Transfluid KR Series Instruction Manual

INSTALLATION

AND MAINTENANCE

BEFORE ASSEMBLlNG AND OPERATING THE FLUID

COUPLlNG, CAREFULL yREAD ALL THE SAFETY AND

OPERATING INSTRUCTIONS REPORTED IN THIS MANUAL.

ALWAYS FOLLOW ALL THE INSTRUCTIONS AND ASSURE

THAT ALL THE OPERATORS STANDING BY THE

MACHINERY ARE WEARING ALL THE PROTECTIVE

EQUIPMENT NECESSARY FOR THE JOB TYPE AND

APPLlCATION BEING PERFORMED.

DO NOT USE THE MACHINERY IF YOU DO NOT

UNDERSTAND THESE INSTRUCTIONS, AND IMMEDIATELY

REFER TO THE MANUFACTURER OR THE CUSTOMER

SERVICE DESK FOR ASSISTANCE.

THE COUPLlNG MUST BE PROTECTED BY A CONVENIENT

COVER GUARD TO AVOID PERSONAL INJURY TO PEOPLE.

fI,XIAL AND RADIAL VENTILATION OPENINGS SHOULD BE

INCORPORATED IN THE GUARD HEAT EXCHANGE.

IF THE COUPLlNG IS FITTED WITH FUSIBLE PLUGS, THE

SAID OPENINGS SHOULD NOT BE DIRECTED TOWARDS

OPERATORS AND ANY HOT OR ELECTRICAL

INSTALLATION.

FLUID COUPLINGS

...KR... , ...KSD, EK

~

trasmissioni inilustrialí

UuJffi~~ITQill~rn

trasmlsslom Industrlall

FLUID COUPLlNGS

INSTALLATION AND MAINTENANCE

..KR.. - ..KSD series

INSTALLATION

11

1.2 Fm KRG model, remove hall coupling G (Ilem 29 -FIG. 4):

For KRD model, disassemble shaft D (item 31 -FIG. 1b). In case fhe fluid coupling is stHI filled with oil, drain it or, to avoid possible

losses, position it vertically with lhe shalt D upwards; alter disassembling the shaft D, block the bearing carrier (item 14) with at least 2

nuts and washers (item 11 and 12),

Check that the threaded hole at the end of the motm 01'gearbox shalt complies with DIN 332 (TAB. A1-A2 and FIG. 4),

1,3

a) without taper bush

1A.a Fit the coupllng on the motor shaft by using a threaded bar

with S dia. (TAB. A 1 and A2) as shown in FIG. 1a, and

using 2 wrenches (hold a to avoid shaft rotatlon, and tum b

to draw the coupling on to the motm shalt),

1,5.a For a correcl assembly, lubricate the connecting surfaces

wlth oil 01' antiseizlng paste, For hot mouniing (not

recommended), do not overcome a temperature of 90°C,

Wllich causes Irreparable damages to oil seals,

b) with taper bush

1.4. In case the bush is not provided with keyway (ílem 50 or 51

-FIG. 1b), remove the key from motor or gearbox shaft

(reverse mounting).

1.5.b Carefully clean all surfaces contacting the bush by oil,

grease, etc., possibly usmg solvent, whether they belong to

motor, gearbox 01'fluid coupling.

1.6.b Fit the bush on the motor or gearbox shaft, intoducing a

screwdriver into the axial cut to make mounting easier;

assure that bush goes as far as the shaft shoulder.

For KRG series, fit half coupling (item 29 -FIG. 4) on driven shaft, taking care that the shaft end does not protrude beyond face X.

Fit the fixing screw and the washer (items 25 and 26 for KR models; items 26 and 27 for KSD models) holding the motor or the gearbox

shaft still;

lock

the fixing screw with a torque wrench, respecting the torque reported in TAB. A 1 and A2.

Only for 13/15 KR KSD models (FIG. 3): fit the allan screw (item d) with flat washer (item e). Holding the motor or gearbox shaft

with a 38 mm wrench b 01'1the end c, lock the allan screw with a torque wrench a, respecting the torque reported in TAB. A2.

N.B.: For a correct assembly with the taper bush, strictly apply to the prescribed locking torque.

1.7

1.8 For KRG models, lock and peg the driven machine, positioning the motor as far as the gap K (FIG. 4) between the half couplings

reaches the Indicated values listed in TAB. C. The error on radius can be checked with a gauge and a straight-edge (FIG. 4): the

angular gap with a feeler, by rotating the coupling at 4 points 90° apart: the errors should not exceed those listed in TAB. C.

Fm KRD model, reassemble shaft D by locking nuts and washers (items 11 and 12 - FIG. 1b) at the prescribed torque (TAB. B).

-

I I

l;: :h:=:>t \_-, I

-, ~tI

31 L. I

f- I

11..12

1.9

FIG.1a

a

b

FIG. 2b (KRG)

FIG. 2a (KSD)

FIG.1b

26-27 i¡

K... FIX SCREW Steel T orque

CK../CCK..

S

spec.

(Nm)

M6 10,9

~7-8 M8 35

M10 8,8 50

M10 10,9 70

9-11-12 M12 85

-

M16 8,8 205

13 -15 ~M20 400

KRD nu! T

orque

CK../CCK,

11 (Nm)

7 - 8 M7 16

9 -11-12 M8 24

13 -15 M10 50

17 -19

21 -24 M14 135

27 -29 M16 205

34 CKRD

..KRG

Fluid Dimensions in mm

coupling KRA1- A2

602 0,2 0,3

7-810 2~0,4

9 -11-12 20 0,35

13 BT 30 0,4

15 40 0,6

3-

17-19 50 0,5

21 -24 60

27 - 29 CT 80 ..i. 0,8

0,6

34 CT 90 5

M12 85

9-11-12 M16 8,8 205

13 -15

17 -19 M20 400

21 -24

27 -29 M24 690

34 M36 1500

urnffiwUJ~urn~[[J

trasmlsslom Industrlall

FLUID COUPLlNGS

INST AL LATION AND MAINTENANCE

)

FIG.4

eeFIG.3

29

"", 'FIXING SCREW

MISALlGNMENT

AXIAL

RADIAL ANGULAR

a+ 1

-0,5 RA1

I'

II

II

I

I I

I I

¡I

A2

TAS. A1

(without bush)

K... FIX SCREW Steel T orque

CK..lCCK..

S

spec

(Nm)

M6 10

M8 24

M10 50

TAS. A2

(with taper bush)

TAS. S TAS.C

7-8

EK series (FIG. 5)

1.10) Assemble the flange A on the corresponding one of the

motor (of the gearbox far 6EK) and tighten bolts D.

1.11) Fit bell housing B onto the gearbox flange (electríc motor for

6EK) and tighten bolts E.

112) Flt the fluid coupling C on the motar shaft, hittíng wlth a soft

hammer on the shaft end X, as lar as it reaches the limit 01

the travel

1.13) For a correct fitting, it is important to lubricate surfaces

with antiseizing paste.

1.14) Fít the coupling / motor assembly into the gearbox hollow

shaft as lar as the Ilange A is connecled lo the bell housíng

B. then lix the bolts F.

1.15) Fit the sale guard G.

CD FIG.5

:§)

@

@

@

2

TAB.D2 OIL QUANTITY (11.)

