TRAMEX Dec Scanner User manual

non-destructive

roof moisture scanner

Introduction..................................................................................................................................2

How the Dec Scanner Works..................................................................................................2

Assembly Instructions..............................................................................................................2

Operating Instructions..............................................................................................................3

• Using the control panel.........................................................................................................3

• Range selection.......................................................................................................................4

• Calibration setting..................................................................................................................4

Conducting a roof survey.........................................................................................................4

Tracing a leak................................................................................................................................5

Types of roofing structure and their more common problems.................................5

Maintenance of the instrument.............................................................................................6

Limitations....................................................................................................................................6

Calibration.....................................................................................................................................6

Warranty.........................................................................................................................................6

Product Development...............................................................................................................7

Safety...............................................................................................................................................7

Technical data...............................................................................................................................7

User Guide

1

TABLE OF CONTENTS

User Guide User Guide

2

INTRODUCTION

Thank you for selecting the Dec Scanner instrument from

Tramex.

The Tramex Dec Scanner is a non-destructive impedance

moisture scanner designed for detecting and evaluating

moisture conditions in roofing and waterproofing systems.

The Dec Scanner has 3 ranges of sensitivity to enable the

surveying of a variety of roof types and roofing depths, and

is equipped to detect moisture in the majority of roofing and

waterproofing systems.

To get the maximum benefit from your Tramex Dec Scanner,

it is suggested that you read this manual to familiarize

yourself with the instrument and its capabilities, before

undertaking any roof investigations.

WHY SHOULD TESTING BE DONE ?

Excess moisture in a roofing and waterproofing system can

affect its performance, reducing thermal resistance values

and energy efficiency, raising energy costs, and eventually

causing structural damage and system failure.

WHEN SHOULD TESTING BE DONE ?

Testing and surveying of roofing systems needs to be

carried out at various stages of the lifetime of the roofing

and waterproofing system:

at installation to ensure roofing quality;

regularly as part of an ongoing maintenance program,

in order to monitor and take remedial action in plenty

of time to prevent major and expensive stripping and

re-roofing;

prior to reparation or re-roofing in order to determine

the cause and extent of damage.

The signals from this instrument will not penetrate

certain types of rubber roofing material such as

some black E.P.D.M and some Butyl Rubber. The

Dec Scanner is not suitable for any roofing with

electrically conductive or metal-faced membranes.

IMPORTANT NOTE

HOW THE ‘DEC SCANNER’ WORKS

The Dec Scanner detects and evaluates the moisture

conditions within roofing and waterproofing systems by

non-destructively measuring the electrical impedance. This is

a method that is very well suited to obtaining comparative

moisture content readings in the many different types of

materials used in the roofing assembly.

The Dec Scanner is a battery powered, electronic instrument,

that generates a low frequency electronic signal. This signal

is transmitted into the material under test via one of the two

electrodes incorporated in the rubber electrode mat, which is

draped on the underside of the instrument. The other

electrode receives the signal that is transmitted through the

material under test. The strength of this signal varies in

proportion to the amount of moisture in the material under

test. The Dec Scanner determines the strength of the current

and converts this to a comparative moisture value. By moving

the Dec Scanner across a roofing surface in a regular pattern,

a continuous reading is obtained, and any areas that contain

moisture can be readily identified.

ASSEMBLY INSTRUCTIONS

Remove the Base Unit from the carry case using the grab

handles.

Check the tightness of the 8 electrode mat retaining

screw fasteners.

To insert the telescopic handle: fully open the flip lock

mechanism, extend the lower part of the handle, insert

the threaded end into the Base Unit and turn clockwise

until tight and secure.

Extend the telescopic handle to the desired height.

Position the meter bracket to the front, ensuring the

arrow is pointing directly down the handle for optimal

infrared communication between Base Unit and Control

Panel Meter. Close and lock the flip lock.

Adjust the hand piece to the desired position.

Remove the Control Panel Meter from the carry case and

clip it onto the meter bracket.

Also included is a folder containing survey sheets and

the warranty card. (This should be completed and

returned to Tramex Ltd, Ireland.)

1.

2.

3.

4.

5.

6.

7.

POWER ON: Press to power on both the Base Unit

and the Control Panel Meter.

LED Indicators:

If communication between the Base Unit and the

Control Panel Meter is interrupted, LEDs on both units

will remain solid. The reading is memorized until

communication is restored.

