Transmille EA015 User manual

EA015

MULTI FUNCTION WORKSTATION ADAPTER

OPERATION MANUAL

Ü

Version 1.10

July 2008

All product names are trademarks of their respective companies

EA015

Multi Function Workstation

Operation Manual

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 2

Guarantee and service

Transmille Ltd. guarantees this instrument to be free from defects under

normal use and service for a period of 1 years from purchase. This guarantee

applies only to the original purchaser and does not cover fuses, or any

instrument which, in Transmille’s opinion, has been modified, misused or

subjected to abnormal handling or operating conditions.

Transmille’s obligation under this guarantee is limited to replacement or

repair of an instrument which is returned to Transmille within the warranty

period. If Transmille determines that the fault has been caused by the

purchaser, Transmille will contact the purchaser before proceeding with any

repair.

To obtain repair under this guarantee the purchaser must send the instrument

in its original packaging (carriage prepaid) and a description of the fault to

Transmille at the address shown below. The instrument will be repaired at the

factory and returned to the purchaser, carriage prepaid.

Note :

TRANSMILLE ASSUMES NO RESPONSIBILITY FOR DAMAGE IN TRANSIT

THIS GUARANTEE IS THE PURCHASER’S SOLE AND EXCLUSIVE

GUARANTEE AND IS IN LEIU OF ANY OTHER GUARANTEE, EXPRESSED OR

IMPLIED. TRANSMILLE SHALL NOT BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS.

Transmille Ltd.

Unit 4, Select Business Centre

Lodge Road

Staplehurst

Kent

TN12 0QW

United Kingdom

Tel : +44 0 1580 890700

Fax : +44 0 1580 890711

Web : www.transmille.com

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 3

TABLE OF CONTENTS

GUARANTEE AND SERVICE.........................................................................................................................2

EA015 MULTI FUNCTION WORKSTATION...................................................................................................4

Design Notes ....................................................................................................................................5

Clamp Meters ..................................................................................................................5

Insulation Testers...........................................................................................................5

Process Control Calibrators..........................................................................................5

Digital Thermometers.....................................................................................................6

Optical Tachometers ......................................................................................................6

Features ............................................................................................................................................6

Using the EA015 with the Virtual Front Panel Software..............................................................8

Installing the Software ...................................................................................................8

Selecting a COM Port .....................................................................................................8

Operation of the Virtual Front Panel.............................................................................9

Functions : Thermocouple Simulation.........................................................................9

Functions : Tachometer Calibration...........................................................................10

Functions : Insulation Resistance ..............................................................................10

Functions : Insulation Test Voltage............................................................................11

Functions : Continuity Resistance & Current............................................................11

Functions : mA & mV Measurement...........................................................................12

STEP 1 : Enter an output value ...................................................................................13

STEP 2 : Setting to DC or AC.......................................................................................14

STEP 3 : Select a function ...........................................................................................14

STEP 4 : Select a Voltage / Current output ................................................................14

Terminals.......................................................................................................................15

STEP 5 : Set Output......................................................................................................16

Changing Output Values..............................................................................................16

Specifications.................................................................................................................................17

Care & Maintenance.......................................................................................................................18

Cleaning the Adapter.................................................................................................................18

Handling Precautions................................................................................................................18

Servicing Information................................................................................................................18

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 4

EA015 Multi Function Workstation

The multi function workstation provides a central work area with all connections routed

conveniently to remote terminals mounted at the front of the adapter.

The adapter extends the capabilities of the calibrator to include :

2 / 10 / 50 TURN CLAMP COIL

INSULATION RESISTANCE OUTPUT

CONTINUITY RESISTANCE OUTPUT

INS. TEST VOLTAGE MEASUREMENT

CONTINUITY CURRENT MEASUREMENT

OPTICAL TACHOMETER CALIBRATION

THERMOCOUPLE SIMULATION

VOLTAGE MEASUREMENT : 3 RANGES

CURRENT MEASUREMENT TO 30mA

CALIBRATOR OUTPUT ROUTING :

VOLTAGE, CURRENT AND HIGH CURRENT TO

DEDICATED WORKSTATION TERMINALS

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 5

Design Notes

Incorporating the advanced clamp coil, thermocouple

simulation and tachometer calibration adapters as well as

process control source / measure capabilities, this workstation

adapter provides a versatile platform for efficient calibration of a

wide range of equipment.

Selection of the specific functions on the workstation requires use of either the EA015

Workstation adapter virtual front panel software (supplied) or use of ProCal software

procedure wizards to create procedures with built in commands for setting up the adapter

functions.

NOTE : The supplied virtual front panel software or ProCal software (optional) must

be used to set output functions.

Clamp Meters

Using the built in 2, 10 and 50 turn coils, clamp meters can be accurately and quickly

calibrated. Using a high accuracy balanced design both wound (AC only) & Magnetic field

(hall effect) AC/DC clamp meters can be calibrated. Three coils in one provide the ability to

calibrate a wide range of coils, from small lower clamps down to 10mm jaw diameter to larger

2000A clamps.

