Tradgardsteknik GX200 User manual

1

OPERATOR MANUAL DE

GB

FR

IT

NL

GX200

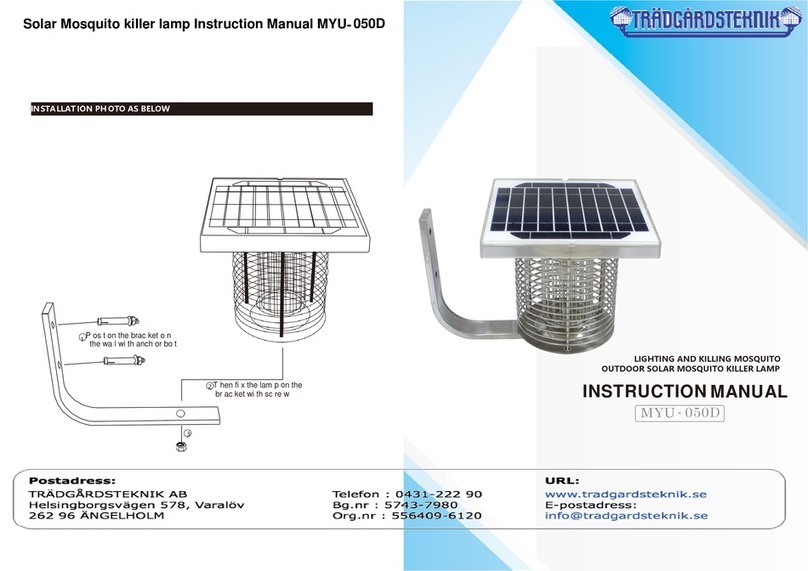

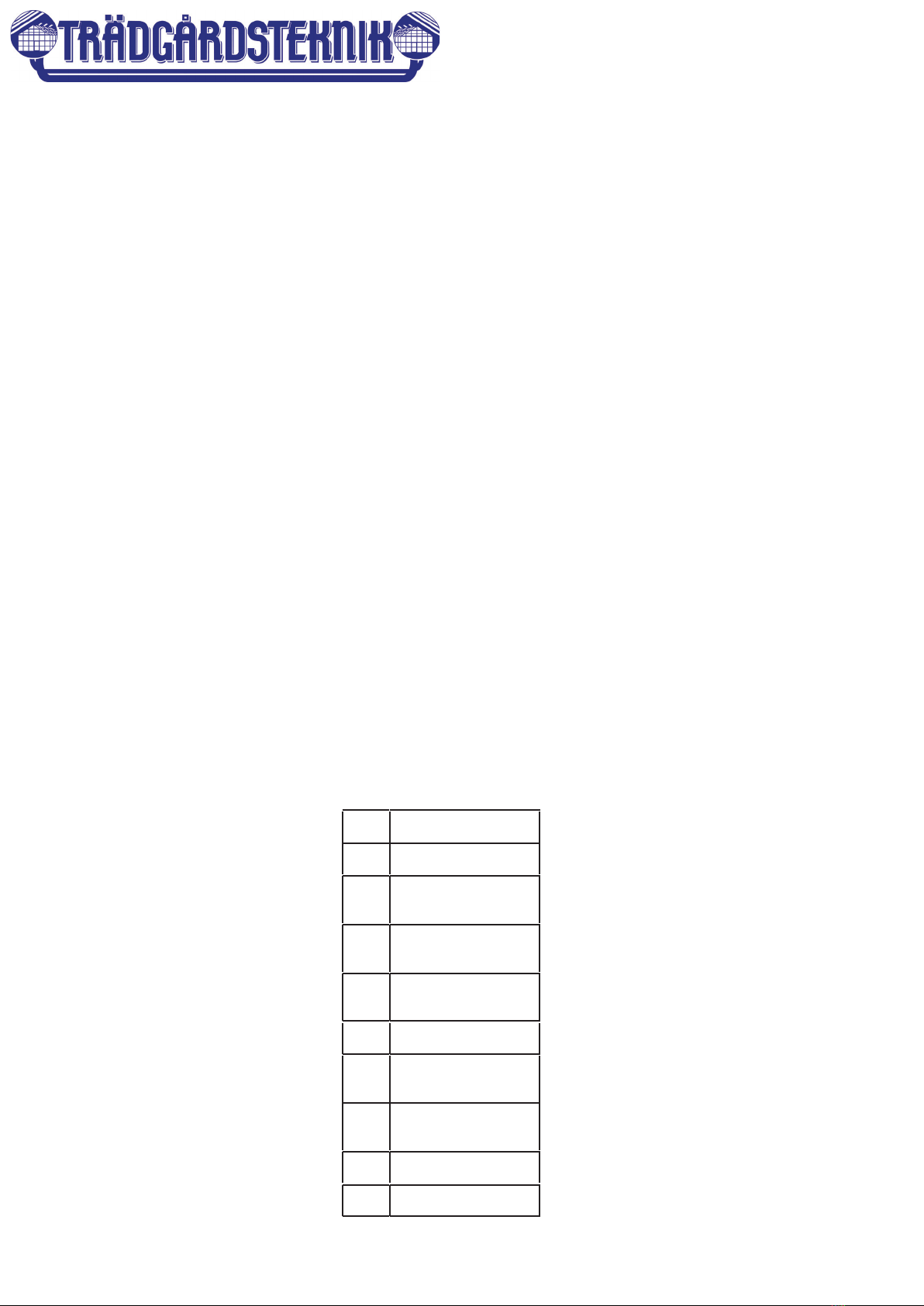

1. Sounding rod

2. Smoke bell

3. Smoke on/off

4. Motor on/off

5. Number of revo

lutions

6. Choke

7. Fuel tap engine

8. Gasoline +

2% Diesel

9. Gasoline

10. 1.5 bar

2.

3. 3.

1.

4.

5. 6.

a

b

a

b

c

d

c

d

a

b

c

d

This manual is protected by copyright. All rights are reserved, especially the right of reproduction,

translation and processing with electronic systems.

INDEX OF CONTENTS

Rodent Destroyer - GX 200

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Field of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Exhaust Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Burns Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Noise Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Starting the engine (see also operator manual engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Switching off engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Rodent Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Searching Out the Rodent Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Using the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Monitoring Gas Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Preparing the next Rodent Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Change of Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Destroying the Runs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 Classication and Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 Follow-Up Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 Time to Apply Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10 Note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Spare parts

IMPORTANT: To enable you to operate and maintain your equipment correctly, you are advised to

read this Instruction Manual through carefully. The Manual will help you to prevent injuries and

