5

winch is equipped with an electrical switch that will light

the red “WINCH DISENGAGED” lamp on the freespool

panel whenever the drum is disengaged from the drive

train. In this position, wire rope can be pulled from the

drum by hand, provided the drum drag brake is not acti-

vated. The extension shaft/capstan drive can also be

operated in this mode without the cable drum rotating.

To disengage the drum, the winch should be stopped

and there should be no load on the cable drum. To

engage the clutch, the drum may have to be rotated

slightly by hand to align the internal splines. When the

clutch is fully engaged, the green “WINCH ENGAGED”

lamp on the freespool panel will be lit.

DRUM DRAG BRAKE

The BP200B has two (2) drag brake cylinders, (one (1)

on the BP200). These can be either air or hydraulically

operated. Their purpose is to control drum movement

when the winch is in freespool mode with the drum dis-

connected from the drive train. They are not designed

nor intended to hold a load. The amount of drag they

provide can be easily adjusted using one of the circuits

shown in the “INSTALLATION” section of this manual.

All hardware for these control circuits is customer pro-

vided.

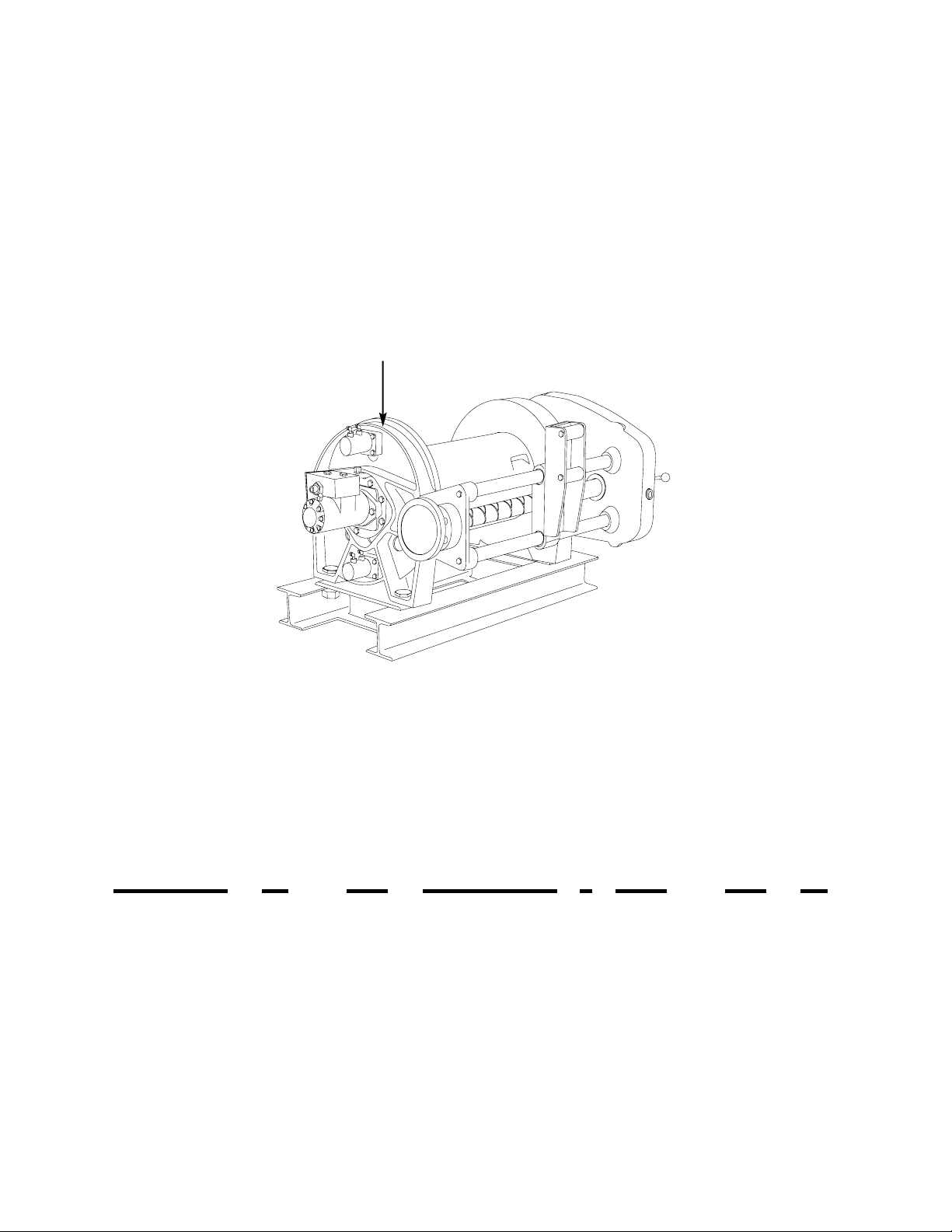

LEVEL WIND

The BP200 winch is equipped with a level wind system

to ensure smooth even spooling of wire rope onto the

drum. The speed of the tension roller assembly in rela-

tion to the cable drum speed is specific to each size

wire rope. In order to change wire rope size, the chain

and sprockets driving the level wind diamond screw

must be changed. Refer to “LEVEL WIND DRIVE

GROUP CONVERSION PARTS” for additional informa-

tion. The system is provided with a manual disconnect

and hand wheel on the diamond screw. The disconnect

lever is located on the side of the winch opposite the

motor. With the lever pointing down in a vertical posi-

tion, the diamond screw is engaged. Rotating the lever

90otoward the front of the winch disengages the screw

and allows it to be rotated using the hand wheel on the

opposite end, near the motor. This feature is used to

properly align the tension roller assembly with the wire

rope on the drum. It may be necessary to perform this

alignment occasionally to compensate for normal wire

rope stretch and/or wear, or when new wire rope is

installed.

INSTALLATION

GENERAL REQUIREMENTS

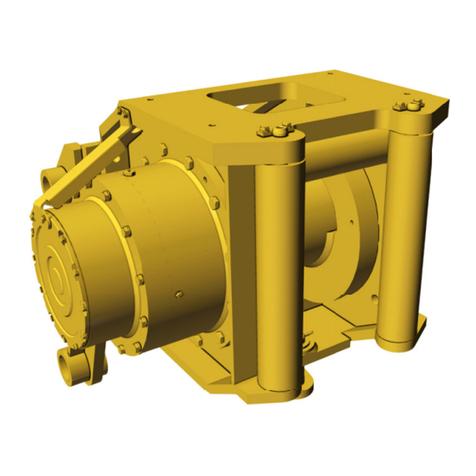

The winch should be mounted with the centerline of the drum in

a horizontal position. Typically, the base will be fastened directly

to the frame of the vehicle.

When mounting the winch, the method of attachment must be