Insulation Testers

Insulation tester calibration is a common requirement and is now easy to perform using the

workstation. Insulation to 2GOhms @ 1000V and continuity to 1kOhm is available from

dedicated terminals. Using the measurement capabilities of the adapter interface, the

workstation also provides insulation test voltage measurement to 1000V and continuity

current measurement.

Process Control Calibrators

Source/measure process control calibrators are commonplace in industry and previously

required several references to calibrate. The workstation integrates all the functions required

to both source and measure the required signals.

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 6

Digital Thermometers

Digital thermometers can be easily calibrated accurately using the workstation’s built in

thermocouple simulation output with automatic cold junction compensation.

NOTE : The EA015 Workstation adapter requires the use of thermocouple compensation

cables for connection between the adapter and the digital thermometer (UUT)

Optical Tachometers

Using a high intensity LED light source, optical tachometers can be calibrated quickly and

easily using the workstation.

Features

Functions of the terminal connections :

EA015 Output / Input Function

Optical Tacho Optical Tachometer Calibration Source (LED)

Thermocouple Simulation Thermocouple Simulation Output

(requires compensating leads)

Continuity Resistance Continuity Resistance Output /

Continuity Current Input

Insulation Resistance Insulation Resistance Output /

Insulation Test Voltage Input

Common Common for Continuity Resistance, Insulation

Resistance, Voltage Measure and Current

Measure

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 7

Voltage Measure DC Voltage Measurement Input

Current Measure DC Current Measurement Input

Voltage Output Voltage output from calibrator

Low Current Output Current output from calibrator (to 2A)

High Current Output Current output from calibrator (to 30A)

