2

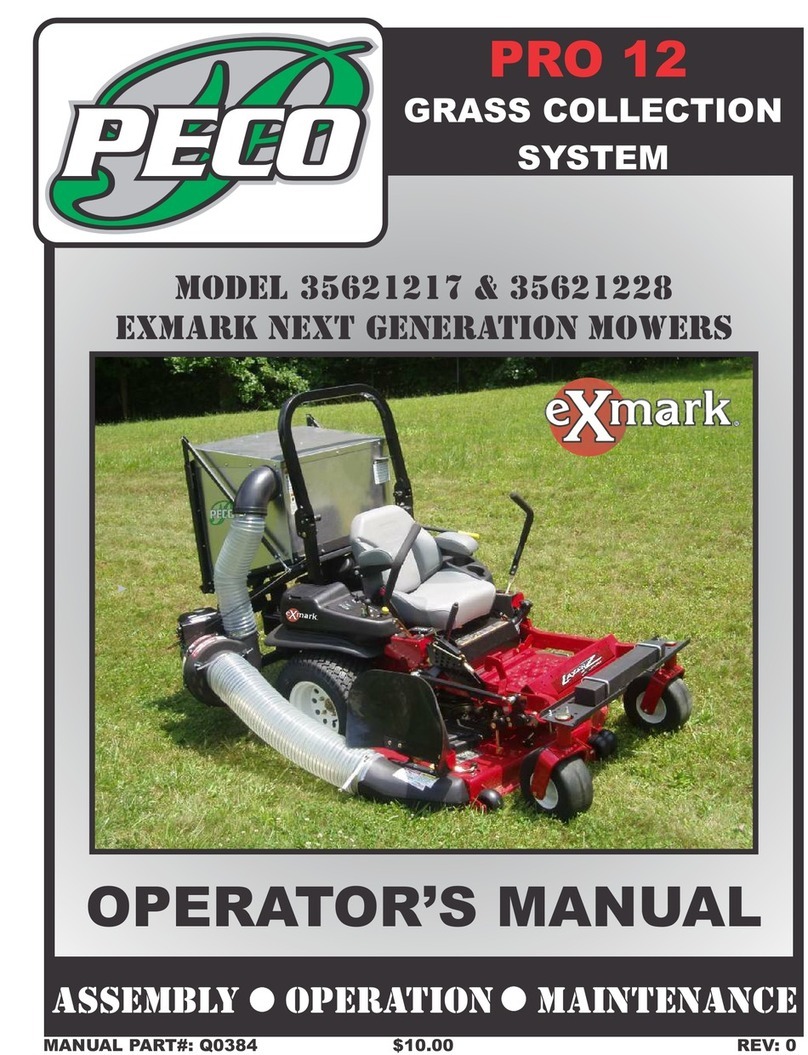

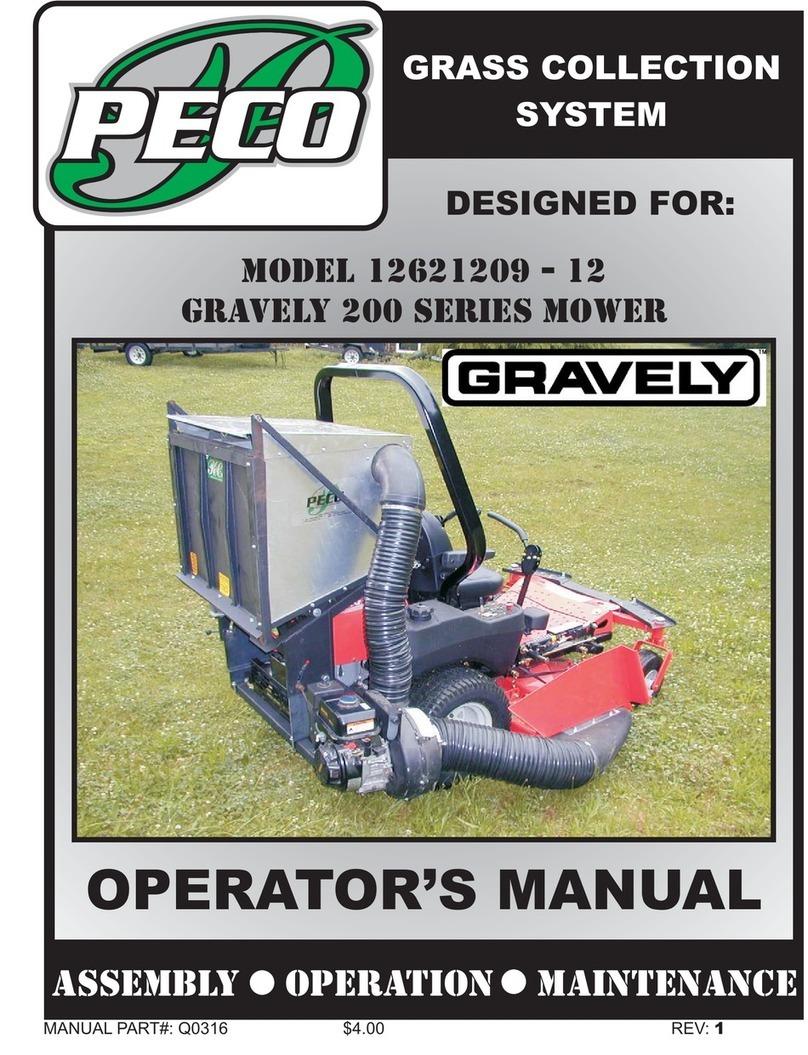

PECO GRASS COLLECTION SYSTEM

TABLE OF CONTENTS

Safety

1. Read the operator’s manual carefully and familiarize yourself with the proper use of your attachment. Do not allow

anyone who is not acquainted with the Safety Instructions to use your attachment.

2. Know the controls and how to stop quickly. READ THE OPERATOR’S MANUAL!

3. Do not allow children to operate the vehicle. Do not allow adults to operate it without proper instruction.

4. Be especially watchful of children and pets darting into the area while operating.

5. Keep your eyes and mind on your unit while mowing or operating your attachment. Don’t let others distract you.

6. Do not attempt to operate your unit or mower when not in the driver’s seat.

7. Always stop unit when emptying the container.

8. Stop unit, shut off deck attachment, set parking brake, shut off mower engine and remove spark plug wire before

removing clogs, removing or replacing hose, boot, blower cone, or performing any maintenance.

9. Mow up and down the face of slopes (not steeper than 10 degrees); never up and down the face of the slope.

10. It is recommended that the container be kept only half full when negotiating any slopes. Start mowing on slopes

when the container is empty.

11. Inspect your lawn and remove any foreign objects before mowing. Never deliberately run the mower across any

foreign object.

12. Wear ear protection if the noise level is offensive.

13. Wear eye protection to prevent debris from damaging your eyes.

SECTION PAGE

Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Safety Alert Symbols- - - - - - - - - - - - - - - - - - - - - - 3

