit stop, through the opening

provided for passage of the wire rope.

• Position the altotir™ winch next to the

wire rope opening, observing the

positioning recommendations specified

in Figure 12.

• Wedge the winch so that it does not

move when operating.

7.4.3 Checks after installation

7.4.3.1 Checks with no load

After installing, check that:

• No interference is observed between the

wire rope, equipped with its hook and

limit stop, and the environment along the

entire load lifting height.

• The winch stops during the up-

movement when the limit stop (Fig. 12,

item 10) comes into contact with the limit

stop lever (Fig. 12, item 9).

If this is not the case, immediately stop

the up-movement and have the limit stop

lever checked by a qualified technician.

• There are at least two coils of wire rope

remaining on the warping drum at the

low unwinding limit.

• The electrical connection has been

correctly made.

18

GB

7.4.3.2 Checks with load

• Fasten the maximum working load to the

lifting hook (Fig. 1, item 2).

IMPORTANT: The load must be

secured to the wire rope by the hook.

The load must be secured by a sling of

appropriate capacity, dimensions and type

for the object to be handled. The winch wire

rope must not be used, under any

circumstances, as a sling by running it

around an object with the hook attached to

the wire rope (Figs. 17 and 18).

When the load lifts off the ground, check that:

• There are no signs of deformation,

cracks or rupture on the seating plane

next to the base tube (Fig. 12, item 2) or

in the immediate environment.

If any problem is observed, immediately

stop the up-movement, set the load on

the ground and have the installation

checked by a qualified technician.

• No interference is observed between the

load and the environment along the

entire lifting height, by acting on the

control unit.

• No deformation on the ground or on

the working platform is observed when

the load is set down.

• The winch does not move on its seating

plane.

The dimensional specifications of the

opening to be provided in the platform are

indicated in Figure 12.

7.5 Commissioning

General checks

Check that:

• The load to be lifted is less than or equal

to the WLL of the altotir™ winch.

• The lifting wire rope is in good condition.

• The safety systems are placed correctly.

• The working area is secured in com-

pliance with the applicable regulations.

Additional checks when using idler pulleys.

Check that:

• The rotation axis of the pulleys is

perpendicular to the wire rope plane.

• The adjustable limit stop is in place on

the wire rope.

8 Maneuvers

8.1 Preliminary conditions

Before performing any maneuvers with the

altotir™ winch, the operator must ensure

that:

- The lighting conditions are satisfactory

along the entire load lifting height.

- The wind speed is compatible with use

of the winch (< 50km/h).

- The climatic conditions are compatible

with the winch operating specifications

(section 4.4).

- The load to be lifted is an equipment

load and not a person.

8.2 Checks before use

Before using the altotir™ winch, the operator

must ensure that:

• The control unit does not show any

visible damage.

• The load to be lifted is less than or equal

to the WLL of the altotir™ winch.

• On the entire lifting height, there is no

risk of interference of the wire rope or of

the limit stops with an obstacle.

• The wire rope is in good condition along

its entire length.

• The control and power cables are not

damaged.

• The safety systems operate correctly.

• The work area is secured in compliance

with applicable regulations.

Additional checks according to installation

configuration:

If the winch is used on a jib crane, check that:

• The jib crane pivots freely along the

working travel range planned.

19

GB

• The fasteners securing the winch on the

jib crane, and the jib crane on the

scaffolding anchoring tube do not show

any abnormal play or damage such as

impact marks, rupture or cracks.

If the winch is used on a frame, check that:

• The rotation axis of the pulleys is

perpendicular to the wire rope plane.

• The adjustable limit stop is in place on

the wire rope.

• The fasteners securing the winch on the

frame anchoring tube do not show any

signs of abnormal play or damage such

as impact marks, rupture or cracks.

If the winch is installed bearing on the base

tube, check that:

• The altotir™ winch is correctly

positioned above the wire rope hole and

the wedging is still in place.

• The seating plane of the altotir™

winch does not show any abnormal

deformation.

8.3 Procedure

8.3.1 General

DANGER:

• The sound environment of the operator

working area must be such that

instructions exchanged during the

maneuvering procedures described in

this section can be clearly understood.

• It is prohibited to take position or to work

under the load being lifted. A prohibited

access area should be defined and

marked out under the load.

8.3.2 Lifting a load

NOTE: Tractel®recommendation:

2 operators required for winch maneuvers.

The first operator is in charge of slinging the

load.

The second operator is in charge of

operating the control unit and setting down

the load in the high position.

Description of winch maneuvering phases

when lifting a load:

• Sling the load

The operator fastens the load to be lifted to

the winch lifting hook (Fig.1, item 2).

IMPORTANT: It is strictly prohibited

to use the lifting wire rope as a sling (Fig. 17).

