2 18-GD07D1-5

Installer’s Guide

applicable local codes may limit this air handler to

installation only in a single story residence & with-

in conditioned space.

10. If the outdoor unit is to be installed later, or by

others, then installation of the air handler must be

made to allow access for refrigerant lines, or attach

refrigerant lines to air handler when installing.

11. Make sure there are provisions for installing con-

densate drain lines.

12. Route refrigerant & condensate drain lines away

from air handler so they do not interfere with ac-

cess panels and filters.

13. When external accessories are used, the additional

height and width requirements must be considered

in the overall space needed.

14. These units are not approved for outdoor installa-

tion.

15. These units are approved for draw-through appli-

cation only.

B. UNIT INSTALLATION

UPFLOW

a. For maximum efficiency, the horizontal drip

tray should be removed. Tray removal requires

that the coil be removed by sliding the coil out

on the coil channel supports. The tray is de-

tached by removing the two screws at the drain

pan and the two screws holding the two brackets

at the top of the coil.

b. Openings where field wiring enters the

cabinet must be completely sealed. The Re-

frigerant lines must be sealed and Electrical in-

lets need to be sealed both the low and the high

voltage. Location of power entry is shown on the

Outline Drawing.

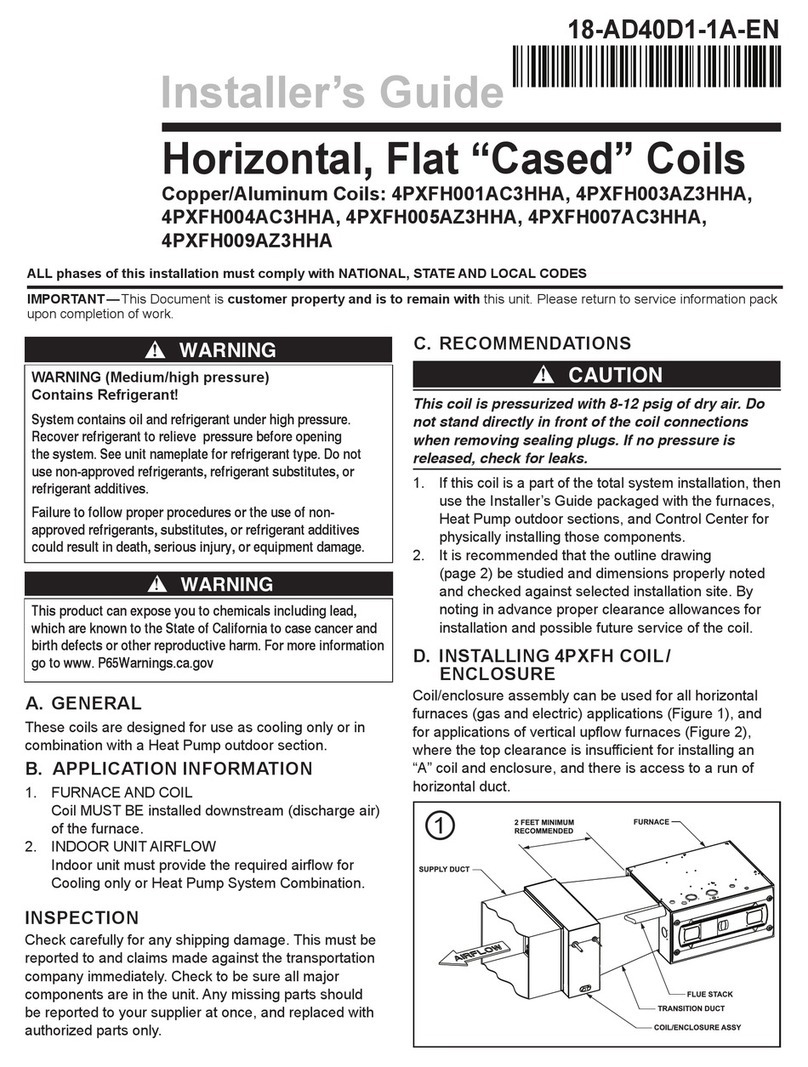

c. Remove the factory installed baffle assembly

from the apex of the coil by removing the 5/16"

hex head screws.

Replace this baffle with the factory supplied nar-

row coil baffle using the screws removed previ-

ously (See Figure 1).

In addition, these air handlers are suitable for instal-

lation in an attic, garage or crawl space with ducted

supply and return air.

This equipment (for models TGB3F42, 48A only) has

been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280 or the equivalent.

“SUITABLE FOR MOBILE HOME USE”

For proper installation the following items must be con-

sidered:

1. If adequate power is available and correct accord-

ing to nameplate specifications.

2. Pursuant to Florida Building Code 13-610.2.A.2.1,

this unit meets the criteria for a factory sealed air

handler.

3. Insulate all ducts, particularly if unit is located

outside of the conditioned space.

4. To ensure maximum efficiency and system

performance, the existing supply and return duct

system static pressures must not exceed the total

available static pressure of the air handler. Refer-

ence ACCA Manual D, Manual S and Manual RS

along with the air handler Product Data and Ser-

vice Facts for additional information.

5. It is recommended that the outline drawing

be studied and dimensions properly noted and

checked against selected installation site. By not-

ing in advance which knockouts are to be used,

proper clearance allowances can be made for in-

stallation and possible future service.

6. The Refrigerant lines must be sealed and Electri-

cal inlets need to be sealed at both the low and the

high voltage.

7. If supplementary heat is to be added, power supply

must be sufficient to carry the load. In addition,

minimum air flow settings, unit and duct clearanc-

es to combustible material must be maintained as

stated on the air handler rating nameplate.

For air handlers not equipped with a factory in-

stalled electric heater, a field installed heater is

available from the manufacturer. Only manufac-

turer-built heaters are approved for use in the air

handler. These heaters have been designed and

tested in accordance with UL standards to provide

safe and reliable operation. A list of approved heat-

ers is provided on the air handler rating name-

plate. Heaters that are not factory approved could

cause damage and are not covered under equip-

ment warranty.

8. If field installed electric heaters are applied, mini-

mum air flow settings, unit and duct clearances to

combustibles must be maintained as stated on the

air handler rating nameplate.

9. If the unit is installed without a return air duct,

For Maximum Efficiency on

Upflow

Remove

and

Discard

Replace

with

Narrow

Baffle

Figure 1