BATTERY LOW indication: When powered on the battery

voltage in the Base Unit and the Control Panel Unit is

measured. If battery level is low:

Base Unit LED will flash for 7 seconds for Base Unit

battery.

Control Panel Unit LEDs 1, 2 and 3 will flash

alternately for 5 seconds for Control Panel battery.

These signals indicate that the battery requires

replacement.

RANGE selection: Press to select the desired Range 1,

2, or 3. The selected range LED will flash. (See below for

Range Selection information.)

Adjust ‘Set Point’ knob, over a known dry area, to read

just above zero to engage meter reading sensitivity. If

the audio signal is ON it will beep. (see Audio Signal

below)

HOLD function: Press while reading to select the

HOLD function when you need to record a comparative

reading. The needle freezes on the analog dial. The Base

Unit LED remains solid while the Control Panel Range

LED flashes.

Press again to release the HOLD function. The Base

Unit LED and the Control Panel Range LED both flash.

AUDIO SIGNAL: Press two times in quick succession

to turn on/off the audio signal. When on, this will beep to

indicate readings of over 5 on the comparative dial. The

audio signal will beep increasingly fast as the moisture

readings increase

3

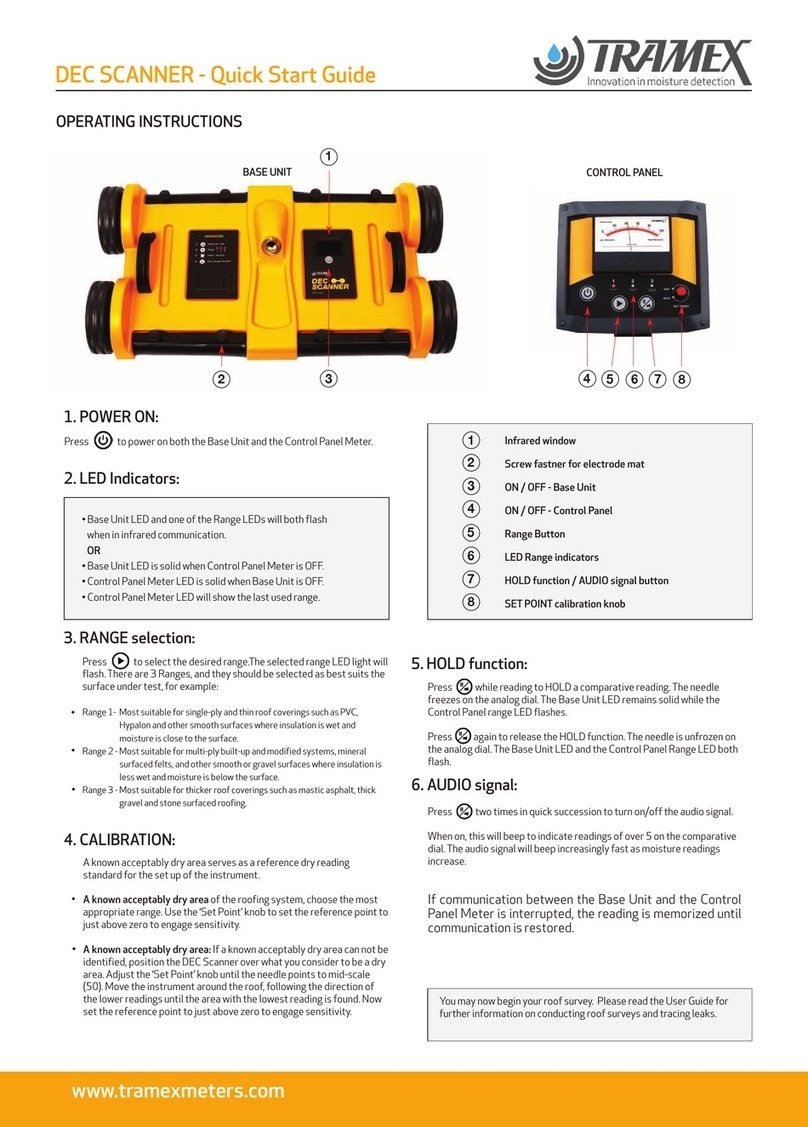

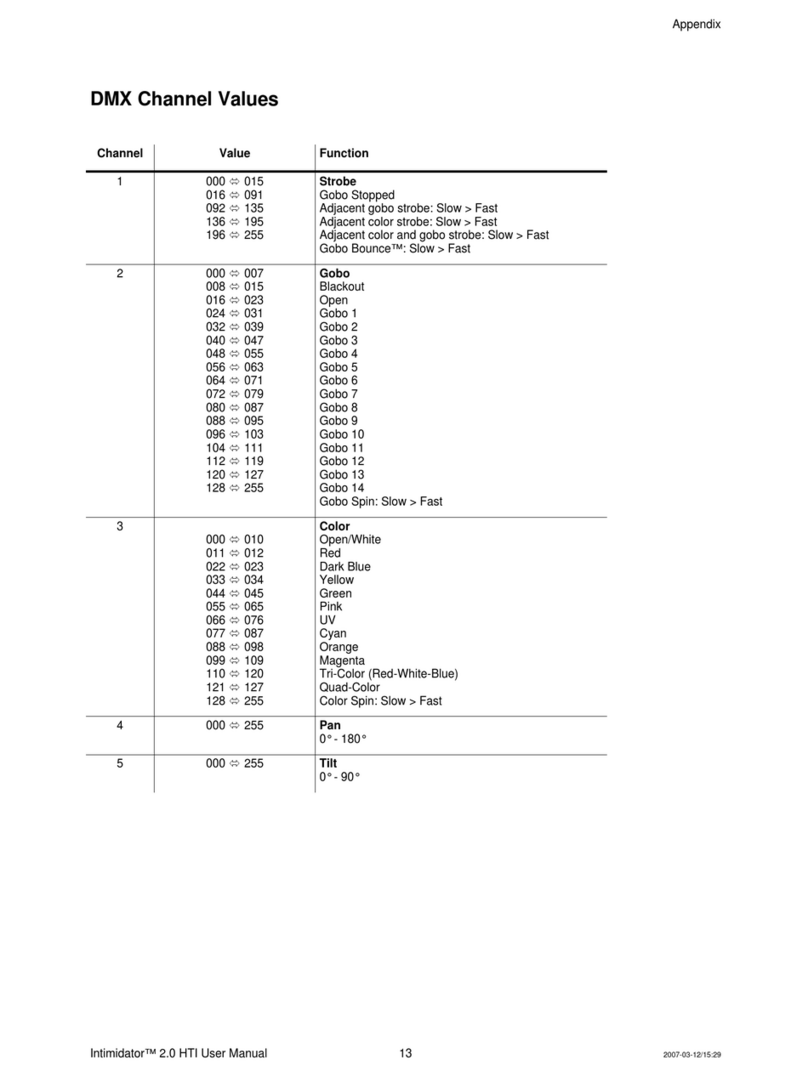

OPERATING INSTRUCTIONS USING THE CONTROL PANEL METER

1

3

45678

2

BASE UNIT

CONTROL PANEL

1

3

8

4

5

6

7

2

Base Unit LED and one of the Range LEDs will both flash

when in infrared communication

OR

