Transforming Technologies BFNG10 User manual

Instruction Manual

Ionizing Air Gun

Model BFNG10

Contents

1Description

BFNG10 1

Safety 2

Specifications 2

2Operation and Use

Environmental Conditions 2

Set-up and Placement 2

Mounting 3

Power and Gas Connection 3

3Maintenance

Periodic Maintenance 4

Cleaning Emitter Points 4

Emitter Point Replacement 5

Service 6

Troubleshooting 6

4Specifications 7

5Assembly and

Mounting Instructions 8

6Service and Warranty 12

7BFNG10 Line Drawing 13

Description

Ionizing Air Gun Model BFNG10

The BFNG10 is a high performance ESD ionizing gun perfect for a

wide variety of industrial applications. The BFNG10 ionizing gun com-

bines portability, fast static decay rates, excellent balance and low com-

pressed air consumption to efficiently remove static and contaminates in

the Semiconductor, Electronic Assembly, Medical Device, Optics, Auto-

motive and Pharmaceutical markets.

About BFN Technology

Dependable, Balanced and Fast. BFN® AC ionizers, from Transforming

Technologies, are built to last. Reliable AC ionization technology is com-

bined with superior mechanical design to assure years of optimal static

neutralizing performance.

• A full 1 year warranty.

• High Frequency AC (68KHz) Ion Emission

• Titanium alloy emitter points for long life.

All BFN series AC ionizing blowers are designed for safe operation un-

der normal use.

Safety:

• Do not use BFN ionizers in flammable or explosive environments.

• Do not insert foreign objects into the air inlet or outlet.

• Make certain the BFN ionizer is properly grounded before operation.

• Do not open or attempt to repair any BFN series product. Breaking

the manufacturing seal will void warranty.

• Do not allow water to enter the gun. Do not operated in high humidi-

ty, or wet areas. This can cause damage to the internal circuits of

the ionizer

• Power off unit before maintenance and cleaning. Wait until fully dry

to power on again if using alcohol to clean.

1

Features & Advantages:

• Point-and-shoot precision ionization.

• Ergonomic handle design: easy to use to achieve high working

efficiency.

• Built in piezoelectric transformer

• Excellent decay time and ion balance,

• High voltage alarm

• Easy to clean and service

• Uses Tungsten emitter points which have a long life and are abra-

sion resistant.

• Optional high efficiency filter that allows use in cleanroom environ-

ments.

Specifications:

• Power Supply: DC 24V/500mA (AC input: 220V/60Hz. 110V/60Hz

alternatively)

• Air Pressure: Less than 88PSI

• Air Line Connection Diameter: 1/4in

• Available Range: 4in—36in.

• Balance: Less than +/-30v

• Decay Time: Less than 2seconds at 12in

• Working Condition: Temp 0-50°C, humidity 20%-80%RH

• Color: Light Grey

• Dimensions: 6.5inX 3.3in X 1.4in (power adapter), 8.25in X 3.42in

X 104in (gun body)

• Cable Length: 6.5ft

• Material: ABS Fireproof

• Weight: 2.1lbs

Kit Includes

• BFN-HFG10 Ionizing Air Gun 1 Set

• Power Adapter 1 Pcs

• Manual 1 Pcs

• Certificate of Calibration 1 Pcs

3

Installation and Operation

1. Power Requirement. The BFNG10 works with common 110 AC

power. Connect the ionizing controller body to a grounded outlet

with the power cable. The switch on the controller body controls

the power to the gun.

2. Mounting. Mount the controller in a fixed location with the includ-

ed bracket. Choose a safe location that to avoid damage to the

controller. Avoid high humidity, wet and dusty locations.

3. Gas Line Connection. Connect the ionizer to a air source

through the 1/4 airline connection at the back of the controller.

The compressed gas supply must be clean dry air or nitrogen. To

prevent particles from entering the console, a 2 micron coalescing

filter or better can be used upstream of the gun console (optional).

Failure to use clean dry air or nitrogen may result in damage to

the BFNG10 Gun.

4. Decay time. The rate at which the ionizer will eliminate static

(decay time) is influenced by the strength of the air flow, and the

distance to the target surface. Lower airflow results in longer de-

cay times. The optimal operating distance is 4in—36in.

5. Air Pressure. The compressed air flow must be less than 88psi.

Higher pressure may influence the operating efficiency or cause

damage to the ionizer.

6. Operating Time. The BFNG10 ionizing air gun is not recom-

mended for continuous use. It is designed for point-and-shoot in-

termittent operation. If continuous operation is needed, contact

Transforming Technologies, there are specifically designed ioniz-

ers for continuous use.

7. Air Filter (Optional). The BFNG10 can be used

with an air filter for clean applications. Model

SPBFN37. The filter is installed inside the control-

ler to insure that the air output is clean and the

ionized air meets the cleanroom requirement. Re-

minder: Air filters have single way air through direction that must

be followed to achieve the filter’s efficiency.

8. Air Volume Controller (Optional). An finger valve can control

the compressed air volume release to the equipment. The valve

is installed in the back of the controller in place of the 1/4 inlet.

4

Caution

• Make sure the compressed air pressure is less than 88PSI ex-

ceeding will make the lower efficiency and possibly damage the

device.