Common Common for calibrator output terminals

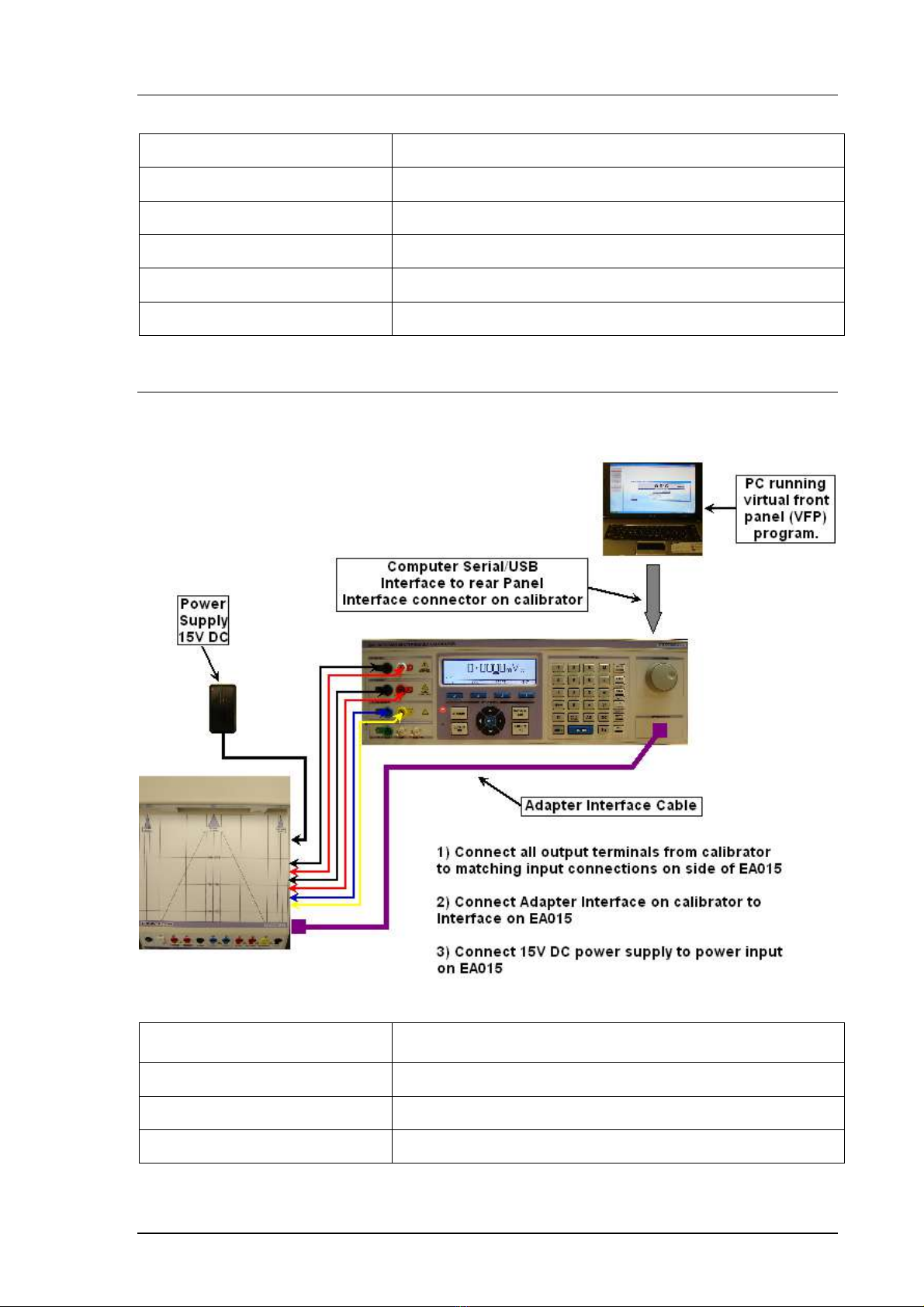

Connection Recommendations

To connect the EA015 Multi function workstation to the 3000 Series multi product calibrator, follow

the connection diagram below :

EA015 Output / Input Function

Power Supply 15V Adapter Power Supply

Calibrator Outputs 3000 Series Voltage & Current Outputs

Adapter Interface Adapter control interface from calibrator

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 8

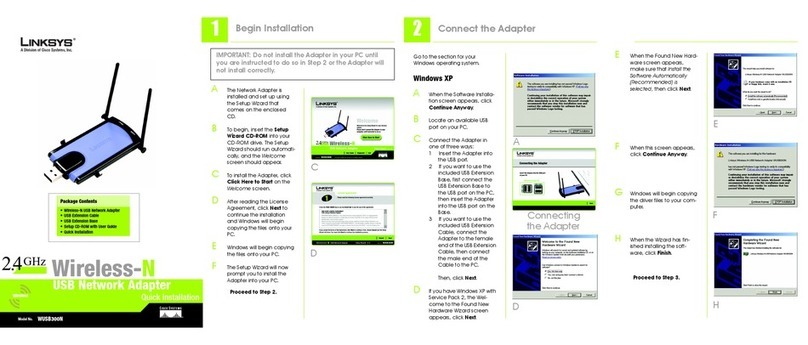

Using the EA015 with the

Virtual Front Panel Software

The EA015 workstation adapter should be connected as shown above.

The main terminals from the calibrator should be connected to the corresponding

terminals on the side of the adapter.

The adapter interface on the calibrator should be connected to the adapter

interface on the EA015 Workstation adapter.

The 15V external power supply should also be connected to the power socket of

the EA015 workstation adapter.

Installing the Software

Insert the CD which is supplied with the EA015 workstation adapter – this should

autorun and install the software.

Once installed run the software by clicking START > ALL PROGRAMS > EA015

Workstation Adapter

Selecting a COM Port

On starting the virtual front panel for the first time, a COM port selection screen will

be displayed. Click on the COM port that is connected to your 3000 Series calibrator

to continue.

If you are using a laptop to connect to the calibrator, the COM port will usually

be COM 1. A desktop computer will usually be COM 2.