Base Unit LED is solid when Control Panel Meter is OFF.

Control Panel Meter LED is solid when Base Unit is OFF.

Control Panel Meter LED will show the last used Range.

Infrared window

Screw fastner for electrode mat

ON / OFF - Base Unit

ON / OFF - Control Panel

Range Button

LED Range indicators

HOLD function / AUDIO signal button

SET POINT calibration knob

1.

2.

3.

4.

5.

6.

7.

8.

User Guide

4

CONDUCTING A ROOF SURVEY

AUTOMATIC POWER OFF: To conserve battery life the

units will automatically power off after 20 minutes in

the following situations:

If infrared communication is interrupted (e.g. if the

Control Panel Unit is removed from its bracket.)

If either of the units are turned off, the other unit will

timeout.

9.

You may now begin your roof survey. Please read on for

information about Range Selection and further Operating

Instructions.

RANGE SELECTION

The Dec Scanner has an integrated and adjustable calibration

ability allowing for accurate comparative readings. There are

3 Ranges, and they should be selected as best suits the

surface under test, for example:

Range 1- Most suitable for single-ply and thin roof

coverings such as PVC, Hypalon and other smooth

surfaces where insulation is wet and moisture is close to

the surface.

Range 2 – Most suitable for multi-ply built-up and

modified systems, mineral surfaced felts, and other

smooth or gravel surfaces where insulation is less wet and

moisture is below the surface.

Range 3 – Most suitable for thicker roof coverings such as

mastic asphalt, thick gravel and stone surfaced roofing.

