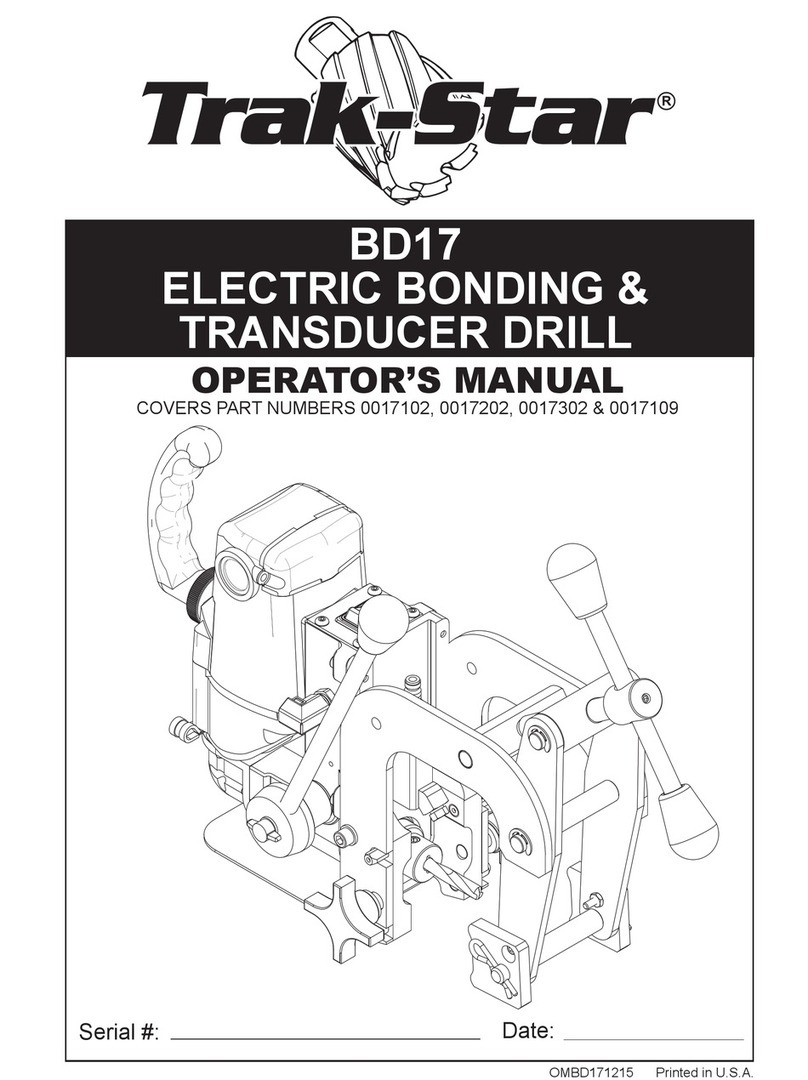

Trak-Star RailBoss User manual

OPERATOR’S MANUAL

PORTABLE 4-STROKE RAIL DRILL --- MANUAL FEED

70 LB. A.S.C.E. TO 155 LB. P.S.

Serial #: _______________________ Date: ______________

2

TRAK-STAR

®

Portable Gas Rail Drill

Model RB28

Welcome to Trak-Star

Congratulations on your purchase of the Trak-Star Portable Gas Rail Drill. Your model is designed to produce

superior holes quickly and effi ciently. Through constant innovation and development, Trak-Star is committed

to provide you with hole-producing tools and products that lead the industrial world.

Before attempting to operate your new Rail Drill, please read all instructions fi rst. These include the Operators

Manual and warning Label on unit itself. With proper use, care, and maintenance, your model will provide you

with years of effective hole drilling performance. Once again, thank you for selecting our product and welcome

to Trak-Star.

1. Open shipping carton and remove the literature and

hardware packages.

2. Read and Follow All Instructions before attempting

to operate your new Rail Drill.

3. Complete and mail the Product Registration Card

NOW

. It is important that Hougen Manufacturing, Inc.,

have a record of product ownership.

4. Open all hardware packages and check contents.

10565 Hex wrench 1/8”

13013 Hex wrench 5/32”

10570 (2) Knobs

03522 Shaft

03635 Pilot

27019 Feed Handle Assy

01592 Coolant Bottle

27091 Oil

5. Lift Rail Drill out of shipping carton using center

carrying handle and rear support handle.

6. Attach the large feed handle onto the drill using the

enclosed 5/32” hex wrench.

7. Attach Clamp Handle using the enclosed 1/8”

hex wrench.

8. ADD 8 OZ OF OIL TO THE MOTOR.

9. Your new Rail Drill was factory adjusted prior to

shipping. Check to make sure that all screws, motor

hold-down screws, drill housing and shoe mounting

screws are snug and have not vibrated loose in

transit.

10. Hookup Coolant Bottle / Hose Assembly (01592).

Connect the quick-disconnect hose fi tting to the Rail

Drill.

11. Reread Safety Warnings listed in this Operator’s

Manual and on the drill unit to avoid injury. Follow

operating procedures.

Your new Rail Drill is equipped with a twist arbor bore to

accept TRAK-STAR Twister Bits. Order cutters separately.

Install pilot thru cutter before attaching cutter to arbor.

Unpacking Your New Rail Drill

Index

Welcome to TRAK-STAR 2

Unpacking Your New Rail Drill 2

Important Safety Instructions 3

Model features 4

Installing / Replacing Cutter 5

Drill and Pressurized Coolant System 6

Clamping Procedures 7

Positioning of Hole Location Template 8

Important Notice 9

Operating Instructions 9

Section Page

Maintenance - - Engine/Drill 10

Clamp Exploded view & Parts 11

RB28 Exploded View 12

Parts List 13

Engine Parts Diagram and parts 14

Rail and Shoe Data 15

Commercial / Industrial Warranty 16

- Factory Authorized Service Centers

Section Page

OIL MUST BE ADDED TO THE

ENGINE BEFORE STARTING.

FAILURE TO DO SO WILL RESULT IN

ENGINE DAMAGE WHICH IS NOT

COVERED UNDER WARRANTY.

WARNING!

3

• Quill and cutter should never be used as a

handhold.

• Keep hands and clothing away from all

moving parts.

• Do not use Twister Bits where ejected slug

might cause injury (slug ejected at end of cut).

• Be sure that all safety devices are properly

adjusted and in use. Also, adhere to all

operating instructions.

• Do not attach Rail Drill to live 3rd rail track.

18.

Non-Conforming Cutting Tools

The TRAK-STAR Model RB28 is designed

to use TRAK-STAR Twister Bits only. The use

of drilling tools having different shank styles is

not recommended as they may not tighten

securely in the TRAK-STAR arbor with risk of

accident or injury.

19.

Save These Instructions

20.