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 9

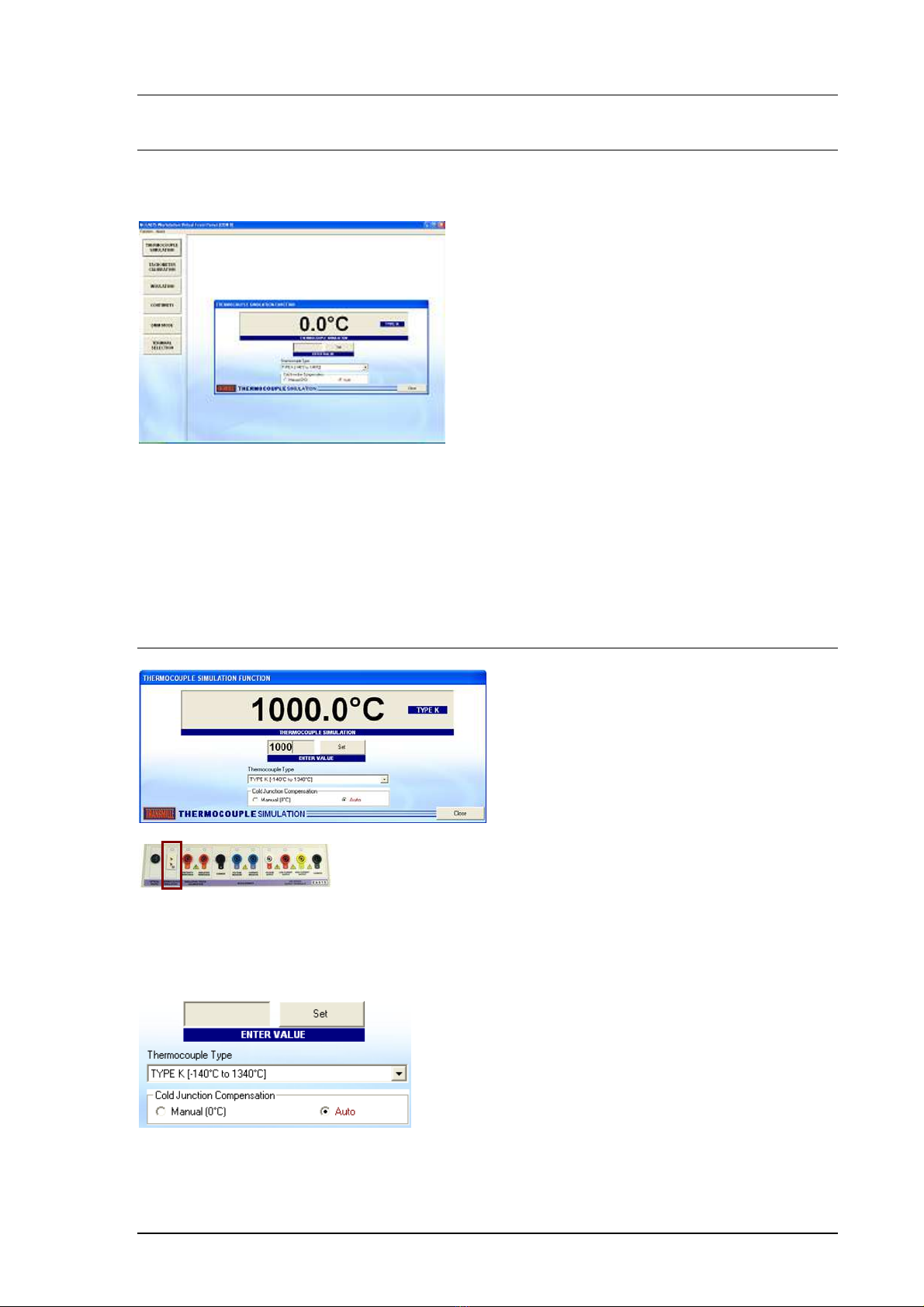

Operation of the Virtual Front Panel

Once the correct COM port is selected, the calibrator will be detected, and the main

screen displayed :

The main functions of the workstation are :

Thermocouple Simulation

Tachometer Calibration

Insulation Resistance & Voltage

Continuity Resistance & Current

mA & mV Measurement

Terminal Switching

Functions : Thermocouple Simulation

Connect temperature meter to thermocouple connector on workstation using

thermocouple compensating cables for the correct thermocouple type. Select

a thermocouple type from the drop down list. Set manual or automatic cold junction.

Enter a temperature in the box marked ENTER VALUE, then click SET. Note if the

temperature is outside the range available, a message will be displayed.