damage.

1.1 Operation

Using a fuel pump, a mixture of petrol and diesel is suctioned off, injected into the special muer

in precisely metered quantities and allowed to vaporize. The resulting fumes are channelled into a

system of ducts via a exible metal pipe and dome-shaped cover. The high pressure of the industrial

engine brings about a rapid distribution of the fumes and the existing oxygen is squeezed out of the

duct system. The pests have no chance to escape. Within seconds their airways are paralyzed. This

leads to a rapid and painless death. If a stunned or dead rodent is eaten by a cat or a bird of prey,

there is no risk of secondary poisoning.

1.2 Construction

The robust and easy-to-handle barrow is galvanized and tted with a dome-shaped fume cover as

well as a probing rod. The heavy duty 5.5 hp Honda engine is in line with the latest technology, has

a long service life and is easy to maintain. For operator safety, it is possible for the fumigator unit to

be switched off during relocation to another site.

1.3 Field of Application

-

Please note the following restrictions as regards the use of this equipment:

1. The device may only be used out of doors. Usage in enclosed spaces incorporates an acute risk

of poisoning due to carbon monoxide.

2. Moles are protected and infestations may only be controlled if an exception permit is obtained

from the responsible local authority (District Oce).

3. Under Animal Welfare Legislation a permit is necessary for the commercial control of vertebrates

as pests. However, the control of vertebrates as pests by private individuals is not subject to permit.

4. Usage in water conservation areas and drinking water protection zones I and II as well as areas

featuring potable water pipes made from plastic within a range of 100m is not permitted.

5. The use of the device for purposes of plant protection in areas under cultivation (elds, greenhou-

ses, woodland etc.) is not permitted.