CALIBRATION SETTING

A known acceptably dry area should always serve as a

reference location for the set up of the instrument.

On a known acceptably dry area of the roofing system,

where the surface and sub-surface insulation and

components are dry, choose the most appropriate range.

Using the ‘Set Point’ knob, set the reference point to just

above zero to engage sensitivity.

If a known acceptably dry area can not be identified,

position the Dec Scanner over what you consider to be an

acceptably dry area. Adjust the ‘Set Point’ knob until the

needle points to mid-scale (50) to allow for readings of

potentially drier areas. Move the instrument around the

roof, following the direction of the lower readings until

the area with the lowest reading is found. Now set the

reference point to just above zero to engage sensitivity.

In these situations the use of a pin type resistance meter

with insulated pins can help determine moisture condi-

tions and depth.

When conducting a survey it is important to verify the

composition of the roofing assembly, acquire any historical

data as regards its age and performance record, and a

roofing plan drawing. Ensure that surface is clean of debris

and dry of rain or dew etc. Aggregate should be dry and of

uniform thickness.

Information Check List:

Complementary Tramex equipment:

Recording the following information will assist you in

completing a comprehensive roof survey.

Building Name and Number

Date of Survey

Name of Surveyor

Visual Inspection of all Roof Flashings

Visual Inspection of Roof Lights & Openings

Visual Inspection of Vents, Chimneys and other Protrusions

Visual defects and anomalies

The Tramex RWS is a handheld roof scanner for

non-destructive moisture evaluation within the insulation

and thickness of the roof. Working on the same ranges as

the Dec Scanner it can be used in conjunction, allowing for

additional readings at edges, near penetrations, equip-

ment curbs and flashings, and for readings from under-

neath the roof when possible.

The Tramex CMEX II is a handheld digital meter designed

for the non-destructive measurement of moisture

conditions in concrete decks, with applications for the

measurement of moisture conditions in wood decks, as

well as ambient relative humidity and dew-point

conditions.

The Tramex Infrared Surface Thermometer will permit

accurate temperature readings of the roof.

The Roof Survey should be conducted using accessories and

tools as suggested and in accordance with the roofing or

waterproofing system manufacturer’s recommendations or

National Roofing Contractors Association Repair Manual

for Low-slope Roof Systems.

5

Procedure: TRACING A LEAK

Make a sketch of the roof, indicating openings and

protrusions etc.

Select a convenient grid span i.e. 5ft (1,5m) and on the

North/South perimeter, mark 1, 2, 3 etc. while on the

East/West perimeter mark A, B, C etc. Transfer these

grid systems markings to your roof sketch. (Fig 4)

Ambient Relative Humidity, Temperature and Dew-point

readings should be noted before, midway through and at

the end of the survey.

Proceed by moving the Dec Scanner along the imaginary

line A and mark location on the sketch graph paper and

roof surface if desired, when moisture is indicated. N.B

In this mock up test, position A4 is the first point of

moisture contact (Figure 4).

As the survey continues, a moisture profile will build up,

indicating areas which require attention. On single ply

roofing, particular attention must be paid to laps and

seams.

Take additional readings, near penetrations, equipment

curbs and flashings, at edges, as well as other roof areas

commonly identified as areas of possible moisture ingress.

The location and depth of extra-depth insulation, such as in

an over-laid system or tapered insulation, should be

confirmed with a pin-probe resistance type meter.

Should a precise percentage of moisture be required, a

sample can be removed from the site, sealed in a plastic

bag and checked in a laboratory, by weighing, drying and

reweighing, to calculate the exact amount of moisture

present. It is important to also examine the plys of the

roofing felt after taking the test cut, as moisture may be

present between the plys or within the fibre of the felt.

Figure 4. Grid system markings

As moisture penetration into the building can be a consider-

able way from the original point of entry through the

punctured membrane, the Dec Scanner will be found useful

in tracing a leak to its source. (A sloping roof is more likely

to suffer from extended leaks than a flat one).

Calibrate on a known dry area as detailed previously,

using the scale most appropriate to the type of roof.

Take the instrument to the general area above the

internal leak.

Scan the area in an ever widening pattern, until the

source of the leak is located (Fig.5)

TYPES OF ROOFING STRUCTURE AND

THEIR MORE COMMON PROBLEMS.