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 10

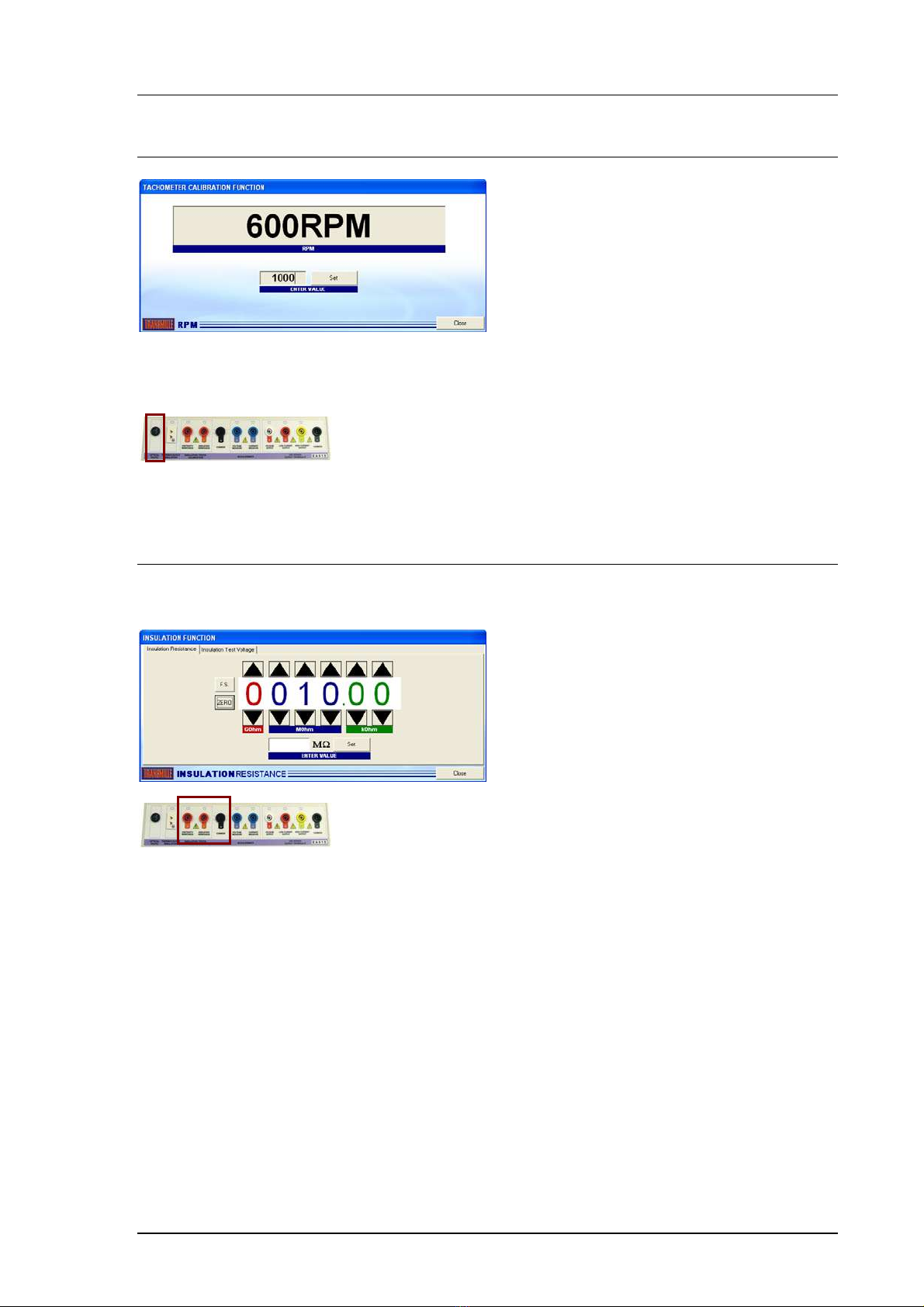

Functions : Tachometer Calibration

Enter an RPM value in the box marked ENTER VALUE, the press the SET button.

The tachometer LED will illuminate – point the optical tachometer at the LED.

Note : The workstation RPM output must be set using the virtual front panel software – the

3000 Series front panel function cannot be used.

Functions : Insulation Resistance

Select the INSULATION RESISTANCE tab

Connect meter to terminals marked Insulation resistance. Select a resistance by

either :

1 : Selecting a value using the up/down buttons

2. Entering a value (in M Ohms) in the box marked

Use the F.S. button to set to 199999

Use the zero button to jump directly to ZERO

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 11

Functions : Insulation Test Voltage

Select the INSULATION TEST VOLTAGE tab

Connect meter to terminals marked Insulation resistance.

1 : Select a voltage range using the range buttons

2. Apply voltage from the Insulation tester

Functions : Continuity Resistance & Current

Connect meter to terminals marked continuity resistance.

Function will default to 1 Ohm range, with continuity current measurement. Select

continuity resistance as required by clicking the buttons available.

Note : Continuity current is available on the 1 Ohm range only

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 12

Functions : mA & mV Measurement

Connect meter to terminals marked voltage measure or current measure as required

Select current or voltage range as appropriate – voltage / current will be displayed

on the virtual front panel display.

Functions : Terminal / Coil Switching

This function requires the calibrator to be connected to the

workstation using the side terminals, shown left

This function allows the calibrator output to be controlled for voltage and either direct

current or current via the 2/10/50 turn coil. The current output can be routed through

the coil for clamp meter calibration.