6. Sole responsibility for the proper use of the equipment and compliance with the restrictions on

use lies with the user.

7. Before buying or using it for the rst time, ask your responsible authority (district oce) for a

permit.

2. Safety

Read the entire Instruction Manual carefully before starting up

the machine for the rst time. Failure to observe the following

safety instructions may have fatal consequences.

2.1 Exhaust Gases

The device may only be used out of doors. Usage in enclosed

spaces incorporates an acute risk of carbon monoxide poiso-

ning.

Only open the fuel tap to the auxiliary tank once the dome-sha-

ped cover is rmly positioned on the ground. The operator must

always work against the wind in order to avoid inhaling any fu-

mes. Close the fuel tap to the auxiliary tank when relocating.

2.2 Burns Hazard

Maintain an adequate distance from the exhaust system and

exible metal pipe. This gets hot!

2.3 Noise Emissions

The operator must wear hearing protection and observe the lo-

cal noise regulations. The sound pressure level is 87 dB(A).

2.4 Fuel

Switch off the before refuelling. No smoking. Keep away from

naked ames. Avoid fuel spillage. Do not allow any fuel to come

into contact with clothing. If this happens, change your clothes

– danger to life!

2.5 General

You yourself are responsible for the correct and safe usage of the device. It is also your responsibili-

ty to ensure that any persons you allow to operate the Rodent Destroyer are given proper instruction.

Never allow the Rodent Destroyer to be operated by children or people who are not familiar with the

instructions for the use of the equipment.

Remember that the owner is responsible for all accidents and/or damage that may affect other per-

sons or their property.

This device may only be used for its designated purpose (see. Section 1.3 Area of Application).

Failure to comply will render any warranty claim or liability on the part of the manufacturer null and

void. No liability will be accepted for damage which is caused by failure to observe the provisions

of this Manual.

3. Technical Data

Dimensions:

Height 64 cm, Width 59 cm, Length 126 cm

Weight:

approx. 37 kg (without fuel)

Engine:

Honda GX 200T

Cubic capacity 196 cm3

Output net 4.1 kW / 5.5 PS

Sound level:

3400 U/min: 87dB(A)

2200 U/min: 78dB(A)

Fuel:

Engine: Unleaded petrol (no oil)

Auxiliary tank: Unleaded petrol with 2% diesel (2dl diesel for every 10l of petrol)

Chassis:

Hot-dip galvanized barrow with rubber wheel

Auxiliary tank: 10 litre for petrol/diesel mixture (2dl diesel for every 10l of petrol)

Accessories:

Inclusive of probe rod and Operating Instructions

4. Starting Up

4.1 Preparation

Re-fuelling. Note: Petrol is highly ammable and highly explosive. Fire and explosions can cause

burns and/or damage to property. Fuel must only be stored in containers that have been specically

designed for this purpose. Keep out of the reach of children. Only re-fuel the equipment out of doors

and do not smoke while re-fuelling. Use a funnel to top up. Top up fuel levels prior to starting the

engine. Never remove the ller cap or top up with petrol while the engine is running or if the engine

is hot. Do not ll the fuel tank to the brim. Only top up the tank with the amount of petrol required to

keep the uid level 10mm below the bottom of the ller neck. Leaving sucient space in the tank

will allow the fuel to expand. In the event of a petrol spillage do not attempt to start the engine, in-

stead push the device clear of the spilled fuel and avoid any open ames until the fumes from the

fuel have vaporized.

Fuel: Engine Unleaded petrol (no oil)

Auxiliary tank Max. 10 litres petrol – diesel mix

Mixing ratio: 2% diesel

(2 dl diesel to every 10l petrol)

Information The diesel will not affect the operation of the

equipment; it serves only as a marker to indicate

the presence of fumes.

4.2 Starting the engine (see also operator manual engine)

Do not allow the engine to run in conned spaces where there is a risk of hazardous carbon mon-

oxide fumes accumulating.

Set On/Off switch

to On position “ I “

Open fuel tap

Close choke

Set throttle control to Start position

Start engine using recoil starter

As

soon

as

the

engine

starts

to

turn

over,

open

the choke

and give

the

engine

approx.