Built-up-Roofing Systems (BURs): Comprising of 3 or 4

layers of roofing felt, with bitumen adhesive between

each layer. ( Fig.6 ). Problems include:

Mechanical damage from maintenance personnel.

Fissures or cracks in the membrane, caused by

building settlement or expansion and contraction.

Blistering caused by moisture trapped in the roof

system during construction.

Modified Bitumen Systems: This type of material is

either adhesive or heat applied as a single layer system,

or with a base layer of bituminous felt. Sometimes

problems occur on the laps and upstands if material is

not fully sealed during construction.

Single Ply Roofing: Usually applied in welded sheet form,

direct to the insulation. Problems usually occur from

mechanical damage and maintenance personnel,

pin-holes, bird damage and faulty seams during

construction.

Figure 5.

1.

2.

3.

User Guide

6

CALIBRATION

WARRANTY

MAINTENANCE OF THE INSTRUMENT

LIMITATIONS

Warranty claims

Figure 6. Typical Built-Up Roof on metal deck.

Apart from the replacement of the 9V PP3 alkaline batter-

ies, the only maintenance check required is the regular

examination of the electrode mat. Clean with a damp cloth

and soapy solution, but never use solvent to clean the

surface. If damage is identified, the mat should be replaced.

In the event of instrument malfunction, return the instru-

ment immediately to your supplier.

The Tramex Dec Scanner and RWS Roof and Wall Scanner

are not suitable for use on any roofing with electrically

conductive or metal-faced membranes. Metal and other

electrically conductive surface coverings and near-surface

embedded metallic components are not suitable for

surveying with these instruments because of the electrical

conductivity of these materials. Most types of black EPDM

produce false positive readings when tested with this

method due to the material’s high dielectric constant. The

degree to which these false positives need to be factored

out will affect the depth of signal penetration. Aluminum foil

on top-faced insulation or waterproofing membranes give

false positive readings, however liquid-applied aluminum

pigmented emulsified asphalt based coatings do not

normally have a significant effect on the readings.

Requirements for quality management and validation

procedures, such as ISO 9001, have increased the need for

regulation and verification of measuring and test instru-

ments. It is therefore recommended that calibration of the

Dec Scanner should be checked and certified in accordance

with the standards and/or protocols laid down by your

industry (usually on an annual basis) by an authorized test

provider. The name of your nearest test provider and

estimate of cost is available on request. Calibration adjust-

ments should not be carried out by anyone other than

Tramex or their authorized service provider who will issue a

calibration certificate on completion.

Tramex warrants that this instrument will be free from

defects and faulty workmanship for a period of one year

from date of first purchase. If a fault develops during the

warranty period, Tramex will, at its absolute discretion,

either repair the defective product without charge for the

parts and labor, or will provide a replacement in exchange

for the defective product returned to Tramex Ltd. This

warranty shall not apply to any defect, failure or damage

caused by improper use or improper or inadequate mainte-

nance and care.

In no event shall Tramex, its agents or distributors be liable

to the customer or any other person, company or organiza-

tion for any special, indirect, or consequential loss or

damage of any type whatsoever (including, without limita-

tion, loss of business, revenue, profits, data, savings or

goodwill), whether occasioned by the act, breach, omission,

default, or negligence of Tramex Ltd., whether or not

foreseeable, arising howsoever out of or in connection with

the sale of this product including arising out of breach of

contract, tort, misrepresentation or arising from statute or

indemnity. Without prejudice to the above, all other warran-

ties, representations and conditions whether made orally or

implied by circumstances, custom, contract, equity, statute

or common law are hereby excluded, including all terms

implied by Section 13, 14 and 15 of the Sale of Goods Act

1893, and Sale of Goods and Supply of Services Act 1980.

The Warranty card should be completed and returned to

Tramex Ltd, Ireland. A defective product should be returned

shipping pre-paid, with full description of defect to your

supplier or to Tramex at the address shown on the back of

this guide.

7

PRODUCT DEVELOPMENT

SAFETY

TECHNICAL DATA

It is the policy of Tramex to continually improve and update

all its products. We therefore reserve the right to alter the

specification or design of this instrument without prior

notice.

This Users guide does not purport to address the safety

concerns, if any, associated with this instrument or its use. It

is the responsibility of the user of this instrument to

establish appropriate safety and health practices and

determine the applicability of regulatory limitations prior

to use.