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 13

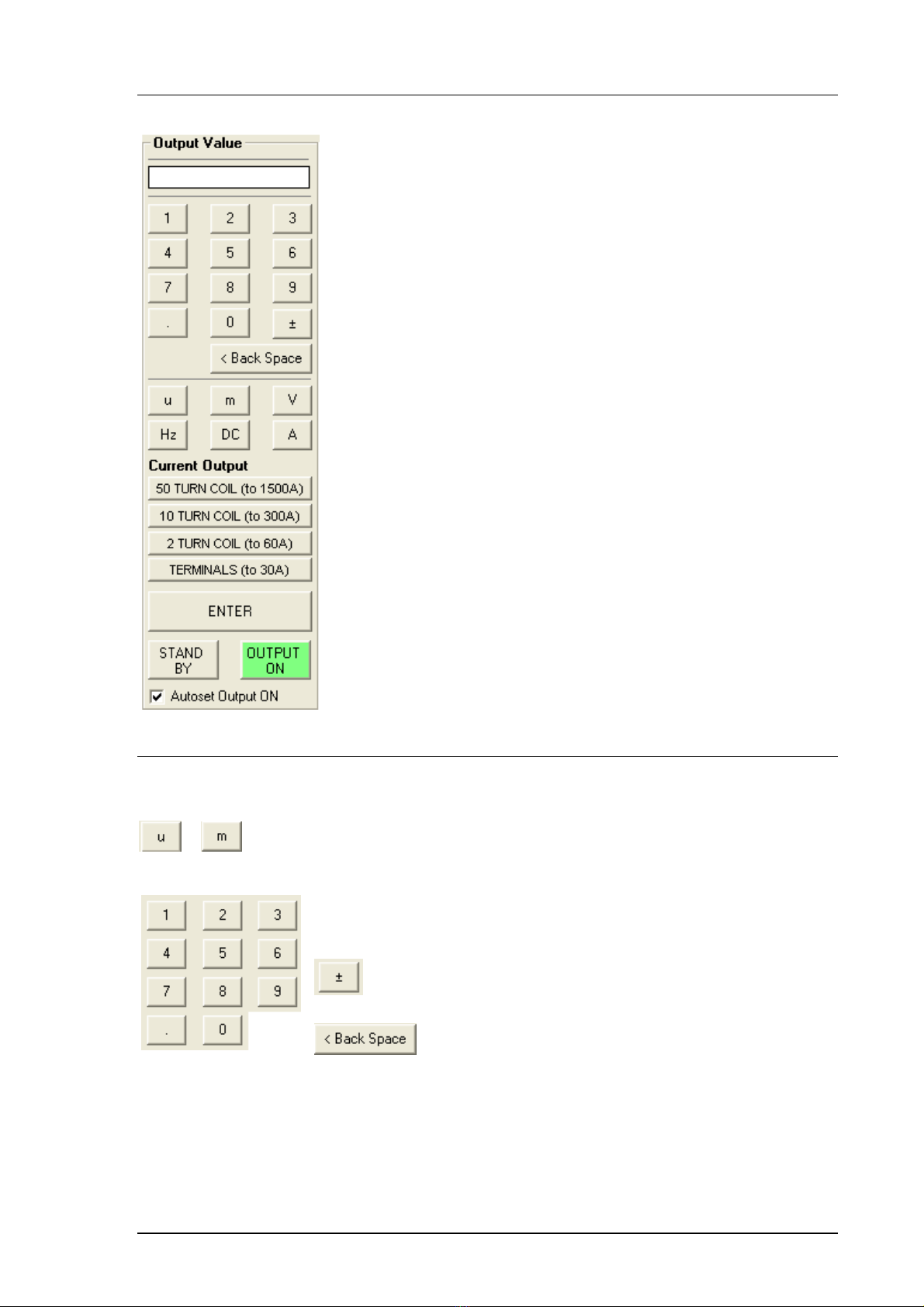

The output panel, shown left, allows the user to select a

value to output and then automatically set the calibrator

output and switch to the appropriate terminals / coil output

on the workstation adapter.