Read all instructions concerning the motor

in your HONDA Engine Operator’s manual.

1.

Read All Instructions

2.

Keep Work area clean

Cluttered area and benches invite injuries. Keep dirt

and chips from under Twister Bit area and drill shoe.

3.

Consider Work Area Environment

.

Keep work area well lit.

4.

Keep Children Away

Do not let visitors contact tool.

5.

Store Idle Tools

When not in use, tools should be stored in a dry, and

a high or locked-up place -- out of reach of children.

6.

Do Not Force Tool

It will do the job better and faster at the rate for which

it was intended.

7.

Use Right Tool

Do not force small tool or attachment to do the job

of a heavy duty tool.

Do not use tool for purpose not intended -- for example

do not use a circular saw for cutting tree limbs or logs.

8.

Dress Properly

Do not wear loose clothing or jewelry. They might

entangle with spinning chips or get caught in moving

parts. Rubber gloves and nonskid footwear are

recommended when working outdoors. Wear sturdy

leather gloves when working indoors.

14.

Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

wrenches are removed from tool before Starting drill

unit.

15

Stay Alert

Watch what you are doing. Use common sense.

Do Not operate tool when you are tired.

9.

Always Wear Safety Glasses or Goggles.

10.

Do Not Overreach

Keep proper footing and balance at all time.

11.

Secure Work

Clamp work securely using appropriate shoe size and

shape.

Tighten Clamp by using two hands with handle

placed in central position and tighten securely.

12.

Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Do not use dull or broken Twister cutters. Follow

instructions for lubricating and changing accessories.

Inspect gas line periodically and, if damaged, have

repaired by authorized service facility.

Keep handles dry, clean, and free from oil and

grease.

13.

Disconnect Tools

Disconnect spark plug wire from spark plug when not

in use, before servicing, and when changing

Twister Bits or accessories.

16.

Check Damaged Parts

Before further use of drill, a part that is dam-

aged should be carefully checked to determine

that it will operate properly and perform its

intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and

any other conditions that may affect its opera-

tion.

A part that is damaged should be properly

repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in

this instruction manual.

(See last page for authorized Service Centers)

17.

Additional Safety Precautions

Important Safety Instructions

4

PLEASE READ THE HONDA ENGINE OPERATOR’S

MANUAL. INSTRUCTIONS ON THE OPERATION,

SAFETY, AND MAINTENANCE PROCEDURES ARE

CONTAINED IN A SEPARATE MANUAL.

IMPORTANT:

Before starting the machine, it is impera-

tive that the operator know and understand instructions

for safe operation.

Add engine oil to motor and use regular

unleaded gasoline only.

Ignition switch located on engine---stops motor, spindle, and cutter

rotation. See diagram at left.

“ON” / “OFF” Switch

“ON” / “OFF” Switch

The World’s Most Reliable

4-Stroke Rail Drill

Honda Engine Instructions

Honda Engine Instructions

Honda Engine Instructions

GAS MUST BE SHUT OFF BEFORE

TRANSPORTING DRILL.

5

TRAK-STAR Twister Disposable Rail Cutters

Made from Premium H.S.S.

• Gold Coating for All Around Drilling

• Black Coating for Improved Performance

in New Harder Rail.

TRAK-STAR Rail Drills are designed to use Twister

Bits, and to achieve maximum effi ciency from your

unit, we recommend that no substitutes be used.

** Twister Bits are economical and disposable

--- there is no need to resharpen --- however it is

possible. Tools can be sharpened 2 to 3 times.

Send cutters to Trak-Star to the attention of the

Resharpening Department.

** Twister Rail Bits have been shown to drill holes

in rails up to 4X faster than twist drills or spade

drills, and they produce clean, round, burr-free

holes without the need to chamfer.

** Multiple cutting edge design, along with proper

coolant fl ow, produces a cool cut raising the rail

temperature in the hole no more than 35°F above

ambient temperature. This prevents work harden-

ing, stress cracking, service failures, and repeated

repairs.