• Stop using when the red LED light is on. This signifies at High

Voltage issue and the gun may not be eliminating static. Check

the unit for proper operation (Verification procedure below); return

to Transforming Technologies if needed.

• Keep away from humid, corrosive, flammable, and dusty environ-

ments. Do not allow water to enter the unit.

• The compressed air must be clean and dry.

Verification

Transforming Technologies Ionizers are inherently balanced by de-

sign, so there are no calibration adjustments. Periodic verification of

the calibration is recommended, per ANSI/ESD SP3.3-2006 Periodic

Verification of Air Ionizers. Verification frequency may be set by the

individual user, but is recommended to be not less than one time per

year.

Equipment needed is a Charge Plate Monitor such as Transforming

Technologies 287A or 288B. Test the ionizer's ion output (decay

time) and balance according to the Charge Plate's instructions. Com-

pare the ion output and balance to the ionizer's published data sheet

and verify the numbers are within limits.

The ionizer can be sent to Transforming Technologies and our techni-

cians can verify the ionizers calibration. Our intent is to clearly identify

the type of calibration service we provide. We provide a basic, tracea-

ble calibration service that is sometimes referred to as Level 1 calibra-

tion.

Maintenance

Emitter Point Cleaning Procedure

The BFNG10 requires minimal maintenance. While

the BFNG10 does not generate particles itself, dust

particles, moisture, and oil from compressed air can

affect the performance of the air gun. Periodic clean-

ing of the emitter point is necessary to ensure the air

gun is working properly. Remove the plastic tip to expose the metal

emitter point. Take care because the tip is very sharp. Clean the tip

with IPA and a clean cloth. Allow the tip to completely dry before using

(1-5 mins).

Clean the tip at least once a year. The frequency of emitter point clean-

ing will depend on the environment and quality of the air source. Ap-

pearance of the tip and the performance of the gun will signify a clean-

ing is needed.

If the unit does not work properly, please contact Transforming Technol-

ogies. DO NOT take apart the unit, or attempt to provide self mainte-

nance as this will void the warranty.

Service and Warranty

Transforming Technologies, LLC provides a limited warranty for the

Model BFNG10 ionizing air nozzle. All new products are guaranteed to

be free from defects in material and workmanship for a period of one (1)

year from the date of shipment. Liability is limited to servicing (after

evaluating, repairing or replacing) any product returned to Transforming

Technologies. The company does not warrant damage due to misuse,

neglect, alteration or accident. In no event shall Transforming Technolo-

gies be liable for collateral or consequential damages.

To receive service under warranty, please contact Transforming

Technologies Technical Support.

About Transforming Technologies

Since 1998, Transforming Technologies has helped electronic man-

ufacturing facilities to protect their products and processes from the

many serious problems associated with static electricity.

Transforming Technologies offers a wide range of unique and out-

standing products to detect, protect, eliminate and monitor electrostatic

charges. Our products are integral components of an effective static

control program.

5

6

3719 King Rd | Toledo, OH 43617 | P: 419-841-9552 | F: 419-841-3241 | info@transforming-technologies.com

Table of contents

Other Transforming Technologies Other manuals

Popular Other manuals by other brands

Kohler

Kohler RIALTO K-3386-JA installation instructions

aFe Power

aFe Power 48-46214-YC Installation instructions manual

Kodak

Kodak IM5 user guide

Jen-Ken Kilns

Jen-Ken Kilns TAP Tall Bonnie Glo user guide

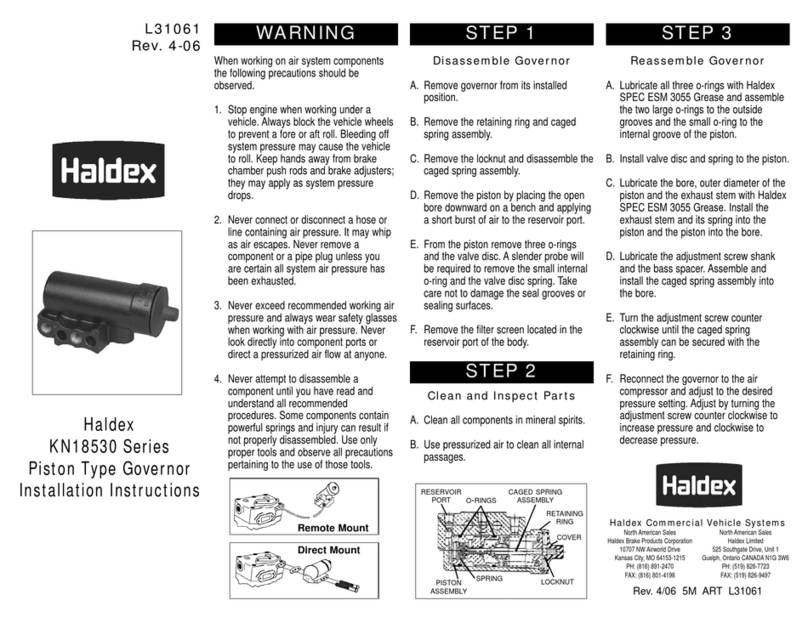

Haldex

Haldex KN18530 Series installation instructions

Altec Lansing

Altec Lansing INMOTION CLASSIC brochure