30

Installation and Maintenance

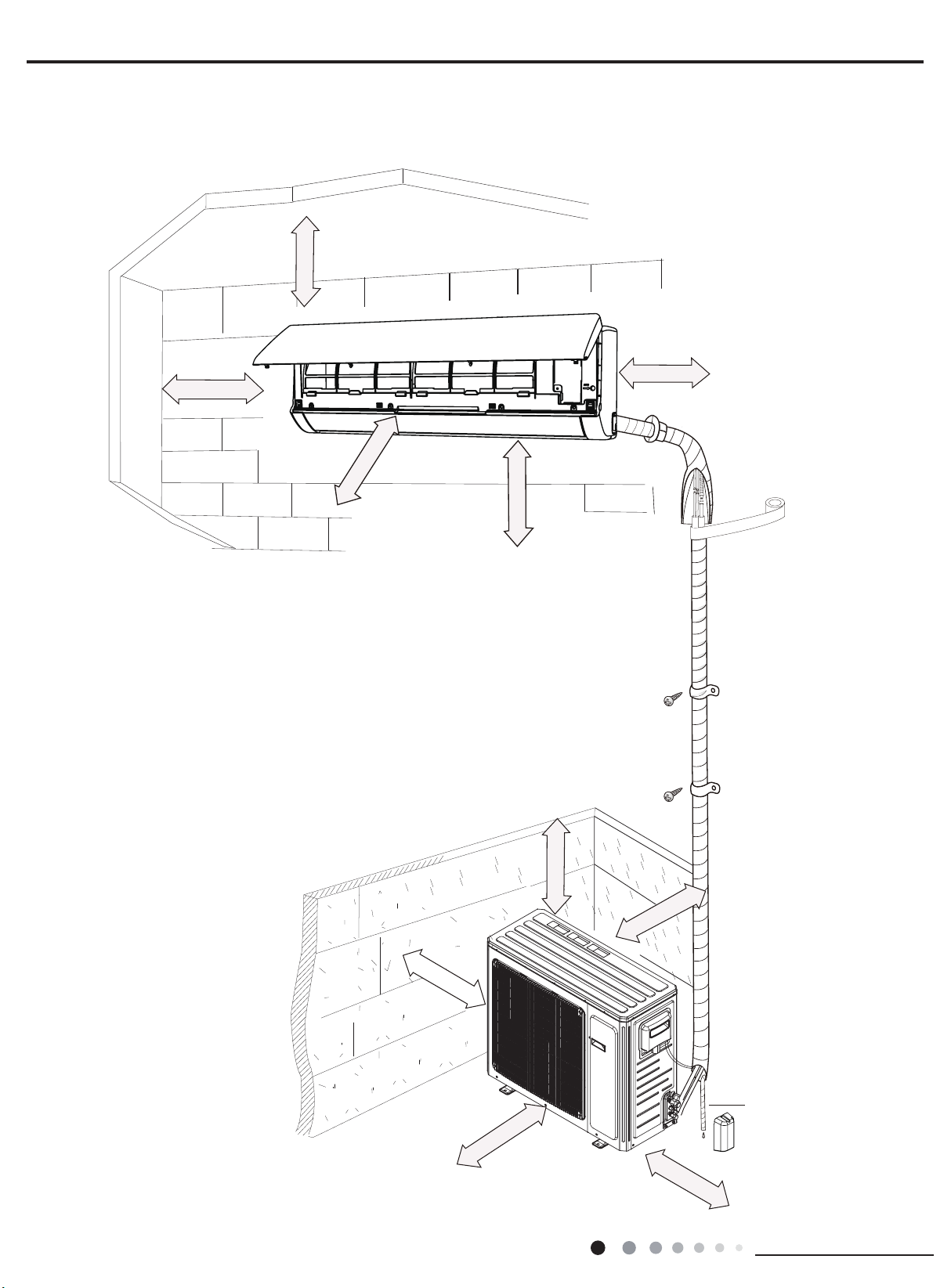

No. Name No. Name

1 Indoor unit 8 Sealing gum

2 Outdoor unit 9 Wrapping tape

3 Connection pipe 10 Support of outdoor

unit

4 Drainage pipe 11 Fixing screw

5Wall-mounting

frame 12 Drainage plug(cooling

and heating unit)

6Connecting

cable(power cord) 13 Owners manual,

remote controller

7 Wall pipe

1. Safety Precaution

(1) Must follow the electric safety regulations when installing

the unit.