Cutter

Size,

inches

Decimal

Equivalent

Gold -

TiN Coated

Part Number

Black -

TiAlN Coated

Part Number

7/8 .08750 15228 15328

15/16 .09375 15230 15330

1 1.0000 15232 15332

1-1/16 1.0625 15234 15334

1-1/8 1.1250 15236 15336

1-3/16 1.1875 15238 15338

1-1/4 1.2500 15240 15340

1-5/16 1.3125 15242 15342

1-3/8 1.3750 15244 15344

1-7/16 1.4375 15246 15346

1-1/2 1.5000 15248 15348

1-11/16 1.6875 15254 15354

Pilot for Twister Bits 03635

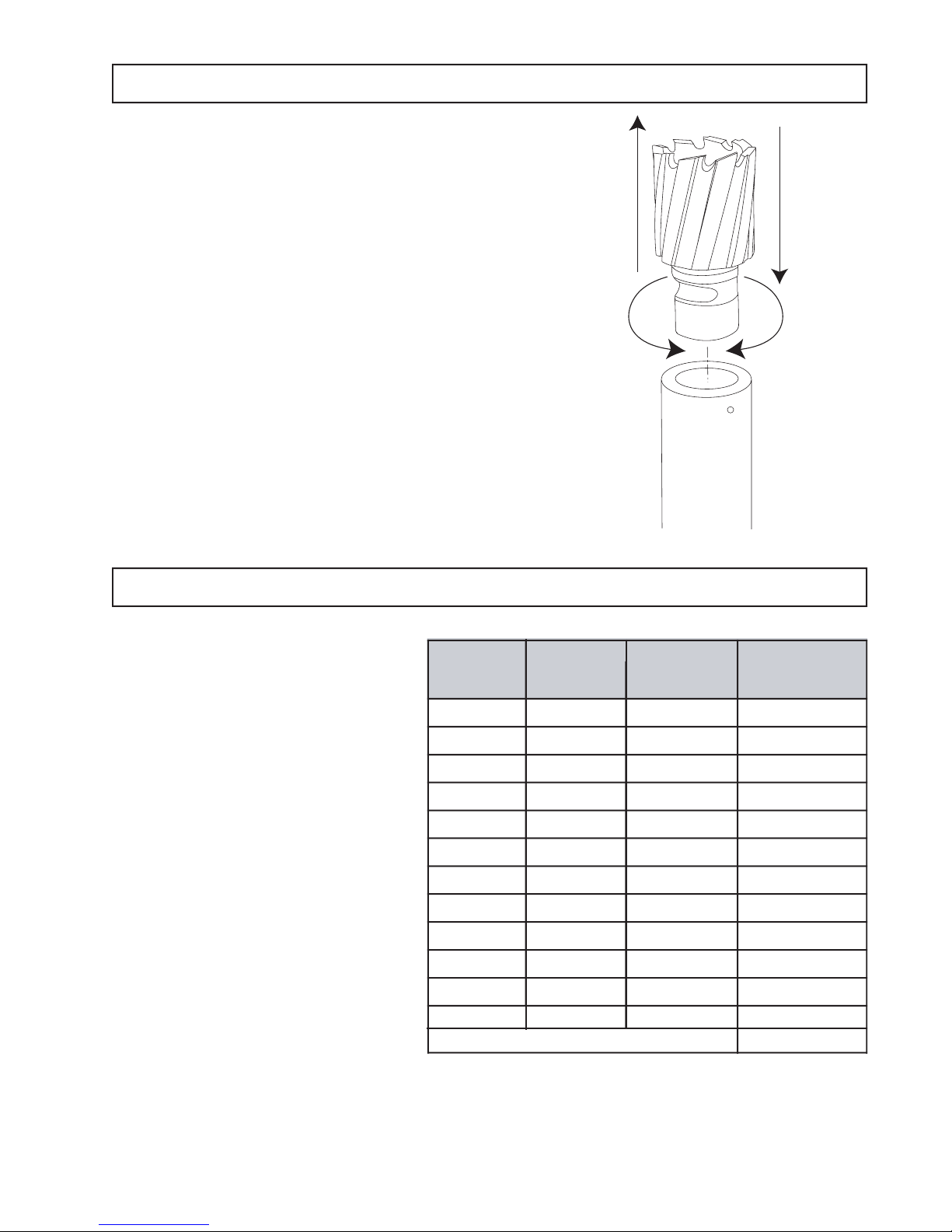

Installing / Replacing Twister

TM

Bit

1. Be sure engine is stopped and turned off. Turn off

coolant at shut-off. The spring seat system located

within arbor was not designed to be 100% leak proof.

2. Position arbor so the cutter area is easily accessible.

Do not depress pilot pin during procedure to release

seal. Doing so will result in releasing pressurized

contents of arbor cavity and coolant loss. Some loss,

however, is normal due to cavity between cutter shank

and spring seat.

3. Insert pilot in shank end of Twister Bit.

4. Insert the Twister Bit until long fl at on cutter shank is

aligned with roll pin inside arbor. Twist cutter clockwise

(do not depress pilot in case of cutter replacement for

reason noted in #2). The cutter is automatically held

into place.

Insert Cutter

into Arbor

Twist

OFF ON

Twist

Drill & Pressurized Coolant System

1. Install correct shoes for rail type being drilled.

2. Install correct size Twister Bit with pilot and secure

to drill arbor. See Cutter Installation procedure.

3. Fill coolant bottle with TRAK-STAR cutting fl uid ( a water

3. Fill coolant bottle with TRAK-STAR cutting fl uid ( a water 3. Fill coolant bottle with TRAK-STAR cutting fl uid ( a water

soluble and biodegradable product) Conventional fi ll

access is achieved by removing pump handle.

Caution: Contents under pressure. Partially open

to slowly release pressure before removing.

4. Attach coolant bottle quick connect hose fi tting to drill

on the backside of drill under motor.

5. Pressurize coolant bottle (approximately 20 pumps)

6. Open coolant shut off valve.

7. Depress pilot pin approximately 1/4” and watch for

coolant fl ow from the end of the cutter. NOTE - Coolant

is under pressure -- stay out of path of spray. If coolant

does not fl ow, rotate valve further to open or unclog

coolant system.

6

RotaMagic™ Concentrate Cutting Fluid

A good fl ow of cutting fl uid to the tool is important. It cools

and lubricates the cutting edge, helps evacuate the chips,

keeps the slug from expanding, and helps eject the slug.

Various mineral and sulphur base oils are quite popular,

however, water base solutions have better cooling qualities.

Listed is our own recommended Concentrated Cutting Fluid

for Twister Bits and similar cutting tools. It is a water soluble,

biodegradable product. This cutting fl uid contains no ingredi-

ents that are on the U.S. Government Hazardous Materials

List. It is a super concentrated form that will require a 10:1

mixture of water.

RotaMagic™ Concentrate Cutting Fluid

Coolant Quick Connect Hose and Nipple

rebmuNredrO noitpircseDeziS

4-24711 **snollaG4

34711 +snollaG5

NISEMOC.ETARTNECNOCFOTNUOMADERUSAEM**

FOSNOLLAG44SEKAMDNASRENIATNOCNOLLAG1-4

DIULFGNITTUCELBASU

EKAMLLIW,LLUF,RENIATNOCNOLLAG-5NISEMOC+

DIULFGNITTUCELBASUFOSNOLLAG55

01569 On/Off Valve

05621 Quick Connect Fitting

01592 Coolant Bottle and Hose Assy

Coolant System Replacement Parts

Do Not Use Straight Water or Window

Washer Fluid. Damage to Drill Will Occur!

Only Use Trak-Star RotaMagic Coolant.

7

FIGURE A.

FIGURE B.

FIGURE C.

FIGURE D.

CLAMPING PROCEDURES

STEP #1:

WITH CLAMP IN OPEN POSITION,

REST UNIT ON RAIL BASE. BOTTOM

OF SHOES SHOULD CONTACT

TAPER ON RAIL BASE.

(SEE FIG. A)

** PERFORMANCE TIP: CLOSE

CLAMP UNTIL CLAMP PAD CON-

TACTS WEB OF RAIL PRIOR TO

STEP #2.

STEP #2:

RAISE REAR OF RAIL DRILL TO

LOCATE SHOES IN PROPER

POSITION.

(SEE FIGURE B)

STEP #3:

WHILE MAINTAINING CONTACT

BETWEEN SHOES AND RAIL,

TIGHTEN CLAMP.

(SEE FIG. C)

STEP #4:

WHEN UNIT IS FIRMLY CLAMPED,

CHECK FOR PROPER SHOE AND

PAD CONTACT ON BOTH SIDES

(SEE FIG. D)

WARNING: IMPROPER CLAMPING WILL CAUSE PREMATURE

CUTTER FAILURE

* When properly clamped to the rail there will be

a small gap between the top of the shoe and the rail.

Positioning of Optional Hole Location Template

Template is positioned on head of rail with tapered tip fl ush

with end of rail and side locking screws fastened to rail

head. Notches in template give precise location of hole

centerlines to be drilled.

The rail clamp assembly has a locating arm which rests

in the template notches. The locating arm is adjustable to

accommodate the full range of rail sizes.

To use the locating arm, raise the drill unit over the rail with

the template attached and gently rest drill down until shoes

make contact with the rail. Flip the arm to make contact

with the template. Slowly slide drill across the template

until the arm falls into notch.

The arm must contact the sides of the matching notch.

Following the Clamping Instructions, clamp unit onto rail.