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

I INTRODUCTION AND DESCRIPTION - - - - - - - - - - - - 5

1-1 Introduction - - - - - - - - - - - - - - - - - - - - - - - - - 5

1-2 Description - - - - - - - - - - - - - - - - - - - - - - - - - 5

II INSTALLATION FOR USE - - - - - - - - - - - - - - - - - - - - - 6

2-1 Preparation Of Mower - - - - - - - - - - - - - - - - - - 6

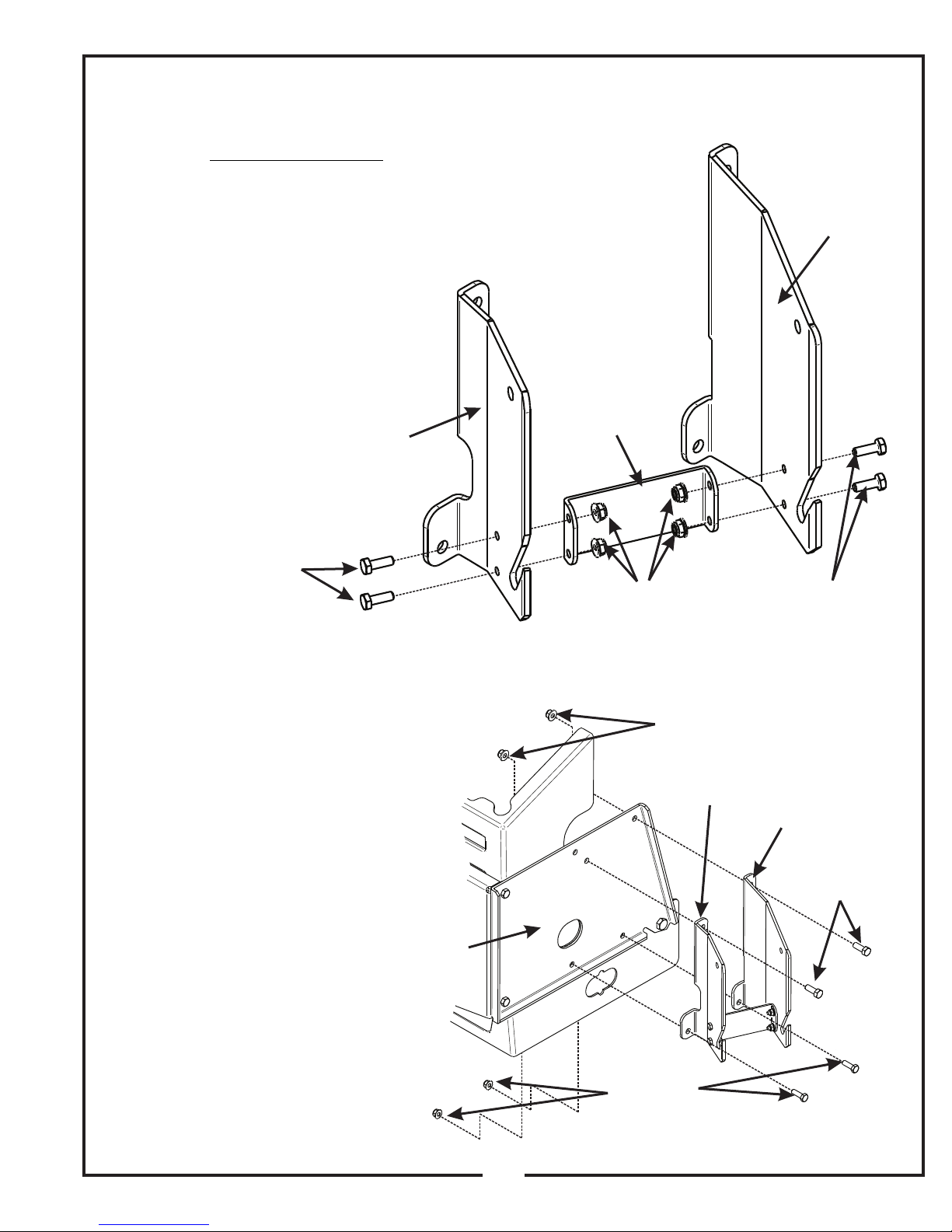

2-2 Frame Bracket Installation - - - - - - - - - - - - - - - 7

2-3 Exhaust Diverter Installation - - - - - - - - - - - - - - 8

2-4 PTO Mount Plate Component Installation- - - - - - 9

2-5 PTO Assembly Installation - - - - - - - - - - - - - - - 10

2-6 PTO Handle Installation - - - - - - - - - - - - - - - - - 10

2-7 Belt Installation And Adjustment - - - - - - - - - - - - 11

2-8 Cam Assembly Adjustment - - - - - - - - - - - - - - - 12

2-9 Outer Engine Mount Tube Installation - - - - - - - - 12

2-10 Engine Mount Arm Assembly Installation - - - - - 12

2-11 Engine/Blower/Blade Assembly Installation - - - - 12

2-12 Lower Mount Tube Installation - - - - - - - - - - - - 13

2-13 Upper Frame Assembly Installation - - - - - - - - - 13

2-14 Top Assembly To Upper

Frame Assembly Installation - - - - - - - - - - - - - 14

2-15 Hinge Kit Installation - - - - - - - - - - - - - - - - - - 14

2-16 Inlet installation - - - - - - - - - - - - - - - - - - - - - - 14

2-17 Blower Cone Installation - - - - - - - - - - - - - - - - 15

SECTION PAGE