(2) According to the local safety regulations, use qualified

power supply circuit and air switch.

(3) Make sure the power supply matches with the requirement

of air conditioner. Unstable power supply or incorrect wiring

may result in electric shock,re hazard or malfunction. Please

install proper power supply cables before using the air

conditioner.

(4) Properly connect the live wire, neutral wire and grounding

wire of power socket.

(5) Be sure to cut off the power supply before proceeding any

work related to electricity and safety.

(6) Do not put through the power before nishing installation.

(7) If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similary qualied persons in

order to aviod a hazard.

(8) The temperature of refrigerant circuit will be high, please

keep the interconnection cable away from the copper tube.

(9) The appliance shall be installed in accordance with national

wiring regulations.

3.2 Installation Parts-checking

3.3 Selection of Installation Location

3.4 Requirement For Electric Connection

3.5 Installation of Indoor Unit

Air-conditioner Air switch capacity

36K 25A

1.Please contact the local agent for installation.

2.Dont use unqualied power cord.

2. Grounding Requirement:

(1) The air conditioner is rst class electric appliance. It must

be properly grounding with specialized grounding device

by a professional. Please make sure it is always grounded

effectively, otherwise it may cause electric shock.

(2) The yellow-green wire in air conditioner is grounding wire,

which Can't be used for other purposes.

(3) The grounding resistance should comply with national

electric safety regulations.

(4) The appliance must be positioned so that the plug is

accessible.

(5) An all-pole disconnection switch having a contact separation

of at least 3mm in all poles should be connected in xed wiring.

(6) Including an air switch with suitable capacity, please note

the following table. Air switch should be included magnet

buckle and heating buckle function, it can protect the circuit-

short and overload. (Caution: please do not use the fuse only

for protect the circuit)

1. Choosing Installation Iocation

Recommend the installation location to the client and then

conrm it with the client.

2. Install Wall-mounting Frame

(1) Hang the wall-mounting frame on the wall; adjust it in

horizontal position with the level meter and then point out the

screw xing holes on the wall.

(2) Drill the screw xing holes on the wall with impact drill (the

specification of drill head should be the same as the plastic

expansion particle) and then ll the plastic expansion particles

2. Indoor Unit:

(1) There should be no obstruction near air inlet and air outlet.

(2) Select a location where the condensation water can be

dispersed easily andwont affect other people.

(3) Select a location which is convenient to connect the

outdoor unit and near the power socket.

(4) Select a location which is out of reach for children.

(5)

The location should be able to withstand

the weight of

indoor unit and wont increase noise and vibration.

(6)

The appliance must be installed 2.5m above oor.

(7) Dont install the indoor unit right above the electric

appliance.

(8) Please try your best to keep way from uorescent lamp.

3. Outdoor Unit:

(1) Select a location where the noise and outow air emitted by

the outdoor unit will not affect neighborhood.

(2) The location should be well ventilated and dry, in which

the outdoor unit wont be exposed directly to sunlight or strong

wind.

(3) The location should be able to withstand the weight of

outdoor unit.

(4) Make sure that the installation follows the requirement of

installation dimension diagram.

(5) Select a location which is out of reach for children and far

away from animals or plants.If it is unavoidable, please add

fence for safety purpose.

Note:

1. Basic Requirement:

Installing the unit in the following places may cause

malfunction. If it is unavoidable, please consult the local dealer:

(1) The place with strong heat sources, vapors, ammable or

explosive gas, or volatile objects spread in the air.

(2) The place with high-frequency devices (such as welding

machine, medical equipment).

(3) The place near coast area.

(4) The place with oil or fumes in the air.

(5) The place with sulfureted gas.

(6) Other places with special circumstances.

(7) The appliance shall not be installed in the laundry.

(8) It’s not allowed to be installed on the unstable or motive

base structure (such as truck) or in the corrosive

environment (such as chemical factory).