When the hole is completed, raise the arm by fl ipping the

arm back toward the body of the drill. Before drilling next

hole remove chips around cutter. Then move the drill side-

ways, ensuring the arm is clear of the notch, and fl ip arm

down. Slide the drill sideways until arm falls in the next

notch, and repeat the procedure as necessary.

Note: The locating arm must be fl ipped back, resting

on the body of the drill before putting the drill unit on

the rail. Failure to do so can result in damage to the

hole locating arm system.

Hole location templates are offered as optional equipment.

Four of these templates are provided with established hole

spacings. The 40570 template is produced to customer

specifi ed hole spacing. See chart for the template to match

your application.

8

Template

Part No.Hole Spacing

40570 Customer Specified

40701 3-1/2" X 6" X 6"

40702 2-11/16" X 5-1/2" X 5-1/2"

40703 2-1/2" X 5" x 5"

40704 2-1/2" X 6-1/2" X 6-1/2"

40706 2- 23/32" x 5-1/2" x 5-1/2"

Locating Arm

Location Template

28-1/2"

"A"

"B"

"C"

Specify “A”, “B”, “C” when ordering custom template

Custom Template Spacing

Operating Instructions

NEVER RUN ENGINE INDOORS OR IN ENCLOSED,

POORLY VENTILATED AREAS. ENGINE EXHAUST

CONTAINS CARBON MONOXIDE, AN ODORLESS

AND DEADLY GAS.

KEEP HANDS, FEET, HAIR, AND LOOSE CLOTHING

AWAY FROM ANY MOVING PARTS ON ENGINE AND

EQUIPMENT.

WARNING - TEMPERATURE OF MUFFLER AND NEAR

BY AREAS MAY EXCEED 150°F (65°C). AVOID THESE

AREAS.

1. Make sure workpiece, cutter and shoe surfaces are

free of chips, etc.

2. Place locator template on rail head.

3. Align drill on locator with the Hole Location Template.

4. Clamp drill to rail and insure proper 10 point contact.

5. Turn on coolant (pump to pressurize system).

6. Move choke lever to “FULL CHOKE”. If restarting a

warm engine after a short shutdown, move choke lever

to “NO CHOKE”.

7. Turn motor on/off switch to “ON” position.

8. Move throttle to idle position.

9. Grasp starter handle and pull rope out, slowly, until it

meets resistance. Let rope rewind slowly. Then pull

rope with a rapid full arm stroke. Let rope return to

starter slowly.

10. Repeat step #9 until engine fi res.

11. Move throttle to run position.

12. Manually feed cutter very gently to start cutting.

13. Once all teeth are cutting aggressively, feed tool

through workpiece at an even rate. Do not over-

load unit to induce an arbor stalling situation. Certain

rail compositions workharden easily. Do not pause

during cut nor release feed pressure if changing hand

grip on feed handle. This will result in premature

cutter wear and drilling problems while in the cut.

14. Move feed handle to retract arbor and cutter. Slug

should eject from spring loaded pilot pin pressure.

15. Move throttle to idle position.

16. At the end of the cut, move ignition switch on engine

to “STOP” or “OFF” position.

17. Loosen clamp and remove drill to clean chips from

around cutter. Drill cycle is complete and you are

ready to go on to the next hole. Shutting off coolant

after use is suggested, if use is intermittent.

If Slug Has Not Fallen Free

, disconnect spark plug

wire from spark plug and shut off coolant supply. Use a

screwdriver to carefully fl ip slug by inserting it between

slug fl ange and cutter gullet. It generally will remove

easily while discharging a squirt of coolant. Avoid

prying with force, damage to the cutter and cutting

edge may result.

WHEN EQUIPMENT WILL NOT BE USED FOR

EXTENDED PERIODS, DISCONNECT SPARK PLUG

WIRE FROM SPARK PLUG AND KEEP IT AWAY

FROM SPARK PLUG.

NEVER STORE ENGINE WITH FUEL IN TANK

INDOORS OR IN ENCLOSED, POORLY

VENTILATED AREAS, WHERE FUEL FUMES MAY

REACH AN OPEN FLAME, SPARK, OR PILOT

LIGHT AS ON A FURNACE, WATER HEATER,

CLOTHES DRYER OR OTHER GAS APPLIANCE.

9

Important Notice

1. Make sure cutter is properly installed.

2. The #1 cause of premature cutter failure is improper clamping. (see page 7 for

clamping procedures.)

3. The # 2 cause of premature cutter failure is improper feed, usually feeding too slow.

4. Always use caution when contacting the rail with the cutting tool. Allow the cutter to

completely enter the rail before applying full feed pressure.

5.

GAS MUST BE SHUT OFF BEFORE TRANSPORTING DRILL.

10

Maintenance -- Engine/Drill

Maintenance -- Engine/Drill

AIR CLEANER

:

IMPORTANT: NEVER RUN ENGINE WITHOUT

COMPLETE AIR CLEANER INSTALLED ON ENGINE

1. To remove and install fi lter:

Press tabs on the top of the air cleaner, and remove

the cover. Remove and inspect the foam fi lter for

discoloration or dirt accumulation. If either is present,

service per below instructions. Clean inside of cover

and body thoroughly.

2. To service fi lter

Foam Filter

: Clean and re-oil every three months or

every 25 operating hours. Clean and re-oil daily if use

in extremely dusty conditions. Wash in water and

detergent solution and squeeze (don’t twist) until all

dirt is removed. Rinse thoroughly in clear water. Wrap

in a clean cloth and squeeze (don’t twist) until

completely dry. Saturate with motor oil and squeeze to

distribute oil and remove excess oil.