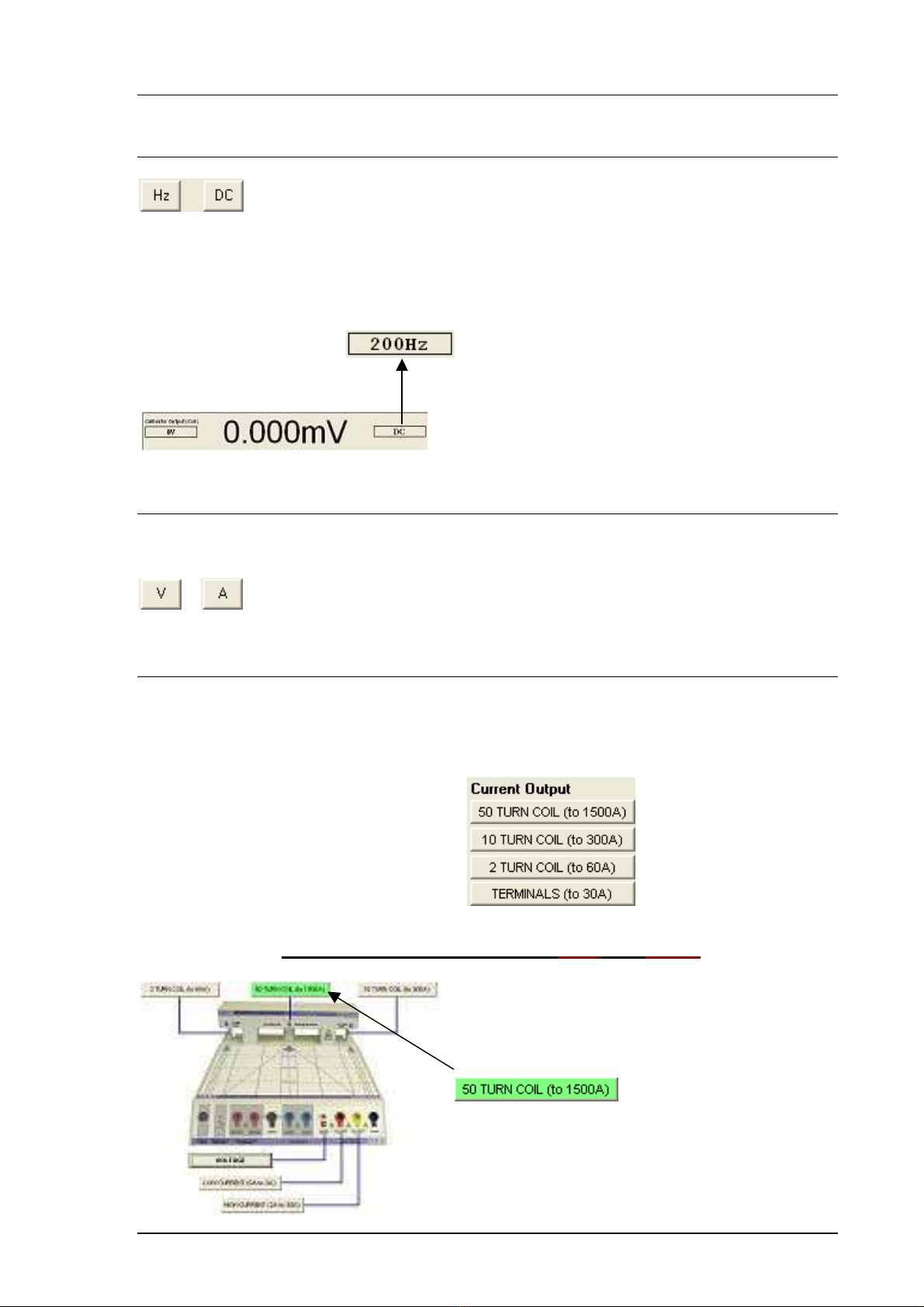

STEP 1 : Enter an output value

The output value is entered using the keypad. Micro or milli can be selected using

the buttons provided :

micro milli

Numeric buttons 0-9 and decimal point – use these to enter a

value.

Set positive or negative value – note a number must be

entered first before clicking this Button.

Backspace – use this to erase the last character

entered in the output value box.

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 14

STEP 2 : Setting to DC or AC

Use the DC button to set to DC, or enter a frequency using the keypad, then press

Hz to set an AC frequency.

Frequency display within main window – DC or a frequency,

eg. 50Hz.

STEP 3 : Select a function

Select either Voltage or Current by using the buttons provided :

