Trane BAYAHEMIKIT001A User manual

Other Trane Air Handler manuals

Trane

Trane BAYDUCT010A User manual

Trane

Trane GAM5 Series Assembly instructions

Trane

Trane A4AH5E19A1B30A Assembly instructions

Trane

Trane 2TEE3F31A1000A Assembly instructions

Trane

Trane BAYBRFBX100A Assembly instructions

Trane

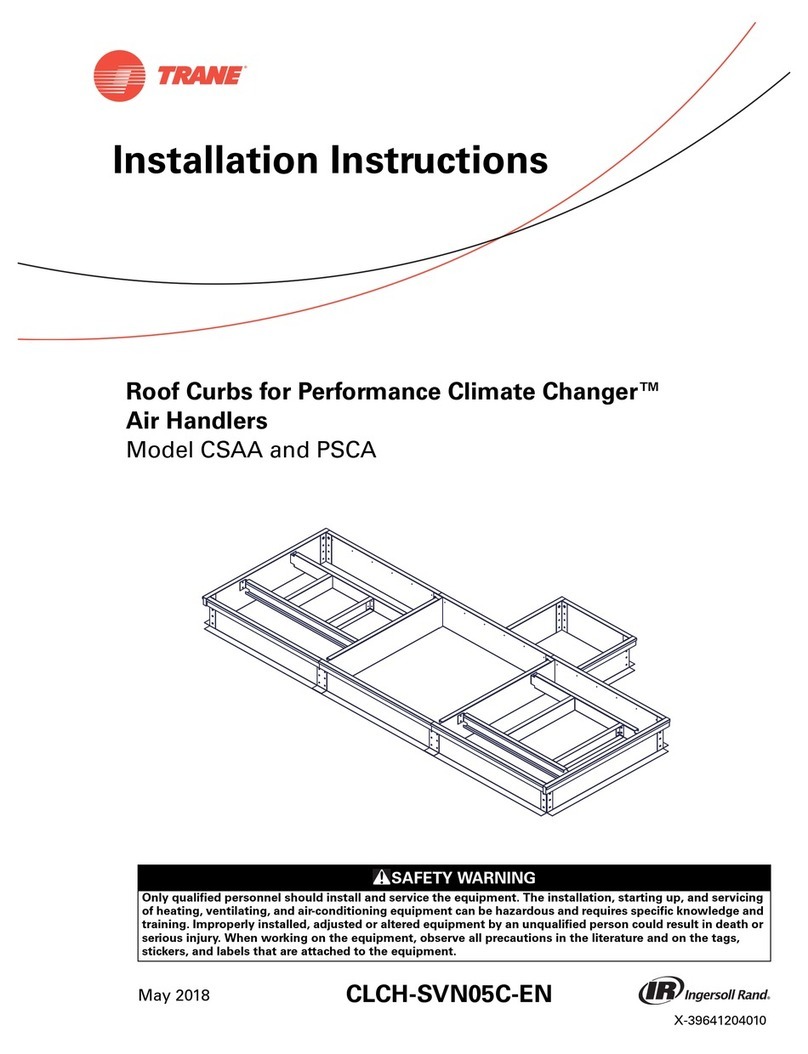

Trane CSAA User manual

Trane

Trane UCCA Installation and operating instructions

Trane

Trane TAM7A0A24H21SC Assembly instructions

Trane

Trane 5 Series Service manual

Trane

Trane 2TEE3F31A1000A Assembly instructions

Trane

Trane Perfomance Climate Changer CSAA Series Installation and operating instructions

Trane

Trane 4YCC4024E1060 User manual

Trane

Trane 7 Series Service manual

Trane

Trane 4TEP3F18A1000A Assembly instructions

Trane

Trane A4AH6E19A1B30B User manual

Trane

Trane TWE031E13FB1 Assembly instructions

Trane

Trane American Standard 4MXD8509A10N0 User guide

Trane

Trane IntelliPak with Symbio 800 Operating instructions

Trane

Trane Horizon OADG Series Installation and operating instructions

Trane

Trane 4YCC4024E1060A User manual

Popular Air Handler manuals by other brands

Klimor

Klimor EVO-S Operation and maintenance manual

Salda

Salda SMARTY XP MOUNTING AND INSTALLATION INSTRUCTION

BLAUBERG

BLAUBERG KOMFORT Roto EC S400 user manual

Trenton

Trenton TPLP Series installation instructions

Kemper

Kemper CleanAirTower operating manual

Daikin

Daikin DV PTC 14 Series installation instructions

Haier

Haier HB2400VA1M20 Installation & operation manual

Webasto

Webasto BlueCool A-Series operating instructions

RDZ

RDZ DA 701 Technical installation manual

Carrier

Carrier 39T Installation, Start-Up and Service Instructions

Armstrong Air

Armstrong Air BCE5V Series installation instructions

ActronAir

ActronAir CAY500T Installation and commissioning guide