3. Reassemble air cleaner.

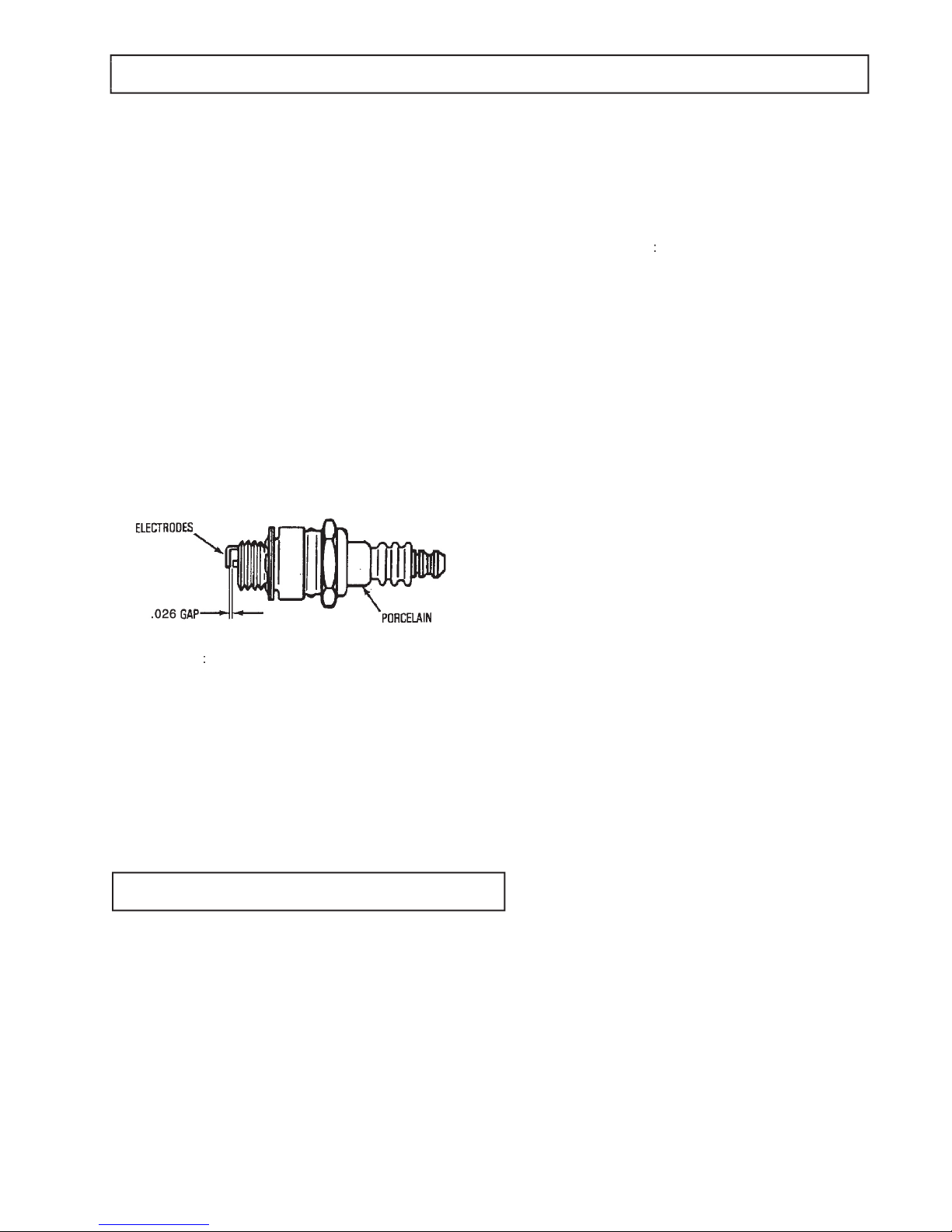

SPARK PLUG

:

1. Check spark plug yearly or every 100 operating hours.

2. Clean around spark plug. Remove and inspect spark

plug.

3. Replace spark plug if electrodes are pitted, burned, or

porcelain is cracked. Use NGK CR5HSB or

equivalent.

4. Check electrode gap with a wire feeler gauge and set

gap at .026” if necessary.

5. Install spark plug and tighten securely.

MUFFLER AND CYLINDER EXHAUST PORTS

The muffl er and cylinder exhaust ports require cleaning

after every 100 hours of operation. For this maintenance

procedure, we recommend that you take your engine to a

Authorized TRAK-STAR Service Center or your

Honda Registered Service Dealer.

COOLING SYSTEM

:

Important: Frequently remove debris from cooling fi ns, air

intake screen, and levers and linkage. This will help ensure

adequate cooling and correct engine speed.

The RailBoss requires minimal maintenance to keep drill in

top working condition.

• Every four to six months or as needed apply a light

coat of grease to the quill and arbor assembly and the

large screw that tightens the handle.

• Keep drill clean.

• Maintain motor as outlined in your Honda motor

operator’s manual.

Maintenance -- Drill

11

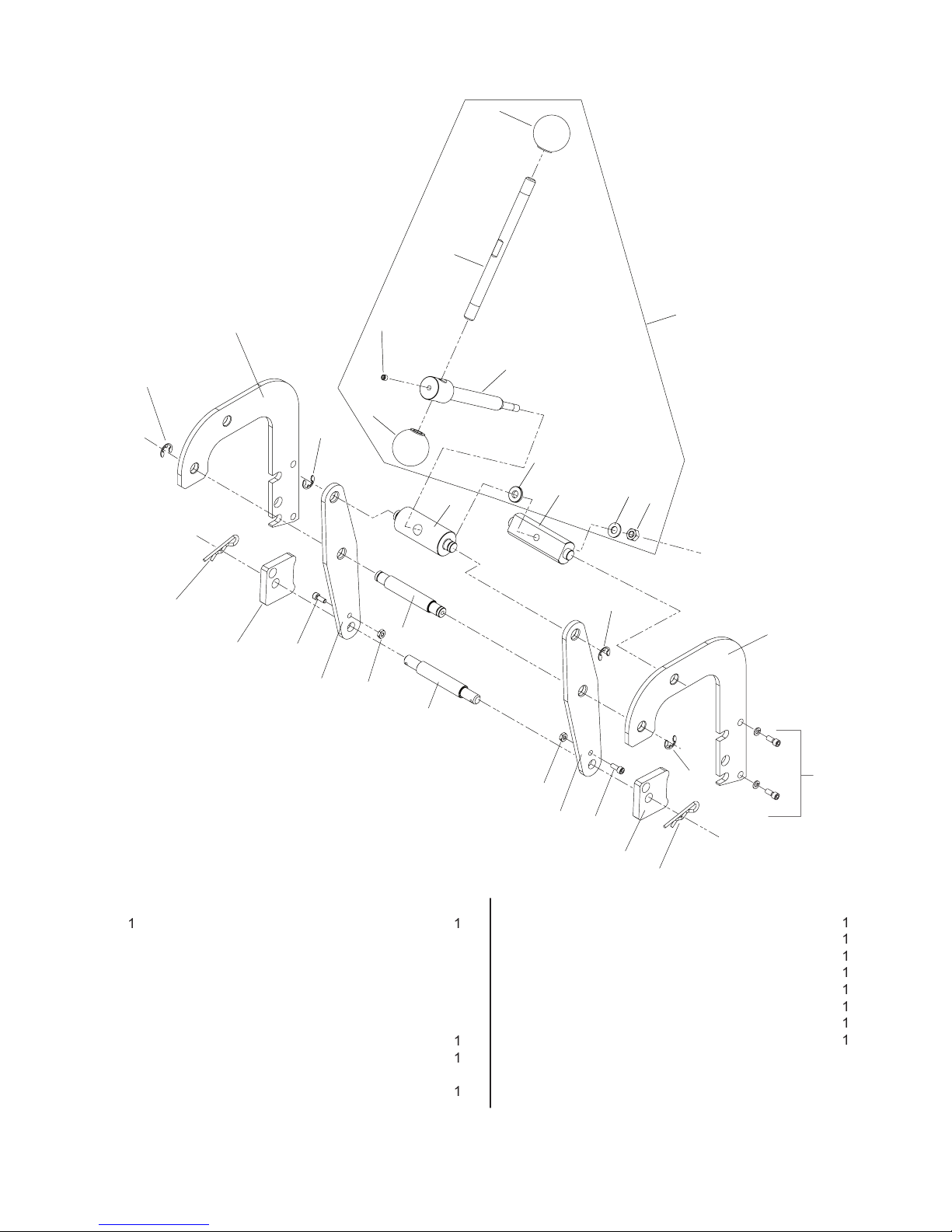

Clamp Exploded View (P/N: 27115)

No.