capable of withstanding the full 20,000 pound line pull.

It is important that the winch be mounted on a surface that will

not flex when the winch is in use, since this could bind the work-

ing parts of the winch. Also, be sure the winch is mounted on a

flat surface. If necessary, use shim stock to insure proper

mounting. The mounting surface should be flat within + or -.020

inches (.5 mm).

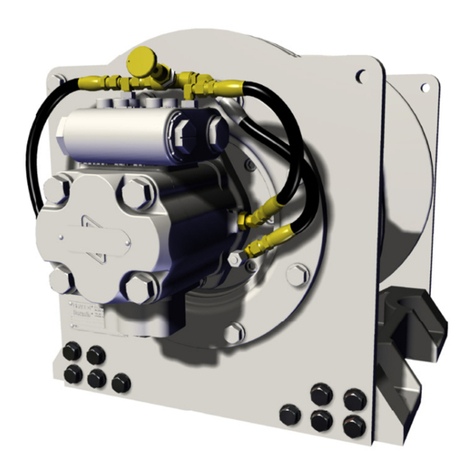

Hydraulic lines and components that operate the winch should

be of sufficient size to assure minimum back pressure at the

winch. Back pressure should not exceed 100 psi (690 kPa) for

maximum motor seal life. 150 psi (1,030 kPa) is the maximum

peak intermittent allowable back pressure. A motor case drain

from the shaft end drain port to tank is required.

The winch directional control valve must be a three-position,

four-way valve with a motor spool having both work ports open

directly to tank, when the valve is in the center position.

The extension shaft must be attached to the end of the winch

opposite the motor. The shaft may be connected to the cou-

pling in one of two positions, allowing a 2 inch adjustment in

length.

The hydraulic oil filter should have a 10 micron nominal rating

and be a full-flow type.

High quality hydraulic oil is essential for satisfactory performance

and long hydraulic system component life.

Oil having 150 to 330 SUS viscosity at 100°F (38°C) and vis-

cosity index of 100 or greater will give good results under normal

temperature conditions. The use of an oil having a high viscosity

index will minimize cold-start trouble and reduce the length of

warm-up periods. A high viscosity index will minimize changes in

viscosity with corresponding changes in temperature.

Maximum cold weather start-up viscosity should not exceed

5000 SUS with a pour point at least 20°F lower than the mini-

mum temperature.

Under continuous operating conditions the temperature of the oil

at any point in the system must not exceed 180° F (82° C).

120-140° F (49 - 60° C) is generally considered optimum.

In general terms; for continuous operation at ambient tempera-

tures between 50 and 110° F (10 to 43° C), use SAE 20W; for

continuous operation between 10 and 90° F (-12 to 32° C), use

SAE 10W; for applications colder than 10°F, contact the

BRADEN Service Department. The use of multi-viscosity

oils is generally not recommended.

Refer to the following drawings for winch control circuit,

drag brake circuit and freespool circuit.

NOTE: Continuous operation at high speeds and loads

may require the use of an oil cooler in the hydraulic sys-

tem to maintain acceptable oil temperature.