3

minu-

tes

to

warm up.

During

this

tim the

fuel

tap

to

the

auxiliary

tank

should be closed so as to inhibit

the development of the gas.

To enable the fumes to develop, open petrol tap to auxiliary tank.

Important: When operating in idling mixture, the tap for the

fumes development function must be set to OFF.

To ensure operator safety, the petrol tap to the auxiliary

tank must be closed if the unit is moved to another location.

This will ensure that the development of the gas is inhibited.

Ein

Aus

Aus

Note: Engine exhaust fumes contain carbon monoxide, an odour-free, lethal poison. Do not allow

engine to run in conned spaces or enclosed areas. During the gassing process, keep children and

pets away; note wind direction.

4.3 Switching off engine

Close fuel tap to auxiliary tank, wait 1 minute

Set throttle control to idling mixture

Set On/Off switch to Off position “O“

Close fuel tap

Aus

5. Maintenance

Check engine oil every 5 hours

First oil change after 20 hrs, after that every 100 hrs (0.6 l, SAE-15W40)

Replace air lter and prelter if dirty (Honda 17210-ZE1-822)

Replace spark plug if dirty (NGK BPR6ES)

Replace petrol lter to auxiliary tank every 50 hours (MU20028)

For further works on the engine see Honda Operator Manual

Tyre pressure max. 1.5 bar

Never use water under pressure to clean the device

All nuts and bolts must be rmly seated to ensure that the device is maintained in a

safe operating condition

6. Storage

Never store the Rodent Destroyer with petrol in the tank inside a building where fumes may come

into contact with a naked ame or sparks. Allow the engine to cool before storage inside buildings.

If the fuel tank has to be drained, this operation should be carried out in the open air.

7. Rodent Control

There are 10 key principles that constitute the secret to success.

7.1 Searching Out the Rodent Run

Search out the rodent run with the probe and open up a hole approx. 5cm in diameter. NOTE: The

device may only be used in the open air. Using it in enclosed spaces incorporates an acute risk of

carbon monoxide poisoning.

7.2 Using the Machine

Attach the dome-shaped cover and press down securely. Allow the engine to run at full throttle for

approx. 5 minutes. NOTE: Only open the petrol tap once the dome-shaped cover is rmly pressed

down on to the ground.

7.3 Monitoring Gas Distribution

If there is an adjacent run, carry out a precise check on whether all the passageways are lled with

fumes (check for rising fumes, it may be necessary to check with the probe). For purposes of iden-

tifying exactly where the fumes are, the system requires the addition of 2% diesel. The addition of

diesel or oil has no effect on the action of the device. This serves only to mark out the rodent runs.

NOTE: The operator must always stand upwind of the dome-shaped cover. There must be no other

persons – especially children or pets – in the vicinity.

7.4 Preparing the next Rodent Run

During the 5 minute running time you can search out the next run and make the necessary preparations.

Use the probe rod to mark the hole. If very large runs are involved (often up to 50 metres in length) we

recommend placing the dome-shaped cover at 2 – 3 locations.

7.5 Change of Location

In the interests of operator safety, it is essential that, in the event of a change of location,that the

petrol tap to the auxiliary tank is closed. This will ensure that fume development is impeded. Lift the

dome-shaped cover, hang it on the machine and close the hole immediately with the foot so that the

fumes cannot escape. Move the machine to the new location and place the dome-shaped cover over

the previously prepared hole and open auxiliary tap.

7.6 Destroying the Runs

Go back to the previously fumigated run and tread on all mounds and passageways constructed by

the rodents to close. By so doing you will ensure that any migrating rodents are unable to nd any

open passageways that they can use. If a rodent happens to become entrenched despite this, it will

need to push up fresh earth to create new passageways. In the event, these will be readily identia-

ble and a second attempt made at refumigation.

7.7 Classication and Procedure

Always fumigate over a wide area. If possible, encourage your neighbours to join in. On hillside loca-

tions always commence fumigation from the top (gases are heavier than air). Where there are stret-

ches of woodland or banks of streams adjacent, then you should start here and work in the direction

of open meadow land because this is where the rodents will often keep an escape route open.

