TRANE

®

i

General Information

Foreword

These instructions do not attempt to

cover all variations in systems, nor to

provide for every possible contigency

to be met in connection with

installation. Should further information

be desired or should particular

problems arise which are not

sufficiently covered for the purchaser's

purpose, the matter should be referred

to the manufacturer.

Warranty

Warranty is based on the general terms

and conditions of Trane Company. The

warranty is void if the equipments is

repaired or modified without the written

approval of the manufacturer, if the

operating limits are exceeded or if the

control system or the electrical wiring

is modified. Damage due to misuse,

lack of maintenance or failure to comply

with the manufacturer's instructions or

recommendations is not covered by the

warranty obligation.

Reception

On arrival, inspect the unit before

signing the delivery note. Specify any

damage on the delivery note, and send

a registered letter of protest to the last

carrier of the goods within 72hours of

delivery. Notify the local Trane Sales

Office at the same time. The unit

should be totally inspected within 15

days of delivery. If any concealed

damage is discovered, stop unpacking

the shipment. Take photos of the

damaged material if possible. Notify

the Carrier immediately by phone and

registered mail. Notify the local Trane

Sales Office. Concealed damage must

be reported within 15 days of delivery.

Check the unit nameplate to confirm

that the proper unit was shipped.

Available power supply must be

compatible with electrical

characteristics specified on

component nameplates.