• Lifting the load off the ground.

By successively and momentarily pressing

the up button on the control unit (Fig. 1,

item 21), the operator lifts the load off the

ground, making sure that no part of the load

may come off during the lifting operation.

• Lifting the load

By pressing and holding the up button on the

control unit (Fig. 1, item 21), the operator lifts

the load.

DANGER: The operator must have

uninterrupted eye contact with the load

throughout the lifting height, in particular, he

must:

- Keep the load from swinging or turning.

- Keep all obstacles at a distance from the

wire rope and load.

- Avoid any slack wire rope on the strand

loaded.

• Stop lifting the load.

The operator releases the up button on the

control unit. At this moment, the operator

must check that the load has actually

stopped.

• Align and set load down in high position.

- If the winch is used on a jib crane:

The operator grabs the carrying handle

(Fig.1, item 11) and pivots the jib crane in

order to place the load vertically above the

location where it will be set down.

The operator sets down the load by acting on

the down button on the control unit.

- If the winch is used on a frame or bearing

on the base tube:

20

GB

Table of contents

Other Tractel Group Winch manuals

Popular Winch manuals by other brands

Badland

Badland ZXR 2500 user manual

Columbus McKinnon

Columbus McKinnon DGUV V54 operating instructions

Ingersoll-Rand

Ingersoll-Rand Force 5 FH5 Parts, operation and maintenance manual

jakob

jakob HIT-TRAC 8B user guide

Warrior Winches

Warrior Winches 80SPS12 Assembly & operating instructions

BRP

BRP Can-Am HD 4500 2020 Operator's guide

Harken

Harken 16.2 Two Speed Winch Installation service

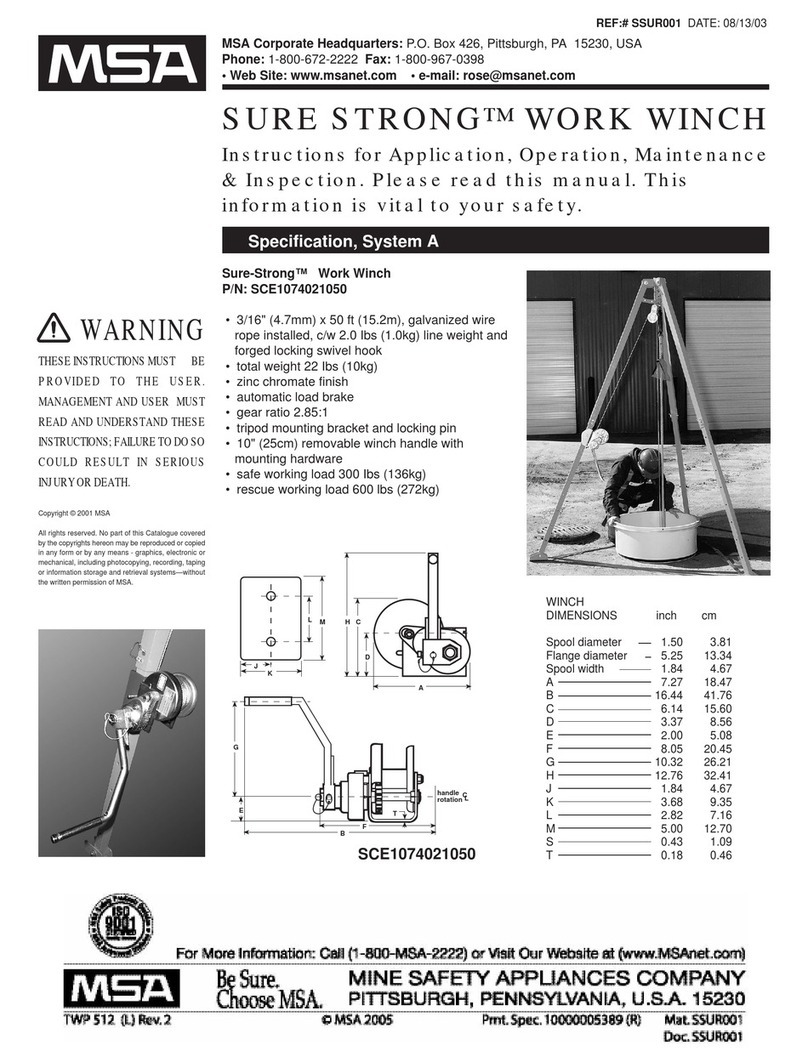

MSA

MSA SURE STRONG SCE1074021050 Instruction for operation and maintenance

Lewmar

Lewmar 5CT quick start guide

Warrior Winches

Warrior Winches 13JR02H-CAD owner's manual

ETC

ETC Vortek NXT User's operation manual

Huchez

Huchez MANIBOX VS Series instruction manual