Volts Amps

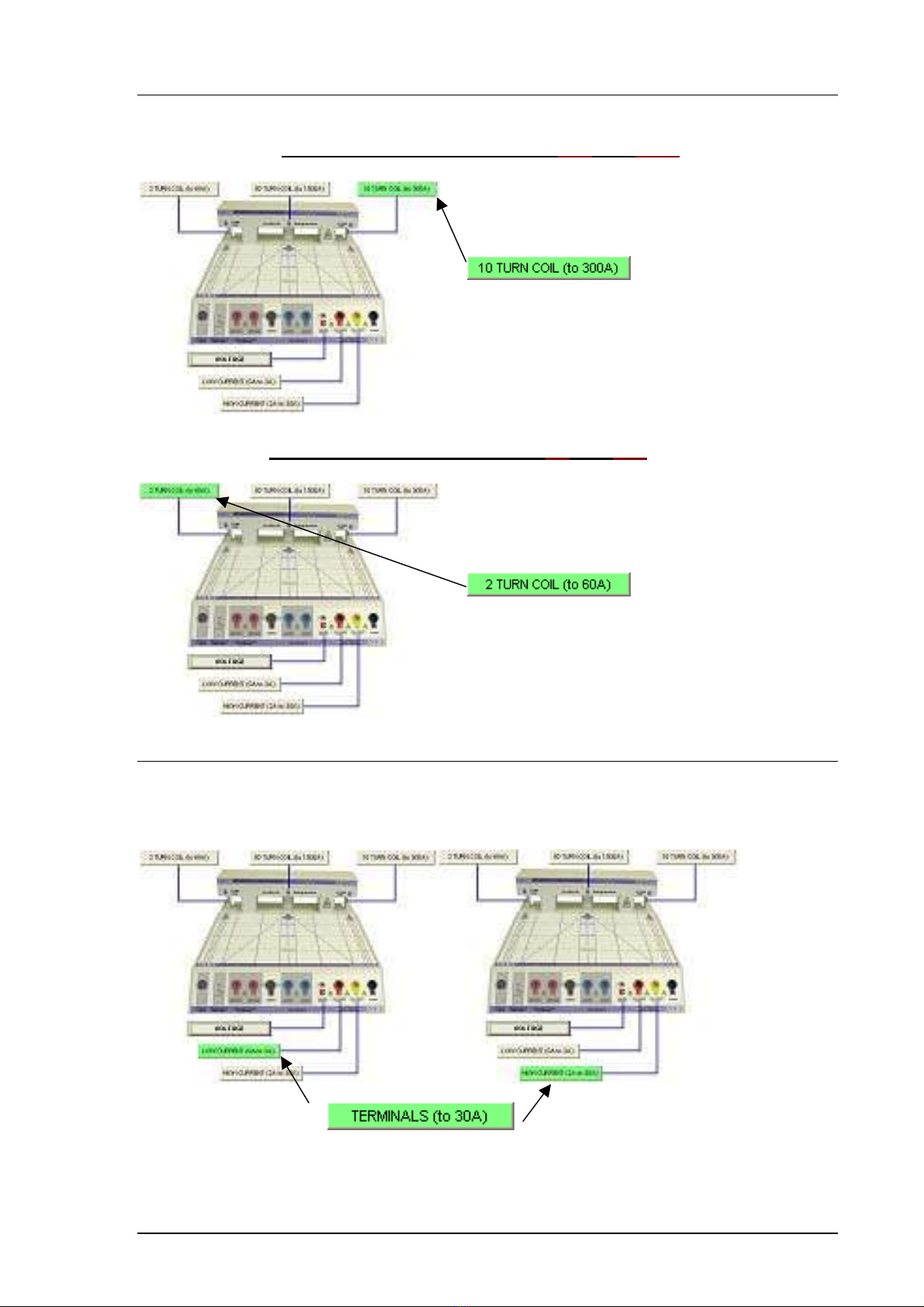

STEP 4 : Select a Voltage / Current output

For voltage, once the output value is set and V is pressed, proceed directly to

STEP 5.

If the value entered is a

current, the choice of where

this should be output from is

available using the buttons

shown right. The available

buttons will flash, indicating

that a choice should be made.

50 Turn Coil : Available for currents between 100A and 1500A

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 15

10 Turn Coil : Available for currents between 10A and 300A

2 Turn Coil : Available for currents between 4A and 60A

Terminals

Available for currents between

0A and 2A (Low Current Terminals)

2A and 30A (High Current Terminals)

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 16

Note : Only the outputs which are available for current value entered are

enabled – if the button is not available (greyed out) this means it is not

possible to output this value using that specific output (eg. It is not possible to

output 2A using the 50 turn coil – minimum value from 50 turn coil is 100A :

2A x 50 turns).

STEP 5 : Set Output

Once the output value is set, press the enter button to set the

output.

Use the STANDBY and OUTPUT ON buttons to control the

output.

The Autoset Output On option allows the output to be

automatically switched on when a value is entered. If this option is unchecked, the

output will not be switch on automatically, but left set in standby.

When high voltage (>40V) is output, the

Autoset Output ON is not available.

Changing Output Values

If the output value is changed, the VFP program will check if this is possible using

the current range selected. If it is not possible to output this value, the current output

buttons will flash to indicate that a different output should be selected.

Note : Only the outputs which are available for current value entered are enabled,

e.g.

Example : 1000A Output Set

50 TURN COIL (to 1500A) enabled,

all other modes disabled as not

possible with 1000A Selected.

10 TURN COIL – Max. Output = 300A

2 TURN COIL – Max. Output = 60A

TER

MINALS

–

Max. Output

=

30A

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 17

Specifications

GENERAL SPECIFICATIONS

Output

Connections 9x 4mm Safety Terminals

1x thermocouple socket (neutral copper)

1x Optical LED output

Control

Interface ‘D’ type connector for use with

3000 Series Adapter Interface

Power Supply 15V External Power Supply Unit

PERFORMANCE SPECIFICATIONS

Clamp Meter Calibration 2 / 10 / 50 Turn

Up to 1500A (Simulated)

Insulation Tester Calibration

Continuity Resistance

Insulation Resistance

Continuity Current Measurement

Insulation Test Voltage Measurement

Up to 1kOhm

Up to 2Gohms / 1000V

Up to 300mA

Up to 1000V

Digital Thermometer Calibration J, K, T, R, S, B, N, E

Process Control Calibration

DCV Measurement

DCI Measurement

DCV/I Source from calibrator

100mV/1V/10V Ranges

30mA Range

AC/DC 1000V • 30A

Optical Tachometer Calibration Range : 60 to 60,000 RPM

EA015 MULTI FUNCTION WORKSTATION

OPERATION MANUAL

Transmille Ltd. Page 18

Care & Maintenance

The only maintenance instructions for the adapter is periodic cleaning. See below for

details on the cleaning procedure and precautions for handling.

Cleaning the Adapter

To keep the external enclosure of the adapter in good condition, clean the outer

case with a soft cloth. Do not use any liquids in cleaning the enclosure – removal of

surface dust is all that is recommended.

CAUTION

Do not use cleaning fluids or solvents for cleaning as these may damage the

enclosure and affect the plastic materials used in the transconductance amplifier.

Handling Precautions

The adapter is designed for mechanical stability, but should not be subjected to

excessive shock or be dropped. Transportation is recommended using the original

packaging with avoidance of extreme changes of temperature.

Servicing Information

The adapter is provided certified from the factory, and uses precision components

that are not user repairable. If the instrument is damaged it should be returned to the

factory for repair and recalibration.

Table of contents

Other Transmille Adapter manuals