Part No.

Description

Qty.

No.

Part No.

Description

Qty.

27066

27110

03501

27062

90098

27022

10662

27024

27023

04532

02470

1

2

3

4

5

6

7

8

9

10

11

Retaining Clip Set

Primary Clamp Arm

Hitch Pin

Clamp Pad

Screw #10-24 x 3/4”

Secondary Clamp Arm

Lock Nut - #10-24

Pin

Pin

Knob

Set Screw 1/4-28 x 3/8”

1

2

2

2

2

2

2

1

1

2

1

03522

27027

27026

04782

27025

40074

03563

27080

12

13

14

15

16

17

18

19

Clamp Turn Handle

Clamp Feed Screw

Bushing

Flat Washer

Bushing

Flat Washer 5/16”

Hex Nut 5/16-18

Clamp Handle Assy

1

1

1

1

1

1

1

1

1

2

3

45

67

8

9

1

10

11

12

10

13

14

15

16 17 18

7

5

2

4

3

1

1

6

19

Screws & washers

not included in

clamp assembly

27

88

33

To Motor

(P/N: 27038)

18

35

37

36

27

32

23

26

20

44

24

22

50

51

53

52

1

2

3

4

5

5

6

12

13

17

15

16

14

19

49

25

See Page 11 for Clamp Parts

80*

58

57

57

60

61

59

57

57

58

65 64

56

#80 includes: 62 - 65

#81 includes: 43(2x), gear & shaft

#82 Includes: 43 - 46, gear & shaft

#83 Includes: 43(2x), gear & shaft

#84 Includes: 43(2x), gear & shaft

#85 Includes: 5 - 12

#86 Includes: 57 - 61

#87 Includes: Assy #80 & #86

#88 Includes: 35 - 37

#89 Includes: 1 - 4

#90 Includes: 13 - 17

#91 Coolant Hose Assy (Not Shown)

#92 Rail Clamp Assy

43

43

43

43

43

81*

45

82*

48

83*

84*

11

7

8

9

71

10

85*

43

43

86*

87*

55

34

33

34

28

27

Assemblies

89

90

26

62

92*

38

39

40

42

46

63

70

72

20

54

12

RB28 Housing & Gear

Box Exploded View

Housing & Gear Box Parts

13

No.

Part No.

Description

Qty.

No.

Part No.

Description

Qty.

27019

04919

04809

27059

04815

27046

04794

27047

24160

04793

27048

27051

27029

27028

01153

04859

40038

27060

27005

11050

27064

27063

04838

02071

04810

90027

01121

75313

10624

90028

27054

50038

90077

04836

27035

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

22

23

24

25

26

27

28

32

33

34

35

36

37

38

39

FEED HANDLE ASSY

THUMB SCREW

WASHER FLAT

KEY

SCREW

FEED GEAR BEARING

O RING

FEED GEAR SHAFT

RET RING

FLAT WASHER

KEY

FEED GEAR

LOCATING ARM

BRACKET LOCATOR

PIN DOWEL 3/16 X 1/2

SCREW

SCR-SHC 10-32

CARRYING HANDLE

MOTOR HOUSING

SCR-SOC SET 1/4-28

CLUTCH ROTOR

CLUTCH HOUSING

WASHER-SHIM

PIPE PLUG

MOTOR MOUNT

WASHER FLT 1/4 ID

SCR-SHC 1/4-28

SCR-SHC M6

SCR-SHC 1/4-20

WSR-HEL LOCK 1/4”