CK... 2 3 4

11 3.350 3.050 2.750

12 4.800 4.200 3.600

13 5.800 5.200 4.700

15 8.600 7.700 6 AOO

17 13.60 12.80 1170

19 16.50 15.20 14.00

21 2300 21.30 1930

24 31.20 28.60 26.00

27 50.00 46.50 43.00

29 6300 59.00 54.00

34 92.50 88.50 83.50

TAB. D1 OIL QUAI'HlTY (11.)

K... X 1 2 3 4

60.505 OA80 OA55 OA25 0.390

70.920 0.860 0.800 0730 0.650

81.510 1A05 1.295 1.190 1.080

91.950 1.820 1.690 1.550 1AOO

11 2.750 2.550 2.350 2.100 1.850

12 4100 3.875 3.575 3.250 2.900

13 5.200 4.850 4A50 4.050 3.600

15 7650 7.150 6600 6.000 5 AOO

17 11.70 10.90 10.00 9.100 8.200

19 14.20 13.30 12.30 11.20 10.00

21 19.00 17.80 16AO 15.00 1350

24 28 AO 26.50 2460 22.60 20.50

27 42.00 39.00 36.00 33.50 31.50

29 55.00 51 00 47.00 44.00 41.50

34 82.50 76.60 70.60 66.20 62.50

TAB.D3 OIL QUANTITY (11.1

CCK... 34

15 9.30 8.00

17 16.36 14.86

19 18.76 16.86

21 2730 24.30

24 35A3 31.63

27 59.35 55.15

29 70.60 65.20

34 96.70 86 AO

SIZE CUSIBLE PLUG O.nolT]

l.,C,;?TorquE- iNmj

6hb 12 1/2'

7-8-988 23 í/4

11 12

13 -15

17- 19 ceo 29 31e'

21 ,24

27 -29 8E:: 44

34

TIrnffiw~üllillu[]

trasmlsslom mdustnall

2. FLUID COUPLlNGS FILLlNG INSTRUCTIONS

KR... - KSD - EK SERIES

TI'ansfluld fluld coupllngs are no! supplled wlth 011

Therelore 11IS necessary to achleve the lollowlng pracedure:

2.1 Positlon the coupllng axls horizontally (FIG. 6). turn I1until the

X mark cast Into the houslng gets al tlle top vertical (maxlmum

fill). so that tlle 011plug (item 13) Is Inclined as shown III the

plcture

FIIIwlth 011untll it overflows out 01 the filler hole. Whlle fllllng,

gently rack the coupllng on its axls to make sure all air excess

IS vented out of the clrcult, 01', If posslble. remove also tlle cap

located In correspondence on the other rotor. The quantltles to

be Intraduced are those reported in TAB. 01.

Screw the cap (or both caps) at the prescribed torque (TAB.

E) and make sure no leakages occur; otherwise use thread

sealant on filler plug tllreads.

The líllings marked X-1-2-3-4 may be chosen by the opel'ators

to meet the be sI performance In terms 01 start-up and steady

runnlng operatíon.

With the maxlmum fill X a conditlon 01 mlnlmum slip and

maxlmum performance Is achieved: the startlng torque !

nominal torque ratlo gets higher (values generally comprised

between 1.8 and 2.2) decreaslng the 011quantlty Inslde the

coupling (fII11-2-3-4), the opposite result Is obtained.

HIgh slip causes overheating of 011contalned in the worklng

circuit, wlth a consequent decrease IIIoverall performance.

For normal operatlng conditions, use only ISO HM 32 (01'

equivalent SAE 10W) 011 types listed in TAB. O. At low

amblent temperatures, use ISO HM 10 (01' equivalen!

SAE 5W) ol!.

For vertical mounted appllcatlons, the coupllngs

recommended 011fllls are reported in TAB. 01.

22

2.3

24

2.5

2.6

27

TAB.D

FLUJD COUPLlNGS

INST ALLA TION

AND MAINTENANCE

CKR... / CCKR... - CKSD... / CCKSD... SERIES

Fluid couplillgS Wltll delayed IIIIchambel (CK series) have the mal n

purpose ot reduclng tlle startíng torque / nominal torque ratlo to

values up to 1.6 . Thls aspecl Is Improved by furtherly enlarglng the

delayed flll chambel (CCK series) up to values of 1.3 of the above

ratío

2.8 The startíng torque Ilmítatlon can be achieved by reducíng the

oil quantlty ínto the worklng clrcult (till 2-3-4) without

IIlcreaslng the slip value a! rated speed. In standstill positlon,

the delayed lill chambel actually COlltalllS par! 01 the oil II11that

Ilows to the working clrcuit durlng start up.

2.9 The 011 passes Irom the delayed IIII chamber to the workíng

clrcuit tllrough calibrated orifices (FIG. 7) oWlng to

centnlugal lorce. Starting Irom slze 21 K, such orillces

dlameters can be modílied even when the coupllng is already

assembled, slmply by replacing a calibrated bleed plug (item

b) screwed IIlto the valve (Item 57). When reassembling the

valve, always remember to flt the copper seal (Item 58) and

make sure no leakages occur.

This technical solution allows a very simple and easy

operation, to be achieved in a very short time and (what is

more important) without disassembling the fluid coupling.

210 For each starting torque ! nominal torque ratío, Transfluld can

give the exact oíl lill. The Iluíd coupllngs with a delayed fill

chamber are generally foreseen with fill 2 (TAB. 02), while

the ones equlpped wlth a double delayed fill chamber with

fill 3 (TAB. 03).

As fluid couplings are supplied without 011, lollow the

instructlons reported at par. 2.1 - 2.2 - 2.3 -2.6.

211 For vertical mounted appllcatlons, the coupllngs

recommended oíl fills are reported In TAB. 02 and 03. Oue to

delayed lill chamber peculiarity, for vertical mounting the

chamber must be downward.

Aglp

Aral

BP

Castrol

RECOMMENDED OIL ISO HM 32 (SAE 10W) CLASSIFICATION

OSO 32 Chevron HYDRAULlC OIL 32 Mobil DTE 24

VITAM GF 32 El! ELFOLNA 32 Shell TELLUS OIL 32

ENERGOL HLP 32 Esso NUTO H 32 T exaco RANDO OIL HD 32

HYSPIN AWS 32 IP HYDRUS OIL 32 Total AZOLLA zs 32 FIG.6

~~.,.,

1/

.

/~

/

..

57\.

...

:

.......

I

....

"',

(

"

", ~..-\ ..

.~ \ . :

I\\/

~// b

rl~~

l

.

'"

...

:I~

.

~

..

¡

J{1/ ,

,~

FIG.7

TAB.E

/

-,~.-

3

SYMPTOM CAUSE REMEDY

INSUFFICIENT OIL LEVEL

Check level and possibly

lop up

TOO HIGH TOO MANY CONSECUTIVE START-UPS

Wail lor cooling belore reslarllng, or reduce number 01 slarl-ups

TEMPERATURE HIGHER ABSORPTIONS THAN SPECIFIED ON TAG

Remove causes and I or reVlew dtmensionlng

HIGH AMBIENT TEMPERATURE

Improve coupllng ventllallon

FUSIBLE

PLUG JAMMED OR OVERLOADED DRIVEN MACHINE

Remove causes

INTERVENTION TOO NEAR HEAT SOURCE

Remove source or Introduce a shleld

TOO CLOSE PROTECTION COVER

Introduce convenlenl

alr

passages lo Improve heal exchange

OIL LEVEL

Check otllevel and IIII wllh Ihe rlgh! !ype 1I necessary

PERFORMANCE

I~eplace 1I neCeéSary (lAB [) al page

3)

OECREASE OIL TYPE SPECIFICATION

VerlÍv whelhel rec,pondlng lo recommended 011 speclllcalions

AMBIENT

TEMPERATURE LOWE~; THAN O°C

carreel olllype (see par 26 al page

3)

INSUFFICIENT OPERA TING FAUL TY MOTOR Ct'led

mojo:

101811119:¡peed

(¡í 8léctrlc, check cOnnec1¡ons,!