Dimensions:

Dec Scanner 30”W x 15¾ “D x 6¼”H

(762mmW x 400mmD x 158mmH)

Carry case 38”W x 20”D 12”H

(940mmW x 508mmD x 305mmH)

Weight:

Dec Scanner 24.6lbs (11.15Kg)

Carry Case 21.9lbs (9.95Kg)

Outer carton & packing 4.4lbs (2.0Kg)

Total Shipping Weight 51lbs (23.16Kg)

Dimensional Shipping Weight 66lbs (30 Kg)

Battery:

Each unit operates with a PP3 9V alkaline battery (supplied).

The Base Unit has a battery life in excess of 72 hours.

The Control Panel Unit has a battery life in excess of 50 hours.

(These times will be greatly extended if Lithium PP3 batteries

are used.)

www.tramexmeters.com

Tramex Ltd.

Unit F, Glencormack Business Park, Kilmacanogue,

County Wicklow, Ireland.

Email:sales@tramexmeters.com

USA (Toll free) & Canada:

Tel: 1800-234-5849

EU & Rest Of World:

Tel:+353 1 681 4450

FIND US ON:

Other manuals for Dec Scanner

1

This manual suits for next models

1

Table of contents

Other TRAMEX Scanner manuals

Popular Scanner manuals by other brands

Epson

Epson Perfection V600 PHOTO Start here

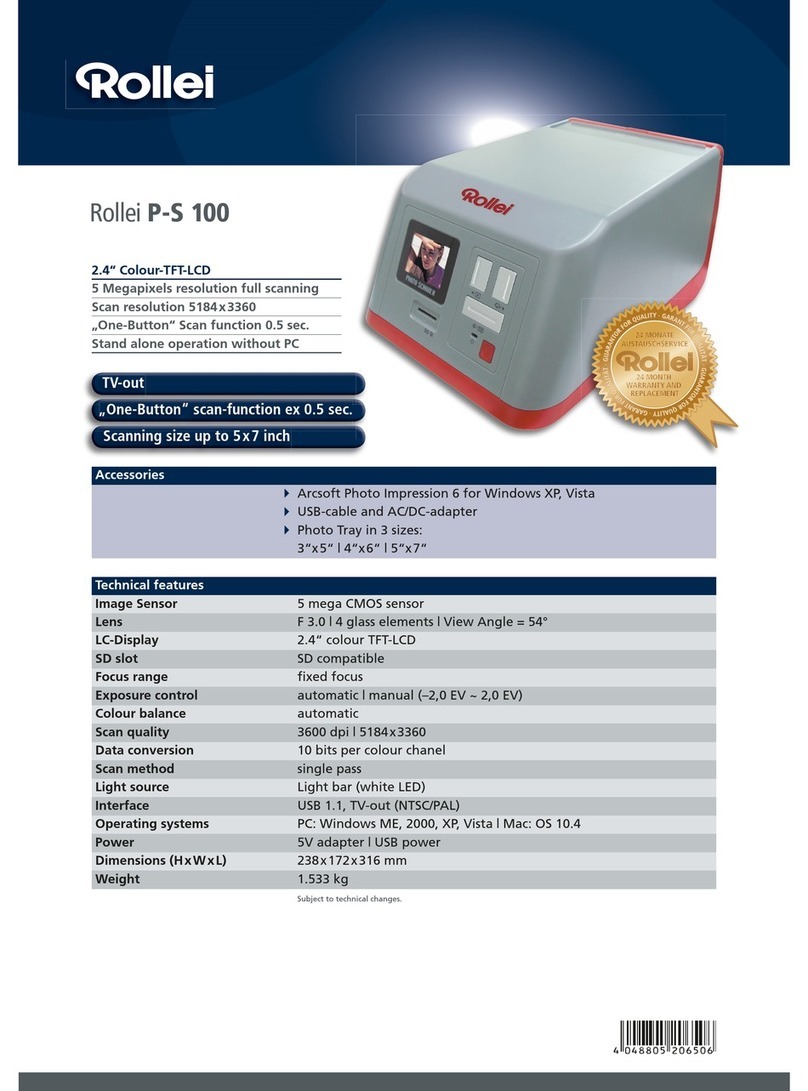

Rollei

Rollei P-S 100 datasheet

Biocentric Solutions

Biocentric Solutions GuadDog owner's manual

Sensorio

Sensorio LZR -S600 user guide

Epson

Epson 4490 - Perfection Photo Important safety instructions

Colortrac

Colortrac SmartLF 4080E Installation & operating instructions