SUPPORT HANDLE

WASHER-HELI

SCR-BHC 10-32

O RING 1” ID

EJECTOR PIN ASSY

1

1

1

1

3

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

40*

42

43

44

45

46

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

70

71

72

27016

04807

24100

27057

04804

27014

27015

27113

40558

40107

40110

04918

04787

27033

27031

04791

04788

04790

27034

40232

02363

27032

04736

04737

05196

24088

04792

COOLANT SEAL

O-RING

BALL BEARING

KEY

BALL BEARING

ENGINE DRIVE SHAFT

DRIVE GEAR/SPINDLE

HOUSING ASSY

SCR-SHC 5/16

WASHER 5/16-HELI

WASHER LOCK 1/2

4 POINT HANDLE

SPRING

PILOT PIN

BRG-NUT

THRUST WASHER

THRUST BEARING

NEEDLE BEARING

QUILL

NEEDLE BRG 40MM

O RING

ARBOR

LIP SEAL

RET RING

TEFLON WASHER

FLAT WASHER

PIN

1

2

1

1

1

1

1

1

4

4

2

2

1

1

1

4

2

1

1

1

1

1

1

1

1

1

1

Assemblies

80

81

82

83

84

85

86

87

88

89

90

91

92

27038

27040

27041

27044

27042

27043

27045

27050

27030

27081

27019

27082

27065

27115

2.5 HP HONDA MOTOR

ARBOR ASSEMBLY

GEAR ASSY

DRIVE GEAR ASSY

GEAR ASSY

GEAR ASSY

FEED GEAR ASSY

QUILL ASSEMBLY

ARBOR & QUILL ASSY

SUPPORT BRACKET ASSY

FEED HANDLE ASSY

LOCATING PIN ASSY

COOLANT HOSE ASSY

CLAMP ASSY

* MUST ALSO PURCHASE #42

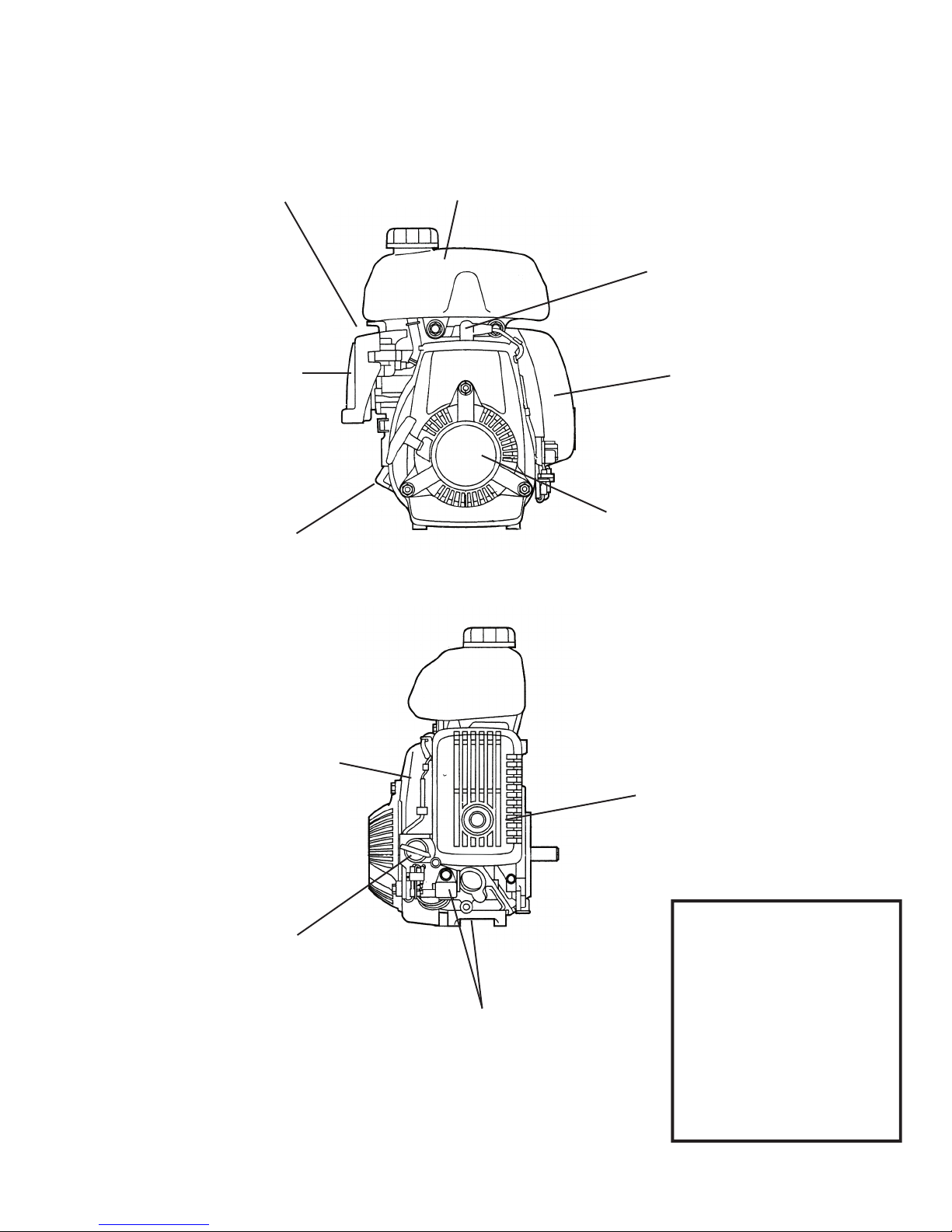

Engine Parts

14

Cover HD5988670

Element HD5988639

Gasket HD5988662

Flange Bolt HD6006084

Carburetor Assy HD6841118

Gasket Set HD3521192

Air Cleaner Housing HD5988647

Back of Cleaner Housing HD5988647

Air Cleaner Guard 27093

Air Cleaner/Carburetor Parts

Starter Parts

Recoil Assy HD5988795

Nut HD0636951

Knob HD5383948

Rope HD5988845

Pulley HD5988829

Recoil Case HD5988803

Muffler Parts

Muffler HD5988720

Muffler Protector HD5988746

Bolts for Protector HD0941096

Spark Arrester HD5988753

Spark Plug

Spark Plug HD5384631

(NGK CR5HSB)

Fan Cover

Cover HD5988779

Long Bolts HD5988969

Short Bolt HD5988977

Coil Assy Ignition HD5988852

Oil Alert

Oil Alert Unit HD5858444

Oil Level Switch HD6005870

(Under Housing)