SPEED STAR / DEL TA INSERTION TIME II

reaulred lime 100 lorlg, reduce 1I lo J s max

ANDIOR

EXCESSIVE SLIP JAMMED OR BRAK.ED DRIVEI," MA.CHINE

RHnove cause~-

NOISE ANO ALlGI,MENT Checl ailgnrTiél-:1I,p8ge i r'2H 18)

VIBRA TION FAUL TY BEARINGS

DléaSSerriDIe,

repiélce becHlrlQ;:,

(árld relatl\lE: SE:éJis)

WHISTLE PROTECTIOI, COVER ~dTIé111ém Pd;~~;éJr~E:;<

between

cO\ler

and rn8chmE

UrnffiwfB~Qill~w

trasmlSSlom mdustrlall

3. OPERA TION ANO MAINTENANCE

3.1 The normal operaling procedures have lo be carried on

keeping balance and temperature under control.

l\jol 10 damage Ihe coupling seals, lemperalure musl no!

overcome 90'C. For hlgher values, all Ihe seals bul Ihe rolaling

ones In Viton (items 15 and 20), have lo be made of a special

material 100.

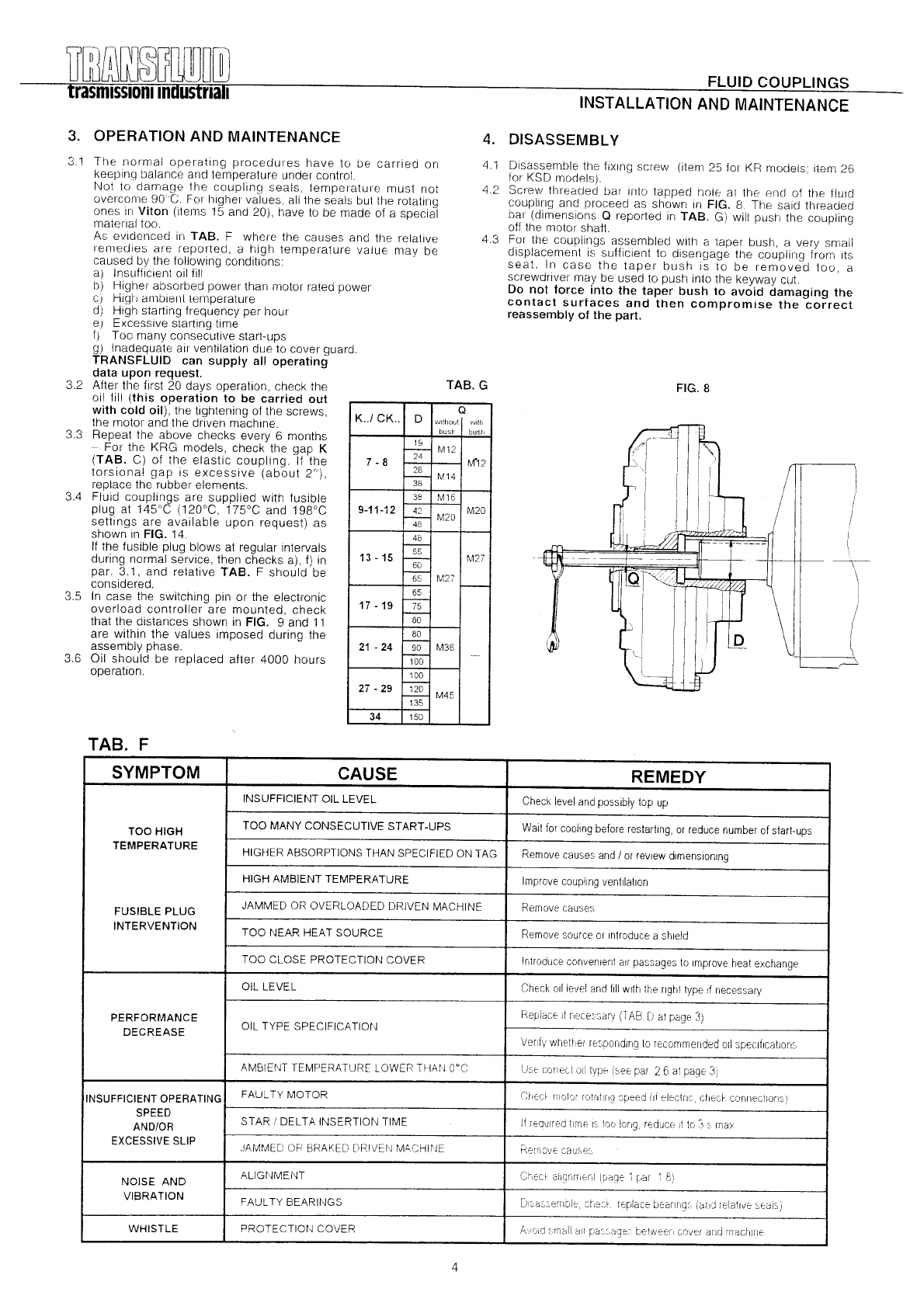

As eVldenced in TAB. F where the causes and the relalive

remedies are reported, a high temperature value may be

caused by the following condillons:

a) Insufficlenl oil fill

b) Higher absorbed power Ihan motor rated power

C) HIgli Clmbíenl lemperature

d) High starting frequency per hour

e) Excesslve slartlng time

f) Too many consecutive start-ups

g) Inadequate aír ventilation due to cover guardo

TRANSFLUID can supply all operating

data upon request.

3.2 After the first 20 days operalion, check the

oil fill (this operation to be carried out

with cold oil), the tightening of the screws,

the molor and the driven machine.

3.3 Repeal Ihe above checks every 6 months

-For the KRG models, check the gap K

(TAS. C) of the elastic coupling. If the

torsional gap is excessive (about 2°),

replace the rubber elements.

3.4 Fluid couplings are supplied with fusible

plug al 145"C (120°C, 175°C and 198°C

settíngs are available upon request) as

shown in FIG. 14.

If the fusible plug blows al regular intervals

during normal service, then checks a), f) in

par. 3.1, and relalive T AS. F should be

considered.

3.5 In case the switching pin or the electronic

overload controller are mounted, check

that the dístances shown in FIG. 9 and 11

are wilhin the values imposed during the

assembly phase.

3,6 Oil should be replaced after 4000 hours

operation.

K.,I CK., Q

Dwithouj with

busl' bush

7-8

19

24

28

38

38

42

9-11-12

13 -15

48

48

55

60

65 M27

65

75

80

80

90 M36

100

100

120 M45

135

150

17 -19

21 -24

27 -29

34

TAB. F

FLUIO COUPLlNGS

INSTALLATION AND MAINTENANCE

4. OISASSEMBL y

4.1 Disassemble lile fixing screw (ilem 25 for I<R models; ilem 26

tor KSD models).