Installation

General Information

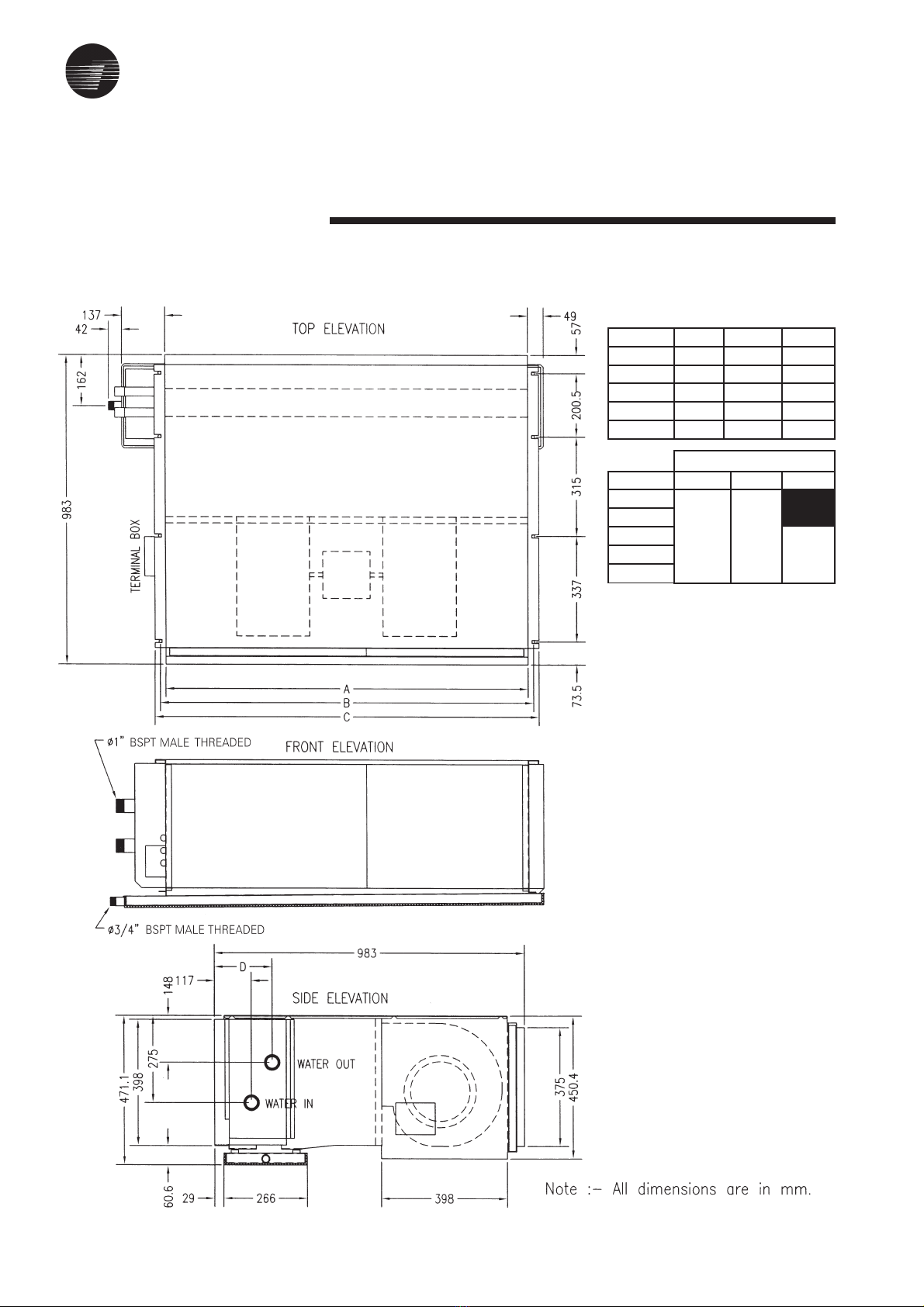

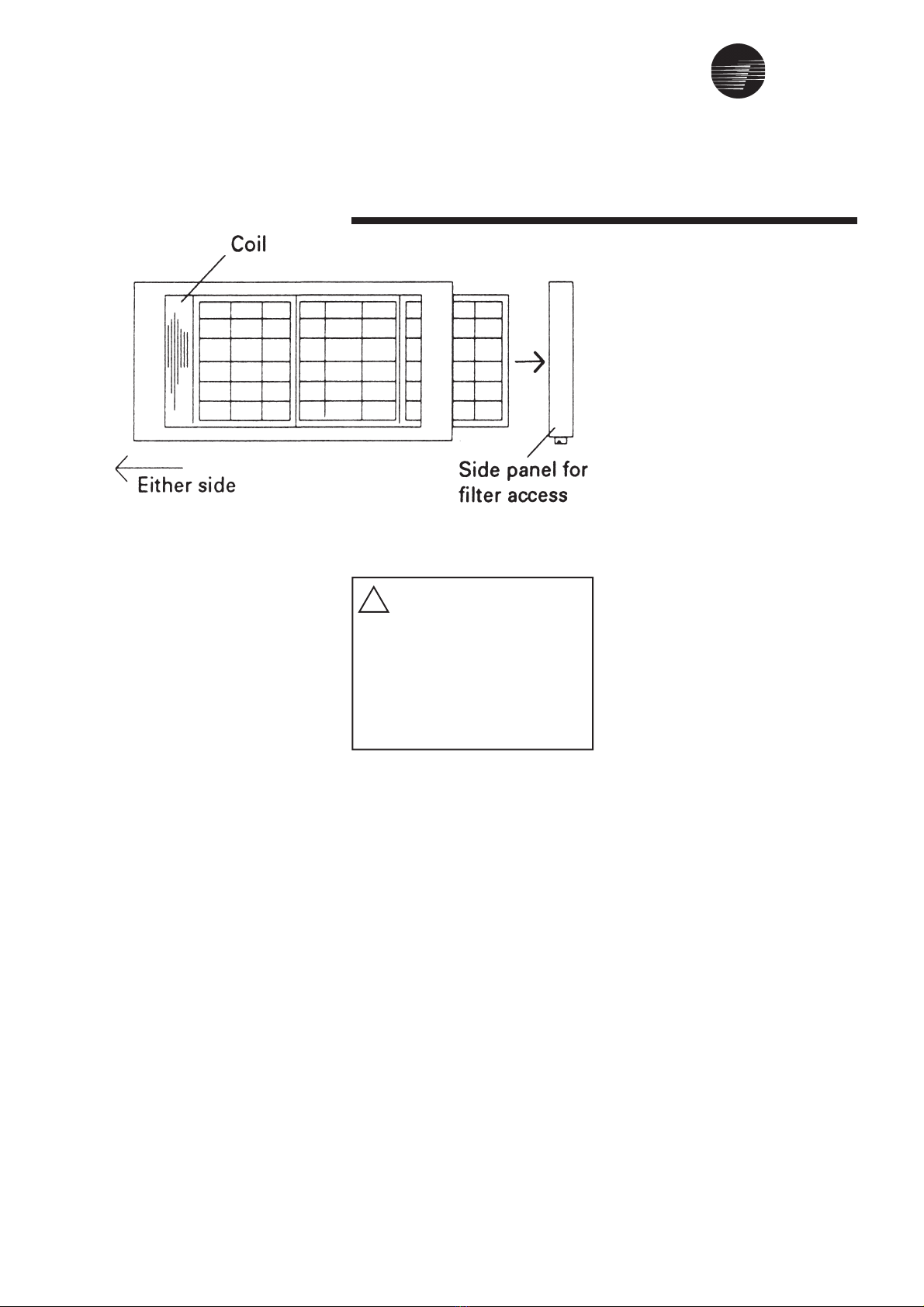

This manual covers the installation,

operation and maintenance of the

Trane FWDD Chilled Water Blower Coil

units. These new air handler models

are completely redesigned to

incorporate a single slab coil

assembly, improved application

flexibilty, servicing and maintenance

accessibility and an improved

accessory line.

Note:

"Warnings" and "Cautions"

appear at appropriate places in this

manual. Your personal safety and the

proper operation of this machine

require that you follow them carefully.

The manufacturer assumes no liability

for instllations or servicing performed

by unqualified personnel.

Handling

The unit will be supplied with a

shippling base and protective

packaging over the unit casing. The

packaging should be kept on the unit

during handling or storage on site.

If it is necessary to remove the

packaging for inspection prior to

completion of on site handling, retain

packaging parts and reapply them by

tapping in position to prevent damage

to the casing. The unit as supplied

has a shipping base which is suitable

for handling by a fork lift truck. If it is

necessary to sling the unit, use

spreader bars under the shipping

base. Ensure that ropes do not cause

abrasion to the surface of the unit.