2-18 Boot To Mower Deck Installation - - - - - - - - - - - 15

2-19 Hose Clamp Preparation- - - - - - - - - - - - - - - - 16

2-20 Length Of Hose Adjustment - - - - - - - - - - - - - - 17

2-21 Upper Hose Installation - - - - - - - - - - - - - - - - 17

2-22 Lower Hose To Blower Cone Installation- - - - - - 17

2-23 Lower Hose To Boot Installation - - - - - - - - - - - 17

2-24 Impeller Blade Removal And Replacement - - - - 18

2-25 Weight Kit Installation- - - - - - - - - - - - - - - - - - 19

2-26 Throttle Cable Kit Installation - - - - - - - - - - - - - 20

2-27 Installation And Removal Of Collection Bags - - - 21

Exploded Views and Parts List - - - - - - - - - - - - - 22-32

III OPERATING INSTRUCTIONS - - - - - - - - - - - - - - - - - - - - - - -

33

3-1 General Safety - - - - - - - - - - - - - - - - - - - - - - - 33

3-2 Operation & Tips On Mowing - - - - - - - - - - - - - - 33

3-3 Disengagement Of The Blower - - - - - - - - - - - 33

3-4 Unloading The Collection System - - - - - - - - - - - 33

IV MAINTENANCE - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

4-1 Maintenance Checklist - - - - - - - - - - - - - - - - 33-34

4-2 Lubrication- - - - - - - - - - - - - - - - - - - - - - - - - - 34

V PARTS AND SERVICE - - - - - - - - - - - - - - - - - - - - - - 34

5-1 Parts And Service Information - - - - - - - - - - - - - 34

Safety Decals - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Torque Specifications - - - - - - - - - - - - - - - - - - - - - 36