4.2 Screw threaded bal In10 tapped hole al Ihe em! of tlle iluld

coupllng and proceed as shown in FIG. 8 The said tllreaded

bar (dimensions Q reported in TAS. G) will pusl-I the coupling

off the molor sllaft.

4.3 For Ihe couplings assembled witll a laper bush, a very small

displacemenl is sufficienl to disengage the coupling from ItS

sea!. In case the laper bush is to be removed 100, a

screwdriver may be used to push inlo the keyway cut.

Do nol force into the taper bush to avoid damaging the

contact surfaces and then compromise the correct

reassembly of the par!.

TAB.G FIG.8

M12 M"12

M14

M16 M20

M20

M27

4

Uu~ffiwg]lJllilli~rn

trasmlsslom Industrlall

5. ACCESSORIES

Fluid couplings can be equipped, beyond the standard fusible plug.

with similar safety devices avoiding oil to escape, and that, in the

case 01 the electronic overload controller, can manage a lew more

palameters too.

The luslble plug is present as an element 01 further safety though

being set al a highel' temperature value.

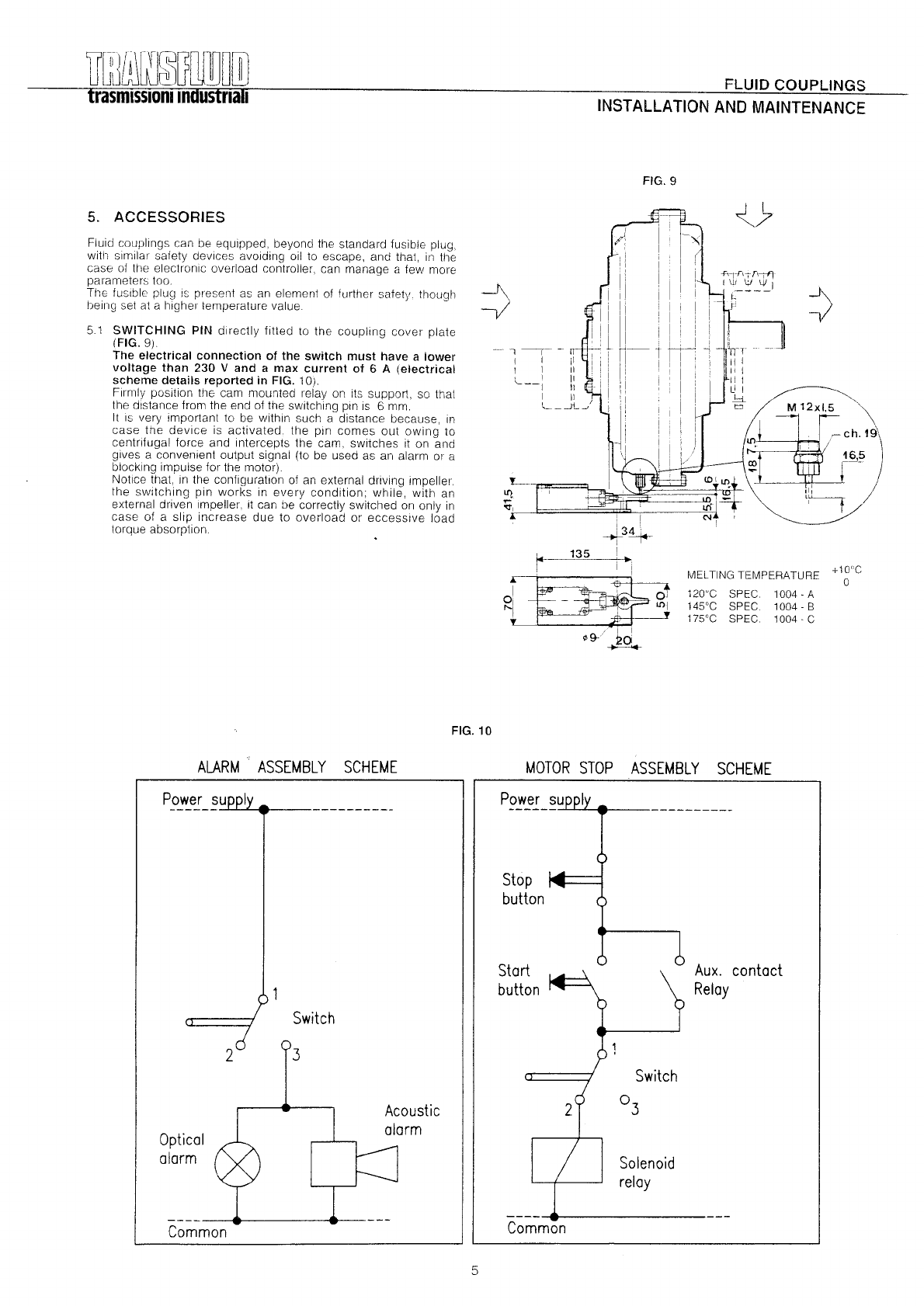

51 SWITCHING PIN directly fitted 10 the couplíng covel plate

(FIG.9).

The electrical connection of the switch must have a lower

voltage than 230 V and a max current of 6 A (electrical

scheme details reported in FIG. 10).

Fllmly position the cam mounted lelay on its support, so tha!

the dlslance lrom the end 01 the switching prn is 6 mm.

11IS very imporlant to be within such a distance because, in

case the device is activated, the pln comes out owing 10

centrifugal lorce and intelcepts Ihe cam, switch es it on and

gives a conveníent outpul signal (to be used as an alarm or a

blocking impulse for the motor).

Notice that, in the configuratlon 01 an external driving impellel

the sWltching pin works in every condition; while, with an

external dliven Impellel' it can be correctly switched on only in

case of a slip increase due to overload 01 eccesslve load

tOlque absorption.

ALAR M ASSEMBLY SCHEME

Power SU

23

Switch

Optical

alarm

Acoustic

alarm

Common

FLUID COUPLlNGS

INSTALLATION AND MAINTENANCE

FIG.9 ~?

-A

¡/

-Frrfl -;- TI---¡--ff

I \JJ \;1 \i/ I

c---

F' =>

_.. '1 ,-' .. n

1 I ¡I

1 1 I1

,IIt

'1 Ii .

I I1

L_.JL /

L-.

lt)

-.:

<t, . !

--+3~

i

I.i 135 :.

I I I

U._~;E!

