Fieryred WIN14500R-ROPE User manual

This manual suits for next models

1

Table of contents

Other Fieryred Winch manuals

Popular Winch manuals by other brands

Warrior Winches

Warrior Winches 80SPS12 Assembly & operating instructions

Paccar Winch

Paccar Winch Braden PD35A Installation maintenance and service manual

AL-KO

AL-KO 450 A Compact Translation of the original operating instructions

Comeup

Comeup CWS-80 instruction manual

MSA

MSA Workman Winch User instructions

AL-KO

AL-KO 351 Plus Translation of the original operating instructions

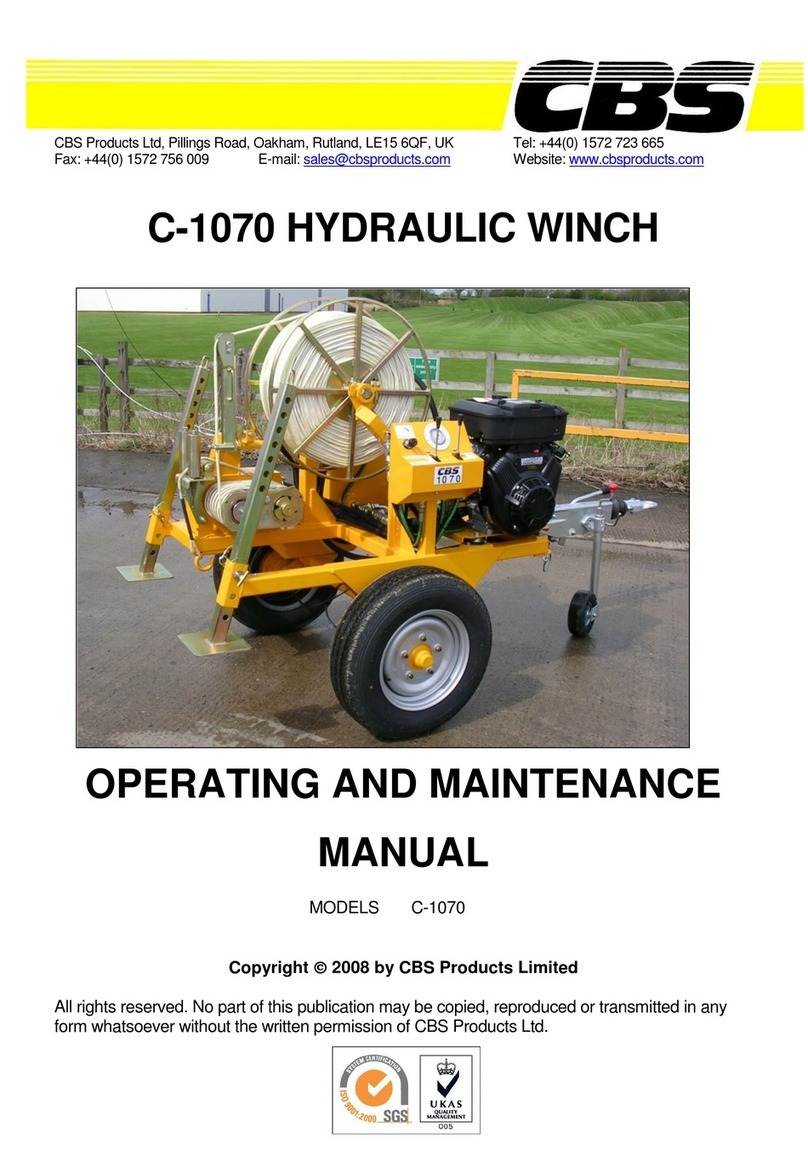

CBS

CBS C-1070 Operating and maintenance manual

Ingersoll-Rand

Ingersoll-Rand force5 FA5A-SXK1 Parts, operation and maintenance manual

Kellfri

Kellfri 21-KW1000 operating instructions

Runva

Runva 10DB Assembly & operating instructions

Wintech

Wintech 301 Operation and maintenance manual

therM

therM TA150KGMR1 owner's manual

American Landmaster

American Landmaster 17153 installation instructions

Badland

Badland APEX 57535 Owner's manual & safety instructions

Red Winches

Red Winches Cobra-2 Workshop manual

DINAMIC OIL

DINAMIC OIL S20 instruction manual

Quadratec

Quadratec Synthetic Q10000c Operator's guide

Columbus McKinnon

Columbus McKinnon SW K GAMMA Translated Operating Instructions