Gas Tank

Tank HD6005748

Cap HD6673289

Bolt HD2251288

Fuel Tube HD6005771

Fuel Filter HD1452945

Oil Fill

Cap w/ gasket HD6005573

Engine Oil 27091

Switch

On/Off Switch HD2787869

Governor Parts

Governor Arm HD6005672

Governor Rod HD6005680

Governor Spring HD6005698

Throttle Return Spring HD6005706

These parts and others not

listed here are available from

Trak-Star by calling

866-245-3745

Parts and service regarding

Honda Motor ONLY are also

available at your local

Honda Service Center

Motor

Complete Motor 27038

15

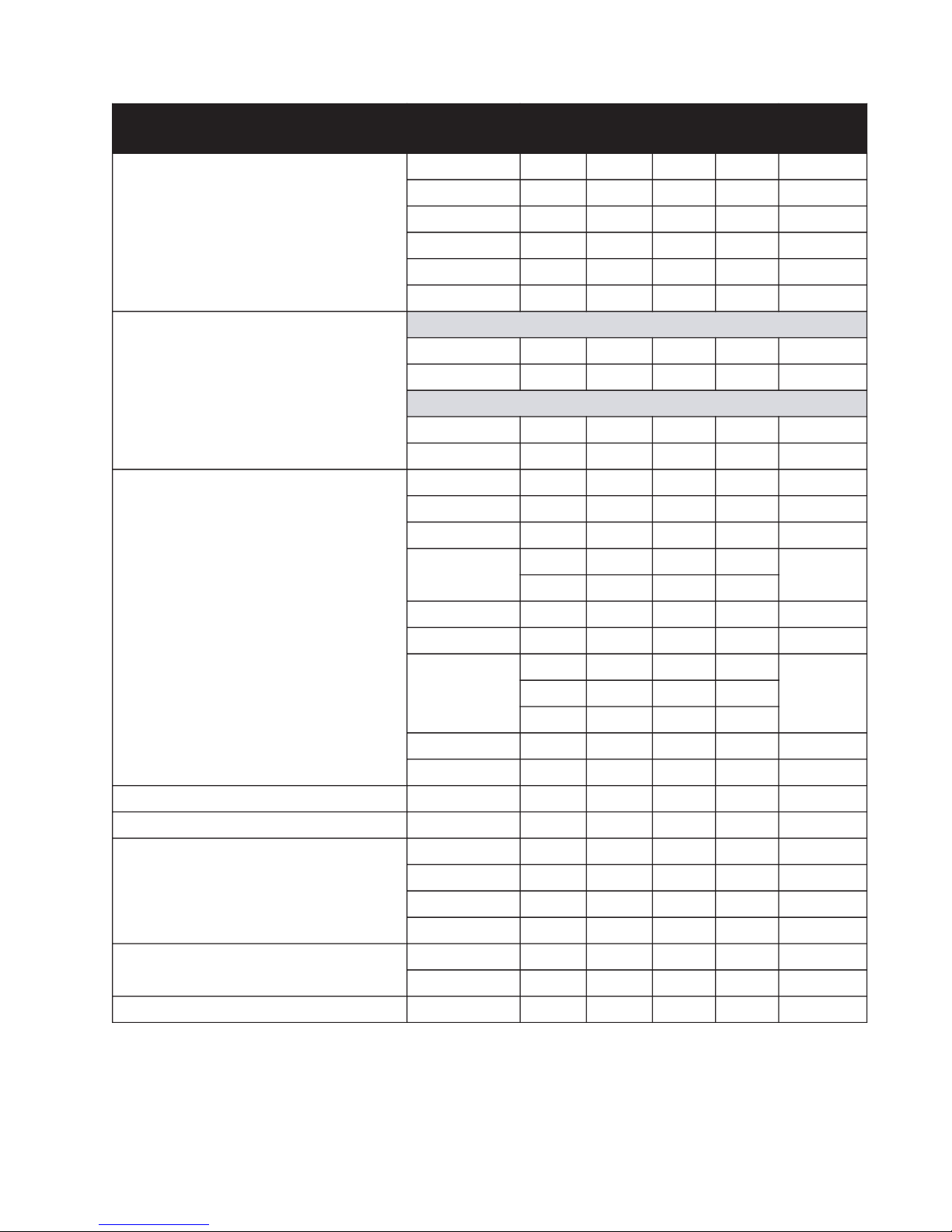

Rail & Shoe Data

Railway Association or System Tee Rail

Section (lb.) Section Designation Shoe

Part No.

ASCE - American Society

of Civil Engineers

70 7040 70 AS 701 01906

75 7540 75 AS 753 01907

80 8040 80 AS 800 01908

85 8540 85 AS 851 01909

90 9040 90 AS --- 01910

100 10040 100 AS --- 01911

ARA - American

Railway Association

Type "A" - High Rail for High Speeds

90 9020 90 RA 902 01927

100 10020 100 RA 1003 01928

Type "B" - Lower Rail for Heavy Loads @ Slower Speeds

90 9030 90 RB 905 01908

100 10030 100 RB 1002 01910

AREA - American Railway

Engineering Association

100 10025 100 RE 10025 01894

110 11025 110 RE 1100 01895

112 11228 112 RE 1121 01896

115/11911525 115 RE 115001897

11937 119 RE 1190

130 13025 130 RE 1300 01898

131 13128 131 RE 1311 01899

132/136/141

13228 132 RE 1321

0190213622 136 RE 13637

--- 141 --- ---

133 13331 133 RE 1330 01901

140 --- 140 RE --- 01903

CSX 122 --- 122 CB --- 01918

UP (former C & NW) 100 10035 100 DM 10035 01926

PS - Pennsylvania System

85 8531 85 PS --- 01912

100 10031 100 PS --- 01913

130 13031 130 PS --- 01914

155 15531 155 PS --- 01919

NYC (Dudley) - New York Central &

Hudson River Railroad

105 10524 105 DY --- 01915

127 12723 127 DY --- 01916

PRR - Pennsylvania Railroad 85 8533 85 PR --- 01917

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone: (866) 245-3745 • Fax (800) 309-3299

E-Mail: info@trak-star.com

On-line: www.trak-star.com

OMRB281105 R707 Printed in U.S.A.

© 2007 Hougen Manufacturing, Inc.

Hougen Manufacturing has received the

Association of American Railroads

Quality Assurance Program Certifi cation

Hougen Manufacturing, Incorporated warrants its Trak-Star Rail Drills, Portable Magnetic Drills, Electro-hy-

draulic Hole Punchers for one (1) year and other products for ninety (90) days from date of purchase against

defects due to faulty material or workmanship and will repair or replace (at its option) without charge on any

items returned. This warranty is void if the item has been damaged by accident or unreasonable use, neglect,

improper service, or other causes not arising out of defects in material or workmanship. No other expressed

warranty is given or authorized. Hougen Manufacturing, Inc., disclaims any implied warranty of MERCHANT-

ABILITY or FITNESS for any period beyond the expressed warranty and shall not be liable for incidental or

consequential damages. Some states do not allow exclusions of incidental or consequential damages or limi-

tation on how long an implied warranty lasts and, if the law of such a state governs your purchase, the above

exclusion and limitation may not apply to you. This warranty gives you specifi c legal

rights and you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized

Repair Center or to Hougen Manufacturing, Inc. 3001 Hougen Drive, Swartz Creek, Michigan 48473.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

©

2007 Hougen Manufacturing, Inc.

Commercial / Industrial Limited Warranty

Commercial / Industrial Limited Warranty

FACTORY AUTHORIZED WARRANTY SERVICE CENTERS

Hougen Manufacturing, Inc. Kenbil Service Co.

3001 Hougen Drive 2900 Adams Street B-14

Swartz Creek, MI 48473 Riverside, CA 92504

(866) 245-3745 (951) 689-6633

Photographs and Specifi cations shown are accurate in detail at time of printing. Manufacture reserves the

right to make improvements and modifi cations without prior notice.

Hougen, Hougen-Edge, Trak-Star, and Punch-Pro are propriety trademarks of Hougen

Manufacturing, Inc. Ogura and the Ogura logo are proprietary trademarks of Ogura & Co., Ltd. Honda logo

appears courtesy of American Honda Motor Co.

FACTORY AUTHORIZED WARRANTY SERVICE CENTERS

Hougen Manufacturing, Inc. Kenbil Service Co.

3001 Hougen Drive 2900 Adams Street B-14

Swartz Creek, MI 48473 Riverside, CA 92504

(866) 245-3745 (951) 689-6633

Photographs and Specifi cations shown are accurate in detail at time of printing. Manufacture reserves the

right to make improvements and modifi cations without prior notice.

Hougen, Hougen-Edge, Trak-Star, and Punch-Pro are propriety trademarks of Hougen

Manufacturing, Inc. Ogura and the Ogura logo are proprietary trademarks of Ogura & Co., Ltd. Honda logo

appears courtesy of American Honda Motor Co.

Table of contents

Other Trak-Star Drill manuals

Popular Drill manuals by other brands

Dynabrade

Dynabrade 53435 Important operating, maintenance and safety instructions

JEI DRILLING & CUTTING SOLUTIONS

JEI DRILLING & CUTTING SOLUTIONS MINIBEAST Operator's manual

Patriot

Patriot AV0108 user manual

Draper

Draper PR812V instructions

Meister

Meister SB500 Translation of the original instructions

Skil

Skil 3070 Original instructions