~!}-/

kd

~

MELTING TEMPERATURE +1g"C

120°C SPEC. 1004. A

145"C SPEC. 1004. B

175°C SPEC. 1004. C

FIG.10

MOTOR STOP ASSEMBL ySCHEME

Power su

Stop

button

Aux. contact

Relay

Start

button

Switch

°3

Solenoid

relay

Common

5

:z:

oo

w o.. ¡::: o

w:::o « «

o.. IDé o

UJ >- W-' FIG.13

Dé o.. Dé

«ow

>- >

UJ o

ITrnmwg)Uilllfl~rn

trasmlsslom Industrlall

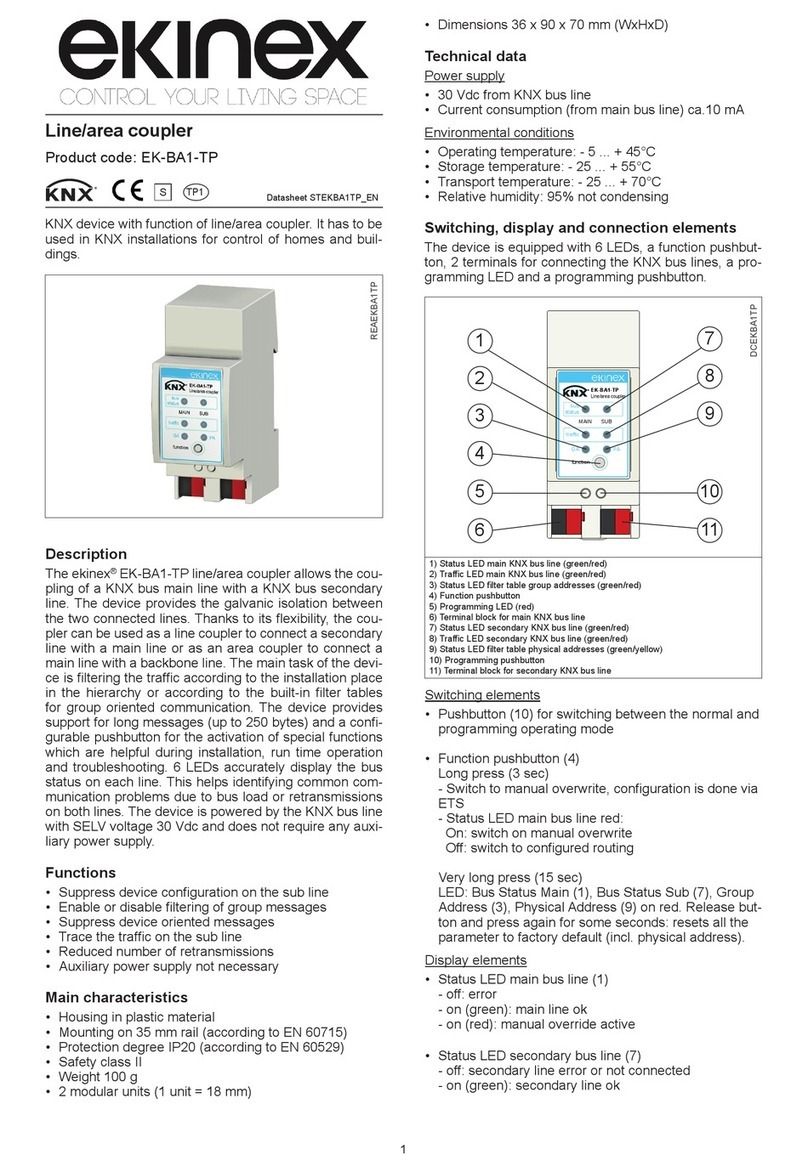

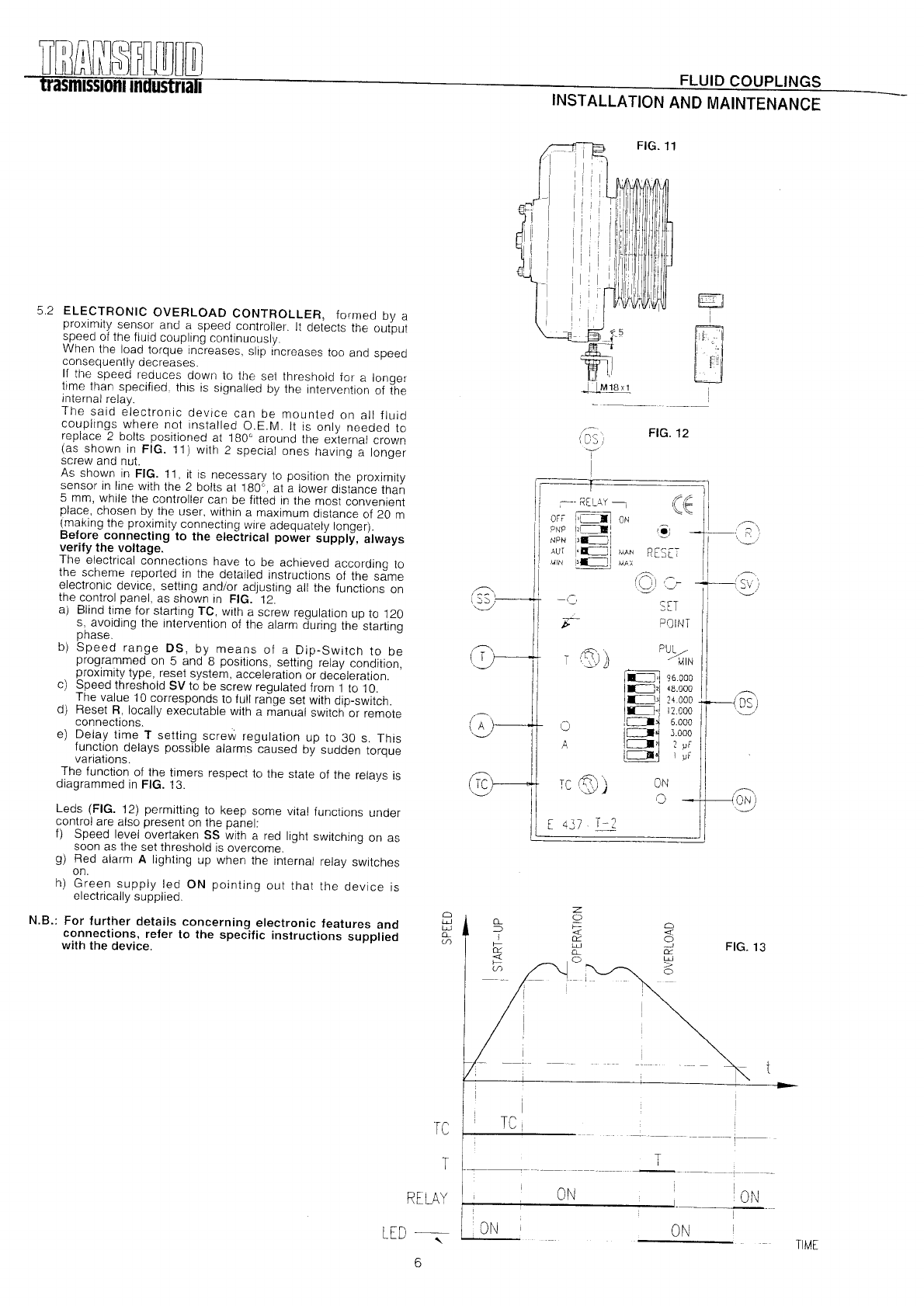

5.2 ELECTRONIC OVERLOAD CONTROLLER, formed by a

proximity sensor and a speed controller. It detects the output

speed of the fluid coupling continuously.

When the load torque increases, slip increases too and speed

consequently decreases.

II the speed reduces down to the set threshold far a longer

time than specified, thls is signalled by the intervention 01 the

internal relay.

The said electronic device can be mounted on all fluid

couplings where not installed O.E.M. It is only needed to

replace 2 bolts positioned at 180' around the external crown

(as shown in FIG. 11) with 2 special ones having a longer

screw and nut.

As shown in FIG. 11, it is necessary to position the proximity

sensor in line with the 2 bolts at 180°, at a lower distance than

5 mm, while the controller can be fitted in the most convenient

place, chosen by the user, within a maximum distance of 20 m

(making the proximity connecting wire adequately longer).