7.8 Follow-Up Checks

Be alert to the possibility of new runs being constructed on meadow-land and elds after each grass

cutting operation or harvest. Orchards, vineyards and vegetable plots are particularly at risk from

browsing or nibbling at the roots.

7.9 Time to Apply Controls

As a matter of principle, controls should be applied all year round. It is in the winter months, snow

covering permitting, that you will nd you obtain the best results. The animals are then weakened

and their rate of reproduction is lower. In order to avoid being suddenly swamped by a high rodent

population, it is essential to ensure that the meadows, elds, orchards and vineyards are constantly

monitored. Note: Remember that large numbers of rodents tend to migrate during the summer

months.

7.10 Note

Rodent control is a straightforward and reliable method of control. It is safe for plants, birds of prey,

cats, dogs, foxes and other benecial organisms. The pests cease breathing due to the lack of oxy-

gen. No secondary poisoning can occur. Even though you may be operating effective controls

It is advisable to take care at the same time to protect the natural enemies of the rodents.

Not using poisons will earn you the gratitude of the birds as well as the birds. We wish you every

success and would appreciate your recommending

8. Troubleshooting

Faults Possible Reasons Elimination Fig.

Engine not running Stop switch set to OFF Set stop switch to ON 1

No fuel / too little fuel Top up fuel

Fuel tap closed Open the engine fuel tap 2

Too little engine oil Top up with engine oil

No fume production Mixer tap set to OFF Set mixer tap to ON 3

Mix canister empty Top up with fuel mixture 4

Nozzle clogged Pull nozzle out of pipe and 5

blow out nozzle to clear 6

Other problems Cause unknown Bring in to specialist workshop

Fig. 1 Fig. 2 Fig. 3

Fig. 4 Fig. 5 Fig. 6

9. Spare parts

MU23002. . . . . . . . . Flexible metal hose 1.10 m

MU23003. . . . . . . . . Hose clamp, galvanized

MU20009*. . . . . . . . Engine Honda GX200, basic unit, excl. muer

MU20009K*. . . . . . . Engine Honda GX200, complete with muer and pump

MU23015. . . . . . . . . Operating hours meter

MU23017. . . . . . . . . Probe rod, galvanized, incl. knob

MU20118. . . . . . . . . Wheel for barrow GX200

MU20218*. . . . . . . . Hose for barrow GX200

MU23126. . . . . . . . . Fuel tap, metal

MU20028. . . . . . . . . Fuel lter

MU20029. . . . . . . . . Fuel pipe, dia. 9mm / 330 mm (pipe in tank)

MU20030. . . . . . . . . Fuel pipe, dia.11.5mm / 1 metre (tank cover as far as engine)

MU23132. . . . . . . . . Fuel nozzle, brass

MU23033. . . . . . . . . Fuel pump

MU23035. . . . . . . . . Clamp for gasoline hose metal Ø11mm

MU23045. . . . . . . . . Clamp for fuel tap 20x45mm galvanized

MU20053. . . . . . . . . Seal for muer Honda GX200

MU20055. . . . . . . . . Muer for model GX 200 (replacement only)

MU20056. . . . . . . . . Muer cover GX200

MU20062. . . . . . . . . Stop switch to Honda engine

MU20163. . . . . . . . . Petrol can 10 litre GX200, excl. lid dia. 43mm

MU20065. . . . . . . . . Dome-shaped fumigator cover GX200

MU20169. . . . . . . . . Can lid, dia. 43mm, for petrol can 20163 incl. elbow

MU20170. . . . . . . . . Set of hoses for tank (incl. lter 20028, hose 20029, lid 20169)

MU20071. . . . . . . . . Clamping ring, galvanized, to muer

MU20417. . . . . . . . . Right hand tube with rubber grip

MU20418. . . . . . . . . Left hand tube with rubber grip

Service parts:

MU20001. . . . . . . . . Air lter Honda 17210-ZE1-505

MU20002. . . . . . . . . Spark plug NGK BPR6ES

SAE15W40*. . . . . . . Engine oil

Table of contents

Other Tradgardsteknik Lawn And Garden Equipment manuals