Before connecting to the electrical power supply, always

verify the voltage.

The electrical connections have to be achleved according to

the scheme reported in the detailed instructions 01 the same

electronic device, setting and/or adjusting all the functions on

the control panel, as shown In FIG. 12.

a) Blind time lor starting TC, wlth a screw regulation up to 120

s, avoiding the intervention of the alarm during the starting

phase.

b) Speed range DS, by means 01 a Dip-Switch to be

programmed on 5 and 8 positions, setting relay condition,

proximity type, reset system, acceleration or deceleration.

c) Speed threshold SV to be screw regulated from 1 to 10.

The value 10 corresponds to full range set with dip-switch.

d) Reset R, locally executable with a manual switch or remote

connections.

e) Delay time T setting screw regulation up to 30 s. This

lunction delays possible alarms caused by sudden torque

variations.

The lunction of the timers respect to the state of the relays is

diagrammed in FIG. 13.

Leds (FIG. 12) permitting to keep some vital lunctions under

control are al so present on the panel:

1) Speed level overtaken SS with a red light switching on as

soon as the set threshold is overcome.

g) Red alarm A lighting up when the internal relay switch es

on.

h) Green supply led ON pointing out that the device is

electrically supplied.

N.B.: For further details concerning electronic features and

connections, refer to the specific instructions supplied

with the device.

LED~

6

RELAY

FLUID COUPLlNGS

INST ALLA TION AND MAINTENANCE

FIG.11

~

¿I

:1

f'l

--~~~----

11

11

,1

l'

11

11

I~' I!

I¿Y-~

:1

/-.

1:OS)

--.,/

I

I

f

~.

REL4Y-,

OFF 1" -IoN

PNP ¡,c=JIi

NPN

!J-=:J!

AUT l'a::=J! \AAN

MIN 1).':" ~I

\AAX

(E 1]

'.' ~~\

RE~~T I1 '~I

~ I1 /~

1,--/1- ~\,.:~~:/)

SET

POINT

FIG.12

-(=¡

T

- (D:'i\

1'.:Y j) P% MIN

IIL H 96000

I

-=:J'I

48.000

-=:J,I

24.000rr--<DS)

..:=J,¡

12.000 .'-.,./

,c=JI~ 6.000

1: =::~ 3000

c=JI'

2 ~F

ic:JI I ~F

(]

A

@

11

[!4CJ~i)¡

ON

(] ,~

ON)

''-.,./

TC

TIME

TT

I

-------- ~--~------

ON ION

ON

GASKET KIT FUSIBLE PLUG RUBBER

SIZE 1186 1535 N 7018 BLOCK

K... CK... CCK.. 120"C 145"C Std 175"C WCODE

6AV AA AB AC 8BT-A

7BV

IBT-S

8 CV -

9DV SA SS SC 12

11 EV ST-C

12KR FV BV

12KSD GV CV -

13 HV OV ST-C

15 KV EV

17 LV FV CA CS CC ST-D

19 MV GV

21 NV HV 16 SToP

24 OV KV

27KR QV LV CT-D/E350

29KR RV MV DA OB DC

34KR SV NV CT-D/E425

K... LOCKING TORQUE

CK... Item 9 Item 10 ¡tem 34

CCK...

screw

Nm screw Nm screwl Nm

6M5 6

M6 10 --

7-8 M6 10

9 - 11 M8 24 M8 24 M8 24

12-13

15-17-19 M10 50 M10 50

21 M12 85 M10 50

24 M14 135 M14 135

27

29 M16 205 M14 135

34 M16 205 M20 400

TIrnffiw[B~[illJ~rn

trasmlsslom Industrlall

FLUID COUPLlNGS

INST ALLA TION AND MAINTENANCE

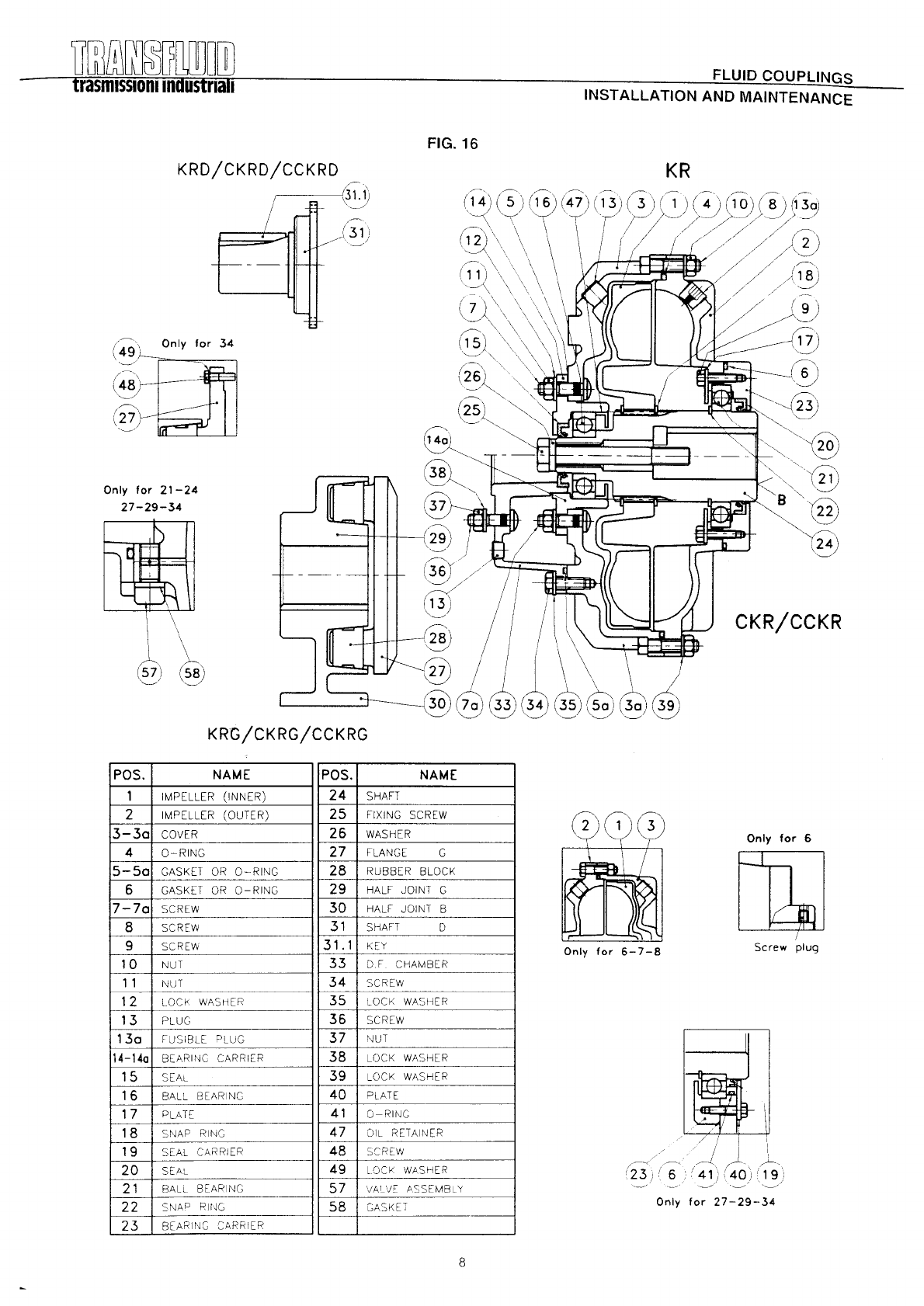

6. RECOMMENOEO SPARE PARTS (FIG. 16 -17)

When ordering spare parts. always specity modei and spec. nr. marked in the positions shown in FIG. 15 (27K, 29K and 34K have got

a plate reporting serial nr. too).

6.1 Seal kit lor KR / KSD items 4-5 (5a lar C ICC. versions)-6-15-20-41 (Items 15 and 20 In Viton, the others only upon request)

6.2 Fusible plug item 13a

6.3 Rubber element (lor ...KRG only) Item 28

6.4 Code numbers are shown on TAB. H

TAB H

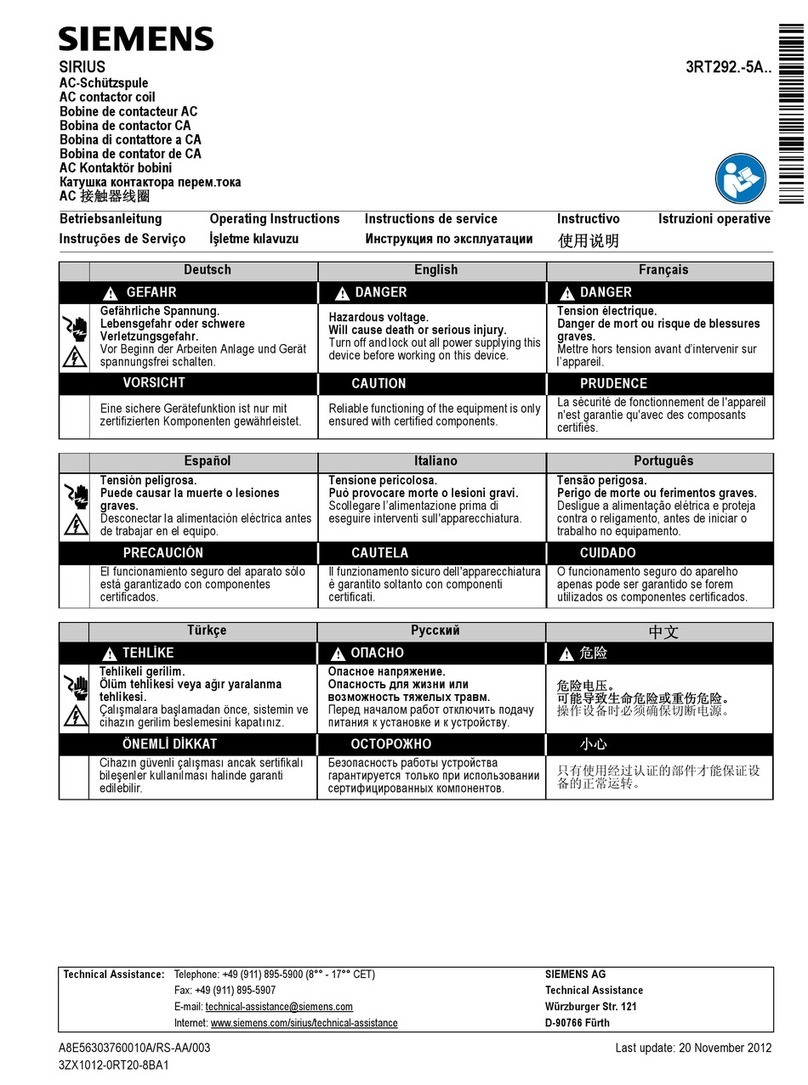

7. O-RINGS ANO BEARINGSREPLACEMENT (FIG. 16-17)

N.B.: To hit the surtaces described in the tollowing, always use

plastic hammers.

7.1 Drain 011Irom coupling by unscrewlng the caps (Item 13) on

cover and delayed II11chamber, and Item 13a.

7.2 1I the Iluid coupllng Is supplled wlth a delayed 1111chamber,

remove it alter unscrewing item 34.

7.3 Unscrew nuts (Item 11), Insert 2screw-drlvers in the slot

between bearlng carrier (item 14) and cover (Item 3), and act

to push bearing carrier and seal (item 15) out.

7.4 Unscrew bolts (Items 8 -10), tap over the cover (item 3) to

remove It.

7.5 Remove bearing (item 16) wlth an extractor, as well as the 011

retalner (Item 47).

7.6 Remove the snap rlng (Item 18) and then the impeller (item 1).

7.7 Remove screws item 9 and plate washer Item 17. Bump on

plane B 01 the shalt (item 24 lor ..KR, Item 25 lar ..KSO) and

sllde the bearlng carrier (Item 23 lor ..KR, Item 24 lar ..KSD)

away wlth the seal (Item 20).

7.8 When reassembllng, proceed Inversely by replaclng bearlngs

and all seals. Use sealing paste between the plate washer

(Item 17) and the impeller (Item 2).

N.B.: To lock al! bolts and caps, reter to the listed torques:

TAB. K tor items 9 - 10 - 34

B 11

E 13

FIG.14

FUSIBLE PLUG @@

.I

120'C 145'C

@@

\--- Fusible alloy

175'C 198'C

TAB.K

FIG.15

Date (moth . year)

7

POS. NAME

1IMPELLER (INNER)

2IMPELLER (OUTER)

3-30 COVER

4 O-RING

5-50 GASKET OR O-RING

6GASKET OR O-RING

7-70 SCREW

8

SCREW

9

SCREW

10 NUT

11 NLJT

12 LOCK WASHER

13 PLUG

130 FUSIBLE PLUG

14-140 BEAPINC CARRIER

15 SEAL

16 BALL BEARINC

17 PL",TE

18 SNAP RINC

19 SEAL CARRIER

20 SEAL

21 BALL BEARINC

22 SNAP RlljC

23 BEARINC CARRIER

POS. NAME

24 SHAFT

25 FIXING SCREW

26 WASHER

27 FLANGE G

28 RUBBER BLOCK

29 HALF JOINT C

30 HALF JOINT B

31 SHAFT D

31.1 KEY

33 DF CHAMBER

34 SCREW

35 LOCK WASHER

36 SCREW

37 NUT -~

38 LOCK WASHER --

39 LOCK WA.SHER

40 PLATE

41 O-RII,C

47 OIL RETAINER

48

SCREW

49 LOCk W¡OSHER

57 VALV[ ¡OSSEMBLy

58 CA.SKET .--

TIrnffiw~[fDill~rn

trasmlsslom Industrlall

FLUID COUPLlNGS

INST ALLA TION AND MAINTENANCE

FIG.16

KRD/CKRD/CCKRD (,~\

I\3~~

/

(~\ Only for 34

ff~

\27)~

Only lor 21-24

27-29-34

I

1\

11 ~

\

A\

(2?) \~)

KR

5(í3 (47) (1~3)(3) (1 ) ( ~(íD'l (8) (130)

\\T

\.r?/~//~>/Ji,

I/ / /'J

\////)í]

\// // '

\//j~)

/

3

~'

(15)

~, "

(2-S( ",,

"

:=: '" "',

'"

(25\) ~'.

\:~~ ~

C' "\

\~ -~ -

&",

\12J

0

~'-..J23'1

~'CJ"'-, ~

"''.'''', ''(~

''''''' \

"'

.''(21)

", ~

~.'@

~)

CKR/CCKR

KRG/CKRG/CCKRG

Only lor 6

rn;J

Screw plug

Only lar 6-7-8

,--o

23)

.-.

Only lor 27-29-34

8

POS. NAME POS. NAME

1 IMPELLER (INNER)

21

BALL BEARING

2 IMPELLER (OUTER) 22 SPACER

3-30 COVER 23 SNAP RING

4O-RING 24 BEARING CARRIER

5-50 GASKET OR O-RING 25 SHAFT

6

GASKET OR O-RING

26

FIXING SCREW

7-70 SCREW 27 WASHER

8SCREW 28 INTEGRAL SHEAVE

9SCREw 29 BOLTED SHEAVE

10 NUT 30 SCREW

11 t"UT 31 WAVE SPRING

12 LOCK WASHER 32 COVER

13 PLUG 33 D.F CHAMBER

130 FUSIBLE PLUG

34

SCREw

14-140 BEARING CARRIER

35 LOCK

WASHER

15

SEAL

39 LOCK WASHER

16 BALL BEARING 47 OIL RETAINER

17 PLATE 50 LOCK WASHER

18 SNAP RING 57 VALVE A,SSEMBLY

20 SEAL 58 GASKET

UUJffiw~uurn~rn

trasmlsslom Industrlall

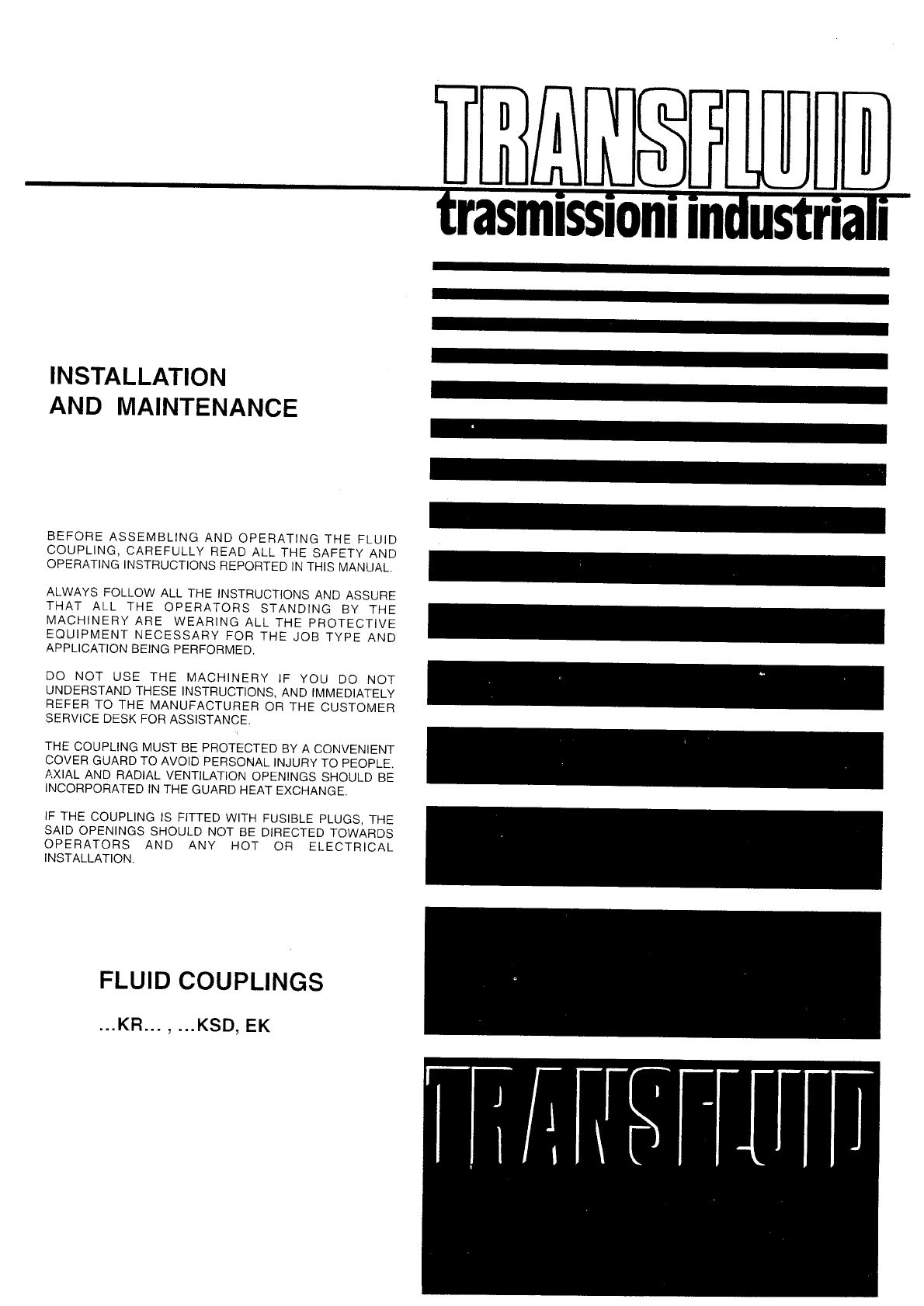

FIG.17

FLUID COUPLlNGS

INST ALLA TION AND MAINTENANCE

KSD

1(4-160i (8) (G~ (2) (18)

/>--J /~,-j//'._~//,-_/ //~//')~

/ // /// /~~-

(/ // //// //// /J,~

-/~/ // --!G\!

/// ..~ ;;¿

/// //' J29\

/~_// '-':'::;

)§

~r24'i

--

"--'---/

Only lar 6-7-8

Only lar 21-24

27-29-34

~\

(~

34 ~

(35J~

\~( 3

\~

\\\

\.~) @

CKSD/CCKSD

KSI/CKSI/CCKSI

Only lar 17-24

22

~

21

B

23

@)

(28)

Only lor 6

i

Screw plug

TRANSFLUID s,r,l, - Vla V, Montl, 19 - 20016 Pero (Milano) Italy - Tel. +3902339315,1 - Fax +39 0233910699 - E-mail tfitaly@tinit

9904 150 GB

9

This manual suits for next models

7

Table of contents

Popular Industrial Equipment manuals by other brands

ABB

ABB HT613219 Operation manual

SUHNER ABRASIVE

SUHNER ABRASIVE ROTOmax 4.2 TWIN Technical document

Invertek Drives

Invertek Drives Optidrive E3 ODE-3 Series user guide

AGI BATCO

AGI BATCO 1500 Series Operator's manual

Delem

Delem DA-65W Reference manual

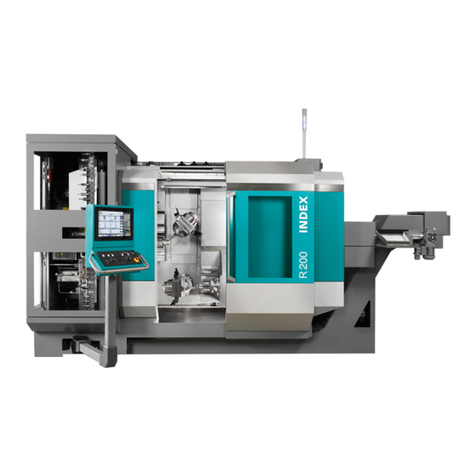

Index

Index R200 Operating instructions and Maintenance instructions